E-Stop Safety Module – Models ES-UA-5A and ES-VA-5A

External Device Monitoring

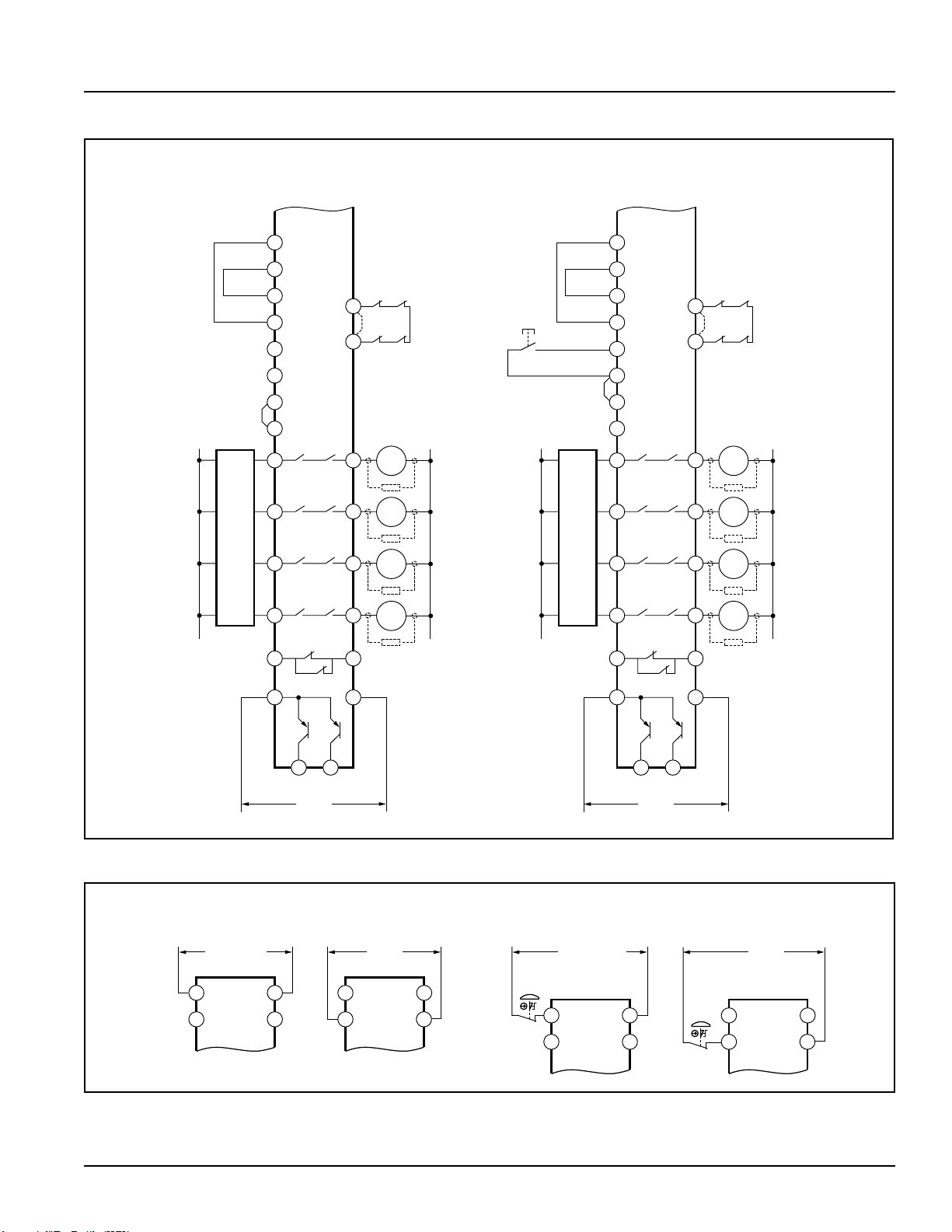

To satisfy the requirements of Safety Category 4 of EN 954-1, the Master Stop Control

Elements must each offer a normally closed, forced-guided monitor contact. One

normally closed monitor contact from each Master Stop Control Element is wired in

series to the S31-32 feedback input (see Figures 4 and 5). In operation, if one of the

switching contacts of either master stop control element fails in the shorted condition, the

associated monitor contact will remain open. Therefore, it will not be possible to reset

the E-Stop Safety Module. If no MSC-monitor contacts are monitored, a jumper must be

installed between terminals S31 and S32 (see Figures 4 and 5). It is the responsibility

of the user to ensure that any single failure will not result in a hazardous condition

and will prevent a successive machine cycle.

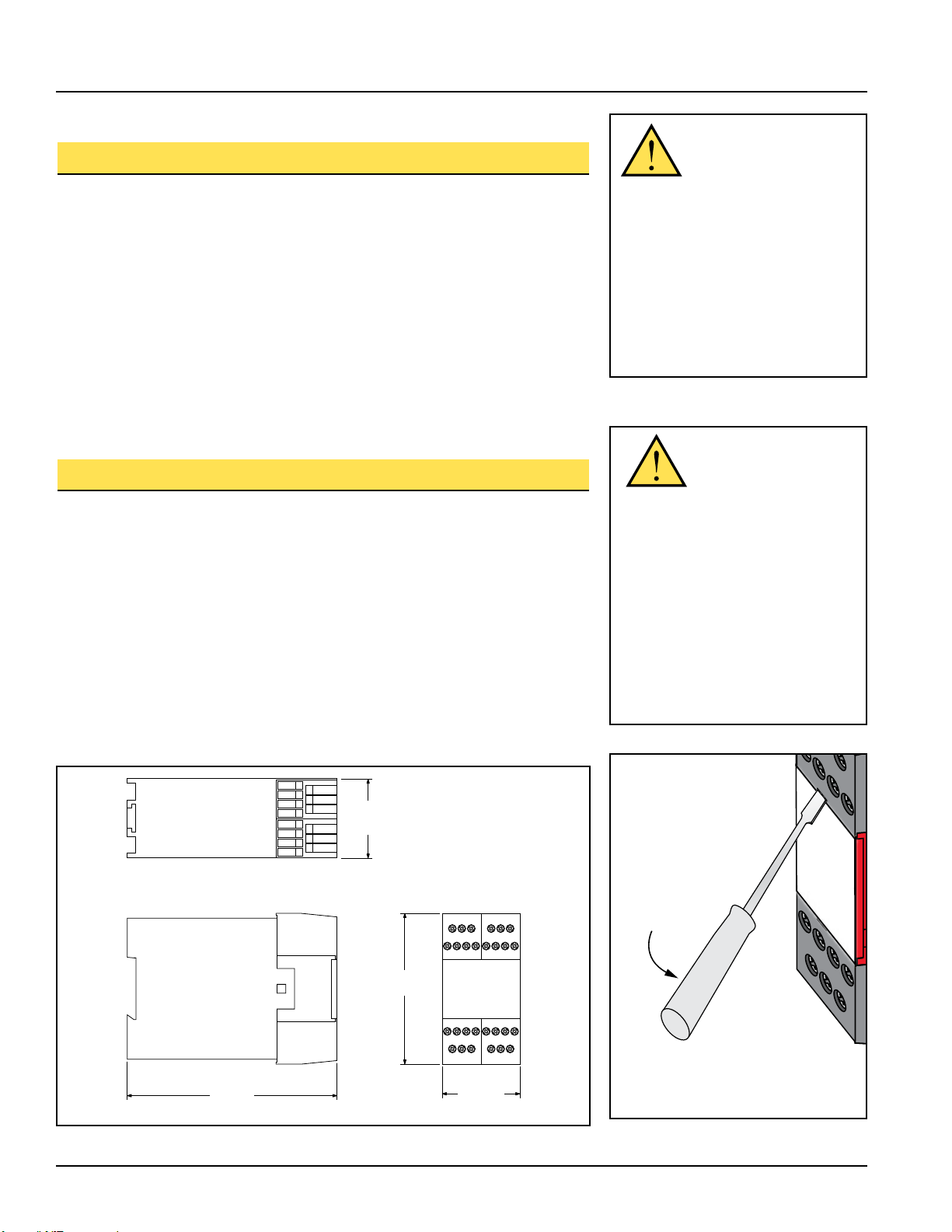

Connection to the Machine to be Controlled

The hookup diagrams (Figures 4 and 5) show a generic connection of the E-Stop Safety

Module’s four redundant output circuits to Master Stop Control Elements MSC1 through

MSC4. A Master Stop Control Element is defined as an electrically powered device,

external to the E-Stop Safety Module, which stops the machinery being controlled by

immediately removing electrical power to the machine and (when necessary) by applying

braking to dangerous motion. This stopping action is accomplished by removing power to

the actuator of either Master Stop Control Element.

Connection of Reset Switch

The Reset Circuit switch can be any mechanical switch such as a normally open

momentary switch, or a two-position key switch. The Reset switch must be capable of

reliably switching 12 to 18V dc at 40 to 100 milliamps. As shown in Figures 4 and 5, the

Reset switch connects between terminals S33 and S34 of the Safety Module.

The Reset switch must be located outside of – and not be accessible from – the

area of dangerous motion, and must be positioned so that any area of dangerous

motion may be observed by the switch operator during the Reset procedure.

To perform a manual reset, close the normally open switch for at least 1/4 second, but no

longer than 2 seconds, and then re-open the switch.

Automatic Reset Mode

Model ES-UA-5A or ES-VA-5A may be used also with automatic reset. If no MSC-monitor

contacts are monitored, a jumper must be installed between terminals S31 and S32 (see

Figures 4 and 5). The E-Stop Safety Module will reset (and the outputs energize) as soon

as the E-stop switch returns to its closed-contact position.

The automatic reset mode is useful for some automated processes. However, if

automatic reset is used, it is necessary to provide an alternate means of preventing

resumption of hazardous machine motion, until an alternate reset procedure is

performed. The alternate procedure must include a Reset/Restart switch, located outside

the area of dangerous motion, which is positioned so that any area of dangerous motion

may be observed by the switch operator during the reset procedure.

Auxiliary Monitor Contact/Solid-State Monitor Outputs Connection

The action of the auxiliary monitor contact, terminals 51/52, inversely “follows” the action

of the safety outputs. The 51/52 auxiliary monitor contact is to be used only for control

functions that are NOT safety-related.

There are two solid-state monitor outputs, each capable of switching up to 100 mA at

12-24V dc. One output at terminal Y32 follows the action of the output circuits (K1 and

K2); the other output at terminal Y35 opens (low signal) when there is an internal power

supply fault. A typical use is to communicate the status of the Safety Module output to a

programmable logic controller (PLC). See Figure 4 for hookup information.

WARNING . . .

Reset

Routine Required

U.S. and international

standards require that a reset routine

be performed after returning the E-stop

switch to its closed-contact position

(when arming the E-stop switch). When

automatic reset is used, an alternate

means must be established to require a

reset routine, after the E-stop switch is

armed. Allowing the machine to restart

as soon as the E-stop switch is armed

creates an unsafe condition which

could result in serious injury or death.

WARNING . . .

Reset Switch Location

Any Reset switch(es) used

must be accessible only from outside,

and in full view of, the hazardous area.

Reset switches must also be out of

reach from within the safeguarded

space, and must be protected against

unauthorized or inadvertent operation

(e.g., through the use of rings or guards).

If any areas are not visible from the

Reset switch(es), additional means of

safeguarding must be provided.