1 GENERAL INFORMATION ABOUT MEASURING WEAR RESISTANCE ON THIN

LAYERS.........................................................................................................................4

1.1 OVERVIEW...........................................................................................................................4

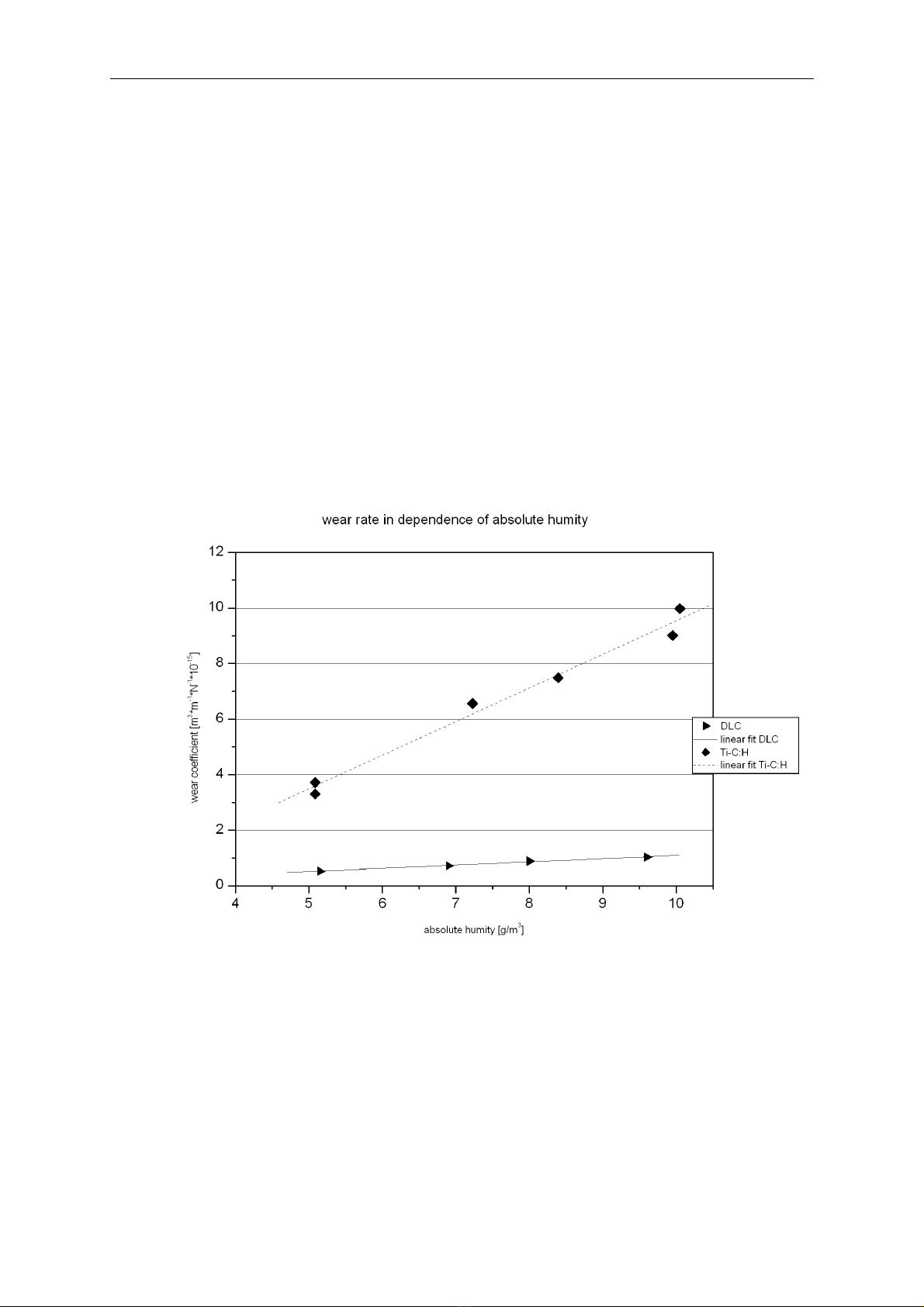

1.2 CLIMATIC INFLUENCES ON TRIBOLOGICAL PROCESSES...............................................................5

1.3 ABRASIVE SLURRY................................................................................................................5

1.4 PLACE OF INSTALLATION.......................................................................................................

1.5 HANDLING THE ABRASIVE SLURRY..........................................................................................

2 TEST PREPARATIONS.............................................................................................7

2.1 SELECTION OF THE TEST PARAMETER (GRINDING PATH / NUMBER OF REVOLUTIONS).....................7

2.2 GRINDING SPEED / BALL OR SHAFT REVOLUTIONS PER MINUTE...................................................8

2.3 BEARING STRENGTH..............................................................................................................8

2.4 CLEANING THE SHAFT...........................................................................................................9

2.5 SPECIMEN...........................................................................................................................9

2. BALL..................................................................................................................................9

2.7 AUTOMATIC DOSAGE APPARATUS...........................................................................................9

2.8 FILLING THE CARTIGE WITH ABRASIVE SLURRY........................................................................10

2.9 DOSING PARAMETERS.........................................................................................................10

2.10 MANUAL DOSAGE WITH A PIPETTE......................................................................................10

3 TEST EXECUTION...................................................................................................11

3.1 ADJUSTING THE SPECIMEN..................................................................................................11

3.2 APPLICATION OF THE ABRASIVE SLURRY (ONLY MANUAL APPLICATION)......................................11

3.3 FURTHER TESTS..................................................................................................................12

3.4 ABORTING A TEST..............................................................................................................12

4 ANALYSIS OF THE WEAR CRATERS....................................................................12

4.1 ANALYSIS BY SURFACE PROFILER..........................................................................................13

4.2 CALCULATION OF THE WEAR COEFFICIENT..............................................................................13

4.3 ANALYSIS BY MICROSCOPE..................................................................................................14

4.4 CALCULATION OF THE WEAR COEFFICIENT .............................................................................14

5 HANDLING...............................................................................................................15

5.1 GENERAL OPERATING INSTRUCTIONS....................................................................................15

5.1.1 KEY FUNCTIONS....................................................................................................................... 15