PICO-GUARD™Fiber Optic Safety Interlock Switches

Models SFI-A1ED and SFI-D1EDPXT.. with Extreme-Duty Stainless Steel Housing

Printed in USA 01/06 P/N 120125 rev. A

These fiber optic safety switches are intended to be used with PICO-GUARD series controllers in

personnel safety and equipment-protection applications.

Features and Description

• Compact, non-contact, easy-to-install means of interlocking doors, guards, gates, and covers

• Uses Banner 2.2 mm OD plastic fiber optic cable (1 mm core)

• Designed to meet Safety Category 4 applications with one switch pair per guard (per ISO13849-1)

• Impact- and chemically-resistant stainless steel and glass construction with PTFE-coated fiber

• Environmental rating of IEC IP67

• Attenuator available (see p/n 109910) for reducing excess gain in short-run applications

• Splice available for easy connection of two fiber sections (see p/n 109910)

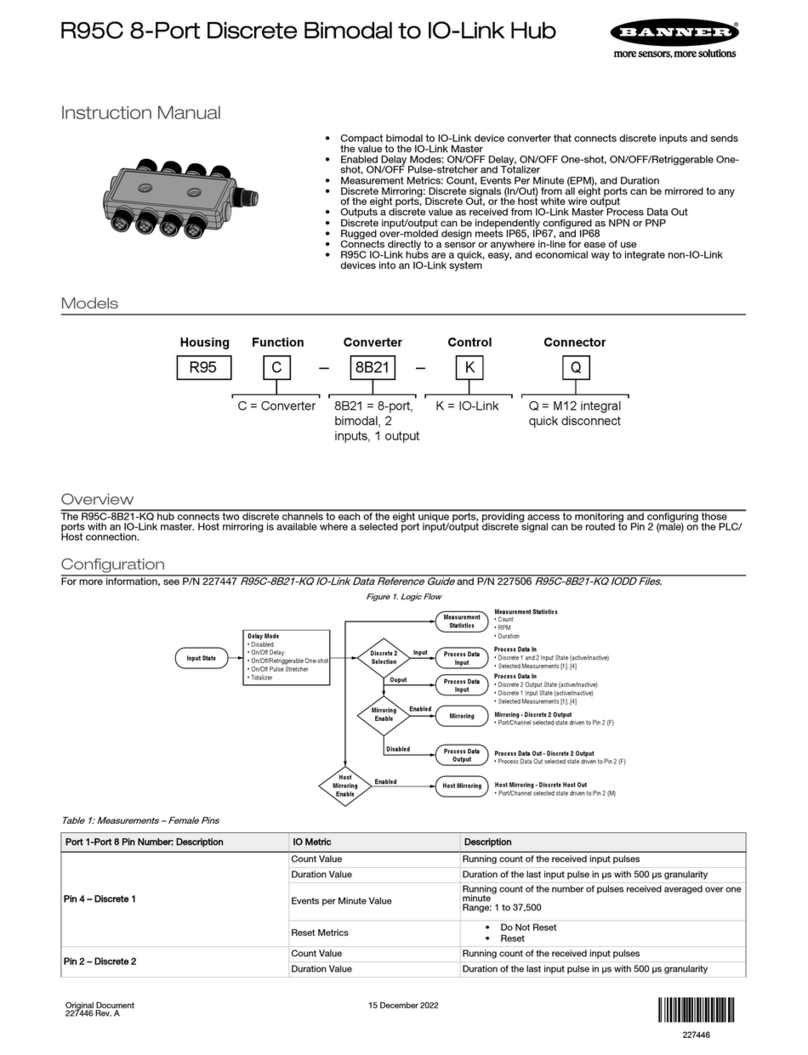

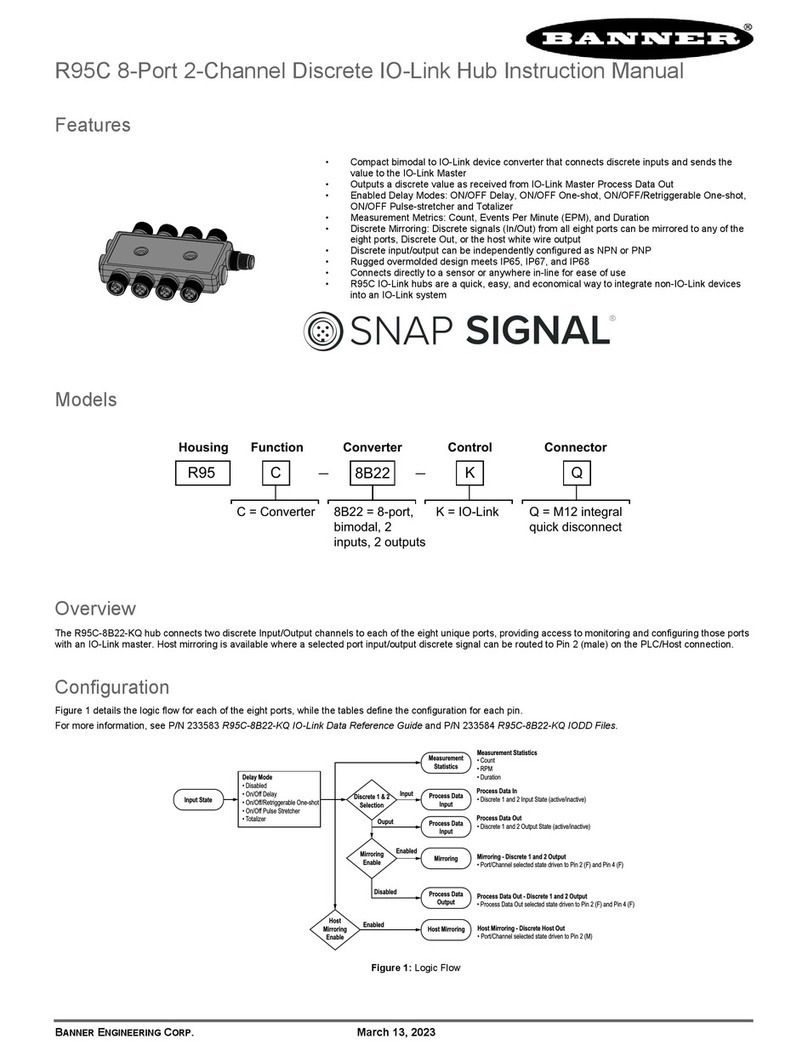

Operating Distance 1-50 mm (0.04" - 2") max.

Switching Distance See Figure 1.

Mounting Holes for M6 screws (mounting hardware not included)

Construction 316 Stainless steel housing, glass window, PTFE sheathed plastic fiber

Temperature Range 0˚ to +70˚ C (+32˚ to 158˚F)

Max. Relative Humidity 95% (non-condensing)

Environmental Rating IEC IP67

Refer to PICO-GUARD Controller Manual

(p/n 69761) and PICO-GUARD Application

and Design Guide (p/n 69763) for complete

installation and operation information.

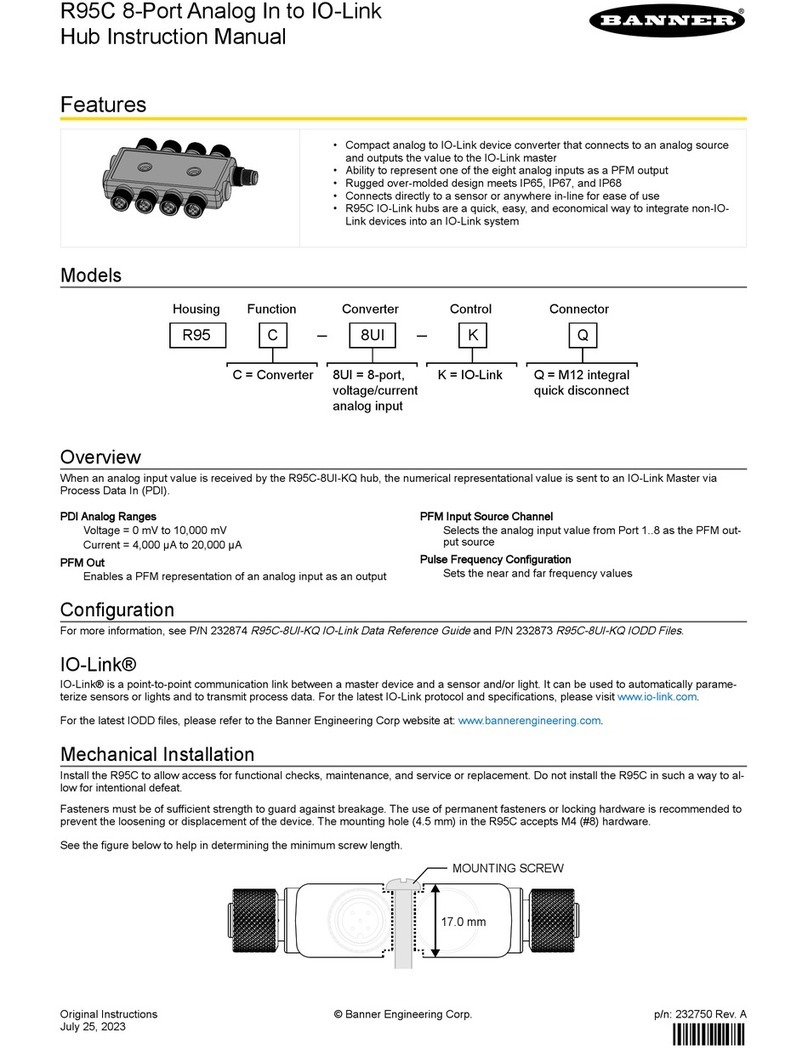

Dimensions

Warning ... Avoid

Misapplication of this Product

PICO-GUARD optical elements

must be properly installed and

interfaced with a PICO-GUARD Fiber Optic

Controller to be considered a safeguard.

See the PICO-GUARD Controller Instruction

Manual (p/n 69761) and the PICO-GUARD

Application and Design Guide (p/n 69763)

for complete installation instructions,

maintenance instructions, and application

limitations.

Use of a Banner PICO-GUARD Fiber Optic

Safety Interlock Switch is generally not

allowed for:

• Establishing a beam for presence-sensing

safeguarding (e.g., perimeter guarding),

• Linear (parallel) movement along the

optical axis (see Figure 2 and the

Application and Design Guide), or

• Machinery with long stopping time and

without a guard-locking mechanism.

Follow all installation and maintenance

instructions with extreme care. The user is

responsible for following all local, state, and

national laws, rules, codes, and regulations

relating to the use of this safeguarding

system in any particular application.

Specifications

Model Fiber Length

SFI-D1EDPXT6 1.8 m (6')

SFI-D1EDPXT15 4.5 m (15')

SFI-D1EDPXT30 9.0 m (30')

SFI-D1EDPXT50 15.3 m (50')

SFI-A1ED –

Models

MM

MM

MM

MM

MM

MM

MM

CSINK

MM

MM

MM

MM

!CCOMMODATES

-HARDWARE

MM

MM

MM

MM

MM

MM

!CCOMMODATES

-HARDWARE

MM

CSINK

MM

MM

MM

Model SFI-A1ED SFI-D1EDPXT.. Models