Contents

1 About This Document .................................................................................................................................................. 4

1.1 Important... Read This Before Proceeding! ......................................................................................................................................4

1.2 Use of Warnings and Cautions ........................................................................................................................................................ 4

1.3 EU Declaration of Conformity (DoC) ................................................................................................................................................4

2 Standards and Regulations .......................................................................................................................................... 5

2.1 Applicable U.S. Standards ............................................................................................................................................................... 5

2.2 OSHA Regulations ...........................................................................................................................................................................5

2.3 International/European Standards ................................................................................................................................................... 5

3 Introduction ...................................................................................................................................................................7

3.1 Features ..........................................................................................................................................................................................7

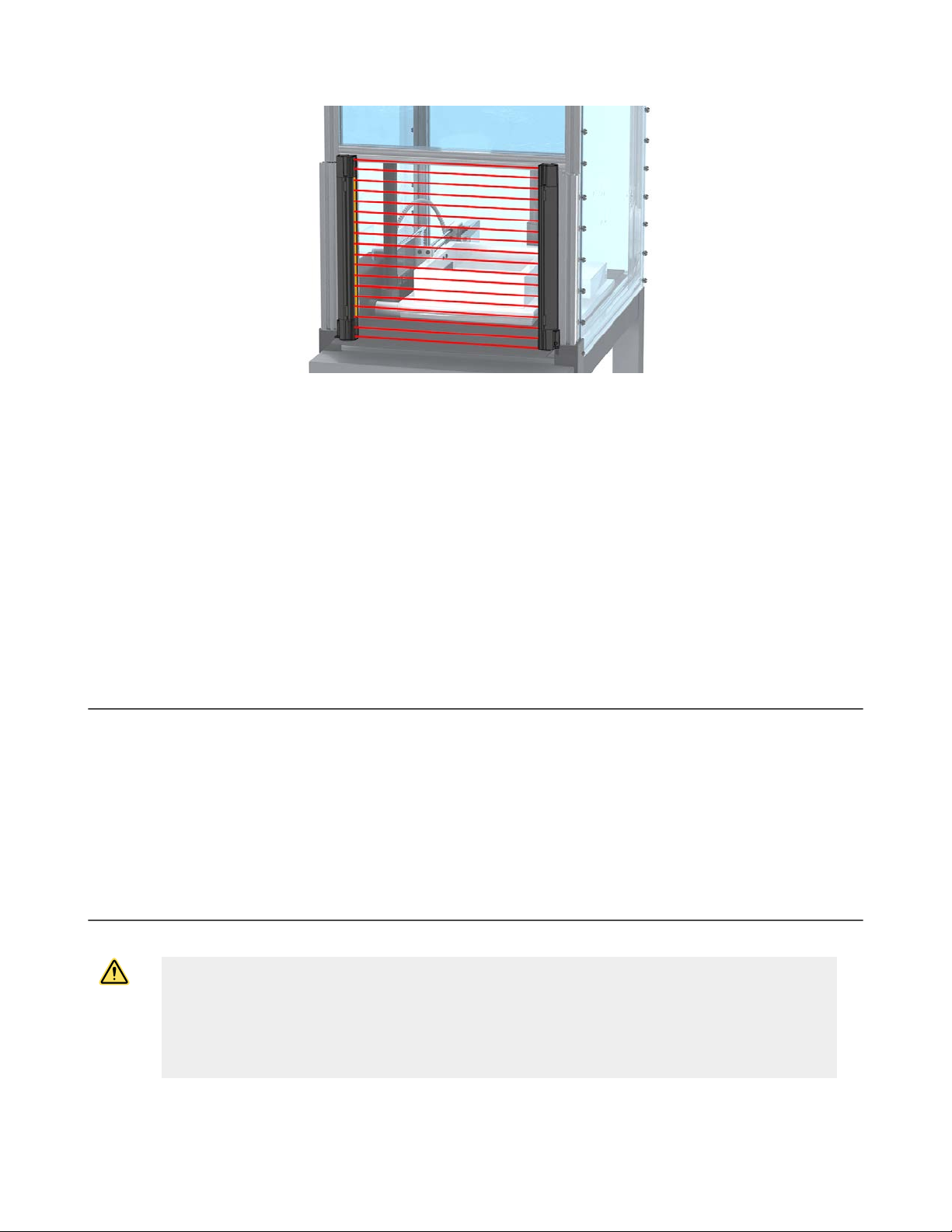

3.2 System Description ......................................................................................................................................................................... 7

3.2.1 Components ............................................................................................................................................................................ 8

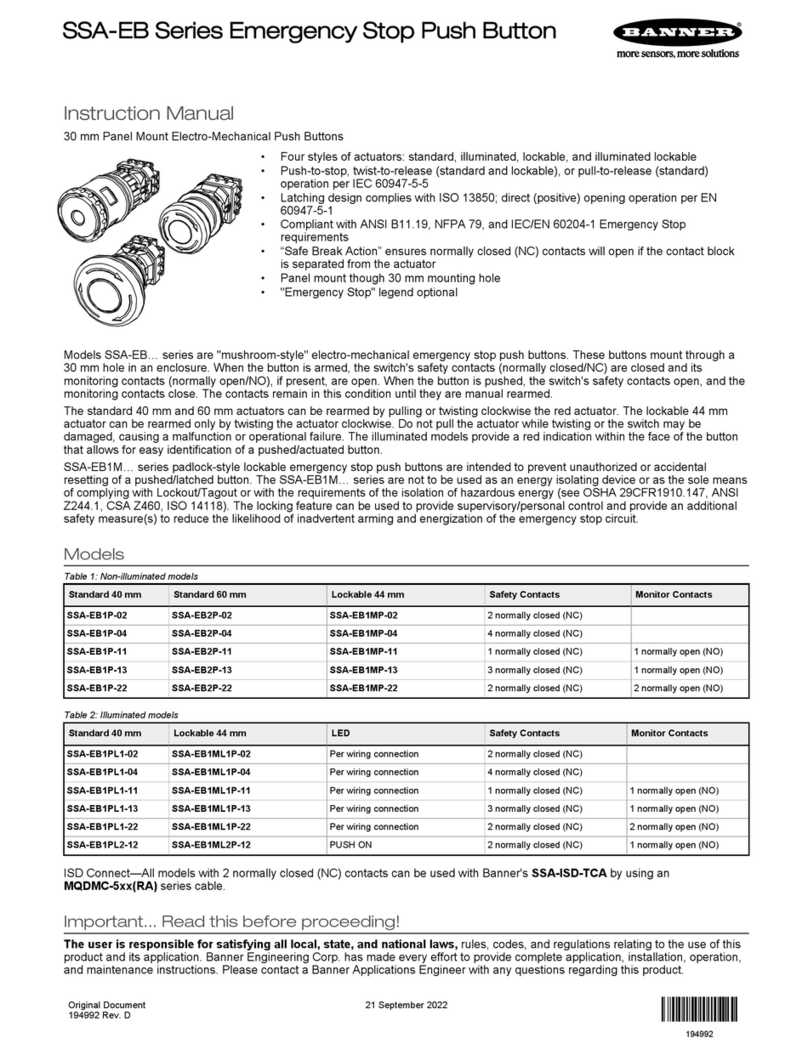

3.2.2 Models ..................................................................................................................................................................................... 8

3.3 Appropriate Applications and Limitations ........................................................................................................................................9

3.3.1 Appropriate Applications ..........................................................................................................................................................9

3.3.2 Examples: Inappropriate Applications .................................................................................................................................... 10

3.4 Control Reliability: Redundancy and Self-Checking ......................................................................................................................10

3.5 Operating Features ....................................................................................................................................................................... 10

3.5.1 Trip Output .............................................................................................................................................................................11

3.5.2 Scan Code Configuration ...................................................................................................................................................... 11

3.5.3 Weak Beam Strength Indication ............................................................................................................................................. 12

4 Specifications ............................................................................................................................................................. 13

4.1 General Specifications .................................................................................................................................................................. 13

4.2 Emitter Specifications ....................................................................................................................................................................13

4.3 Receiver Specifications .................................................................................................................................................................14

5 Mechanical Installation ............................................................................................................................................... 15

5.1 Mechanical Installation Considerations .........................................................................................................................................15

5.2 Calculating the Safety Distance (Minimum Distance) .................................................................................................................... 15

5.2.1 Formula and Examples ..........................................................................................................................................................16

5.2.2 Examples ...............................................................................................................................................................................17

5.3 Reducing or Eliminating Pass-Through Hazards .......................................................................................................................... 18

5.4 Supplemental Safeguarding ..........................................................................................................................................................18

5.5 Reset Switch Location ....................................................................................................................................................................19

5.6 Other Considerations .................................................................................................................................................................... 20

5.6.1 Adjacent Reflective Surfaces .................................................................................................................................................20

5.6.2 Use of Corner Mirrors ............................................................................................................................................................ 21

5.6.3 Emitter and Receiver Orientation .......................................................................................................................................... 22

5.6.4 Installation of Multiple Systems ............................................................................................................................................. 23

5.7 Mounting System Components ......................................................................................................................................................24

5.7.1 Mounting Hardware ............................................................................................................................................................... 24

5.7.2 Sensor Mounting and Mechanical Alignment Verification ...................................................................................................... 26

5.7.3 Mounting Dimensions and Defined Area ............................................................................................................................... 27

6 Electrical Installation and Testing .............................................................................................................................28

6.1 Routing Cordsets .......................................................................................................................................................................... 28

6.2 Scan Code Selection .....................................................................................................................................................................28

6.3 Initial Electrical Connections ......................................................................................................................................................... 30

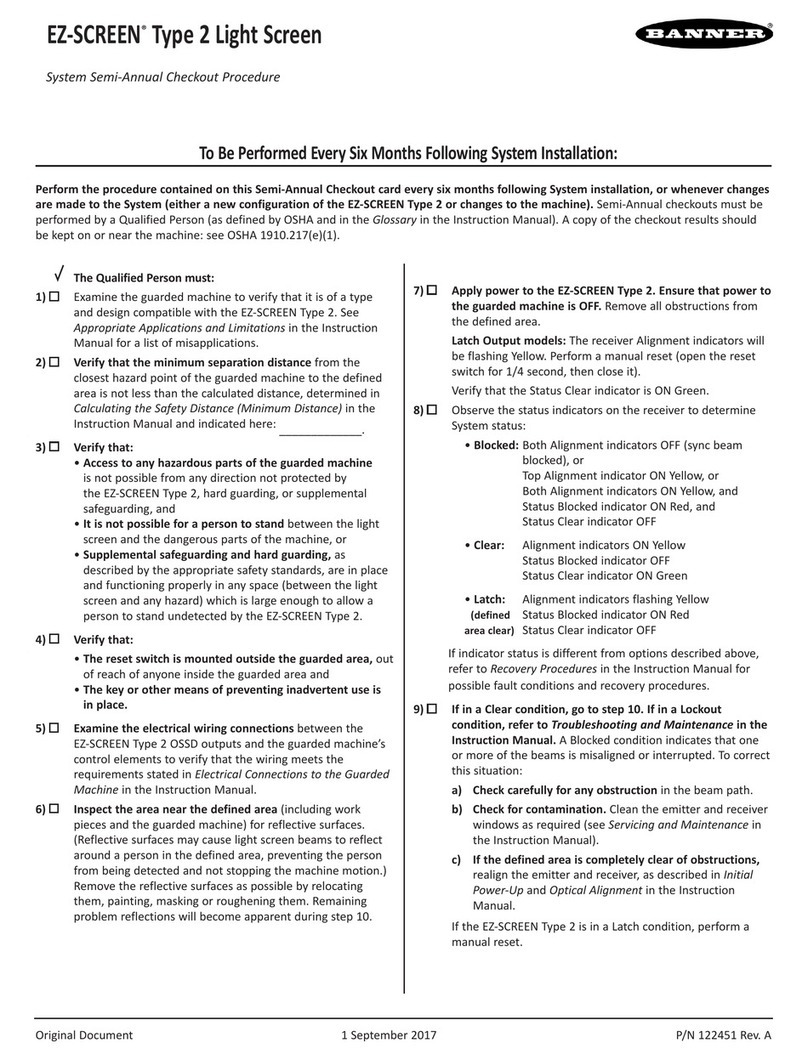

6.4 Initial Checkout Procedure .............................................................................................................................................................30

6.4.1 Configuring the System for Initial Checkout .......................................................................................................................... 30

6.4.2 Apply Initial Power to the S4B System .................................................................................................................................. 30

6.4.3 Optically Align the System Components ............................................................................................................................... 31

6.4.4 Optical Alignment Procedure with Mirrors ............................................................................................................................. 32

6.4.5 Conduct a Trip Test ............................................................................................................................................................... 32

6.5 Electrical Connections to the Guarded Machine ...........................................................................................................................34

6.5.1 Protective Stop (Safety Stop) Circuits ................................................................................................................................... 34

6.5.2 Preparing for System Operation ............................................................................................................................................ 35

6.5.3 Sensor Interchangeability ....................................................................................................................................................... 36

6.5.4 Commissioning Checkout ......................................................................................................................................................36

6.6 Wiring Diagrams .............................................................................................................................................................................38

6.6.1 Generic Emitter Wiring Diagram ............................................................................................................................................38

6.6.2 Generic Receiver Wiring Diagram—Self-checking Safety Module, Safety Controller, Safety PLC .......................................39

7 System Operation ....................................................................................................................................................... 40

7.1 Security Protocol ...........................................................................................................................................................................40

7.2 Normal Operation ..........................................................................................................................................................................40

S4B Safety Light Curtain