DUO-TOUCH®SG – Two-Hand-Control Kits with STB Touch Buttons

page 8

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Electrical Installation

Because the DUO-TOUCH SG Safety Module interfaces to many types of machine

controls, it is not possible to give exact wiring instructions here. The following guide-

lines are general in nature.

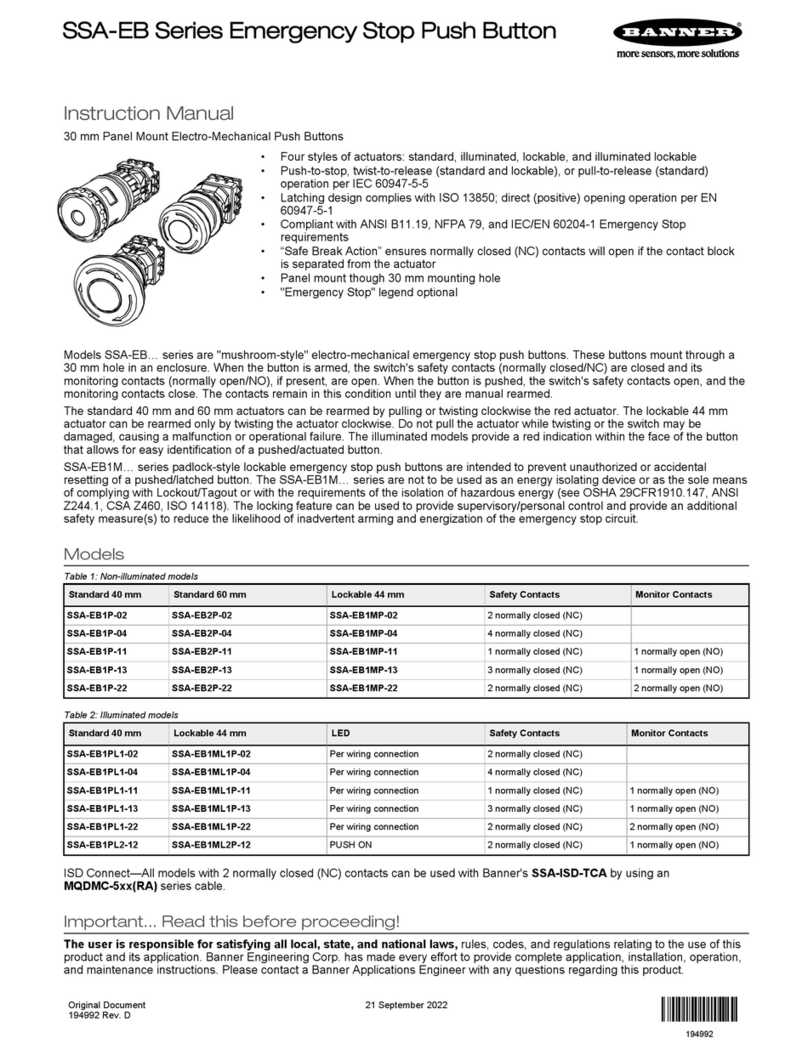

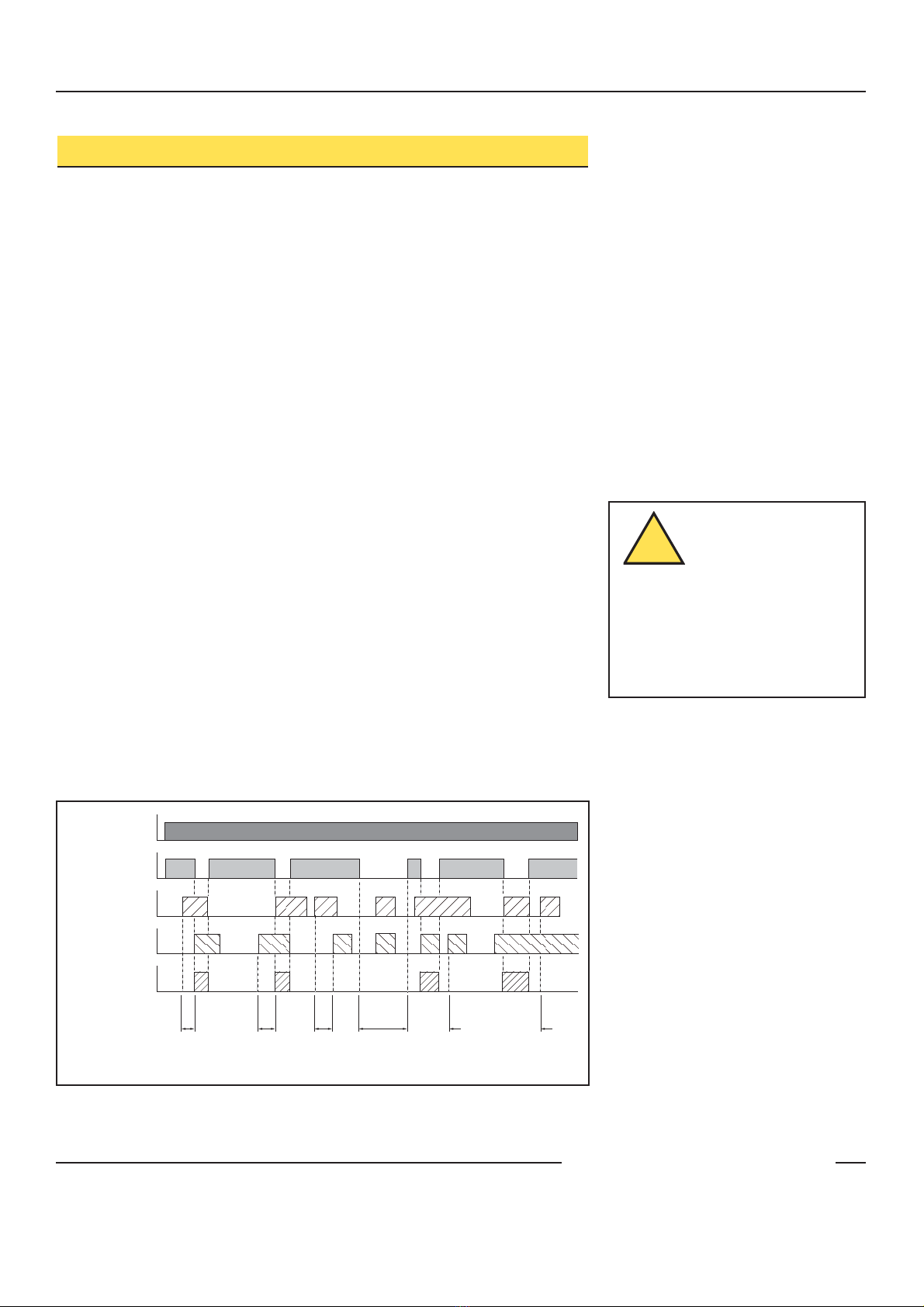

Connection of Input Switches

The STBs are connected to the Duo-Touch SG module as shown in Figures 5a and

5b (page 9). STB1 and STB2 both have one normally open and one normally closed

output contact each, or two current-sourcing complementary outputs each, all capable

of reliably switching 10-20 mA. Connect one STB to terminals S11, S12, S13 and the

other to terminals S21, S22 and S23. If STBs with PNP outputs are used, the system

must be supplied with 24V dc. Wire gauge for the switch connections is not specified.

Connection of Power to the DUO-TOUCH SG Safety Module

The Safety Module requires a 24V ac or dc supply voltage. Power consumption of the

Safety Module is approximately 4,5 VA. Use extreme caution whenever installing ac

power. We recommend to use 1,2 to 1,7 mm2wire for power and output connections. A

hand-operated supply disconnect (e.g. a circuit breaker) must be provided (per IEC/EN

60204). If activation devices other than STB Touch Buttons are used, they must share

the same voltage supply with the Safety Module (see WARNING on page 9).

Connection to the Machine to be Controlled

The wiring diagrams (Figures 5a and 5b) show a generic connection of the Safety

Module’s two redundant output contacts to machine primary control elements MPCE1

and MPCE2. An MPCE is defined as an electrically-powered element, external to the

DUO-TOUCH SG, which directly controls the machine’s normal operating motion so

that it is the last (in time) to operate when motion is either initiated or arrested. Some

older machines offer only one MPCE; for such machines, it is necessary to add at

least a second MPCE to establish control reliability. See: “NOTICE Regarding Machine

Interface”, on the right. As shown in Figures 5a and 5b, a normally-closed forced-

guided monitor contact from each of the two MPCEs must be connected in series

across terminals Y1 and Y2. This feedback loop allows the circuit of the Safety Module

to monitor the state of the MPCEs, and to prevent a successive machine cycle, if an

MPCE fault is detected. When MPCE monitor contacts are not available, a jumper wire

must be installed across terminals Y1 and Y2.

IMPORTANT: When a jumper wire is used, it is the user’s responsibility to provide a

control-reliable means of machine interface, (per EN 954/ISO 13849), to ensure that

any single MPCE component failure will prevent a successive machine cycle.

The outputs of the DUO-TOUCH SG Safety Module are rated at 250V ac/dc maximum,

at 6 amps maximum resistive load. Force-guided Safety relays may be installed between

the outputs of the Safety Module and the MPCEs to increase switching capacity.

Whenever a safety relay is added as an intermediate switching device, a normally-

closed force-guided monitor contact of that relay must be added to the series feedback

loop between Safety Module terminals Y1 and Y2.

When switching inductive ac loads, it is good practice to protect the Safety Module

outputs by installing appropriately-sized arc suppressors. However, if arc suppressors

are used, they must be installed across the load being switched (e.g., across the coils

of external safety relays), and never across the safety module’s output contacts (see

WARNING on page 9).

CAUTION ...

Disconnect Power

Before Wiring

Always disconnect all power

from the DUO-TOUCH SG Safety Module

and the machine being controlled before

making any wire connections.

Insulation of hand controls and associated

wiring must be rated for 250V ac

minimum. If the hand controls have

metal housings, the housings must be

connected to protective earth ground.

Electrical installation of hand controls

must be made by a qualified electrician

and must comply with IEC/EN-60204-1, -2

and all applicable local standards.

NOTICE Regarding the

Machine Interface

The DUO-TOUCH SG Two-Hand-Control

Safety Module has two redundant output

channels for interfacing to the machine

primary control elements. Some machines

have only one control element; for such

machines, it is necessary to duplicate the

circuit of the single control element.

According to EN 954/ISO 13849 Control

Reliability, the device, system, or interface

must be designed, constructed, and

installed so that a single component

failure will not prevent normal stopping

action from taking place but will prevent a

successive machine cycle.

In the case of part-revolution clutch

machinery, each machine control element

must be capable of immediately stopping

the dangerous machine motion, irrespec-

tive of the state of the other element. For

full-revolution clutch machinery, each

machine control element must be capable

of preventing a subsequent cycle, irre-

spective of the state of the other element.

The slower of the two machine control

elements must be used when calculating

safety distance for the hand controls. (See

“Mechanical Installation of Hand Controls”,

page 6 and Warning on page 9.)