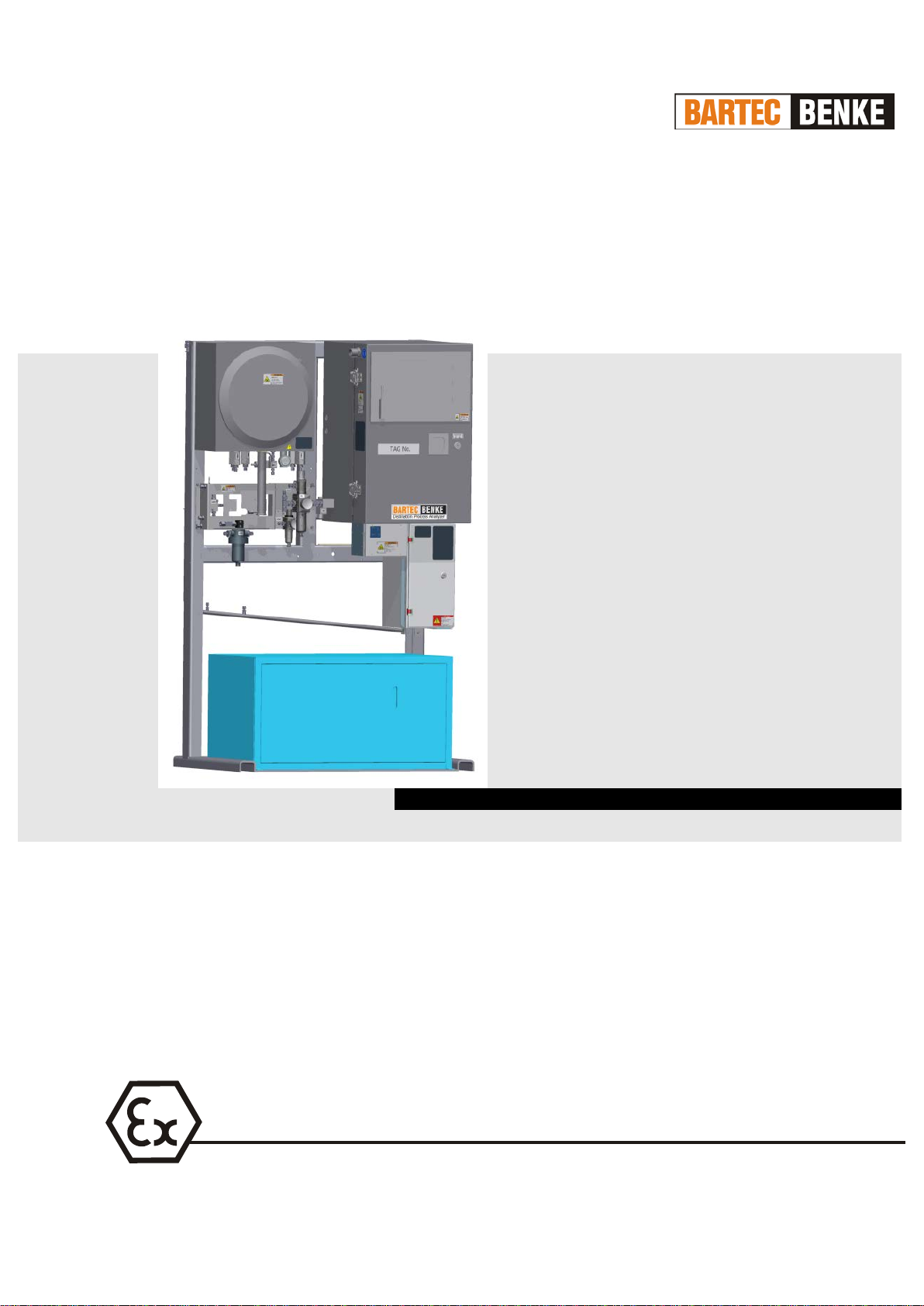

Distillation Process Analyzer DPA-4.5

Contents

3.7 Signal inputs and outputs.............................................52

3.8 Type plates...................................................................53

3.9 Operating and storage conditions................................55

3.10 Emissions.....................................................................56

3.11 Connections.................................................................56

3.12 General specifications..................................................57

4Design and function.............................................................58

4.1 Overview ......................................................................58

4.2 Brief description ...........................................................59

4.3 Measuring principle......................................................60

4.4 Description of subassemblies......................................62

4.4.1 Measuring unit.................................................62

4.4.2 Control unit......................................................64

4.4.3 Fluid technology..............................................66

4.4.4 Junction boxes ................................................68

4.4.5 Sample conditioning system (optional) ...........69

4.5 Optional extensions......................................................70

4.6 Connections.................................................................72

4.7 Operating elements......................................................73

5Transport, packaging and storage .....................................75

5.1 Safety instructions for transport...................................75

5.2 Symbols on the packaging...........................................77

5.3 Transport inspection.....................................................78

5.4 Packaging ....................................................................78

5.5 Center of gravity and suspension eyebolt....................79

5.6 Transport......................................................................80

5.7 Storage.........................................................................81

6Installation and preparation for commissioning...............82

6.1 Safety...........................................................................83

6.2 Requirements for the installation location....................85

6.3 Fixing to the floor..........................................................86

6.4 Mounting optional components....................................87

6.5 Connecting pipelines....................................................87

6.6 Connecting the power supply and signal lines.............92

6.7 Preparations for commissioning...................................95

6.7.1 Rinsing the instrument air and nitrogen

supply lines......................................................95

6.7.2 Supplying with instrument air and nitrogen.....96

6.7.3 Purging the cooling medium supply lines........97

6.7.4 Filling the chiller and supplying cooling

medium............................................................98

6.7.5 Rinsing the product supply lines ...................100

7Commissioning ..................................................................103

4 December 2013