6

Operation and Maintenance Schedule

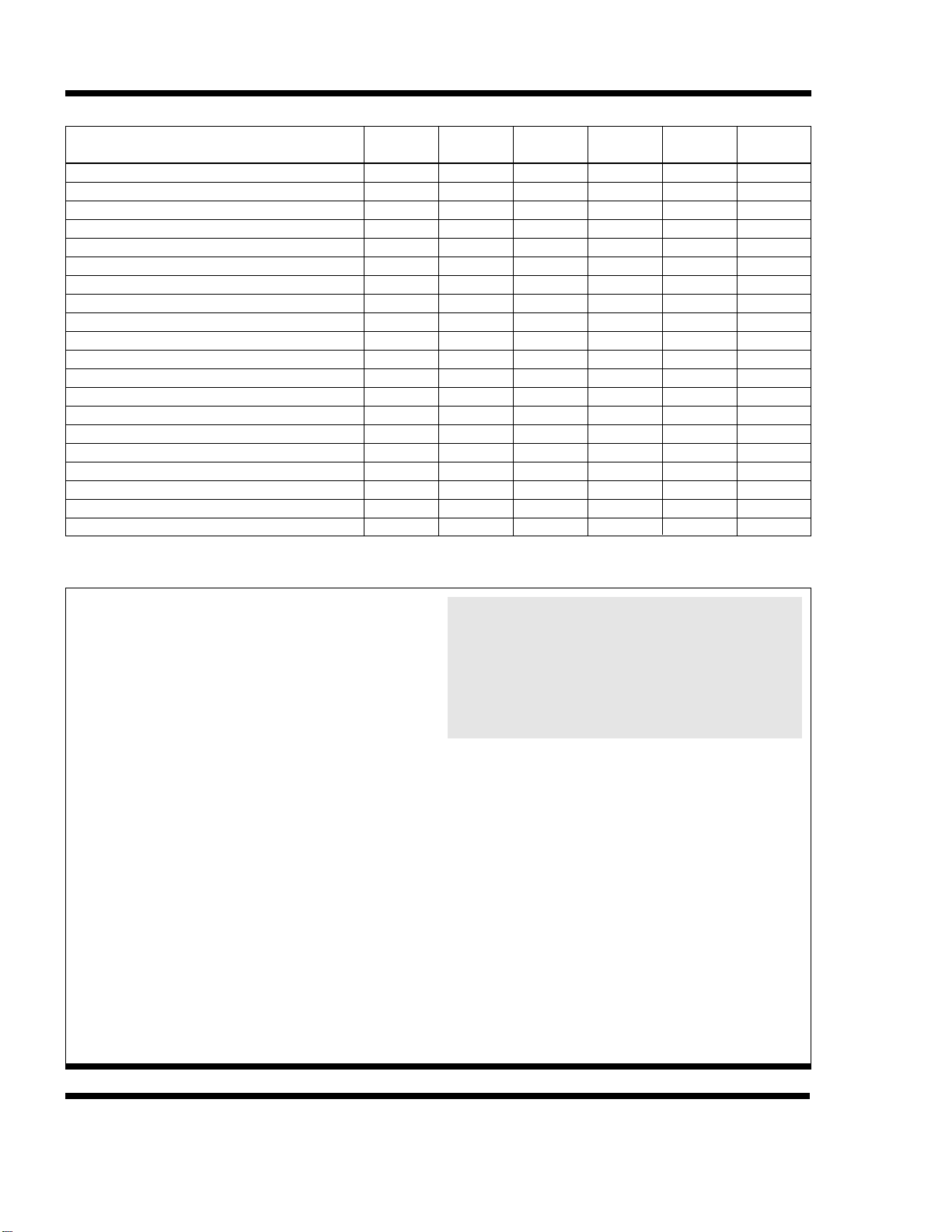

TABLE 1. Recommended Maintenance Services for Series V and Low Profile Series V Equipment.

TYPE SERVICE Start-Up Monthly Every Six

Months Shutdown Annually Ref. Page

Inspect General Condition of Unit

Clean Debris from Unit

Clean and Flush Basin

Clean Basin Strainer

Check and Adjust Basin Water Level

Inspect Heat Transfer Section

Inspect Spray Nozzles

Check and Adjust Fan Belt Tension

Check and Adjust Bleed Rate

Check Operation of Make-up Valve

Check Unit for Unusual Noise or Vibration

Check Fan Bearing Locking Collars

Check Motor Voltage and Current

Lubricate Fan Shaft Bearings

Lubricate Fan Motor Bearings

Lubricate Motor Base Adjusting Screw

Check Fan for Rotation Without Obstruction

Check Fan and Pump Motor for Proper Rotation

Drain Basin and Piping

Inspect Protective Finish

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

XX

X

X

X

X

X

X

X

X

XX

7

7

7

7

8

11

11

11

14

8

7

10

7

9

10

10

7

7

7

12

WARNING: Before performing any maintenance or inspection, make certain that all power has been

disconnected and locked in the off position.

WARRANTIES—Please refer to the Limitation of Warranties applicable to and in effect at the time of sale/purchase of these products.

FREEZE PROTECTION—These products must be protected by mechanical and operational methods against damage and/or reduced

effectiveness due to possible freeze-up. Please refer to the Cold Weather Operation guidelines (page 12) or contact the local B.A.C.

Representative for recommended protection alternatives.

SAFETY: The operation, maintenance, repair of this

equipment must be undertaken only by qualified per-

sonnel. All qualified personnel should be thoroughly

familiar with the equipment, the associated system and

controls, and the procedures set forth in this manual.

Proper care, procedures, and tools must be used in

handling, lifting, installing, operating, maintaining and

repairing this equipment to prevent personal injury

and/or property damage.

Lockout Warning:

For the protection of authorized ser-

vice and maintenance personnel, each fan and pump

motor associated with this equipment must be installed

with a lockable disconnect switch located within sight of

the cooling tower. No service work should be per-

formed on or near the fans, motors, and drives or inside

the unit without first ensuring the fan and pump motors

have been disconnected and locked out.

Electrical Hazard:

All electrical, mechanical, and rotat-

ing machinery constitute a potential hazard, particularly

for those not familiar with its design, construction, and

operation. Accordingly, adequate safeguards (including

the use of protective enclosures where necessary)

should be taken with this equipment both to safeguard

the public (including minors) from injury and to prevent

damage to the equipment, its associated system, and

the premises.

WARNING: PVC eliminators on this product are

not designed to support the weight of a person or

to be used as a storage or work surface for any

equipment or tools. Use of these PVC eliminators

as walking, working or storage surface may result

in injury to personnel or damage to equipment.

Units with PVC eliminators should not be covered

with a clear plastic tarpaulin.

Access:

Depending upon site conditions, it also may be

necessary to install bottom air inlet screens, ladders,

safety cages, stairways, access platforms, and handrails

and toeboards for the safety and convenience of autho-

rized service and maintenance personnel.

At no time should this equipment be operated

without all fan screens, access panels, and access

doors in place.

Caution:

The recirculating water system may contain

chemicals or biological contaminants, including Legionella,

which could be harmful if inhaled or ingested. Accordingly,

personnel who may be exposed directly to the discharge

airstream and the associated drift, mists generated during

operation of the water distribution system and/or fans, or

mists produced by high pressure water jets or compressed

air, should these be used to clean portions or components

of the recirculating water system, should wear respiratory

protection equipment approved for such use by OSHA

and/or local occupational safety and health authorities.