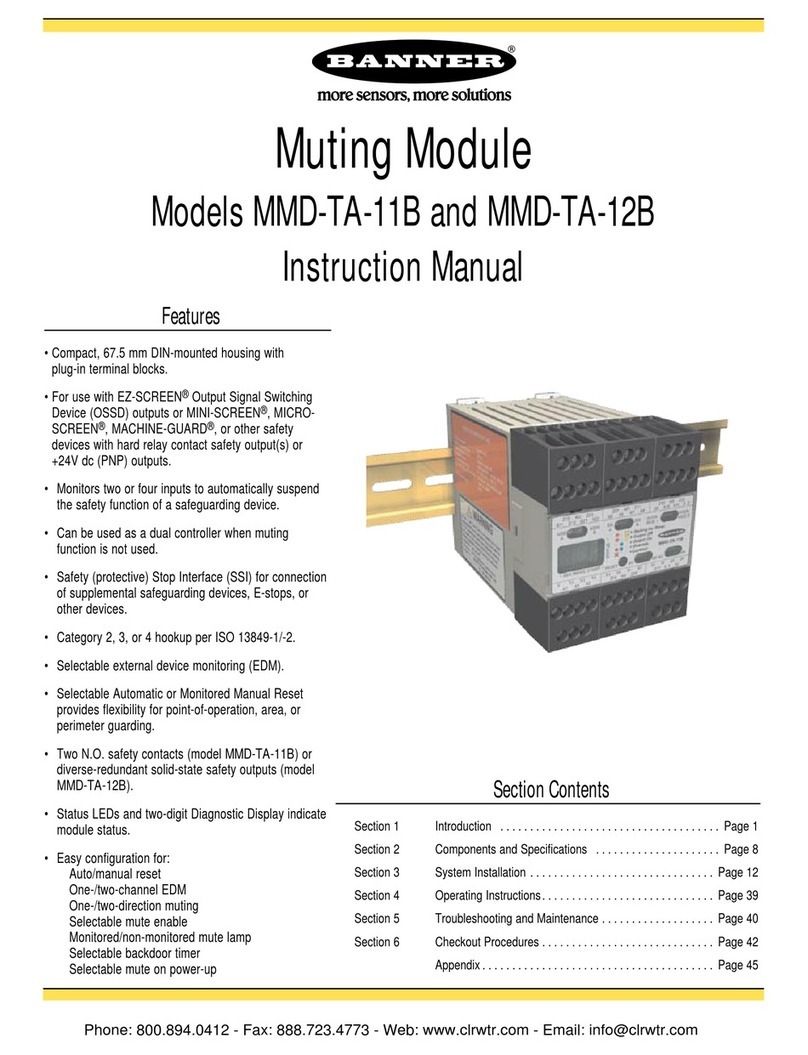

Table of Contents

MM-TA-12B Muting Module

Instruction Manual

Important ...

read this before proceeding!

In the United States, the functions that the

Banner MM-TA-12B Muting Module is intend-

ed to perform are regulated by the

Occupational Safety and Health

Administration (OSHA). Outside of the United

States, these functions are regulated by a

variety of agencies, organizations, and gov-

ernments. Whether or not any particular MM-

TA-12B Muting Module installation meets all

applicable requirements depends upon fac-

tors that are beyond the control of Banner

Engineering Corp. These factors include the

details of how the MM-TA-12B Muting

Module is applied, installed, wired, operated,

and maintained. It is the responsibility of the

installer and user to apply this MM-TA-12B

Muting Module in full compliance with all

applicable regulations and standards.

The Banner MM-TA-12B Muting Module can

guard against accidents only when it is prop-

erly installed and integrated into the machine,

properly operated, and properly maintained.

Banner Engineering Corp. has attempted to

provide complete application, installation,

operation, and maintenance instructions. In

addition, we suggest that any questions

regarding application or use of the MM-TA-

12B Muting Module be directed to the factory

applications department at the telephone

number or addresses shown on the back

cover.

In addition to OSHA regulations, several other

organizations provide informational material

on the use of safeguarding devices. The user

is referred to the American National

Standards Institute (ANSI), the Robotics

Industries Association (RIA), the Association

for Manufacturing Technology (AMT), and

others. Banner Engineering Corp. makes no

claim regarding a specific recommendation of

any organization, the accuracy or effective-

ness of any information provided, or the

appropriateness of the provided information

for a specific application. See Appendix C for

information pertaining to applicable U.S.,

European, and International standards and

where to acquire copies.

The user has the responsibility to ensure that

all local, state, and national laws, rules,

codes, and regulations relating to the use of

this safeguarding system in any particular

application are satisfied. Extreme care is

urged to ensure that all legal requirements

have been met and that all installation and

maintenance instructions contained in this

manual are followed.

Table of Contents

1.Introduction ...................................................................... page 3

1.1 Overview ........................................................................................page 3

1.2 Operating Status LEDs and Diagnostic Display ............................ page 4

1.3 Automatic or Monitored Manual Reset Select .............................. page 4

1.4 Lockout Conditions ...................................................................... page 5

1.5 Control Reliability: Redundancy and Self-Checking ...................... page 5

1.6 Muteable Safety Stop Interface (MSSI) ........................................ page 6

1.7 Universal Safety Stop Interface (USSI) ..........................................page 6

1.8 OSSD Outputs .............................................................................. page 6

1.9 Auxiliary Output (Aux) ....................................................................page 6

1.10 External Device Monitoring (EDM) ................................................page 7

1.11 Mute Devices and Mute Inputs (M1-M4) ......................................page 7

1.12 Mute Enable (ME) ..........................................................................page 8

1.13 Mute Lamp Output (ML) ................................................................page 9

1.14 Backdoor Timer ..............................................................................page 9

1.15 Mute on Power-Up ........................................................................page 9

1.16 Override ........................................................................................page 10

1.17 One-Way/Two-Way Muting ..........................................................page 10

1.18 Designated and Qualified Persons................................................page 10

2.Specifications .................................................................... page 11

2.1 Accessories ................................................................................ page 13

3.System Installation.............................................................. page 14

3.1 Appropriate Application .............................................................. page 14

3.2 Installing the Module .................................................................. page 17

3.3 Muting Module Configuration .................................................... page 18

3.4 Connector Pinouts/Functions ...................................................... page 18

3.5 Installing Input Devices ................................................................page 20

3.6 Machine Interface Connection – Initial Hookup and Checkout .. page 30

3.7 Permanent Hookup...................................................................... page 32

3.8 Commissioning Checkout .......................................................... page 35

4.Operating Instructions .......................................................... page 39

4.1 Security Protocol ........................................................................ page 39

4.2 Periodic Checkout Requirements................................................ page 39

4.3 Normal Operation ........................................................................ page 39

5.Troubleshooting and Maintenance............................................ page 40

5.1 Troubleshooting Lockout Conditions .......................................... page 40

5.2 Diagnostic Display........................................................................page 40

5.3 Effects of Electrical and Optical Noise ........................................ page 40

5.4 Repairs ........................................................................................ page 42

6.Periodic Checkout Procedures ................................................ page 43

6.1 Schedule of Checkouts ................................................................page 43

6.2 Commissioning Checkout .......................................................... page 43

6.3 Daily Checkout..............................................................................page 46

6.4 Semi-Annual Checkout .............................................................. page 47

Appendix

Appendix A, Mute Timing Sequences ........................................................page 48

Appendix B, Typical Muting Applications ..................................................page 49

Appendix C, Application Safety Standards ................................................page 55