9.1 Creating a new series..............................................................................29

9.2 Continuing a series..................................................................................29

9.3 New serial measurements.......................................................................30

9.4 Continuing a serial measurement............................................................30

9.5 Deleting a series......................................................................................30

9.6 Displaying a series...................................................................................30

9.7 Copying of series to an USB flash drive..................................................31

9.7.1 CSV file format...................................................................................31

9.7.1.1 Single series and subordinated series of a serial measurement....31

9.7.1.2 Summary serial measurements......................................................32

10 System settings............................................................................................34

10.1 Language...............................................................................................34

10.2 Time.......................................................................................................34

10.3 Date........................................................................................................34

10.4 Configuration..........................................................................................34

10.4.1 Date format......................................................................................34

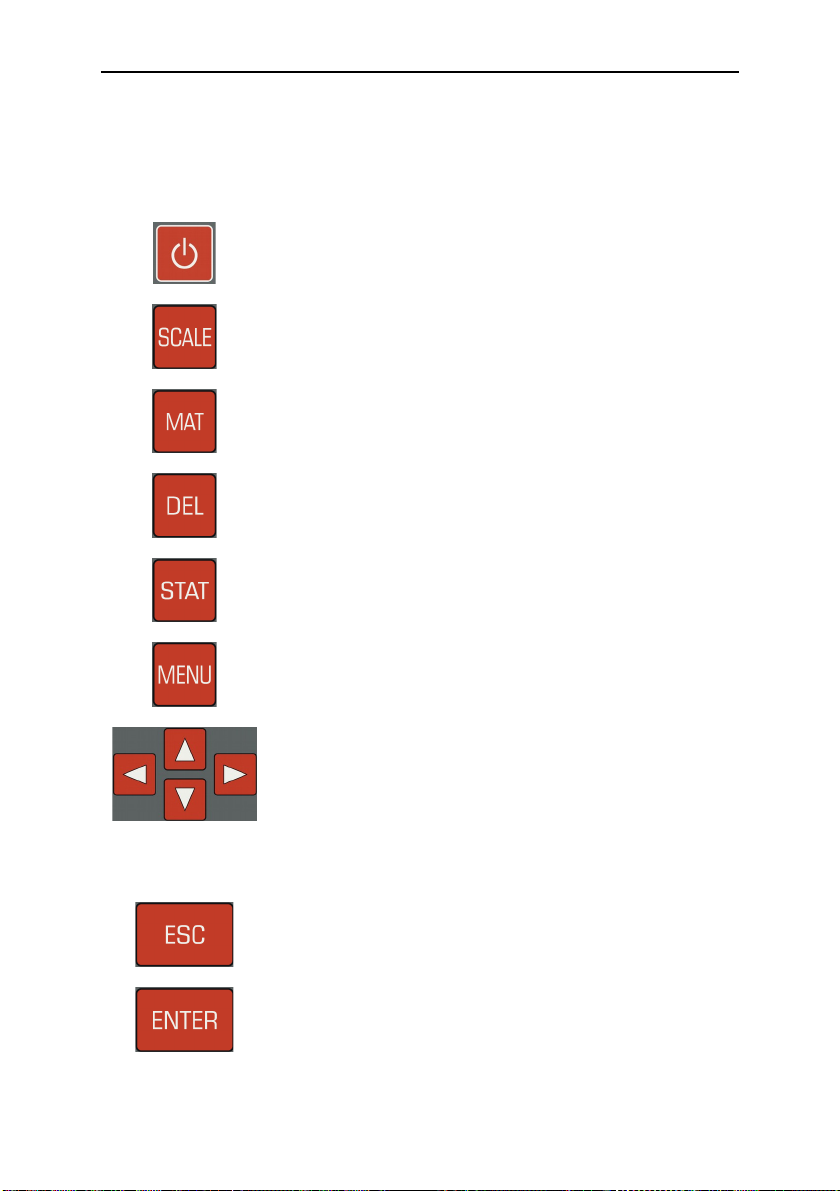

10.4.2 Key SCALE......................................................................................34

10.4.3 Key MAT..........................................................................................35

10.4.4 Query whether the values should be saved in a series...................35

10.4.5 Query whether the values should be printed...................................35

10.4.6 Tensile strength unit........................................................................35

10.5 Factory defaults.....................................................................................36

10.6 System information................................................................................36

11 Maintenance and inspection.........................................................................37

12 The UCI method...........................................................................................38

13 roper disposal............................................................................................40

13.1 Deutsch..................................................................................................40

13.2 Français.................................................................................................40

13.3 Italiano....................................................................................................40

13.4 Español..................................................................................................41

14 Technical Data..............................................................................................42

15 Appendix 1: Hardness conversion validity ranges........................................44

15.1 DIN EN ISO 18265 - Feb.2014..............................................................44

15.2 ASTM E140 - 12b (2019).......................................................................46

16 Appendix 2: License information..................................................................48