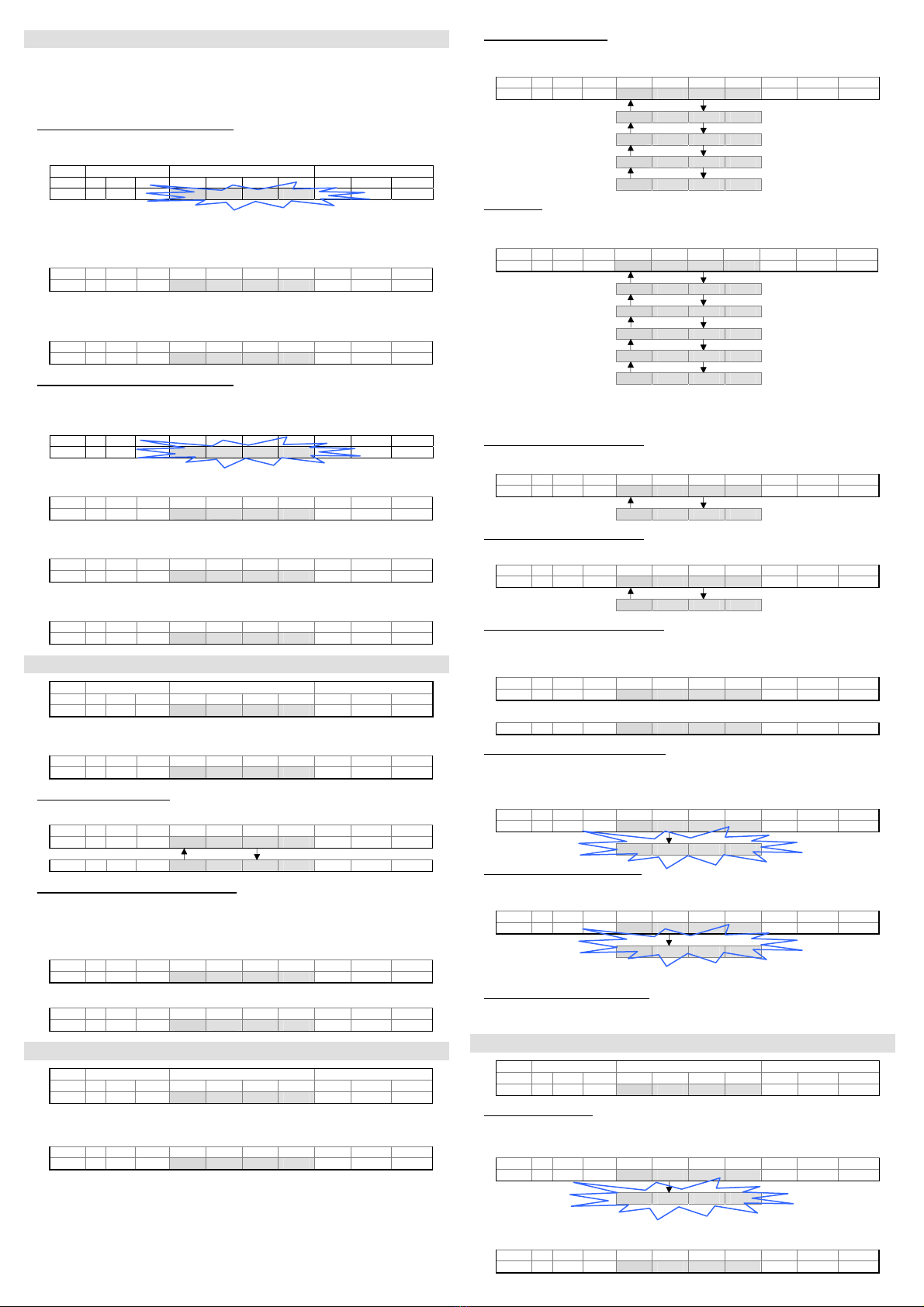

SETTING OF THE 2 THRESHOLDS

The sensor setting is effected placing the object to detect directly in front of the sensor following the

procedure given below:

zpush-button pressed {push-button not pressed

LED on LED off

- Obect detection at OFF/ON output switching

- Position the object inside the measurement area to define the measurement value (depending

on the operating mode used) corresponding to the OFF/ON switching of the digital output.

Display Keyboard

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

4 5 0 {z{

- Press the SET push-button for at least 2s.

- The detected value for the first switching threshold appears (4Hz blinking until the SET push-

button is released).

-The value acquired can be changed using the +/- push-buttons.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

4 5 0 z{z

-The units change if these push-buttons are pressed repeatedly, the tens if kept pressed.

-Press the SET push-button again for at least 0.5 s. to end the detection phase of the first

switching threshold.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

4 5 0 {z{

- Obect detection at ON/OFF output switching

- Position the object inside the measurement area to define the measurement value (depending on

the operating mode used) corresponding to the ON/OFF switching of the digital output.

-The detected value for the second switching threshold appears.

-OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

6 0 0 {z{

-The present value appears (4Hz blinking).

-Press the SET push-button again for at least 0.5 s. to detect the second switching threshold.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

6 0 0 {z{

- The detected value for the second switching threshold appears.

-The value acquired can be changed using the +/- push-buttons.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

6 0 0 z{z

-The units change if these push-buttons are pressed repeatedly, the tens if kept pressed.

-Press the SET push-button again for at least 0.5 s. to end the detection phase.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

6 0 0 {z{

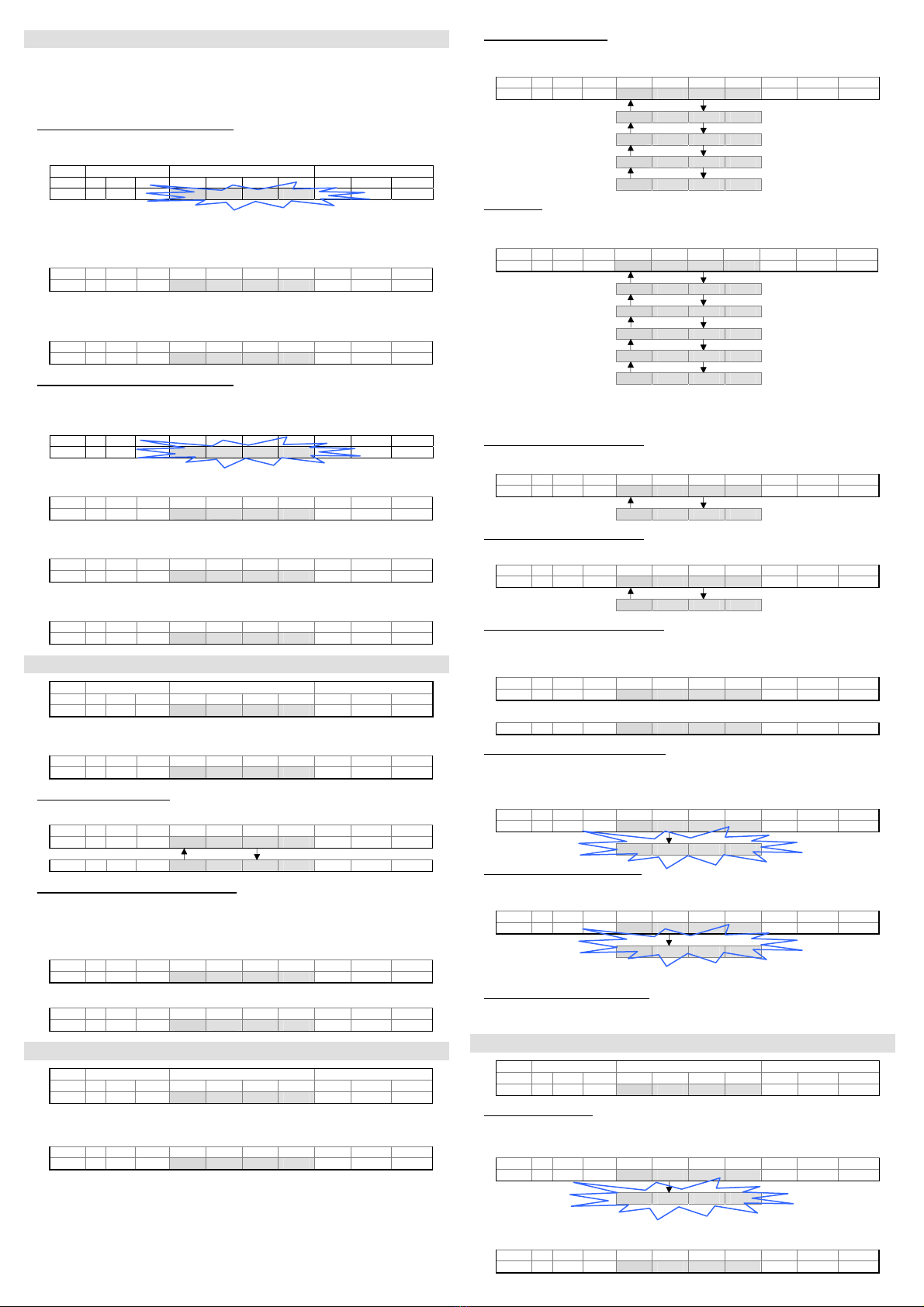

SWITCHING THRESHOLD ADJUSTMENT

Display Keyboard

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

0 4 5 0 z{z

- Press one of the +/- push-buttons for at least 2 s.

-The “tH-1” message appears.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

t H - 1 {{{

- Switching threshold selection

-Use the +/- push-buttons to select the switching threshold.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

t H - 1 z{z

t H - 2 z{z

- Adjustment phase of the switching threshold

-Press the SET push-button for at least 0.5 s.

-The previously detected value appears.

-The value can be changed using the +/- push-buttons.

-The units change if these push-buttons are pressed repeatedly, the tens if kept pressed.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

0 6 0 0 z{z

-Press the SET push-button again for at least 0.5 s. to end the adjustment phase.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

0 4 5 0 {z{

SETTING OF THE PARAMETERS

Display Keyboard

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

4 5 0 {z{

Press the SET push-button for at least 6s to enter into the parameter setting mode.

The "MEnu" message appears.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

M E n u {{{

-Pressing the + and –push-buttons the user can run up and down the menu, reading the

following messages.

- Functioning mode selection

- At each pressure on the SET push-button the user can run through the options of the selected

level.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

E n d z{z

b E G {z{

c E n t {z{

W I d t {z{

A r E A {z{

- Delay setting

-At each pressure on the SET push-button the user can run through the options of the selected

level.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

d - 0 0 z{z

d - 0 5 {z{

d - 1 0 {z{

d - 2 0 {z{

d - 3 0 {z{

d - 4 0 {z{

- The setting of the delay value is in common to both outputs.

When the delay value set is different from zero, the outputs will remain active for a minimum

time equal to the number of milliseconds visualised on the display.

- Visualisation of the threshold 1 data

-Pressing the SET push-button the value of the threshold 1 appears.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

t H - 1 z{z

THRESHOLD 0 4 5 0 {z{

- Visualisation of the threshold 2 data

- Pressing the SET push-button the value of the threshold 2 appears.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

t H - 2 z{z

THRESHOLD 6 0 0 {z{

- Visualsation of the operating area status

- Pressing the SET push-button the operating area status. More precisely; if “FULL” the operating

area is complete, if “REDU“ the acquired area is not complete, but presents some zones that do

not have to be detected .

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

F U L L z{z

or

r E d U z{z

- Reset of the sensor default configuration

-Pressing the SET push-button (the “RESE” message blinks for 2s, 4Hz) the default configuration

is re-set and the user exits from the menu, returning to the normal mode. The default

configuration is: “beg object” operating mode, delay 0, Th1 switching threshold = 100, Th2 =

200.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

r E S E z{z

r E S E {z{

- Memorisation of the parameters set

- Pressing the SET push-button (the “SAVE” message blinks for 2s, 4Hz) all the modified values

are memorised and the user exits form the menu,returning to the normal mode.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

S A V E z{z

S A V E {z{

- Press one of the +/- push-buttons the user can return to the setting menu.

- Exit from the parameter setting menu

After 10s inactivity of the sensor push-buttons, the sensor returns to the normal operating mode

visualising the distance.

ADVANCED FUNCTIONS

Display Keyboard

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

0 4 5 0 z{z

- Operating area selection

- Press contemporarily the + and – push-buttons for at least 2s.

-The “W_Ar” message appears.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

W _ A r {{{

W _ A r {z{

-The operating area configuration is memorised when the push-buttons are released (the W_Ar

blinks for 2s, 4Hz) and the sensor returns to the normal mode.

OUT A M1 M2 Dig1 Dig2 Dig3 Dig4 + SET -

0 4 5 0 {{{