Barnes thermoplay TH-M6 User manual

3

1Index

1Index ..................................................................................................................................3

2Components identification ..............................................................................................4

3Installing specifications ...................................................................................................7

3.1 Special warnings....................................................................................................................................................7

3.2 Insulating the controller.....................................................................................................................................8

3.3 Insulating by means of SSR: hoe does it work ............................................................................................8

3.4 Specifications and technical characteristics................................................................................................8

4Working details.................................................................................................................9

4.1 Drying......................................................................................................................................................................10

4.2 Auto-Tuning (Mould change).........................................................................................................................10

4.3 Soft start .................................................................................................................................................................11

4.4 Synchronous heating.........................................................................................................................................11

4.5 Automatic mode (closed loop) ......................................................................................................................11

4.6 Manual mode (%)................................................................................................................................................11

4.7 “CHECK” status .....................................................................................................................................................12

4.8 Slave.........................................................................................................................................................................12

4.9 Plastic leakage alarm..........................................................................................................................................12

4.10 “Boost” function...................................................................................................................................................12

5System start-up...............................................................................................................13

6Supervisory software .....................................................................................................13

6.1 Common features ...............................................................................................................................................13

6.2 LOGIN – LOGOUT – users management............................................................................................................15

6.3 “main” environment and selection options ..............................................................................................17

6.3.1 Heating start and stop (START – STOP).............................................................................................17

6.3.2 TH-M6 supervisory software exit ........................................................................................................19

6.3.3 Terminal and controller shut-off.........................................................................................................20

6.3.4 Technical service through remote access........................................................................................20

6.3.5 Zone status .................................................................................................................................................21

6.3.6 How to make a selection of some zones and change regulating parameters ...................22

6.4 Table environment.............................................................................................................................................25

6.5 “details” function.................................................................................................................................................26

6.6 SP1 - SP2 switch...................................................................................................................................................28

6.7 “undo” function ...................................................................................................................................................28

6.8 “test” function ......................................................................................................................................................28

6.9 “boost” function ..................................................................................................................................................30

6.10 “synoptic” environment....................................................................................................................................31

6.10.1 Synoptic configuration...........................................................................................................................33

6.11 “recipes” environment ......................................................................................................................................36

6.11.1 Recipe saving .............................................................................................................................................36

6.11.2 Recipe loading...........................................................................................................................................38

6.11.3 Restore the current recipe.....................................................................................................................39

6.11.4 Celsius – Farenheit conversion............................................................................................................40

6.12 “graph” environment.........................................................................................................................................40

6.13 Zone parameters.................................................................................................................................................42

6.14 Common parameters.........................................................................................................................................47

4

6.15 “logs” environment ............................................................................................................................................52

6.16 “alarms” environment, recommended actions ........................................................................................53

6.16.1 Alarms and recommended actions....................................................................................................53

6.16.2 Historical alarms........................................................................................................................................53

6.16.3 Active alarms..............................................................................................................................................55

6.16.4 Alarm configuration ................................................................................................................................56

6.16.5 Alarm shout down...................................................................................................................................57

6.16.6 Alarm acknowledgment ........................................................................................................................58

6.17 “export” environment........................................................................................................................................58

6.18 “hardware setting” environment...................................................................................................................60

7Maintenance ...................................................................................................................62

7.1 Power board replacement...............................................................................................................................62

7.2 Fuse replacement................................................................................................................................................63

8Optional accessories.......................................................................................................63

8.1 Interconnection of two temperature controllers ....................................................................................63

8.2 Digital INPUT - OUTPUT ....................................................................................................................................63

9Supervisory software update ........................................................................................65

10 Warranty......................................................................................................................68

11 Disposal of A.E.E..........................................................................................................68

Rev.

Date

SW. Ver.

New Features

1.0

May 2013

winlog 2.07.23

project 3.0.3

firmware 3.3

First issue

2.0

October

2014

winlog 2.07.40

project 3.07

firmware 3.3

Password added to access to Windows by closing TH-

M6, available only for Thermoplay user. In the start up

opti

ons the “Service” command has been added to

enter in Team Viewer. Options added to alarms (to

shut up, to acknowledge, to configure).

Note: The temperature controllers with software release preceding version 2.07.40 project

3.07 firmware 3.3, are not provided with the additional features included in revision 02.

In order to upgrade these controllers it is required to update the software and replace

the hardware. The new software rev.2.0 is compatible with previous hardware, but the

new features are not operative.

2Components identification

TH-M6 24-48 zones control unit is normally supplied in the following configuration:

•main unit

•cable for connecting 2 controllers (optional), digital input-output cable (optional).

•electrical schemes

•special square key for doors opening

•User and maintenance manual

•CQ certificate

5

Figure 1

6

Figure 2

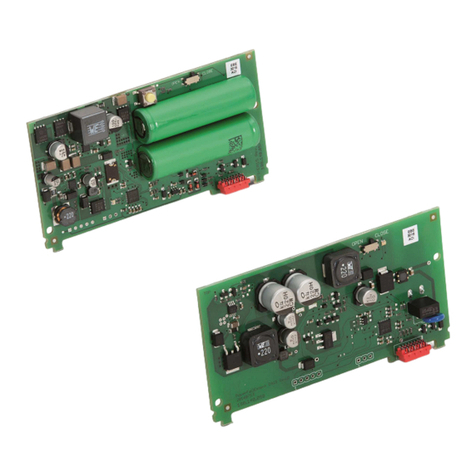

The structure of the temperature controller is visible in figure 1. In function of the number of

zones, 4 - 8 power boards are present. All the boards are connected to the HMI.

This interface allows all the operator procedure as well as the temperature and alarms

supervision of all the loops. The miniature circuit breaker is on the right side of the cabinet.

7

3Installing specifications

The equipment was designed and built for the regulation of “hot runner systems” through the

control of electrical energy supplied to the heating elements of the various parts of the system

(distributors, nozzles, ….) with the aim of keeping process temperatures stable (max

temperature 400°C).

The apparatus allows independent control of each zone.

The control and power connectors (TC) are positioned on the rear panel of the equipment.

The maximum nominal value for the current through each heating zone is 16A.

The maximum nominal value for the current through each “nozzle” zone is 3A.

This is a quite complex apparatus hence its life and reliability are guaranteed only if it is

correctly used and maintained.

Carefully read the advice supplied in this manual because it contains important information

regarding the safety of installation, use and maintenance.

Check the integrity of the apparatus once the packaging is removed. In case of doubt do not

use it and refer to the supplier.

Before connecting the apparatus, check that the specifications of the plate correspond to

those of the electricity supply (the plate is situated at the back of the machine).

This apparatus must be employed solely for the use for which it was specifically

designed, i.e. for the regulation and control of a “hot runner” system of which it is an

integral part. Any other use is to be considered improper and therefore dangerous.

The manufacturer cannot be considered responsible for any damages sustained resulting from

improper, erroneous and/or unreasonable use.

The electrical safety of this apparatus is assured only when connected to an effective ground

(as set out by current regulations). The manufacturer denies responsibility for any damages to

persons or objects resulting from the lack or inadequacy of the ground of this apparatus.

Normally the differential protection device is not included in the controller. This device must

be installed in the main electric supply system.

Ensure that the capacity of the power socket is compatible with the maximum power of the

apparatus (indicated on the plate) and that the local electrical installation satisfies regulations

and in particular: CEI 44-5 (EN 60204-1) art. 7.2.1-7.2.6. and CEI 64-8 art. 473.3.2.1 and art. 7.

3.1 Special warnings

•Ensure that moving parts cannot damage the controller or its connection cables.

•Since the controller is a highly ventilated piece of equipment, it needs to be positioned

such that free circulation of airflow is enabled, therefore leave ample air spaces to allow

the free flow of air.

•Before starting the system, pay special attention to how the supply to the controller is

wired and how it is connected to the mould. Incorrect wiring of main supply phases

into the controller can seriously damage electronic components. Crossing heater

supply looms with thermocouples looms will produce damage to thermocouples

looms or to the thermocouples (inside the mould) themselves.

The manufacturer cannot be considered responsible for damage caused to the controller and to

the mould by customer wiring and connection errors.

8

3.2 Insulating the controller

When the main switch (miniature circuit breaker) is in the OFF position, components inside

the cabinets are all isolated from power supply by means of a mechanical switch.

Do not open the cabinet without first disconnecting the main supply cable from the power

line. Remember that even with main switches in OFF positions, there are unguarded terminals

inside the cabinet witch may have dangerous potential across them.

3.3 Insulating by means of SSR: hoe does it work

Remember that solid state relays cannot make a mechanical break of the contacts since they

are semi-conductor devices.

Hence, even if all the regulators are disabled (or in “Manual” mode with output power set to

“0”) only the current on loads will be 0, there may still be some voltage in the heaters.

On the three-phases with neutral supply system, SSR units are always positioned on the live

side of the supply, this keep the residual voltage to a low value. On the three-phases delta

without neutral system supply there always be phase voltage on the heaters when main switch

is in ON position.

Furthermore the SSR may fail in conducting condition. In this case temperature will arise

even if theoretical power is set OFF.

3.4 Specifications and technical characteristics

Table 1: technical characteristics

Supply Voltage

400 [V] 3 phases with neutral, 240 [V] 3 phases

without neutral

Voltage bandwidth

Stable within 10% supply voltage swing

SSR

16 A – 3A each zone high – low power zone.

Normal working: zero crossing.

Drying: phase angle fired modulation.

Overload protections

High speed fuse links

Protection for thermocouple reading

circuits

The 6 TC input on each board are insulated

together (insulating voltage 250V) and towards the

supply (insulation double reinforced).

Sampling time on each channel

130 [ms]

Sensor type

Thermocouples type J,K

Control range

According to thermocouples range of measuring

Heater / thermocouples connectors

Harting Han E

Control algorithm

•

Closed loop (PID), open loop (manual), slave

function.

•

Synchronous heating of all the zones

9

Reading scale

Celsius, Farenheit.

Main overload protection

Miniature circuit breaker

Operating temperature

0 – 50 [°C]

Alarms and warnings

•

Over temperature

•Band around SP (High, Low, Ok)

•Thermocouple failure

•Inverted thermocouples

•Heater failure

•Fuse failure

•SSR failure

•Supply line missing

•Wrong powers supply connection

•Loop break alarm

•

Plastic leakage

Operator terminal

•

Terminal for rough environmental conditions

fanless, IP65 protection class

•Monitor: LCD/TFT 10” Wide Led; 250 cd/m

•Contrast 500:1

•Resolution 1024x600 (max 1024x768)

•4 wires resistive touch screen

•Aluminium alloy front panel

•Zinc plated case or Aluzink

•Intel ATOM Z510P 1.1 Ghz processor

•Intel GMA 500 256 MB VGA (shared)

•2 x USB 2.0

•Double Ethernet connection 10/100/1000 Mbit RJ45

•RAM: SODIMM DDR2 da 2GB

•4 GB industrial compact flash

•Windows Xp embedded

•Optional Wi LAN

•

Optional Ethernet LAN

4Working details

The apparatus is designed to regulate in the best manner the power supplied in each zone

so that the temperature reaches and maintains in time the value set in the active Set point.

When turning on the temperature controller it is possible to choose to activate the drying

phase and auto-tuning. Terminated the drying phase on every zone a ramp is activated

increasing the temperature while limiting the maximum power supplied (soft start). At the end

of the soft start every zone continues heating without any limits regarding the power supplied.

When each zone reaches a temperature equal to 75% of the active set point, the auto-tuning

procedure begins. Only when the zones terminate this last phase, normal regulation begins,

until reaching and maintaining the active set point.

There are some features that make TH-M6 24-48 zones system different from a simple

apparatus for temperature control. The main ones are:

•possibility to manage a non limited number of working recipes

10

•historical data as well as alarms are stored. It’s possible to select and export data based

on a specified time range

•synchronous preheating of all the zones, regardless to the thermal inertia

•regulating outputs offset to avoid absorption high current peaks

•synoptic view allows to the operator to relate each zone to its physical position

•events log allows to identify “who made what”

•TEST environment helps to automatically validate electrical connections between

controller and mould

•connection of the controller with the injection machine for the emergency

management (optional)

•plastic leakage alarm

•BOOST function

4.1 Drying

After a long period of no usage the heaters in the injection system could have absorbed

moisture. The insulating material of the heaters is highly hygroscopic and loses its properties.

The drying function with phase angle modulation allows to supply to all the elements and for a

certain duration (common parameter “Drying time”, Idx 11) at a reduced voltage (common

parameter “Drying voltage”, Idx 12). This allows the elimination of the humidity present without

forming dangerous electrical discharges towards ground.

Phase angle modulation causes major problems of electromagnetic compatibility. Whereby

we absolutely advise to protect the line with a power filter before the controller connection.

Table 2: supply filters

Filter

Phase maximum current

Schaffner FN3280H-36-33*

36

Schaffner FN3280H-64-34*

64

Schaffner FN3280H-80-35*

80

Schaffner FN3280H-120-35*

120

* or equivalent

Note: enable the drying function only if indispensable .

4.2 Auto-Tuning (Mould change)

In closed loop (mode AUTO) the power supplied on each heating element is calculated by the

controller according to the thermocouple feedback. During the Auto-Tuning phase the

controller performs a self calibration of its regulating parameters. This allows a perfect

behaviour, without overshoot in the phase of temperature rising and avoiding fluctuations

during the steady state.

We advice you to turn the Auto-Tuning function on (select the option

in Figure 11) at every mould change or at the first installation.

11

At every successive start, heating begins with the same parameters active during the last stop.

The zone parameters calculated automatically during the tuning phase are: “Pb” (Idx 14), “Int”

(Idx 15), “Der” (Idx 16), “Fuzzy overshoot control” (Idx18).

If the Auto tune function is enabled, after the Soft Start, the heating goes on until 75% (common

parameter “% SP end Soft Start - start Auto Tuning” (Idx 1)) of the active set point.

Independently, each zone starts the tuning procedure (the displayed status is “TUNE”).

It is normal that the duration of auto-tuning phase is different on each zone (longer in the

zones with bigger thermal inertia).

Only when all the zones have finished the procedure (status of all the zones is back to “AUTO”)

normal heating restarts until the set point is reached.

Note: regardless of common parameter “% SP end Soft Start - start Auto Tuning” (Idx 1), Auto Tuning is inhibited if

at the heating start current temperature is higher than 75% of the Set Point.

See paragraphs 6.13 and 6.144 for zone and common parameters specifications.

4.3 Soft start

During the soft start phase the power output is limited by a maximum value of 15% (default

value of zone parameter “Output power high limit during Soft Start” (Idx 6)). In the status area

appears “SOFT”. In case of brief interruption, soft start is automatically deactivated: it is sufficient

that the temperature of one zone is superior to the level of inhibition temperature set (common

parameter “Temperature threshold to abort Soft Start” (Idx 16).

4.4 Synchronous heating

A delayed start-up of the nozzles (and in general of low thermal inertia) in respect to the

manifold zones (high thermal inertia) is no longer necessary: all the zones follow the same

incremental temperature ramp. In this way, the set point is reached contemporaneously (the

tolerance is given by the common parameter “Synchronous heating tolerance” (Idx 5)) in all the

elements of the injection system avoiding problems such as material degradation for excessive

time at high temperature.

4.5 Automatic mode (closed loop)

In “automatic” mode the power supplied on the load is automatically set by the temperature

controller. The operator can modify the value of the set point, not the percentage power

supplied.

If the temperature controller finds an anomaly on the thermocouple, the power

supplied is immediately 0% (zone parameter “Security power” (Idx 9)).

4.6 Manual mode (%)

In “manual” mode the temperature controller supplies the load with the power value set by

the operator. The set point is no longer active. The temperature controller could work in this

mode even in the case of thermocouple failure.

12

4.7 “CHECK” status

At the controller start, all the zones with one of the anomalies listed below:

•heater failure

•thermocouple failure

•heater and thermocouple not connected

are automatically disabled.

The status of these zones is “CHECK”, the output power is 0%. These zones are not considered

by digital output functions. (see paragraph 8.2).

It’s possible to manually modify the “CHECK” status to “MAN”, “SLAVE” or “OFF.

Only if the anomaly is removed it is possible to change the status to “AUTO” manually or by

mean of restarting the controller.

4.8 Slave

Is a valid alternative to manual functioning in case the thermocouple fails. It is possible to

submit a zone (“SLAVE” zone) to another (“MASTER” zone) having the same thermal

characteristics. The same power will be supplied and updated in time to the two heaters.

4.9 Plastic leakage alarm

In case plastic material leaks, the power absorption of the heater increases substantially. The

temperature controller finds this increment in the power necessary to maintain a certain “set

point” temperature and signals the anomaly allowing for a rapid intervention.

“Normal” absorption is memorised for each zone when the operator responds positively to

the question “Are the moulded pieces OK?”.Reset of the values memorized happens at each

modification of the set point and every time the Auto-Tuning function is activated.

4.10 “Boost” function

With some nozzles and some polymers, at the production start-up, it’s compulsory to increase

Set Point temperature in all the nozzle zones.

It’s possible to set a different temperature increase in each regulating zone (zone parameter

“BOOST delta” (Idx 7)). This function can be enabled and disabled manually for all the zones

contemporary after the Set Point is reached.

13

5System start-up

1. Connect the power supply cable, paying attention to the correspondence between the

network voltage and what is specified in the identification plate.

2. Plug power and thermocouples cable both in the mould and controller side.

3. Turn ON the controller.

4. Wait for the complete start of the terminal. Normally the supervisory software automatically

starts. Otherwise, double-click the icon “Runtime” on the desktop.

Figure 3: start icon

6Supervisory software

Figure 4: start window

6.1 Common features

Figure 5: start page “main”

14

As soon as the supervisory software start is compete, Figure 5 page will be displayed.

Particularly, upper bar allows to navigate between all the environments.

Table 3: upper bar

main

Main page, refer to paragraph 6.3

table

Table page, refer to paragraph 6.4

synoptic

Allows to identify each zone on the real mould

Refer to paragraph 6.10

recipes

Recipes management, refer to paragraph 6.11

graph

Graph historical data (temperature and Set Point of the selected

zones). Refer to paragraph 6.12

alarms

Active and historical alarms. Refer to paragraph 6.16.1

export

Export of historical working data of the selected zones according to a

selected time range.

Refer to paragraph 6.17

zone setup

Allows to visualize and change “zone parameters”.

Refer to paragraph 6.13

common setup

Allows to visualize and change “common parameters”.

Refer to paragraph 6.14

hardware settings

Allow to visualize and change hardware settings and identification

label of each zone. Refer to paragraph 6.18

Table 4: right side bar

login – logout

Login and logout functions. Refer to paragraph 0

logs

Event log page. Refer to paragraph 6.15

test

Make test on the selected zones. Refer to paragraph 6.8

SP1-SP2

Switch between SP2-SP1. Refer to paragraph 6.6

boost on – boost off

Switch ON and OFF “boost” function.

Refer to paragraph 6.9

help

Display the help page according to the active page.

If controller has more than 50 zones, allows the scrolling

between the pages.

details

Displays all the details of the selected zone.

Refer to paragraph 6.5

multisel

If pushed, allows the contemporary selection of many zones.

Refers to paragraph 6.3.6

range

If pushed, allows the selection of a range of zones. Refer to

paragraph 6.3.6

set. all – deselect

Select – deselect all the zones of the controller.

set

Allows to change the status and Set Point values of the

selected zones. Refer to paragraph 6.3.6

undo

Undo the last setting that was made.

Refer to paragraph 6.7

Start - Stop Heating start and stop. Refer to paragraph 6.3.1

15

Table 5: lower bar

Last alarm (red background if still active) User

Date and

time

6.2 LOGIN – LOGOUT – users management

At software start-up, page of Figure 5 is displayed. All the functions are blocked until login is

made. Push button on the right side bar:

Figure 6: login

Select the user and enter the numerical password (Table 6).

Table 6: default users

User name

Access level

Password Not allowed actions

No user -- --

•

all the functions are inhibited

•it’s not possible to turn off the

system

“User” User “1234”

•

zone parameters change

•common parameter change

•recipe management

•TH-M6 supervisory software closure,

terminal shut off

•zone identification labels change

•

Users management

“admin”

Administrator

“1234”

--

If login as a user with level of “Administrator” was made, it’s possible to get access to the

management environment pushing the button of Figure 6:

16

Figure 7: users management page

In this page a list of the available users and the corresponding access levels are displayed.

If one user is selected, button deletes it.

The button allows to create a new user and to specify what will be the relative

access level:

Figure 8: new user creation

After login was made, the active user is displayed in the lower bar (Table 5). Press the button

on the right side bar to make the logout.

17

6.3 “main” environment and selection options

Figure 9: “main” page

In “main” page, each zone appears as in Figure 9 with a virtual instrument. If the controller is

equipped with a number of zones bigger than 50, scrolling buttons on the right side bar are

enabled.

6.3.1 Heating start and stop (START – STOP)

In Figure 9 is showed the page that is displayed after the login. The whole controller is in

“STOP” mode. Press the button to show the option menu of Figure 10.

Figure 10: start option

18

Press the button to display the heating start options (Figure 11).

Refer to paragraph 4.1and 4.2 for all the details dealing with “Drying” and “Mould change”

functions.

Press the button.

Figure 11: heating start options

If the “Drying” option was selected, the page of Figure 12 is showed. The

button allows to stop the routine.

Figure 12

19

Figure 13: “main” after the heating start

Press the button and confirm (Figure 14): the whole controller go back in “STOP”

mode.

Figure 14

6.3.2 TH-M6 supervisory software exit

Referring to Figure 10, select option to get access to the

normal Windows environment. Confirm (Figure 15).

Figure 15

This operation is possible only if the access is performed by a Thermoplay user. Password is

provided by contacting Thermoplay technical service.

20

6.3.3 Terminal and controller shut-off

Referring to the Figure 10, select the option if you want to

close the supervisory software and shut-off the terminal. Confirm (Figure 16).

Figure 16

Now you can turn OFF the whole controller (main switch “3”)

6.3.4 Technical service through remote access

Referring to Fig.10, select the option to start the remote control and give access

to Thermoplay service team, by internet connection, to the customer terminal, as shown in

Fig.17.

Figure 17: Remote control

Table of contents