Balluff Network Interface / IO-Link BNI IOL-719-002-Z012-XXX

www.balluff.com

2 Safety

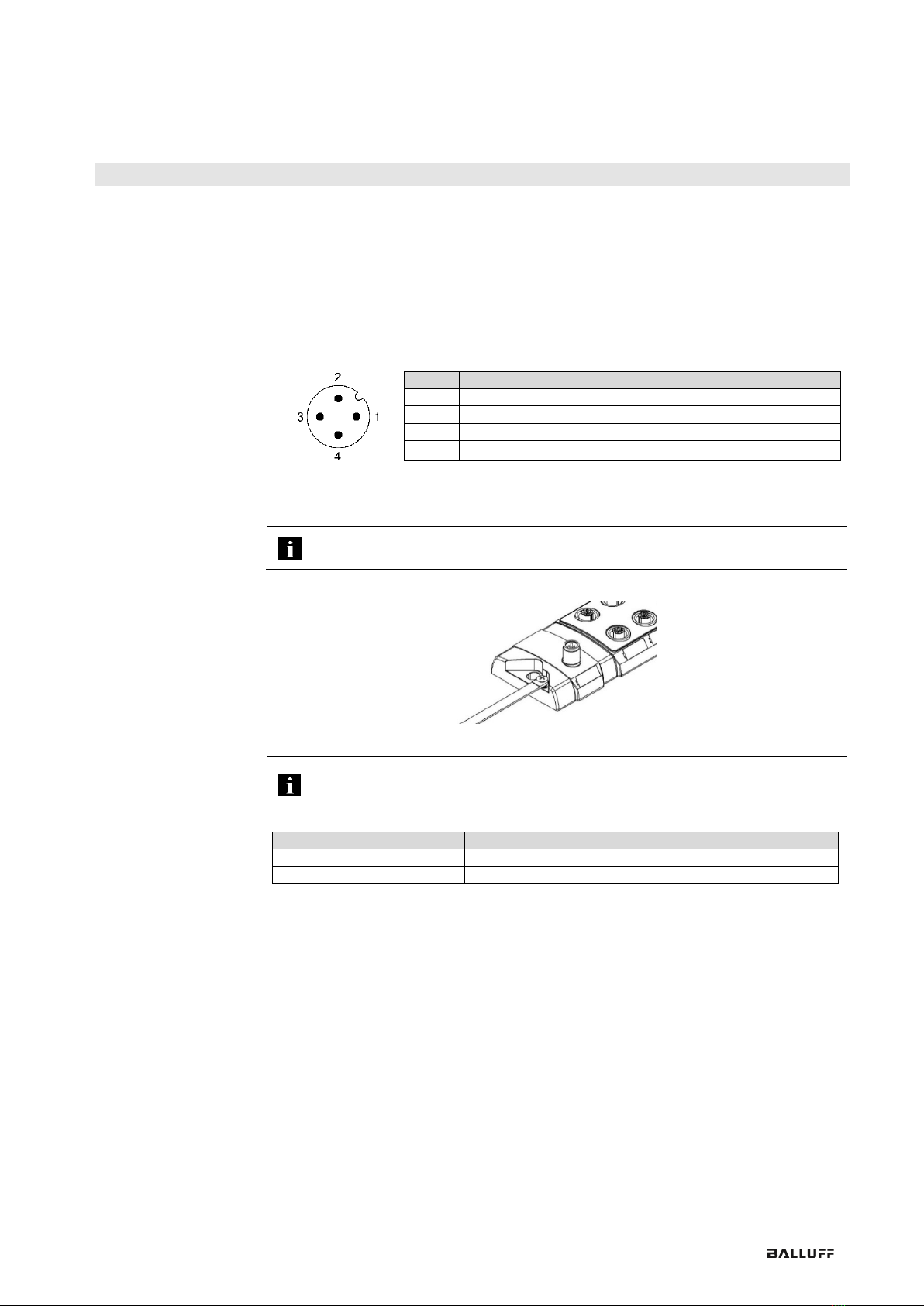

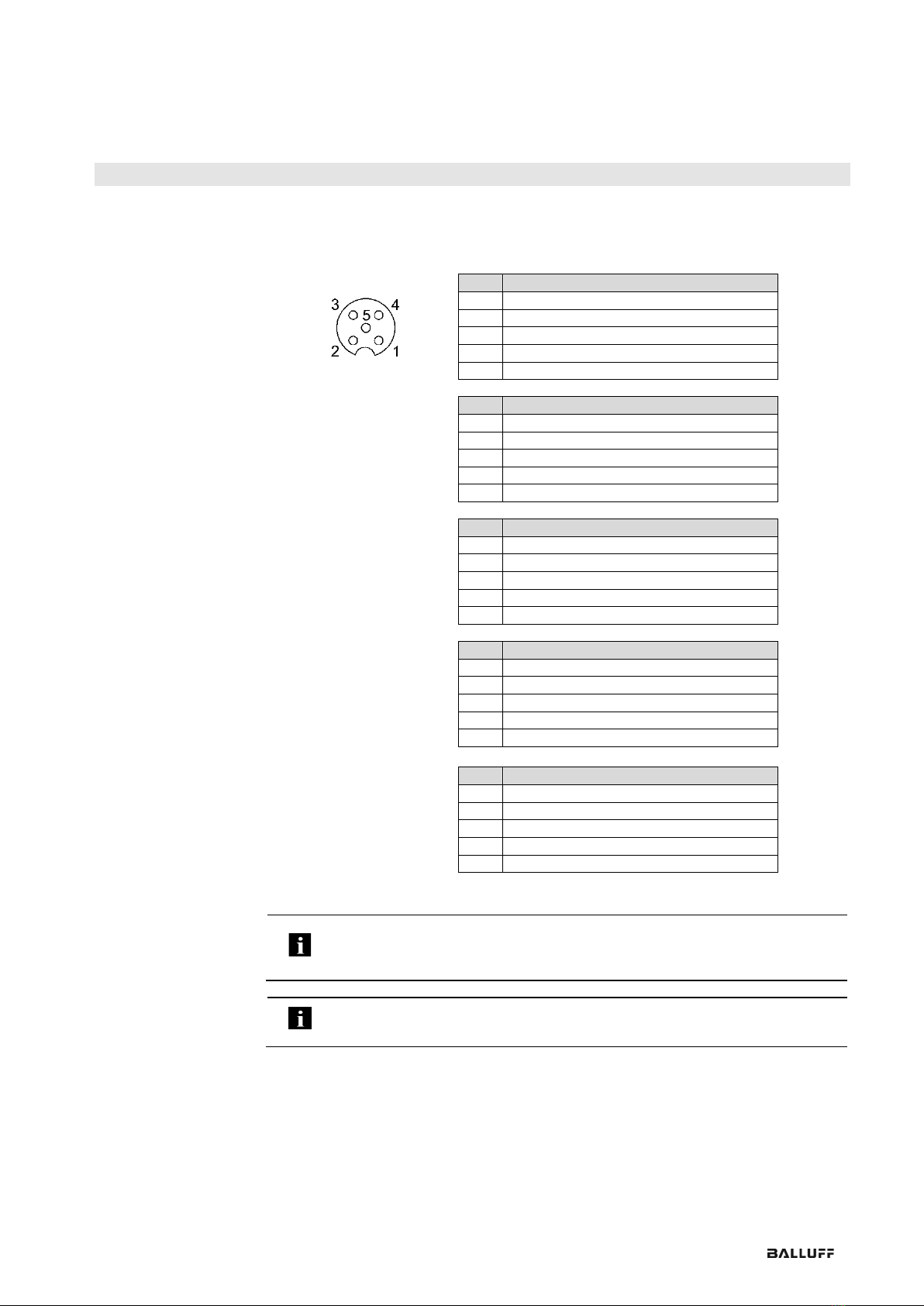

This guide describes the Balluff Network Interface BNI IOL-719-002-Z012-XXX for the

application as peripheral analog input module to establish connection of

RTDs and thermocouple sensors. Hereby it is about an IO-Link device which communicates

by means of IO-Link protocol with the superordinate IO-Link master assembly.

startup

Attention!

Installation and startup are to be performed only by trained specialists. Qualified

personnel are persons who are familiar with the installation and operation of the

product, and who fulfills the qualifications required for this activity. Any damage

resulting from unauthorized manipulation or improper use voids the manufacturer's

guarantee and warranty. The Operator is responsible for ensuring that applicable

of safety and accident prevention regulations are complied with.

notes

Commissioning and inspection

Before commissioning, carefully read the operating manual.

The system must not be used in applications in which the safety of persons is dependent on

the function of the device.

Authorized Personnel

Installation and commissioning may only be performed by trained specialist personnel.

Intended use

Warranty and liability claims against the manufacturer are rendered void by:

•Unauthorized tampering

•Improper use

•Use, installation or handling contrary to the instructions provided in this operating

manual

Obligations of the Operating Company

The device is a piece of equipment from EMC Class A. Such equipment may generate RF

noise. The operator must take appropriate precautionary measures. The device may only be

used with an approved power supply. Only approved cables may be used.

Malfunctions

In the event of defects and device malfunctions that cannot be rectified, the device must be

taken out of operation and protected against unauthorized use.

Intended use is ensured only when the housing is fully installed.

Aggressive

Substances

Attention!

The BNI modules always have good chemical and oil resistance. When used in

aggressive media (such as chemicals, oils, lubricants and coolants, each in a

high concentration (i.e. too little water content)), the material must first be

checked for resistance in the particular application. No defect claims may be

asserted in the event of a failure or damage to the BNI modules caused by such

voltage

Attention!

Disconnect all power before servicing equipment.

In the interest of product improvement, the Balluff GmbH reserves the right to

change the specifications of the product and the contents of this manual at any