Page 9 of 17

Adjusting the Control Handle - 3 Positions

On the Handle (1) of this pallet jack, you can find the Control Lever (7), which can be placed in three

positions (See Figure 4):

LOWER - to lower the load, pull up on the control lever.

NEUTRAL - to place the control lever in this position while pulling the pallet jack or load.

LIFT - to raise the load, push down on the control lever and pump the handle to raise the load.

Figure 4

NOTE: These three positions have been set at the factory to work appropriately as soon as the

handle is attached. However, if the forks do not raise or lower as expected, adjust the control

positions using the following instructions. See Figure 5 on the following page.

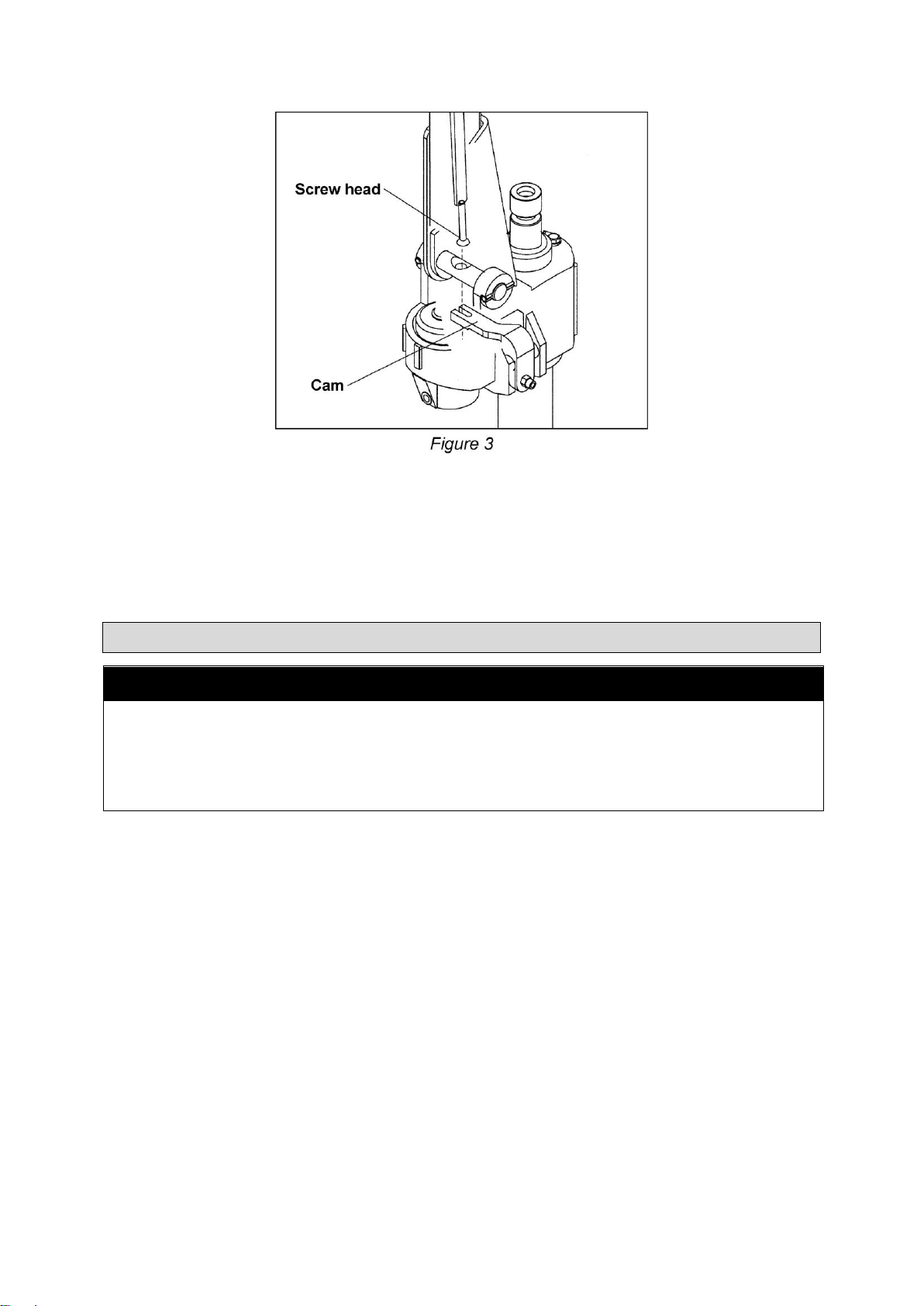

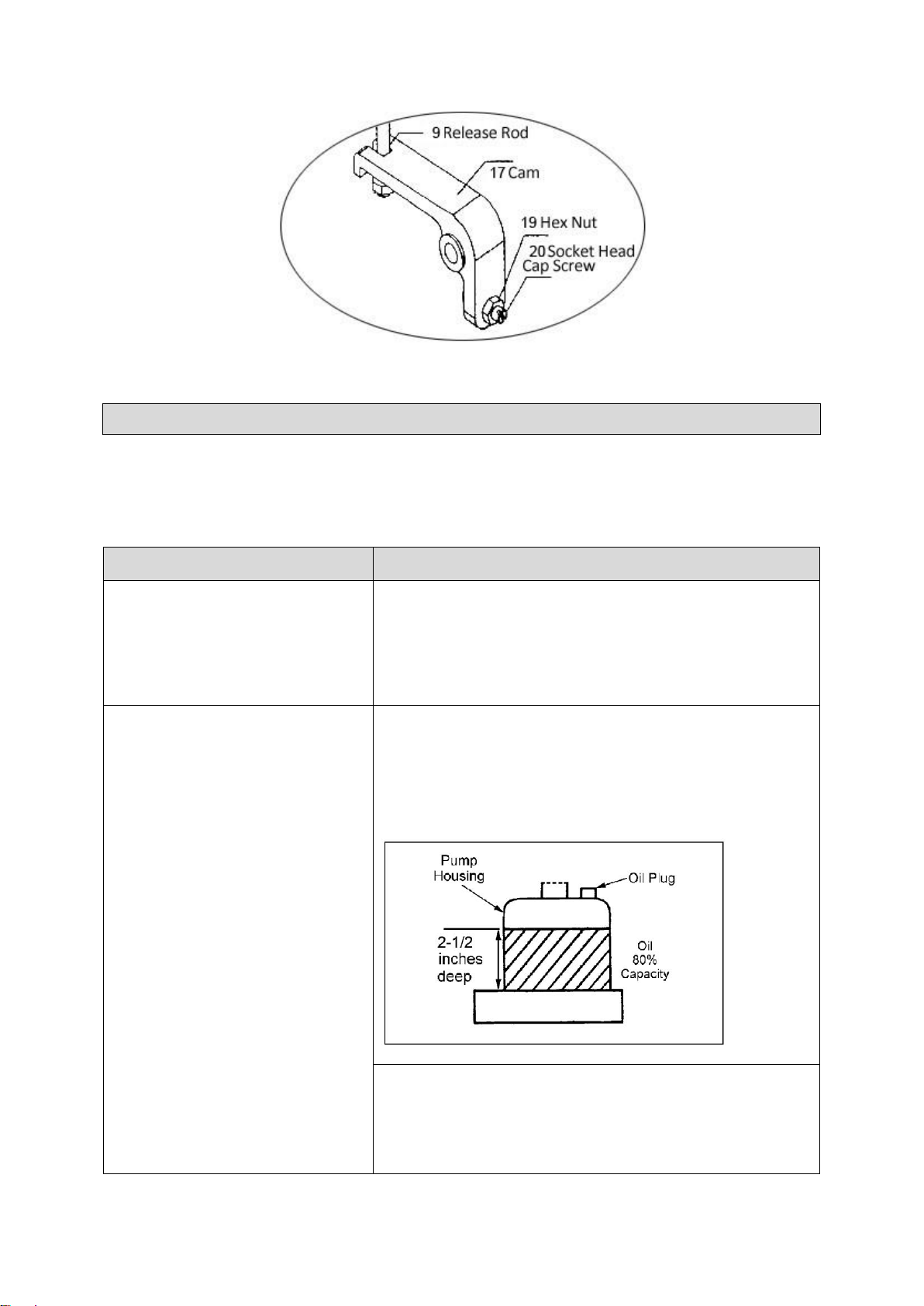

1. The Socket Head Cap Screw (20) is designed to adjust the three control positions. Use a

wrench and a flat screwdriver to loosen the Hex Nut (19) and turn the Socket Head Cap

Screw (20) clockwise, or counter-clockwise. Check to see if the pallet jack works well in the

three control positions. If more adjustments are necessary, proceed to the following steps.

2. Place the control handle in the "NEUTRAL" position. If the fork frame does not rise when

you pump the pallet jack, skip to step 5. If the fork frame does rise when you pump the

truck, turn the Socket Head Cap Screw (20) CLOCKWISE until the fork frame does not rise.

3. Keep the control handle in "NEUTRAL" position. If the fork frame does not move when the

handle is pumped, skip to step 4 without any adjustment. If the fork frame lowers, turn the

Socket Head Cap Screw (20) COUNTER-CLOCKWISE until the fork frame does not lower.

4. Pull the Control Lever (7) upward to the "LOWER" position. If the fork frame lowers, skip to

step 5 without any adjustment. If the fork frame does not lower, turn the Socket Head Cap

Screw (20) CLOCKWISE again until the fork frame lowers.

5. Push the Control Lever (7) down to the "LIFT" position. If the fork frame elevates when you

pump the pallet jack, go back to step 1 to 3 until the pallet jack can work well in all three

control positions. If the fork frame does not elevate, turn the Socket Head Cap Screw (20)

COUNTER-CLOCKWISE again until the fork frame elevates. Repeat steps 1 through 3 until

the pallet jack works in all three control positions.