Baroness SP05 Setup guide

Other manuals for SP05

4

Other Baroness Farm Equipment manuals

Popular Farm Equipment manuals by other brands

J.ASSY

J.ASSY VISUM Monitor Operator's manual

Landoll

Landoll Brillion WFPD38-52 Operator's manual

KUHN

KUHN GMD702F Operator's manual

Raven

Raven Unverferth NutriMax Series Installation & operation manual

Tarter

Tarter RC104BL Operation and assembly manual

Rosensteiner

Rosensteiner RED Q OPERATION AND MAINTENANCE MANUAL, LIST OF SPARE PARTS

enorossi

enorossi RR 420 EVO Use and maintenance manual

Raven

Raven SmarTrax Supplement Installation Manual

Monosem

Monosem MICROSEM Assembly, Adjustment and Maintenance Instructions

Anderson

Anderson RB-200 Operator's manual

Rabe

Rabe Combi-Digger Series operating instructions

Land Pride

Land Pride RCF2084 Operator's manual

PAJ

PAJ Grain Thrower T 2 operating manual

Peco

Peco ESTATE Series Operator's manual

Superior

Superior Dozer Trap Operator and maintenance manual

Johnny's Selected Seeds

Johnny's Selected Seeds 7239 instruction manual

Goldacres

Goldacres Super Cruiser G8 Operator's manual

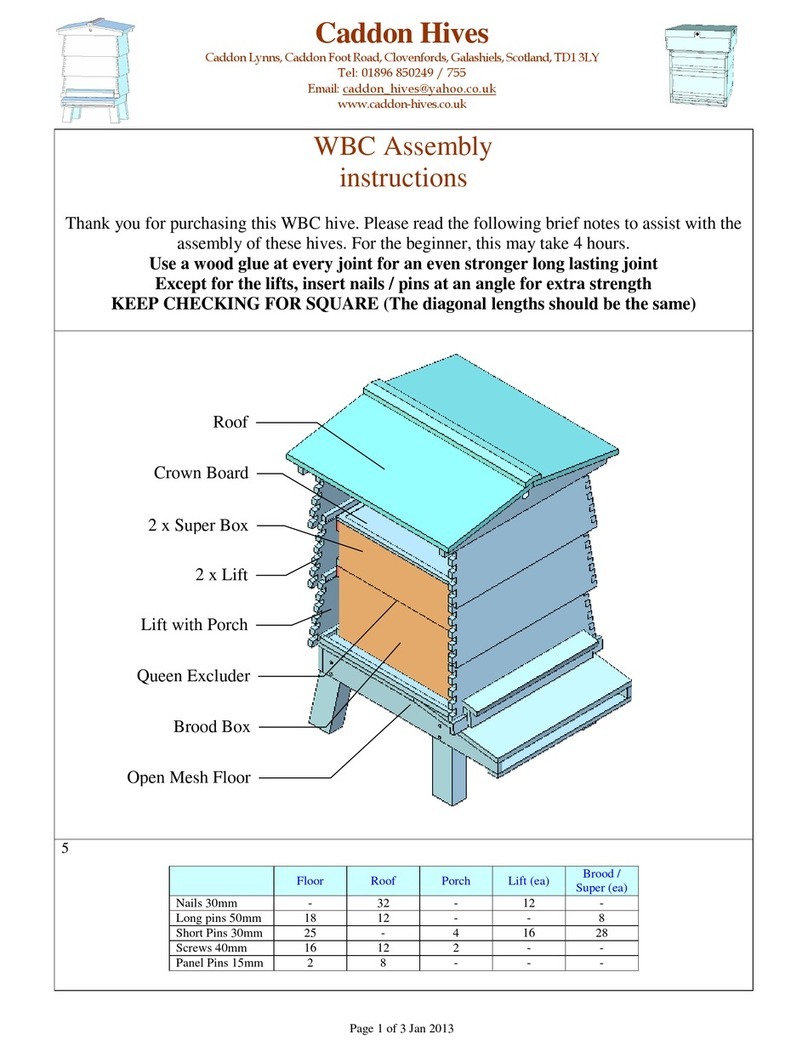

Caddon Hives

Caddon Hives WBC Assembly instructions