Baroness LM351 Operation manual

3-Unit Reel Mower

Owner's Operating Manual

Serial No. LM351: 10001-

"Required reading"

Read this manual before using the machine.

Original Instructions Ver.1.0

California Proposition 65

(For California, USA)

Operating, servicing and maintaining

a passenger vehicle or off-road

vehicle can expose you to chemicals

including engine exhaust, carbon

monoxide, phthalates, and lead,

which are known to the State of

California to cause cancer and birth

defects or other reproductive harm.

Tominimize exposure, avoid

breathing exhaust, do not idle the

engine except as necessary, service

your vehicle in a well-ventilated area

and wear gloves or wash your hands

frequently when servicing your

vehicle. For more information go to

www.P65Warnings.ca.gov/passenge

r-vehicle.

WARNING:

318yi8-005

California Proposition 65_001

California Spark Arrester

(For California, USA)

Warning

Operation of this equipment may create

sparks that can start fires around dry

vegetation.

A spark arrester may be required.

The operator should contact local fire

agencies for laws or regulations relating to fire

prevention requirements.

It is a violation of California Public Resource

Code Section 4442 or 4443 to use or operate

the engine on any forest-covered, brush-

covered, or grass-covered land unless the

engine is equipped with a spark arrester, as

defined in Section 4442, maintained in effective

working order or the engine is constructed,

equipped, and maintained for the prevention of

fire pursuant to Section 4443.

The engine of this machine is not equipped with

a spark arrester.

In some areas there are local, state, or federal

regulations requiring that a spark arrester be

used on the engine of this machine.

EU Regulations

(For EU)

This product complies with all relevant EU

Regulations.

For more information, please refer to the

Declaration of Conformity attached.

LM351

Regulations

Thank you for purchasing the Baroness product.

This manual describes the proper handling,

adjustment, and inspection of your product.

We hope you will use the product safely, and take

advantage of its best performance.

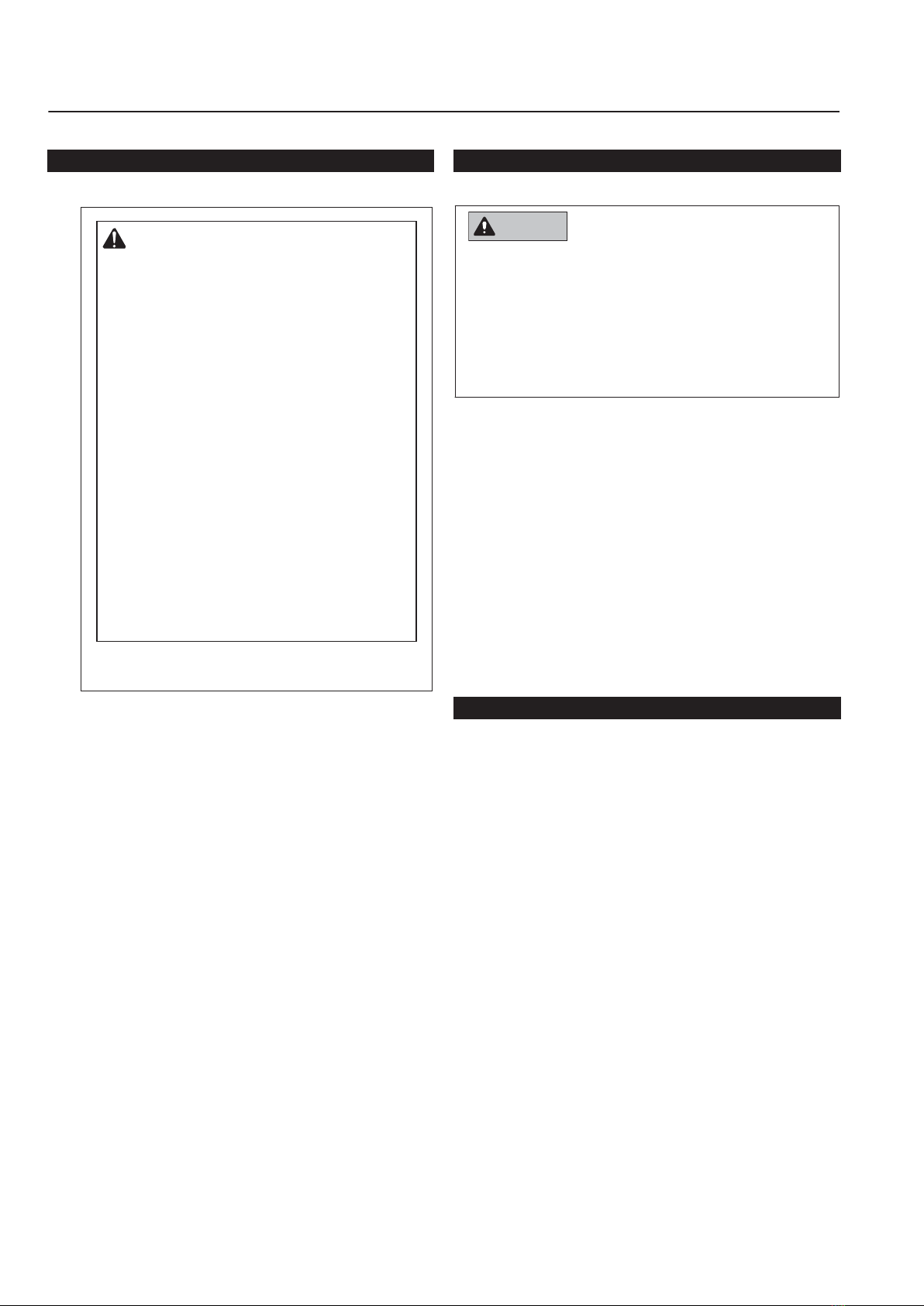

Keeping the Owner's Operating Manual

Keep this Manual in the box on the left side of

the fuel tank.

1

1FC8F185

Keeping the Owner's Operating Manual_001

1Box

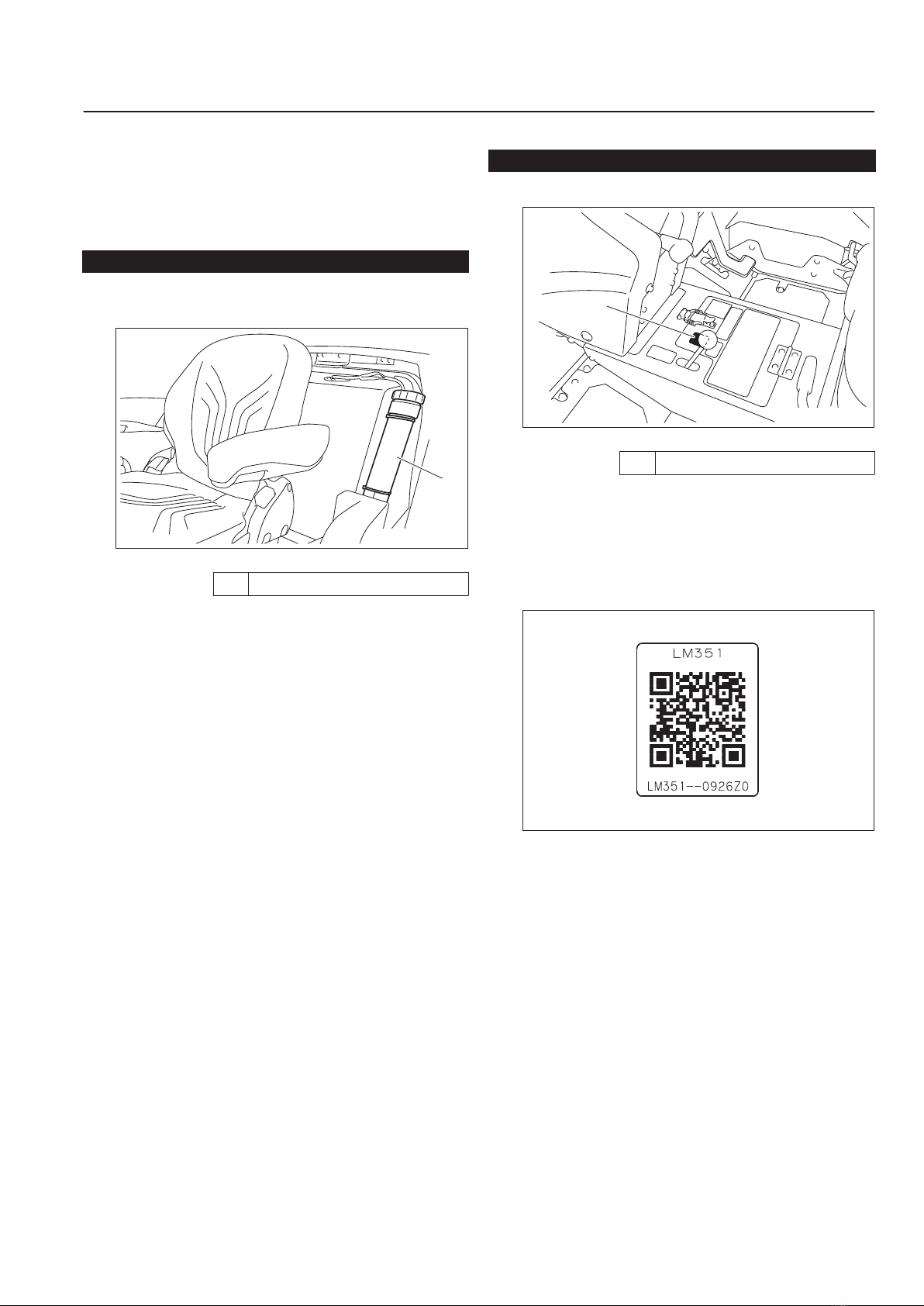

QR Code

A QR code label is affixed on the machine.

1

69A10B2E

QR Code_001

1QR code label

Scan the QR code with your smartphone for

easy access to Baroness Manual Reference

Service where you can browse Owner's

Operating Manual and Parts Catalog.

https://doc.baroness-international.com/manuals/

LM351

6A3C68B6

QR Code_002

LM351

Greeting

Read this manual carefully to ensure that you thoroughly understand how to properly operate and maintain the

product, and to avoid causing injury to yourself or others.

The operator is responsible for operating the product properly and safely.

Maintenance service for this machine should be performed by a mechanic with expertise.

If you have any questions concerning maintenance or genuine parts, please contact a Baroness dealer or

Kyoeisha.

When making inquiries about your product, please specify the model and serial number.

When loaning or transferring the product, please also provide this manual together with the product.

Kyoeisha Co., Ltd.

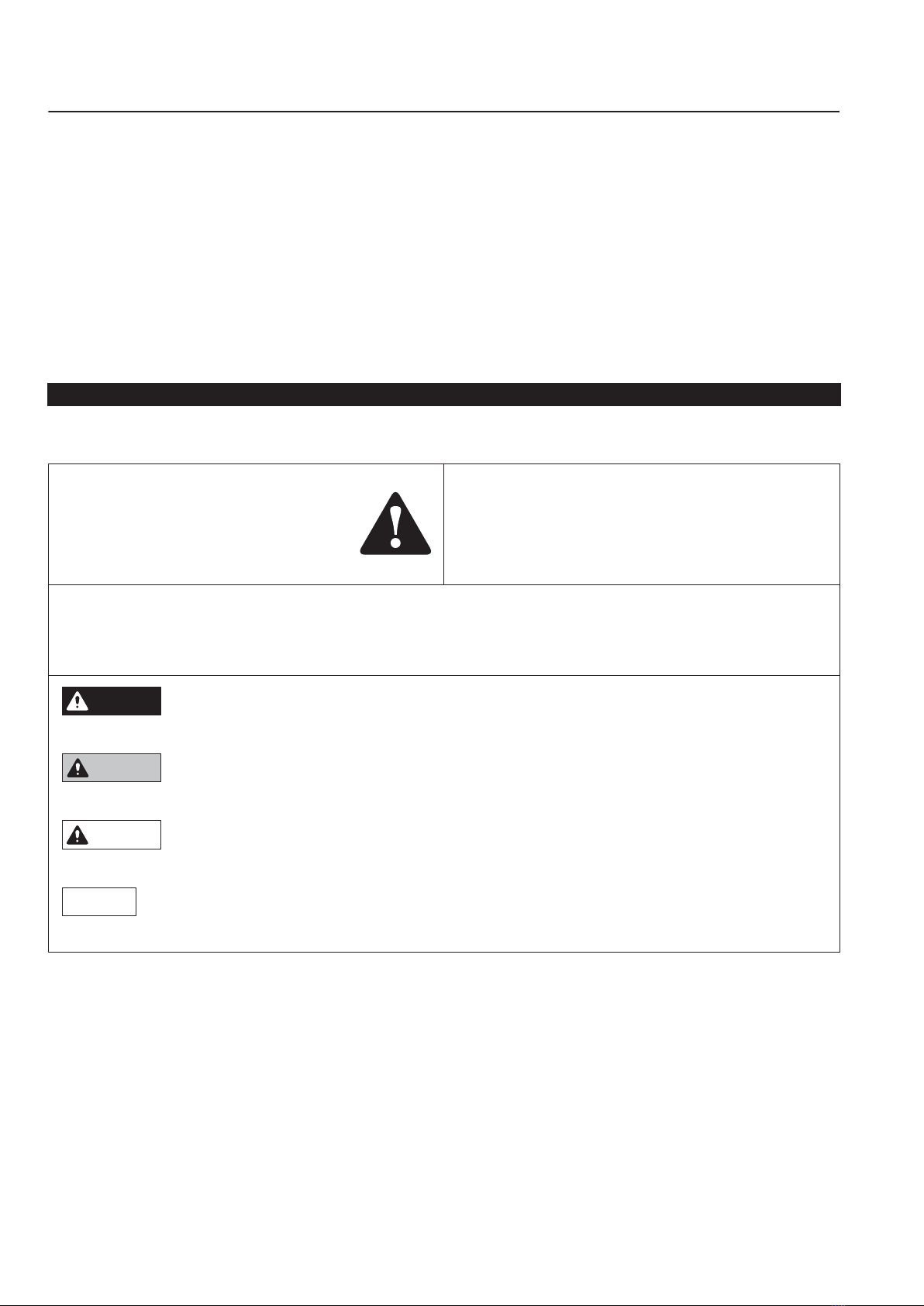

Warning Symbols

This manual uses the following warning symbols for handling precautions that are important for your

safety.

696cq5-001

Warning symbol

This symbol indicates the articles regarding “Danger,” “Warning,” or “Caution.”

Those articles describe important safety precautions and so read them carefully to understand completely before

operating the machine.

Failure to adequately follow these safety precautions may cause an accident.

Danger

Danger

This symbol indicates that serious injury or death will occur if the warning is ignored.

Warning

This symbol indicates that serious injury or death may occur if the warning is ignored.

Caution

This symbol indicates that injury or damage to property may occur if the warning is ignored.

Important

This symbol indicates precautions on the mechanism of the machine.

LM351

Introduction

Precautionary Statement

Caution

The information described in this manual is

subject to change for improvement without

prior notice.

When replacing parts, be sure to use genuine

Baroness parts or parts designated by

Kyoeisha.

Note that the Baroness product warranty may

not apply to defects caused by the use of

parts from other companies.

Prior to use, carefully read the following

manuals to thoroughly understand the contents

for safe and correct operation.

Baroness Owner's Operating Manual

The Engine's Owner's Manual

The Battery's Owner's Manual

Purpose

This product is intended for cutting turf grass at

golf courses.

Do not use this product in any way other than its

intended purpose, and do not modify this

product.

Operating this product for other purposes and

modifying it may be very dangerous and may

cause damage to the product.

In addition, this product is not authorized for

operation as a special motor vehicle. Do not

operate it on public roads.

・

・

・

LM351

Introduction

LM351

Introduction

Safety .............................................................. Page 1-1

Safe Operating Practices ...............................Page 1-2

Disposal .......................................................... Page 2-1

Recycle and Waste Disposal ......................... Page 2-2

Product Overview .......................................... Page 3-1

Specifications .................................................Page 3-2

Names of Each Section ................................. Page 3-4

Regulation Decals ..........................................Page 3-6

Safety Signs and Instruction Signs .............. Page 3-10

Operation Decals ......................................... Page 3-15

Description of Functions ...............................Page 4-1

Light Switch ................................................... Page 4-2

Throttle Lever .................................................Page 4-2

Mower Unit Up/Down Lever ...........................Page 4-2

Reel Rotation Switch ..................................... Page 4-3

Stop Valve ..................................................... Page 4-3

Reel Forward/Reverse Switch ....................... Page 4-4

Key Switch ..................................................... Page 4-4

USB Socket ................................................... Page 4-4

Tilt Lever ........................................................ Page 4-5

Traveling Pedal ..............................................Page 4-5

Pedal Stopper ................................................ Page 4-5

Brake Pedal ................................................... Page 4-6

Parking Brake Lever ...................................... Page 4-6

Reel Rotation/Stop Switching Lever .............. Page 4-6

Instruments on the Operation Panel .............. Page 4-7

Safety Device .................................................Page 4-9

Warning Mechanisms .................................... Page 4-9

Handling Instructions .................................... Page 5-1

Operations Before Service .............................Page 5-2

Inspection Before Use ................................... Page 5-4

Adjustment before Work .............................. Page 5-10

Mounting/Dismounting ................................. Page 5-11

Start/Stop of Engine .....................................Page 5-11

Parking and Stopping .................................. Page 5-13

Move ............................................................ Page 5-13

Cutting Work ................................................ Page 5-14

Transporting .................................................Page 5-14

Cleaning After Use .......................................Page 5-15

Appended Table ............................................. Page 6-1

Tightening Torques ........................................Page 6-2

Daily Check List ............................................. Page 6-7

Maintenance Schedule .................................. Page 6-8

LM351

Contents

LM351

Contents

Safe Operating Practices ...................... Page 1-2

Training ..................................................Page 1-2

Preparation ............................................ Page 1-2

Operation ...............................................Page 1-3

Maintenance .......................................... Page 1-4

Storage .................................................. Page 1-5

Safety

LM351

Safety

Page 1-1

Failure to adequately follow these safety

precautions may cause an accident resulting in

injury or death.

Danger

Danger

This product is designed to ensure safe

operation and has been tested and inspected

thoroughly before shipment from the factory.

The product is equipped with safety devices to

prevent accidents.

However, whether the product demonstrates

its original performance level depends on the

manner in which it is operated and handled,

as well as the manner in which it is managed

on a daily basis.

Inappropriate use or management of the

product may result in injury or death.

Observe the following safety instructions to

ensure safe operation.

Safe Operating Practices

Training

Read this manual and other training material

carefully.

Be familiar with the controls, safety signs,

and the proper use of the equipment.

If the operator or mechanic can not read the

language used in this manual, it is the

owner's responsibility to explain this material

to them.

All operators and mechanics should seek

and obtain professional and practical

instruction.

The owner is responsible for training the

users.

Such instruction should emphasize:

The need for care and concentration when

working with ride-on machines.

Control of a ride-on machine sliding on a

slope will not be regained by the

application of the brake.

The main reasons for loss of control are

Insufficient wheel grip

Being driven too fast

Inadequate braking

The type of machine is unsuitable for its

task

Lack of awareness of the effect of

ground conditions, especially slopes

Incorrect hitching and load distribution

1.

2.

3.

[1]

[2]

-

-

-

-

-

-

Never allow children or people unfamiliar

with these instructions to use or service the

machine.

Local regulations may restrict the age of the

operator.

The owner/user can prevent and is

responsible for accidents or injuries

occurring to themselves, other people, or

property.

Keep in mind that the owner, operator, and

mechanic are responsible for accidents or

hazards occurring to other people or their

property.

The ROPS is an integral and effective safety

device.

Do not remove or alter the ROPS.

Replace a damaged ROPS.

Do not repair or alter.

You can find additional safety information

where needed throughout this manual.

Determine the left and right sides of the

machine from the normal operating position.

Preparation

Evaluate the terrain to determine what

accessories and attachments are needed to

properly and safely perform the job.

Only use accessories and attachments

approved by the manufacturer.

While operating, always wear substantial

footwear, long trousers, hard hat, safety

glasses, mask, and ear protection.

Long hair, loose clothing, or jewelry may get

tangled in moving parts.

Do not operate the equipment when barefoot

or wearing open sandals.

Inspect the area where the equipment is to

be used and remove all objects such as

rocks, toys and wire which can be thrown by

the machine.

Keep children out of the operating area and

under the watchful care of a responsible

adult other than the operator.

Exercise care in the handling of fuel.

Warning

Fuel is highly flammable.

Take the following precautions:

Store fuel in containers specifically

designed for this purpose.

4.

5.

6.

7.

8.

9.

10.

1.

2.

3.

4.

5.

[1]

LM351

Safety

Page 1-2 Safe Operating Practices

Add fuel before starting the engine.

Never remove the cap of the fuel tank or

add fuel while the engine is running or

when the engine is hot.

Refuel outdoors only and do not smoke

while refueling.

If fuel is spilled, do not attempt to start the

engine but move the machine away from

the area of spillage and avoid creating any

source of ignition until petrol vapours have

dissipated;

Replace all fuel tanks and container caps

securely.

Check that operator's presence controls,

safety switches and shields are attached and

functioning properly.

Do not operate unless they are functioning

properly.

If the brake operation is faulty, be sure to

adjust or repair them before operating the

machine.

If the handlebar has noticeable play, be sure

to adjust or repair them before operating the

machine.

Replace faulty mufflers.

On multi-cylinder/multi-reel machines, take

care as rotating one cylinder/reel can cause

other cylinders/reels to rotate.

Operation

Do not operate the machine under the

influence of alcohol or drugs.

Do not operate the engine in a confined

space where dangerous carbon monoxide

fumes can collect.

Be sure all drives and shift are in neutral and

parking brake is engaged before starting

engine.

Only start engine from the operator's

position.

Use seat belts if provided.

Do not change the engine governor settings

or overspeed the engine.

Operating the engine at excessive speed

may increase the hazard of personal injury.

Never operate the machine with damaged

guards, shields, or without safety protective

devices in place.

Be sure all interlocks are attached, adjusted

properly, and functioning properly.

[2]

[3]

[4]

[5]

6.

7.

8.

9.

10.

1.

2.

3.

4.

5.

Keep hands and feet away from the rotating

parts.

Do not carry passengers.

Never operate while people, especially

children, or pets are nearby.

Only operate in good light, keeping away

from holes and hidden hazards.

Do not operate the machine when there is

the risk of lightning.

Do not stop or start suddenly.

Look behind and down before backing up to

be sure of a clear path.

Slow down and use caution when making

turns and crossing roads and sidewalks.

Use care when approaching blind corners,

shrubs, trees, or other objects that may

obscure vision.

Do not take your eyes off the road ahead.

Do not operate the machine with no hands.

Remember there is no such thing as a safe

slope.

Travel on grass slopes requires particular

care.

To guard against overturning, follow these

instructions.

Do not stop or start suddenly when going

up or downhill.

Engage clutch slowly, always keep

machine in gear, especially when traveling

downhill.

Machine speeds should be kept low on

slopes and during turns.

Stay alert for humps and hollows and

other hidden hazards.

Never use the machine on a slope with an

angle of gradient that is greater than that

specified or in a place where there is a

danger of the machine slipping.

Use extra care while operating machine with

a grass catcher or other attachments.

They can affect the stability of the machine.

Disengage drive to the cutting unit(s), when

other than operating.

Do the following before leaving the

operator's position.

Stop on level ground.

Disengage the all drives.

Set the parking brake.

Stop the engine.

Remove the ignition key.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

[1]

[2]

[3]

[4]

17.

18.

19.

20.

[1]

[2]

[3]

[4]

[5]

Safety

LM351

Safety

Page 1-3

Safe Operating Practices

Stop the engine in the following conditions.

Before refuelling.

Before removing the grass catcher.

Before making height or depth adjustment

unless adjustment can be made from the

operator's position.

Before clearing blockages.

Before checking, cleaning or working on

the machine.

After striking a foreign object or if an

abnormal vibration occurs.

Inspect the machine for damage and

make repairs before restarting and

operating the equipment.

Reduce the throttle setting during engine

run-out.

Do not direct discharge material toward

anyone.

Avoid discharging material against a wall or

obstruction.

Material may ricochet back toward the

operator.

Take care when loading or unloading the

machine into a trailer or a truck.

Load or unload the machine in a flat and

safe place.

Before loading or unloading, set the parking

brake on the truck or trailer, stop the engine,

and chock the wheels.

When transporting the machine on a truck or

a trailer, set the parking brake, stop the

engine, and fasten the machine to the truck

with a rope or other suitable restraining

device that has sufficient strength.

When using a running board, select one with

sufficient strength, length, and width and that

will not cause the machine to slip.

Close the fuel valve before transporting the

machine.

Maintenance

Never allow untrained personnel to service

machine.

Implement the following work before

adjusting, cleaning or repairing.

Stop the machine on level ground.

Disengage drive to the cutting unit(s).

Lower the cutting unit(s) and/or

attachment(s).

Set the parking brake.

Stop the engine.

21.

[1]

[2]

[3]

[4]

[5]

[6]

22.

23.

24.

25.

1.

2.

[1]

[2]

[3]

[4]

[5]

Remove the ignition key.

Wait for all movement to stop.

Allow the engine/muffler to cool before

checking/maintenance.

To reduce the fire hazard, keep hot parts

such as the engine and silencer/muffler,

battery compartment and fuel storage area

free of grass, leaves, or excessive grease.

Clean up oil or fuel spillage.

Appropriately manage and correctly use the

tools necessary for servicing or adjusting the

machine.

Disconnect battery before making any

repairs.

Disconnect the negative terminal first and

the positive last.

Reconnect positive first and negative last.

Use jack stands to support components

when required.

Keep hands and feet away from moving

parts.

If possible, do not make adjustments with the

engine running.

Make sure that parts such as wires are not

touching each other and that their covers

have not come off.

Keep all parts in good working condition and

all hardware tightened.

Replace all worn or damaged decals.

Keep all nuts, bolts and screws tight to be

sure the equipment is in safe working

condition.

Carefully release pressure from components

with stored energy.

Be sure to depressurize the hydraulic system

before performing maintenance operations

on it such as removing hydraulic equipment.

Check whether line connectors in the

hydraulic system are properly tightened.

Before applying hydraulic pressure, check

the connections of the hydraulic pressure

lines and the condition of the hoses.

[6]

[7]

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

LM351

Safety

Page 1-4 Safe Operating Practices

When checking the hydraulic circuit for

pinhole leaks or oil leakage from nozzles, do

not use your hands.

Use items such as paper or corrugated

cardboard to find leakage points.

Be extremely careful with high-pressure oil

as it may pierce your skin, resulting in an

injury.

If fluid is injected into the skin it must be

surgically removed within a few hours by a

doctor familiar with this form of injury or

gangrene may result.

Use care when checking the cylinders/reels

and bed knives.

Wear gloves and use caution when servicing

them.

Be careful during adjustment of the machine

to prevent entrapment of the fingers between

moving blades and fixed parts of the

machine.

On multi-cylinder/multi-reel machines, take

care as rotating one cylinder/reel can cause

other cylinders/reels to rotate.

Check the grass catcher frequently for wear

or deterioration.

Charge batteries in an open well ventilated

area, away from spark and flames.

Unplug charger before connecting or

disconnecting from battery.

Wear protective clothing and use insulated

tools.

If the fuel tank has to be drained, do this

outdoors.

Storage

When machine is to be parked, stored, or left

unattended, lower the cutting unit(s) and/or

attachment(s) unless a positive mechanical

lock is provided.

Allow the engine to cool before storing in any

enclosure.

Only cover the machine with a sheet after

hot parts have sufficiently cooled down.

Never store the equipment with fuel in the

tank inside a building where fumes may

reach an open flame or spark.

If the engine is provided with a shut-off

valve, shut off valve while storing or

transporting.

Do not store fuel near flames.

15.

16.

17.

18.

19.

20.

21.

1.

2.

3.

4.

5.

6.

Swallowing engine coolant can cause injury

or death; keep out of reach from children and

pets.

7.

Safety

LM351

Safety

Page 1-5

Safe Operating Practices

LM351

Safety

Page 1-6 Safe Operating Practices

Recycle and Waste Disposal

About Recycle

Recycling battery etc. is recommended for

environmental conservation and economical

use of resources.

It may be required by local laws.

About Waste Disposal

Make sure that waste generated when

servicing or repairing the machine is disposed

of in accordance with local regulations.

(e.g. waste oil, antifreeze, rubber products, and

wires etc.)

LM351

Disposal

Page 2-2 Recycle and Waste Disposal

Specifications ........................................ Page 3-2

Specifications .........................................Page 3-2

Mower Units ...........................................Page 3-3

Sound Pressure Level ........................... Page 3-3

Sound Power Level ............................... Page 3-3

Vibration Level .......................................Page 3-3

Carbon Dioxide (CO2) Emissions ..........Page 3-3

Names of Each Section ......................... Page 3-4

Regulation Decals ..................................Page 3-6

Positions of Regulation Decals ..............Page 3-6

Description of Regulation Decals .......... Page 3-6

Safety Signs and Instruction Signs ... Page 3-10

About Safety Signs and Instruction

Signs ....................................................Page 3-10

Positions of Safety Decals and

Instruction Decals ................................ Page 3-10

Description of Safety Decals and

Instruction Decals ................................ Page 3-11

Operation Decals ................................. Page 3-15

Positions of Operation Decals ............. Page 3-15

Description of Operation Decals ..........Page 3-15

Product Overview

LM351

Product Overview

Page 3-1

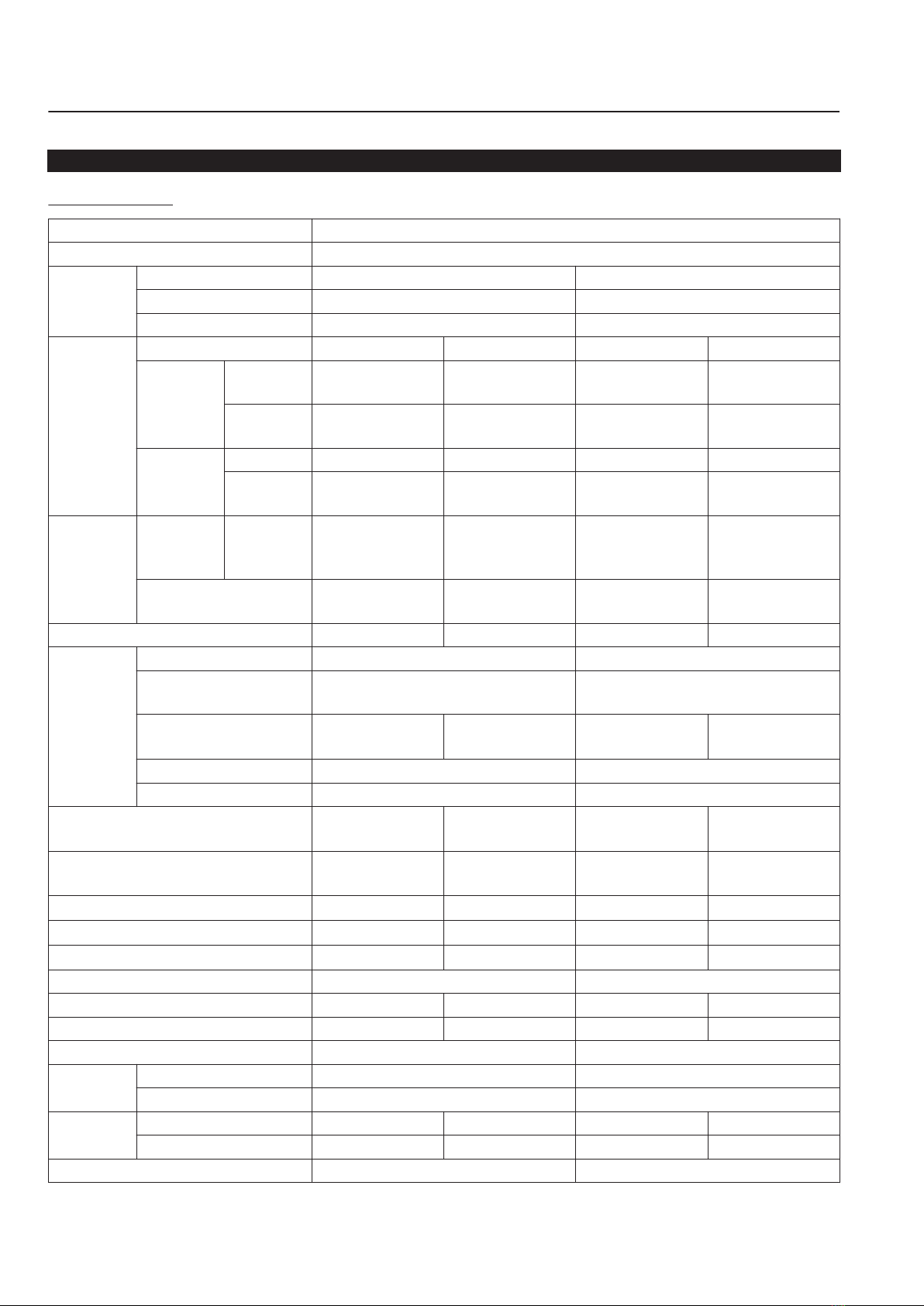

Specifications

Specifications

Model LM351

Name 3-Unit Reel Mower

Mower unit

type

Type Roller type Wheel type

#1 30 in ←

#2・#3 26 in ←

Dimensions

Total length 290 cm 114.17 in 298 cm 117.32 in

Total width

During

operation 208 cm 81.89 in ← ←

During

transport 187 cm 73.62 in ← ←

Total height

ROPS 193 cm 75.98 in ← ←

Steering

wheel 129 cm 50.79 in ← ←

Weight

Machine

(empty fuel

tank)

with ROPS 1065 kg 2347.92 lb ← ←

Grass catchers (for one

machine) 17 kg 37.48 lb - -

Minimum turning radius 494 cm 194.45 in ← ←

Engine

Model Kubota D1105-E4B ←

Type Vertical water-cooled 4-cycle diesel

engine ←

Total displacement 1,123 cm3 (1.123

L) 68.52 cu.in. ← ←

Maximum output - -

Rated output 18.5 kW (25.2 PS)/3,000 rpm ←

Fuel tank capacity Diesel 38.0 dm3

(38.0 L)

Diesel 10.04

U.S.gals ← ←

Fuel consumption 289 g/kW・h

(rated output)

213 g/PS・h (rated

output) ← ←

Engine oil capacity 3.0 dm3 (3.0 L) 0.79 U.S.gal. ← ←

Coolant volume 6.0 dm3 (6.0 L) 1.59 U.S.gal. ← ←

Hydraulic tank capacity 24.0 dm3 (24.0 L) 6.34 U.S.gal. ← ←

Transmission oil capacity - -

Operating width (Mowing width) 184 cm 72.44 in ← ←

Operating height (Mowing height) 10.0 - 46.0 mm 0.39 - 1.81 in 20.0 - 50.0 mm 0.79 - 1.97 in

Number of Blades 5,7 5

Drive Traveling HST (2WD/4WD selectable) ←

Mowing Hydraulic ←

Speed

(HST)

Forward 0 - 15.5 km/h 0 - 9.63 mph ← ←

Reverse 0 - 8.0 km/h 0 - 4.97 mph ← ←

Speed (Mechanical) - -

LM351

Product Overview

Page 3-2 Specifications

Efficiency

14,720 m2/h

(10.0 km/h x

mowing width x

0.8)

3.60 acres/hour

(6.21 mph x

mowing width x

0.8)

← ←

Maximum inclination for operation 20 degrees ←

Tire size Front wheel 23 x 10.50 - 12 ←

Rear wheel 18 x 8.50 - 10 ←

Tire

pneumatic

pressure

Front wheel 120 kPa (1.2

kgf/cm2)17 psi ← ←

Rear wheel 120 kPa (1.2

kgf/cm2)17 psi ← ←

Battery 75D23L ←

Engine plug - -

The factory default maximum engine rpm is 3,100 rpm.

Mower Units

Baroness mower unit that can fit this machine is the model marked with a circle in the "Attachable

unit" column.

LM351

Model Attachable unit Remarks

LH52 22 in -

LH62 22 in -

LH66 26 in -

LS60 30 in 〇

LS62 22 in -

LS66 26 in 〇

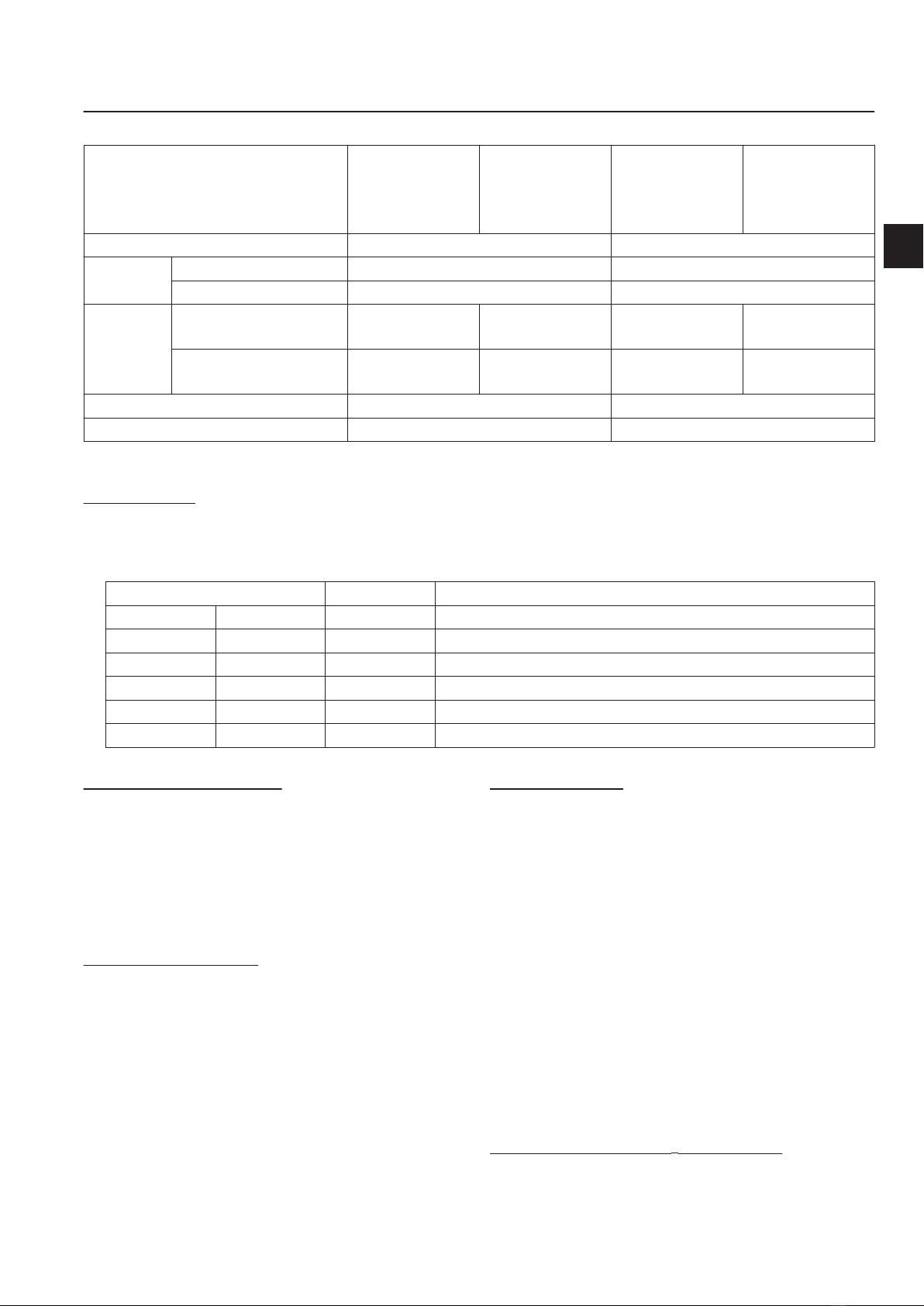

Sound Pressure Level

Sound Pressure Level

This machine was confirmed to have a

continuous A-weighted sound pressure level

of 88 dB by measuring identical machines in

accordance with the procedure specified in

ISO5395-1:2013.

Sound Power Level

Sound Power Level

This machine was confirmed to have a sound

power level of 105dB by measuring identical

machines in accordance with the procedure

specified in ISO5395-1:2013.

Vibration Level

Hand-Arm Vibration

This machine was confirmed not to exceed a

vibration level of 2.5 m/s2 to hands and arms

by measuring identical machines in

accordance with the procedure specified in

ISO 5395-1:2013.

Uncertainty K = 0.4 m/s2

Whole Body Vibration

This machine was confirmed not to exceed a

vibration level of 0.5 m/s2 to the whole body

by measuring identical machines in

accordance with the procedure specified in

ISO 5395-1:2013.

Uncertainty K = 0.1 m/s2

Carbon Dioxide (CO2) Emissions

For the CO2 value on the engine of this

machine, refer to the engine's owner's manual.

Product Overview

LM351

Product Overview

Page 3-3

Specifications

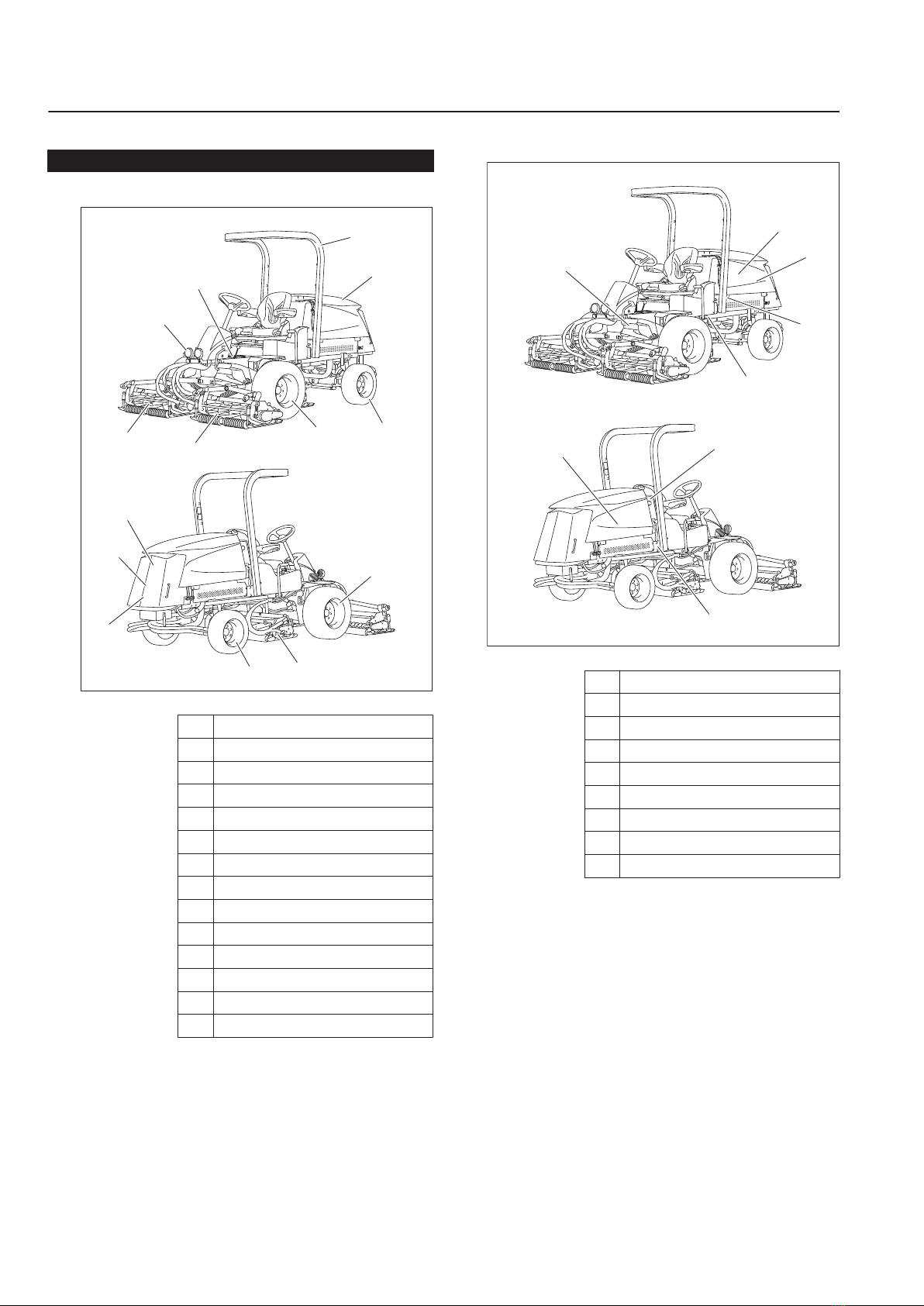

Names of Each Section

Overall View A

2

3

1

13

12

8

9

5,6,7

14 10

10

11

11

4

0413261C

Names of Each Section_001

1Light

2 ROPS

3 Hood

4 Center cover

5 Radiator cover

6 Radiator

7 Oil cooler

8 Air cleaner

9 Battery

10 Front tire

11 Rear tire

12 Mower unit #1

13 Mower unit #2

14 Mower unit #3

Overall View B

3

5

7,8

6

4

9

1

2

0467670A

Names of Each Section_002

1Fuel tank

2 Fuel filter

3 Engine

4 Engine oil filter

5 Reserve tank

6 Water separator

7 Hydraulic tank

8 Hydraulic oil filter (suction filter)

9 Hydraulic oil filter (line filter)

LM351

Product Overview

Page 3-4 Names of Each Section

Table of contents

Other Baroness Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions