3

5.9.3 Machine Primary Control Elements (MPCE) and External Device Monitoring (EDM) Input....................................................... 44

5.10 Auxiliary (Aux.) Output ...................................................................................................................................................................... 46

5.11 Remote Test Input ............................................................................................................................................................................. 46

5.12 Preparing for System Operation ....................................................................................................................................................... 46

5.13 Sensor "Swapability" .......................................................................................................................................................................... 46

5.14 Generic Wiring Diagrams ................................................................................................................................................................... 47

5.14.1 Wiring FSD ............................................................................................................................................................................... 51

Chapter 6 Operating Instructions

6.1 Security Protocol ................................................................................................................................................................................ 53

6.2 System Configuration Settings ............................................................................................................................................................ 53

6.2.1 Access the Configuration Panel ................................................................................................................................................. 54

6.2.2 Inverted Display ......................................................................................................................................................................... 55

6.2.3 Selectable Trip/Latch Outputs .................................................................................................................................................... 55

6.3 Reset Procedures ................................................................................................................................................................................ 55

6.3.1 Manual Resets and Lockout Conditions .................................................................................................................................... 56

6.3.2 Resetting the Receiver ............................................................................................................................................................... 56

6.3.3 Resetting the Emitter .................................................................................................................................................................. 56

6.4 Status Indicators.................................................................................................................................................................................. 56

6.4.1 Emitter Status Indicators............................................................................................................................................................. 57

6.4.2 Receiver Status Indicators.......................................................................................................................................................... 58

6.4.3 Status Indicators for Cascaded Applications ............................................................................................................................. 59

6.5 Normal Operation ................................................................................................................................................................................. 63

6.5.1 System Power-Up ...................................................................................................................................................................... 63

6.5.2 Run Mode ................................................................................................................................................................................. 64

6.6 Periodic Checkout Requirements ........................................................................................................................................................ 64

Chapter 7 Checkout Procedures

7.1 Schedule of Checkouts ........................................................................................................................................................................ 65

7.2 Commissioning Checkout .................................................................................................................................................................... 66

7.3 Shift/Daily Checkout ............................................................................................................................................................................ 67

7.4 Semi-Annual (Six-Month) Checkout .................................................................................................................................................... 67

Chapter 8 Cascade

8.1 Overview of Cascading ........................................................................................................................................................................ 69

8.2 System Components and Specifications .............................................................................................................................................. 70

8.2.1 Cascadeable Emitter and Receiver Models with 14 mm Resolution ........................................................................................ 70

8.2.2 Cascadeable Emitter and Receiver Models with 30 mm Resolution ........................................................................................ 71

8.3 Receiver Display .................................................................................................................................................................................. 72

8.4 Determining Interconnect Cable Lengths ............................................................................................................................................ 72

8.5 Response Time for Cascaded Light Screens ....................................................................................................................................... 74

8.5.1 Individual Response Time and Separation Distance ................................................................................................................. 75

8.5.2 Overall Response Time and Safety (Minimum) Distance ......................................................................................................... 76

8.5.3 Cascade Configuration vs. Response Time ............................................................................................................................... 76

8.6 Cascaded Sensor Configuration Settings ........................................................................................................................................... 77

8.6.1 Configure for Cascaded Operation ............................................................................................................................................ 78

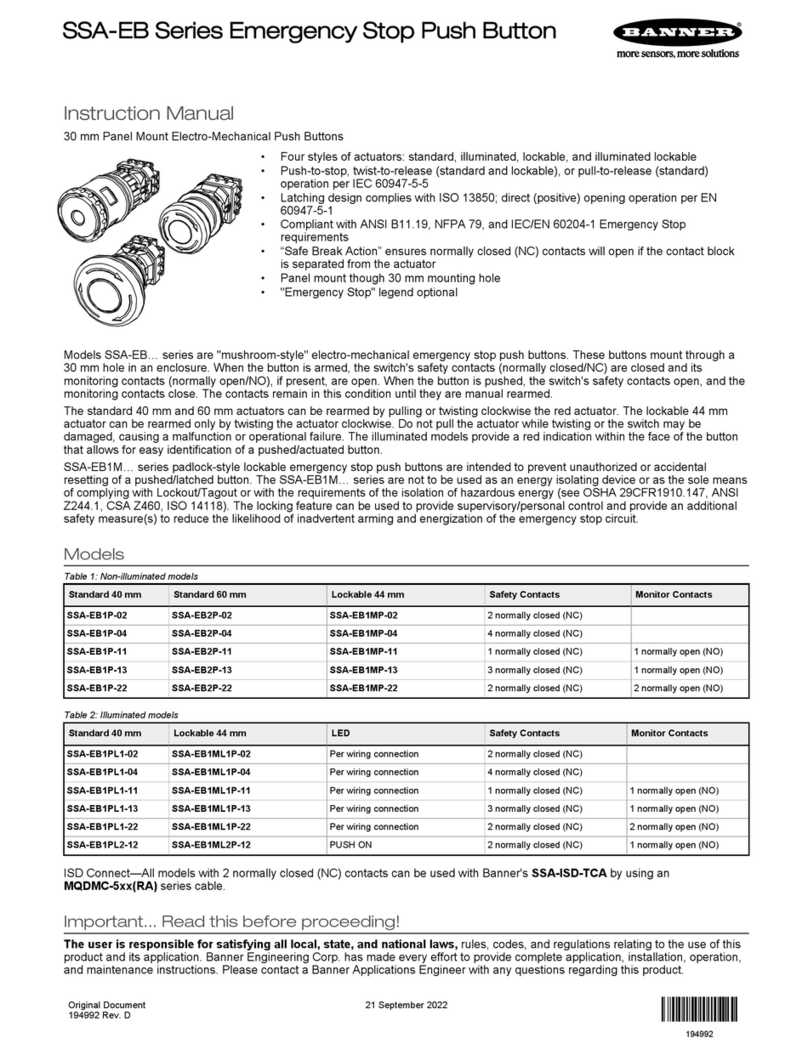

8.7 Emergency Stop Buttons and Rope/Cable Pulls ................................................................................................................................. 79

8.7.1 E-Stop Switch Requirements (Positive-Opening) ...................................................................................................................... 80

8.8 Interlock Switches in Cascaded Systems............................................................................................................................................. 80

8.8.1 Interlock Guarding Requirements ............................................................................................................................................. 81

8.8.2 Positive-Opening Interlocking Safety Switches ......................................................................................................................... 81

8.8.3 Monitoring Series-Connected Positive-Opening Safety Switches ............................................................................................. 82

Chapter 9 Troubleshooting

9.1 Troubleshooting and Lockout Conditions ........................................................................................................................................... 85

9.2 Recovery Procedures ........................................................................................................................................................................... 85

9.2.1 Emitter and Receiver Reset........................................................................................................................................................ 85

9.2.2 Advanced Diagnostics .............................................................................................................................................................. 86

9.2.3 Receiver Error Codes ................................................................................................................................................................ 86

9.2.4 Emitter Error Codes ................................................................................................................................................................... 88

9.3 Test Mode for 5-Pin Emitters ............................................................................................................................................................... 88

9.4 Electrical and Optical Noise ................................................................................................................................................................. 89

9.4.1 Check for Sources of Electrical Noise ....................................................................................................................................... 89

9.4.2 Check for Optical Noise Sources................................................................................................................................................ 89

Chapter 10 Accessories

10.1 Cordsets ........................................................................................................................................................................................... 91

10.1.1 Single-Ended (Machine Interface) Cordsets (One Cable for Each Emitter and Receiver) ...................................................... 91