vi

Five different manuals in total are available for model C15 Single Loop Controller (hereafter referred to as“this unit”).

Read appropriate manuals according to your requirements. If you do not have a required manual, contact the azbil

Group or its dealer. Additionally, you can download necessary manuals from “http://www.azbil.com”.

The user level of this unit can be selected from three levels, “Simple configuration”, “Standard configuration”, and

“High function configuration”. This manual describes the functions you can set up only with “Simple configuration”.

If more advanced application is needed, refer to Single Loop Controller Model C15 User’s Manual for Installation &

Configuration (CP-SP-1148E).

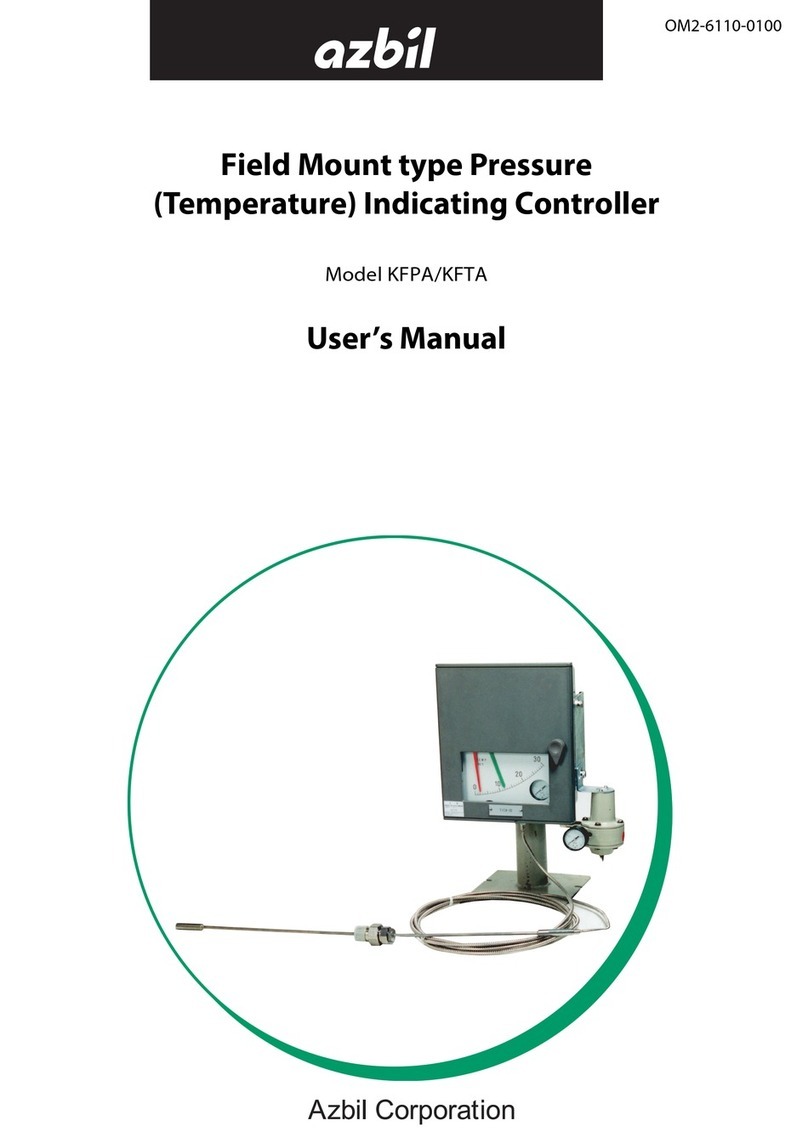

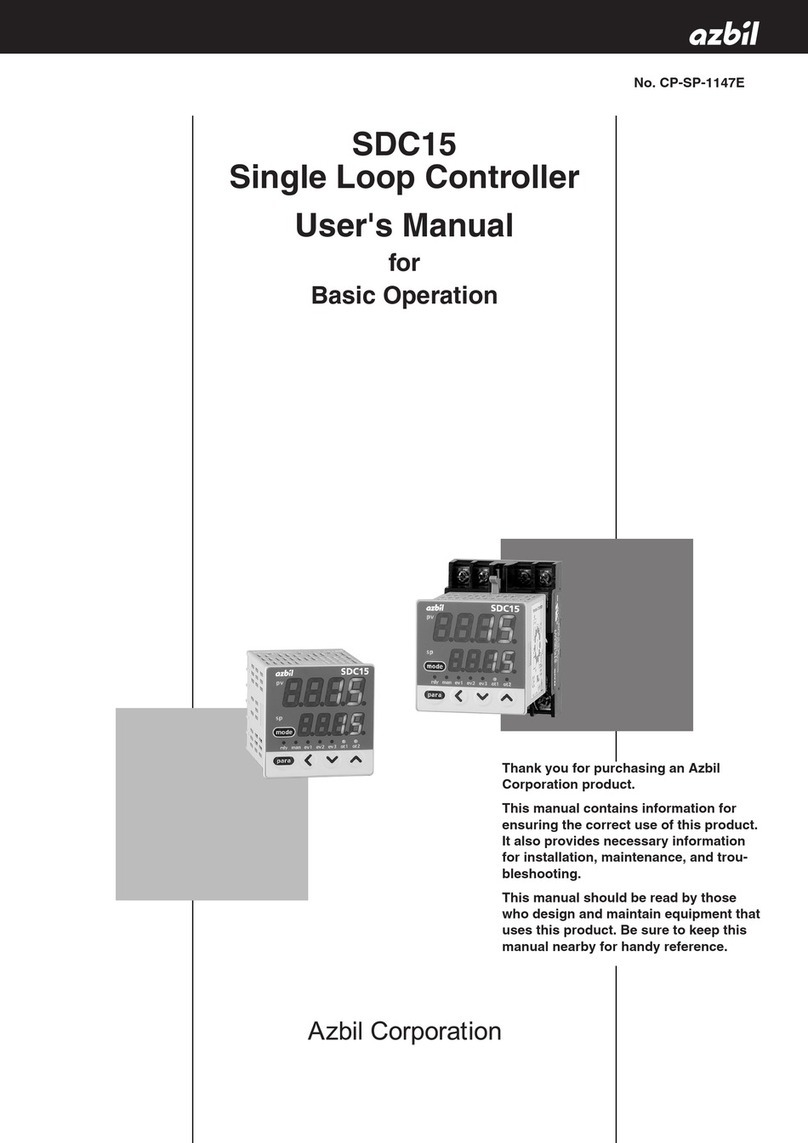

Single Loop Controller Model C15 User’s Manual for Basic Operation

Manual No. CP-SP-1147E

This manual. This manual is optional (sold separately). The manual describes the

functions you can set up only with “Simple configuration”. Personnel in charge of design,

manufacture, operation, and/or maintenance of a system using this unit must thoroughly

read this manual. This manual describes the installation, wiring, major functions and

settings, operating procedures, troubleshooting, and detailed specifications.

Single Loop Controller Model C15 User’s Manual for Installation

Manual No. CP-UM-5287E

This manual is supplied with the product. Personnel in charge of design and/

or manufacture of a system using this unit must thoroughly read this manual.

This manual describes the safety precautions, installation, wiring, and primary

specifications. For further information about operation, refer to other manuals,

Basic Operation and/or Installation & Configuration.

Single Loop Controller Model C15 User’s Manual for Installation & Configuration

Manual No. CP-SP-1148E

This manual is optional (sold separately). The manual describes the hardware and all

functions of this unit. Personnel in charge of design, manufacture, operation, and/

or maintenance of a system using this unit and those in charge of communication

software of a system using the communication functions of this unit must thoroughly

read this manual. This manual also describes the installation, wiring, connections

for communication, all functions and settings of this unit, operating procedures,

communication with host station, such as personal computer, communication

addresses, troubleshooting, and detailed specifications.

User’s Manual for Smart Loader Package Model SLP-C35 for Single Loop

Controller Model C15/25/26/35/36 Manual No. CP-UM-5290E

This manual is supplied with the Smart Loader Package. The manual describes

the software used to make various settings for C15/25/26/35/36 using a

personal computer. Personnel in charge of design or setting of a system using

C15/25/26/35/36 must thoroughly read this manual. The manual describes

installation of the software into a personal computer, operation of the personal

computer, various functions, and setup procedures.

CP-SP-XXXXE

Quick Reference Guide

for Model XXX

Quick Reference Guide for Model C15

Manual No. CP-UM-1213E

For those using this device for the first time or for operators on the work site, this

guide serves as a reference when setting or modifying parameters. Key operations,

menu flowcharts and parameter settings are presented with color illustrations.

The Role of This Manual