531 M1 02 A 16-07-2010 5

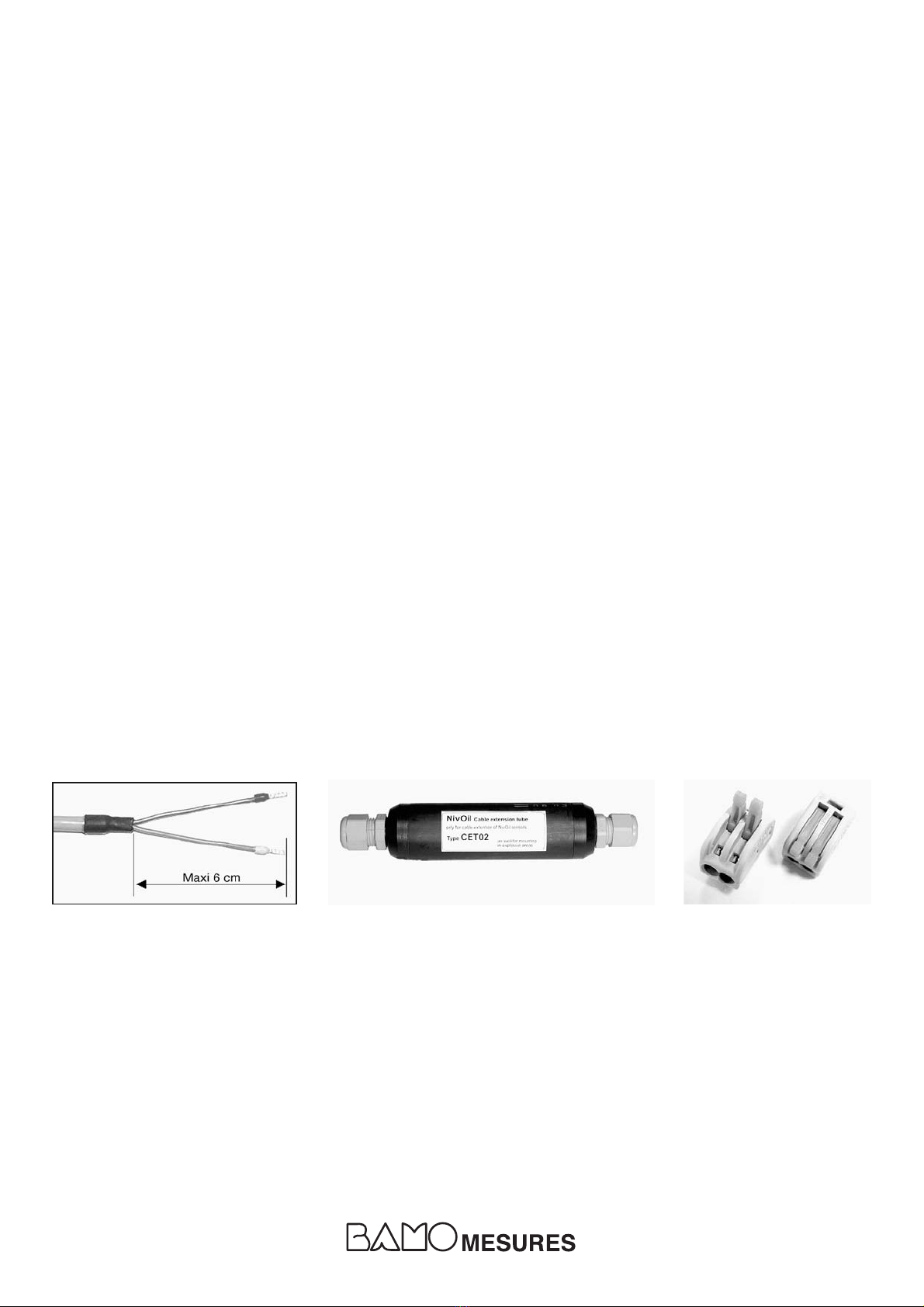

2°) Preparing the cables: Remove the external sheath as on the picture A and fit on a cable ter-

minal ends

Cable extension

The maximal length of an extension is 300 m.

Use the specific cable reference SK-PVC-2x1, ATEX certified.

The easier way to extend the cable accordingly with ATEX rules, is to use the CET02 cable

coupling (Pic.B), reference NivOil-JT, suitable to ATEX zone 0category 1.

The device is delivered with 2 WAGO connectors (Pic. C) for fast coupling.

Cable cross section: 4 mm2as a maximum

Protection: IP 65 (not for a continuous immersion)

The shield must not be connected.

Both ends must be pressed to the limit and pressure cable glands well tightened.

3°) Connect the sensors to the control unit NivOil in accordance with the obligations due to Ex

area, as shown on the drawing.

The measuring loop, as an intrinsic safe circuit, must not be connected to the ground.

Connect the control unit to the main power line.

Pic. C

Pic. B

Pic. A

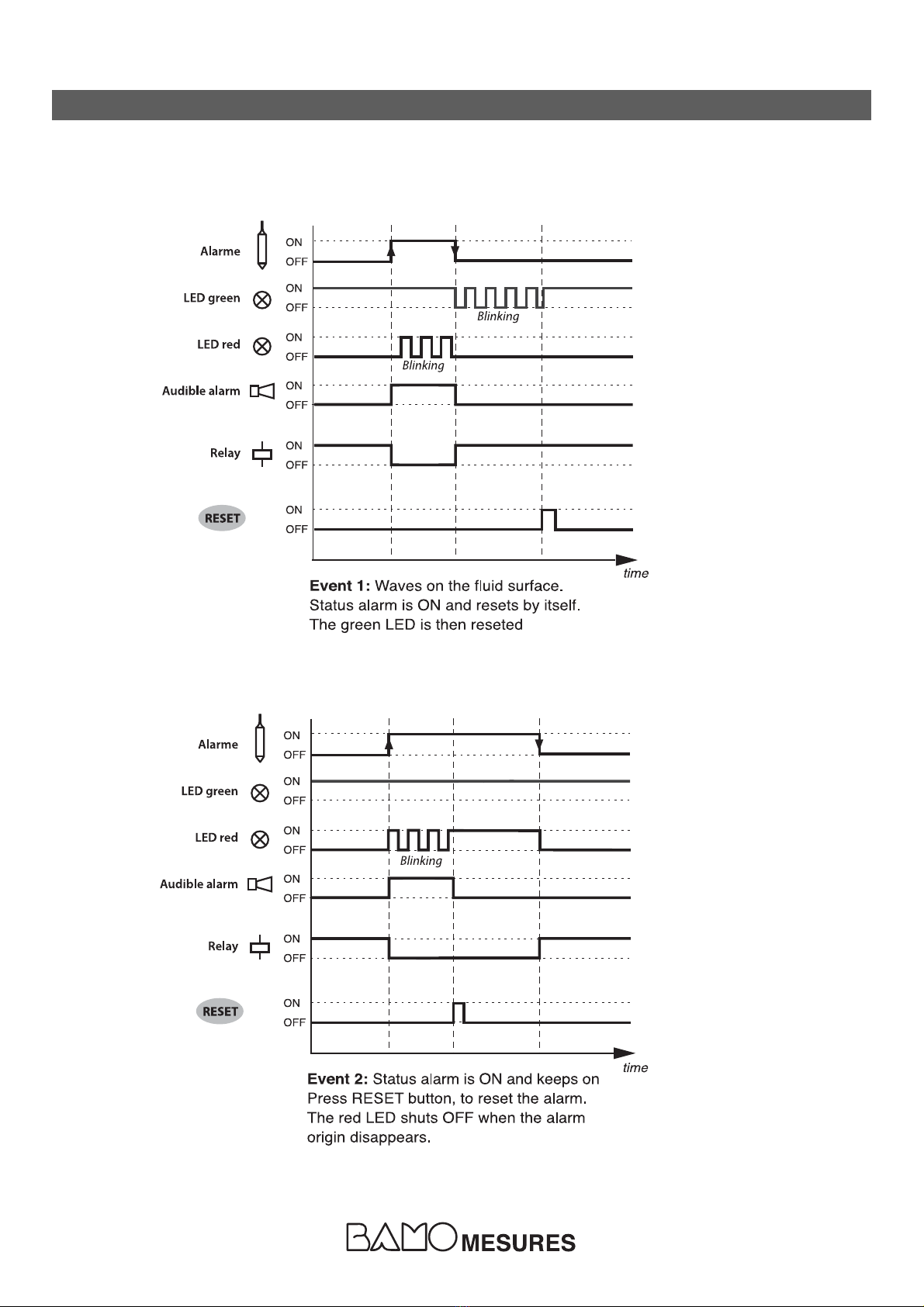

Monitoring modes: continuous monitoring, cyclic monitoring

The energy consumption is adjustable by modifying the duration of each monitoring cycle through

the settings of the DIP switch and the selector. The monitoring frequency is adjustable from 6

minutes to 9 days. Between 2 monitoring, the alarm unit is in sleep mode (monitoring function

in stand by).

When there is not a specific sleep mode period (selector on "0" and DIP 6, 7 and 8 are in ON

position), the alarm unit is continuously monitoring.

When the cyclic monitoring mode is set up, each monitoring cycle begins with a self-diagnostic

of sensors and detection loops in order to begin an alarm routine if necessary.

With 3 sensors connected to the alarm unit, a survey monitoring is completed in about 90 seconds.

The progress of each cycle is shown through a blinking LED (each 4 seconds approx.) on the

front panel.

During the sleep mode period, by pressing the TEST button (1 second approx.) it is possible to

begin directly a monitoring sequence:

lAt this moment, the alarm unit begins its self-diagnostic

lIn case of an alarm condition detected, it begins an alarm routine.

lAfter 90 seconds, the system goes back to the previous cyclic mode.

_________________________