We reserve the right to make technical changes.

Precautions / Road transport

Prepare and check the implement for transport by

road. DO NOT stand or ride on the implement or

remain within its turning circle operating area. Ob-

serve the relevant speed limits and trafc regulati-

ons when transporting the outt by road. Take care

when negotiating curves, as towed implements

tend to swing out. Observe the road trafc regulati-

ons (StVZO or your local equivalent). These regu-

lations normally make the user responsible for the

secure hitching and safe operation on public roads

of the tractor and the implements being towed. The

attachment of towed implements must not lead to

any excess with respect to the permitted axle load,

laden weight or tyre load (depending on speed and

pressure) of the tractor. For safe steering, the front

axle of the tractor must bear at least 20 % of the

vehicle’s unladen weight.

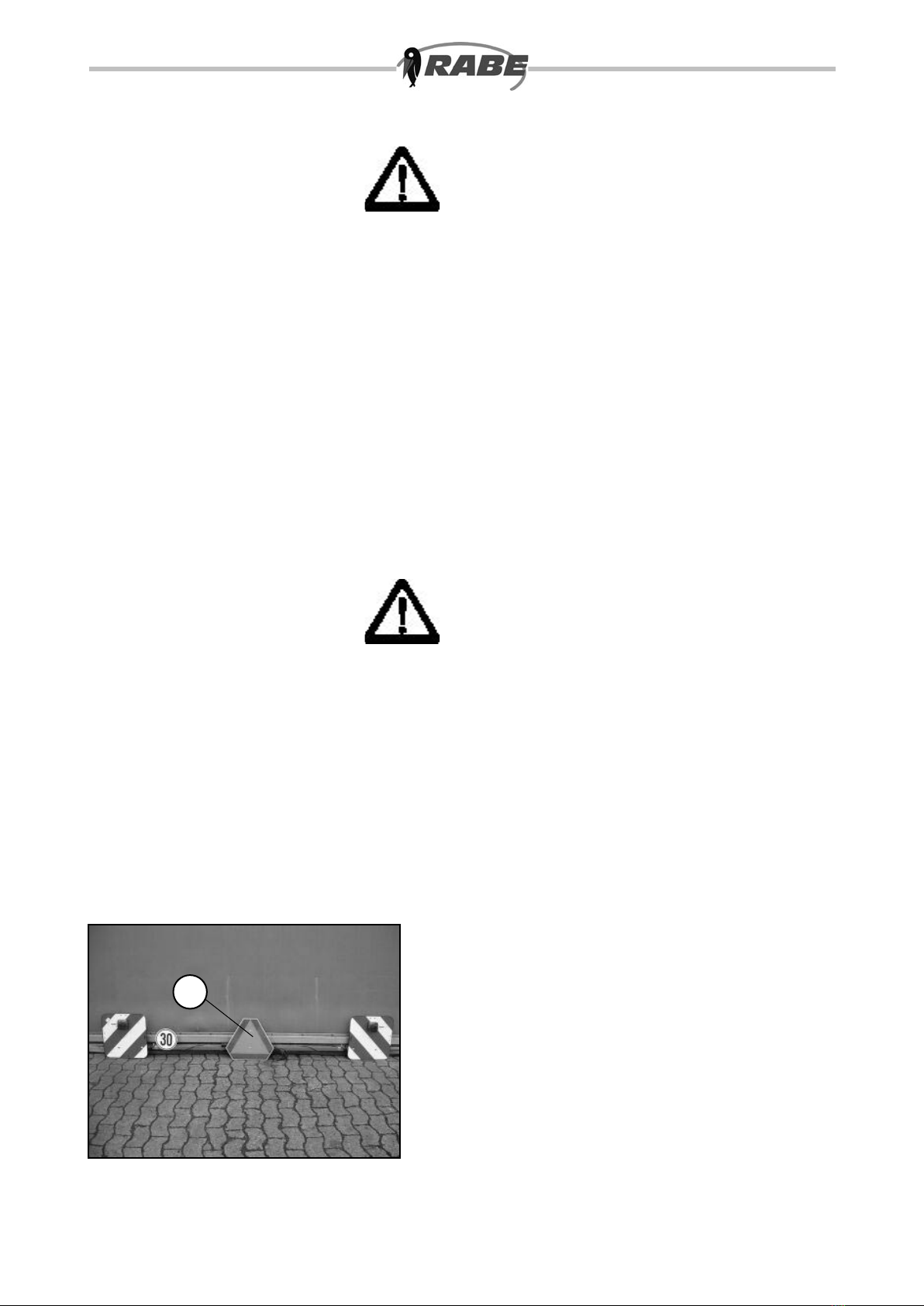

The maximum permitted width of the load is three

metres. A special permit is normally required for

moving oversized loads. In the case of front attach-

ment, the distance between the front end/ground

loosener and centre of steering wheel /tractor must

not exceed 3.5 m. If this ”front-end limit” is excee-

ded, the user must take appropriate measures to

ensure that there is adequate driver visibility at

the farmyard exit, road junctions and crossings.

This can be carried out, for example, by use of a

second person (on foot or in another vehicle) to

give the tractor driver appropriate instructions. No

avoidable overhanging item must endanger other

trafc or road users (sect. 32 StVZO or your local

equivalent). Overhanging items that cannot be

avoided must be covered and tted with warning

notices. Safety devices include appropriate lighting

and signs around all sides and the rear of the ve-

hicle and towed implement, e.g. red/white striped

warning signs measuring 423 x 423 mm. Additional

lighting is required if the towed implement blocks

those already tted to the tractor, or weather condi-

tions make it advisable: e.g. to front and rear, if the

towed implement is wider than the tractor’s lights

by more than 40 cm, or overhangs by more than 1

metre with respect to the existing rear lights.

If an additional pair of headlamps is required for

the front-mounted conguration (with only one

set of headlamps switched on at once), a special

permit is normally required.

A lighting system – with warning panels – can also

be obtained from RABE as an optional extra.

When transporting on public roads in Poland, the

warning triangle (7.1/1) must be xed to the centre

of the machine.

6

7.1

1