The user is responsible for making sure that all machine operators, maintenance personnel, electricians, and supervisors are

thoroughly familiar with and understand all instructions regarding the installation, maintenance, and use of this product, and with the

machinery it controls. The user and any personnel involved with the installation and use of this product must be thoroughly familiar

with all applicable standards, some of which are listed within the specifications. Banner Engineering Corp. makes no claim regarding

a specific recommendation of any organization, the accuracy or effectiveness of any information provided, or the appropriateness of

the provided information for a specific application.

WARNING:

•Not a safeguarding device

• Failure to follow these instructions could result in serious injury or death.

• This device is not considered a safeguarding device because it requires an overt action by an individual

to stop machine motion or hazards. A safeguarding device limits or eliminates an individual's exposure

to a hazard without action by the individual or others. This device cannot be substituted for required

safeguarding. Refer to the applicable standards to determine those requirements.

Emergency Stop Considerations

NFPA 79, ANSI B11.19, IEC/EN 60204-1, and ISO 13850 specify emergency stop requirements, including the following:

• Emergency-stop push buttons shall be located at each operator control station and at other operating stations where

emergency shutdown is required.

• Stop and emergency-stop push buttons shall be continuously operable and readily accessible from all control and operating

stations where located. Do not mute or bypass E-stop buttons.

• Actuators of emergency-stop devices shall be colored red. The background immediately around the device actuator shall be

colored yellow (where possible). The actuator of a push-button-operated device shall be of the palm or mushroom-head

type.

• The emergency-stop actuator shall be a self-latching type.

WARNING:

•Do not mute or bypass any emergency stop device

• Muting or bypassing the safety outputs renders the emergency stop function ineffective.

• ANSI B11.19, NFPA 79 and IEC/EN 60204-1 require that the emergency stop function remains active at

all times.

WARNING:

•Connect two or more devices to the same safety module (controller) in series

• Connecting devices in parallel defeats the switch contact monitoring ability of the module and creates an

unsafe condition that could result in serious injury or death.

• Failure to test each device individually in this manner could result in undetected faults and create an

unsafe condition that could result in serious injury or death.

• Connect the contacts of the corresponding pole of each switch in series. Never connect the contacts of

multiple switches in parallel. Individually actuate (engage) each device, then release (or re-arm) and

reset the safety module. This allows the module to check each switch and its wiring to detect faults.

Perform this check during the prescribed checkouts.

Installation and Maintenance

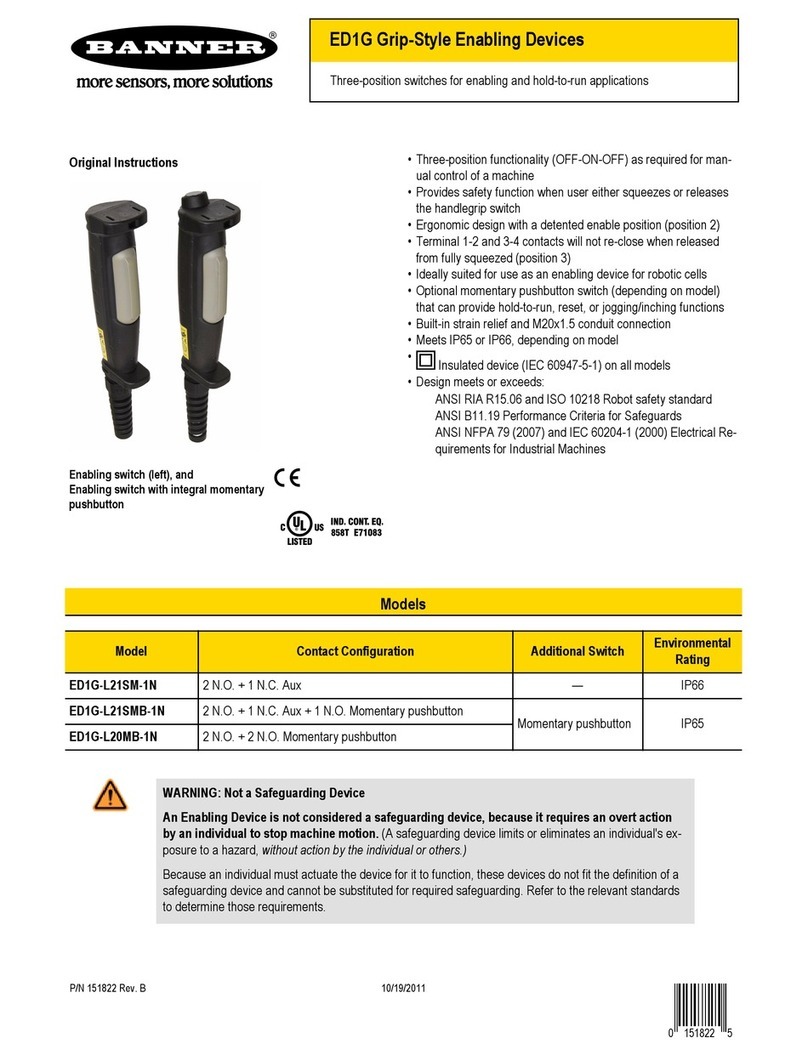

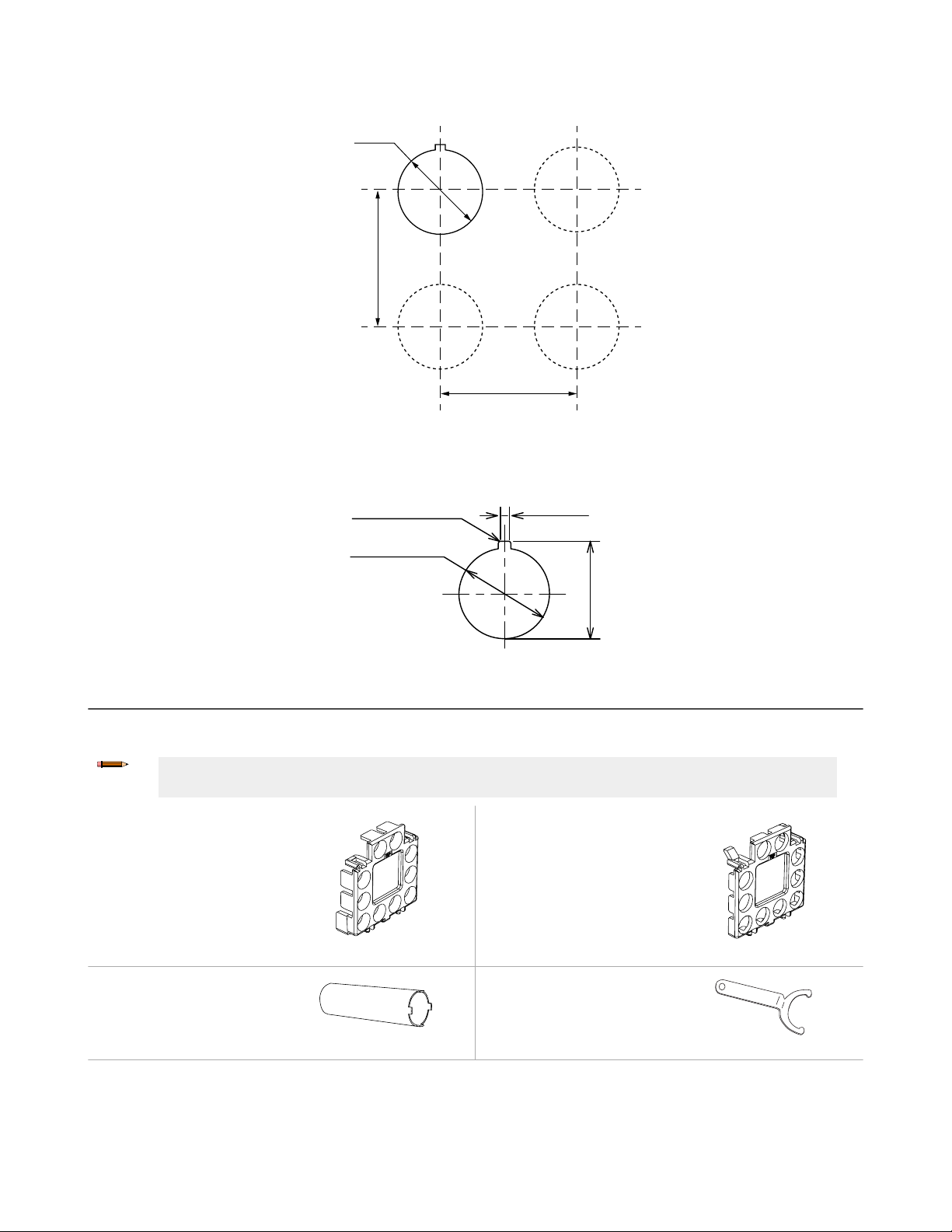

The device must not be affected by environmental conditions. Install the device so that operation is not impeded, but should be

protected against inadvertent operation (for example, accidental actuation by being bumped or leaned against). Do not operate

the switch using a tool. Do not expose the switch to excessive shocks and vibrations, otherwise the switch may be deformed or

damaged, causing malfunction or operation failure. See Dimensions on page 8.

Electrical installation must be made by qualified personnel 1 and must comply with NEC (National Electrical Code), NFPA 79 or

IEC/EN 60204-1, and all applicable local standards. It is not possible to give exact wiring instructions for a device that interfaces to a

multitude of machine control configurations. The following is general in nature; it is recommended to perform a risk assessment to

ensure appropriate application, interfacing/hookup, and risk reduction (see ISO 12100 or ANSI B11.0).

For SSA-EB1M..-.. series padlock-style lockable emergency stop push buttons, make sure that an applicable padlock and hasp is

used. The total weight of the padlock and hasp must not exceed 1500 g (3.3 lbs) or the switch may malfunction or fail.

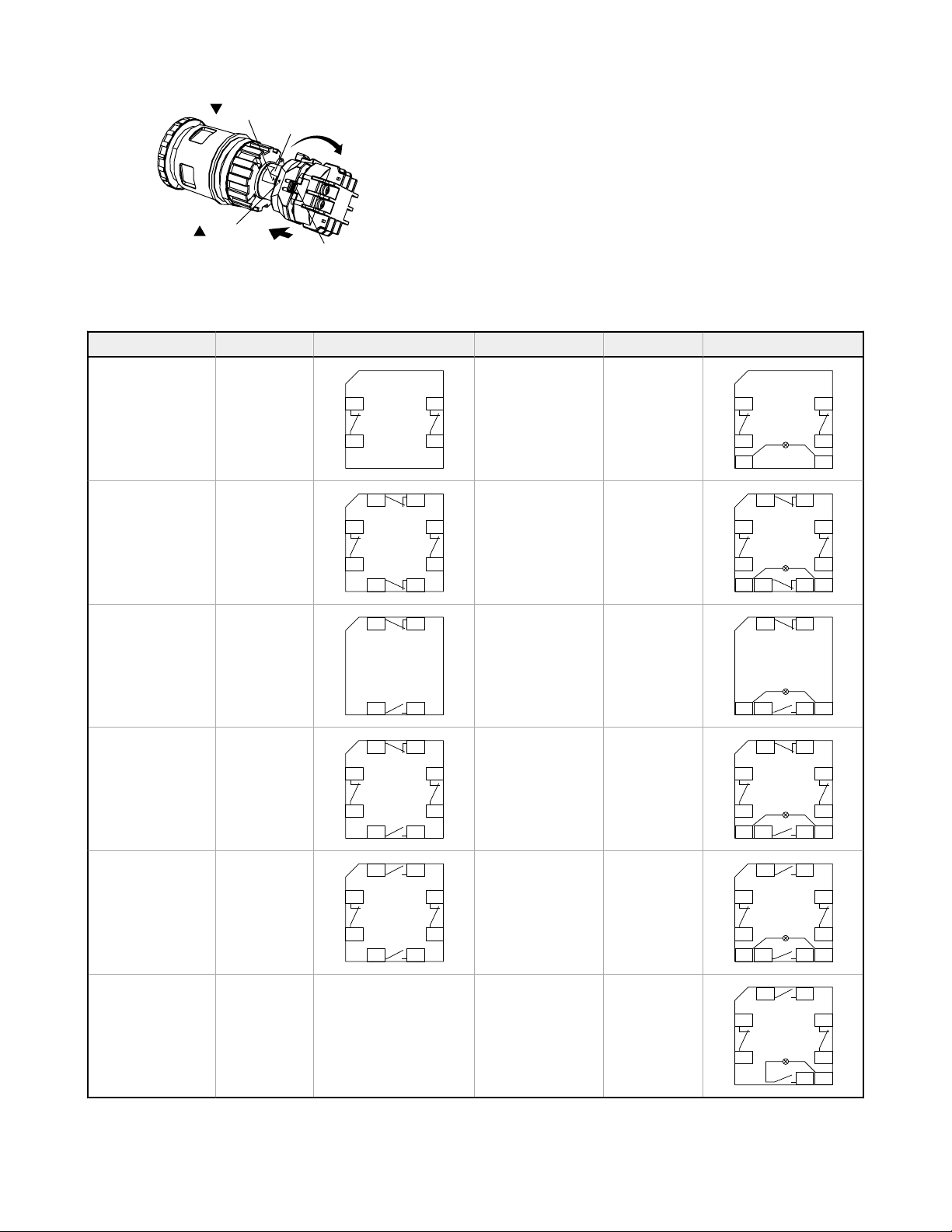

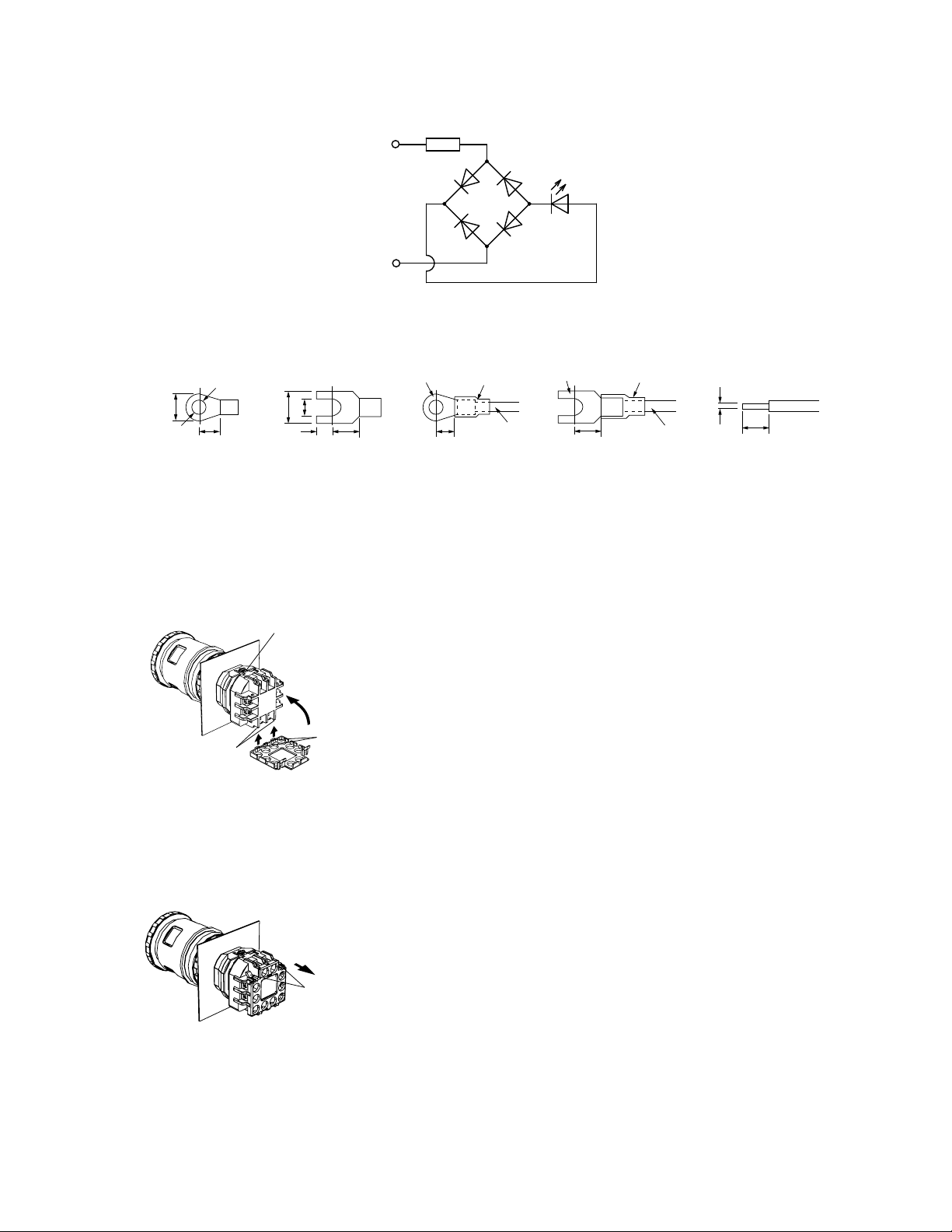

Removing and Installing the Contact Block and Panel Mounting

For more information, please refer to the training video at https://www.youtube.com/watch?v=FjfR6d4ljrA.

1A Qualified Person possesses a recognized degree or certificate or has extensive knowledge, training, and experience to solve problems relating to the

emergency stop installation.

SSA-EB Series Emergency Stop Push Button

2 www.bannerengineering.com - Tel: + 1 888 373 6767 P/N 194992 Rev. D