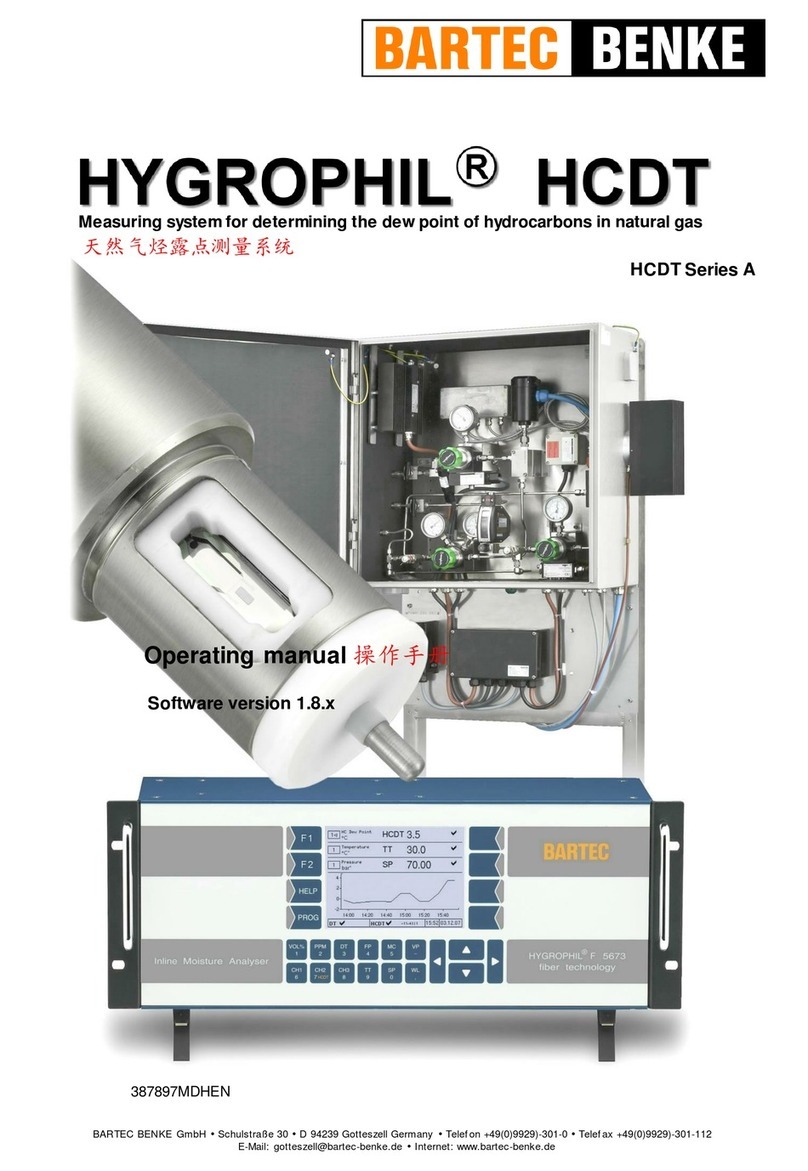

BARTEC BENKE HYGROPHIL F 5673 User manual

BARTEC BENKE GmbH Schulstraße 30 94239 Gotteszell Deutschland Telefon +49(0)9929)-301-0 Telefax +49(0)9929)-301-112

E-Mail: gotteszell@bartec-benke.de Internet: www.bartec-benke.de

HYGROPHIL®F 5673

Series A

Operating manual

Software version 1.8.x

387896MDHEN

Contents

C - 1

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

Contents

Contents Page Issue date

1System description____________________________________________ 1-1

1.1 Measurement principle, Function and applications_____________________ 1-1 09.11.2011

1.2 Declaration of Conformity ________________________________________ 1-2 19.05.2011

1.3 Layout of the humidity measurement system _________________________ 1-4

1.3.1 Operator controls and display elements _____________________________ 1-4

1.3.1.1 Keyboard_____________________________________________________ 1-4

Key functions__________________________________________________ 1-5 26.04.2013

1.3.1.2 Display ______________________________________________________ 1-7 17.03.2011

1.3.2 Interfaces ____________________________________________________ 1-8 17.04.2013

1.4 Technical data________________________________________________ 1-11

1.4.1 Evaluation unit F 5673 _________________________________________ 1-11

1.4.2 CPU plug-in unit type 5673-113 __________________________________ 1-12

1.4.3 Power supply plug-in unit DC 10..36V type 5673-108 _________________ 1-12 19.05.2011

1.4.4 Power supply plug-in unit AC 100..240V type 5673-109 _______________ 1-12

1.4.5 Analog I/O Ex type 5673-114 ____________________________________ 1-13

1.4.6 Interface module type 5673-110__________________________________ 1-15 17.04.2013

1.4.7 Relay-Interface module Type 5673-115 ____________________________ 1-17 19.05.2011

1.4.8 Polychromator plug-in unit type 5673-302 __________________________ 1-18

1.4.9 Humidity sensor L166x _________________________________________ 1-18 17.04.2013

1.5 Spare parts, accessories _______________________________________ 1-20 14.06.2013

2Safety precautions ____________________________________________ 2-1

3Installation ___________________________________________________ 3-1

3.1 General ______________________________________________________ 3-1

3.2 Arrangements for EMC __________________________________________ 3-1

3.3 Sensor L166x _________________________________________________ 3-2

3.3.1 Wiring the sensor L166x _________________________________________ 3-2 17.04.2013

3.3.2 Installing the sensor L166x_______________________________________ 3-6

3.3.2.1 Installing accessories ___________________________________________ 3-6

3.3.2.2 Assembly examples ____________________________________________ 3-6 20.04.2012

3.3.3 Installation advice _____________________________________________ 3-13

4Operation____________________________________________________ 4-1

4.1 Start up ______________________________________________________ 4-1

4.2 Automatic sensor equalizing______________________________________ 4-1 02.11.2011

4.3 Display modes_________________________________________________ 4-2 17.03.2011

4.3.1 Combined display ______________________________________________ 4-3

4.3.1.1 Selecting a line ________________________________________________ 4-3

4.3.1.2 Assigning a channel ____________________________________________ 4-4

4.3.1.3 Assigning a measurement variable_________________________________ 4-4 26.04.2013

4.3.1.4 Fixed values __________________________________________________ 4-5

4.3.1.5 Status indication _______________________________________________ 4-5

4.3.1.6 Graphic ______________________________________________________ 4-5

4.3.1.7 Info line ______________________________________________________ 4-5

4.3.2 Measurement value display with six lines____________________________ 4-6

4.3.3 Measuring the humidity in liquids __________________________________ 4-6

4.3.4 Online graphic display___________________________________________ 4-7

4.3.5 History graphic display __________________________________________ 4-8

4.3.5.1 History Setup__________________________________________________ 4-8 17.03.2011

Defining the presentation period___________________________________ 4-9 17.03.2011

Defining the presentation of the graph _____________________________ 4-10

4.3.5.2 Display the history graphic ______________________________________ 4-12

Hide Graphs _________________________________________________ 4-12 17.03.2011

Changing the display mode _____________________________________ 4-13 17.03.2011

Contents

C - 2

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

Contents Page Issue date

4.4 Data export__________________________________________________ 4-14

4.4.1 Copy data ___________________________________________________ 4-14 17.03.2011

4.4.2 Converting data ______________________________________________ 4-15

4.4.3 Export service information to an external data medium________________ 4-16 17.03.2011

5Programming _________________________________________________5-1

5.1 General instructions _____________________________________________5-1

5.2 Calling up programming mode_____________________________________5-2

5.3 Selecting and opening the menu ___________________________________5-3

5.4 Editing parameters ______________________________________________5-4

5.4.1 Selecting the parameter setting ____________________________________5-4

5.4.2 Selecting the parameters for editing_________________________________5-5

5.4.3 Numerical entries _______________________________________________5-5

5.5 Structure of the programming menu_________________________________5-6 20.04.2012

5.6 Program parameters___________________________________________ 5-12

5.6.1 Dimension units ______________________________________________ 5-12

5.6.2 Analog outputs _______________________________________________ 5-13

5.6.3 Analog inputs ________________________________________________ 5-16

5.6.3.1 Temperature_________________________________________________ 5-16 17.03.2011

5.6.3.2 Pressure____________________________________________________ 5-17 17.03.2011

5.6.3.3 CO2content _________________________________________________ 5-17 17.03.2011

Default values________________________________________________ 5-17

5.6.4 Limits ______________________________________________________ 5-18

5.6.5 Selecting the MC Calculation Method _____________________________ 5-19 02.11.2011

DIN EN ISO 18453____________________________________________ 5-20

Custom User Factor ___________________________________________ 5-21

5.6.6 Edit Gas Data________________________________________________ 5-22 02.11.2011

5.6.6.1 Predefined gases _____________________________________________ 5-23 09.11.2011

5.6.6.2 User specific gases ___________________________________________ 5-24

Create a user specific gas ______________________________________ 5-24

Edit a user specific gas ________________________________________ 5-27

Delete a user specific gas ______________________________________ 5-28

5.6.7 Modbus/Profibus______________________________________________ 5-29 29.03.2011

5.6.8 Date and time________________________________________________ 5-30

5.6.9 Serial output _________________________________________________ 5-31 17.03.2011

5.6.10 Assigning a liquid to a channel___________________________________ 5-32

5.6.10.1 Default curves________________________________________________ 5-33

5.6.10.2 User specific curves ___________________________________________ 5-34

5.6.11 Edit Liqiuid Curves ____________________________________________ 5-34

5.6.11.1 Default curves________________________________________________ 5-34

5.6.11.2 User specific curves ___________________________________________ 5-35

Create a new curve ___________________________________________ 5-35

Edit a curve__________________________________________________ 5-39

Delete a curve _______________________________________________ 5-39

5.6.12 Offset ______________________________________________________ 5-39

Cancel offset_________________________________________________ 5-40

5.6.13 Reset configuration to default____________________________________ 5-41 17.03.2011

5.6.14 Language ___________________________________________________ 5-42 02.11.2011

5.6.15 System Information____________________________________________ 5-43 09.11.2011

Export service information to an external data medium________________ 5-43 09.11.2011

5.6.16 Change Password ____________________________________________ 5-44

5.6.17 Maintenance menu____________________________________________ 5-44

Contents

C - 3

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

Contents Page Issue date

6Error handling ________________________________________________ 6-1

6.1 Limit transgressions ____________________________________________ 6-1

6.2 Warnings_____________________________________________________ 6-2

6.3 Errors _______________________________________________________ 6-2

6.4 HELP key ____________________________________________________ 6-3

7Maintenance _________________________________________________ 7-1

Cleaning the sensor ____________________________________________ 7-1 17.04.2013

8Bus systems _________________________________________________ 8-1

8.1 Modbus ______________________________________________________ 8-1 26.04.2013

8.2 Profibus______________________________________________________ 8-6 04.06.2012

9Appendix ____________________________________________________ 9-1

List of resistance and side effects for fibre-optic sensor L166x ___________ 9-1

Default liquid saturation characteristic curves in HYGROPHIL®F 5673 ____ 9-3

Predefined gases in HYGROPHIL®F 5673 __________________________ 9-5 09.11.2011

Contents

C - 4

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

All rights reserved and subject to change.

Duplication, processing and distribution of this document,

including parts thereof, is prohibited without the prior

written consent of BARTEC BENKE.

Copyright © 2015

by BARTEC BE

NKE GmbH

Schulstraße 30,

D-94239 Gotteszell

Document: 387896MDHEN valid from: 10.11

Revision: Software version 1.8.x 14.06.2013

Author: G. Rothe

Translation E. Bauernfeind

System description

1-1

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

1 System description

1.1 Measurement principle, Function

and applications

HYGROPHIL®F 5673 is a high-quality, microprocessor-controlled fibre-optic

hygrometer for measuring the moisture or trace humidity at low dew-point

temperatures in gases and liquids.

HYGROPHIL®F 5673 works in multi-channel operation with a temperature-

compensated fibre-optic sensor developed especially for measuring the

moisture content in gas mixtures and liquids.

Measurement of water dew point temperature

(Gas humidity)

The water dew point is measured with the HYGROPHIL®F and sensor type

L166x.

The moisture sensor, type L166x, consists of a robust multi-layer of optically

high and low refractive layers connected to 2 fibre-optical cables.

Due to a special thermal coating technique, pores with the diameter of a wa-

ter molecule are generated on the layer.

Due to the moisture equilibrium content, water is deposited in the layer and

changes the refractive index of the irradiating light (air: 1,00/water 1,33).

Within the layer system this results in a wavelength shift in proportion to the

moisture prevailing in the medium.

This shift is measured by the evaluation unit and assigned to a dew point.

The L166x probe makes measurements which are temperature compen-

sated (by the integrated Pt100).

In short, the HYGROPHIL®F 5673 works in conjunction with a combination

sensor which fibre-optically determines the moisture content and measures

the temperature in the medium with a Pt100.

Apart from the extremely robust construction of the sensor, it is above all

else, the measurement technique which offers several decisive advantages.

Some of the advantages of this patented measuring method are as follows:

●High measuring confidence, including precision, reproducibility and low

hysteresis.

●Long-term stability of the sensor (no drift!)

●Measurement is possible on the high-pressure side (pressure dew point!)

●Application in explosive areas (zone 0 and higher)

●Simple installation and upgrading (Swagelok, Parker, …)

The L166x was developed especially for natural gas applications and is now

applied in trace moisture measurement for a large number of different gases

and liquids.

Due to the usage of high-quality materials, the sensor is extremely robust

and resistant to most media.

System description

1-2

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

1.2 Declaration of Conformity

System description

1-3

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

System description

1-4

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

1.3 Layout of the humidity measurement

system

The measurement system consists of an evaluation unit and up to three hu-

midity sensors.

The evaluation unit is designed as a 19“rack which can take several plug-in

units. The evaluation unit can also be installed as a desktop device.

The humidity sensor consists of a sensor layer and an integrated tempera-

ture sensor, the fibre-optic cable and the plug connector, which also contains

the sensor´s adjustment data.

The humidity sensor is available in three standard dimensions: 36 mm,

100 mm and 225mm. Sensors with length of 407mm and 458mm are avail-

able on request.

1.3.1 Operator controls and display elements

All operator controls and display elements are at the front side of the evalua-

tion unit. The device is not equipped with a mains switch. If required, you

have to disconnect the device from the mains supply (mains plug). If operat-

ed as a desktop device, the two front feet of the evaluation unit can be swiv-

elled out for easier operation and a better viewing angle.

1.3.1.1 Keyboard

The device is operated via touch-sensitive keys on the front side of the de-

vice (numeric and measurement variable keys) and via certain key functions

of the touch-screen. All keys are touch-sensitive, i.e. you don’t need to press

them, only touch them.

Display

Keyboard

HYGROPHIL®F 5673, front view

System description

1-5

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

Key functions

Indication of the water vapour content [Vol%], optional relative humidity [RH]

(see section 4.3.1.3)

Indication of the water vapour content in parts per million volume or in parts

per million weight

Indication of the Dewpoint Temperature

Indication of the Frost Point Temperature

Indication of the Moisture Content [mg/m3] or [lb/MMscF]

Indication of the water Vapour Pressure

Selection of the measurement channel (see section 4.3.1.2)

Indication of the temperature at the measuring point (True Temperature)

Indication of the pressure at the measuring point (Sample Pressure)

Indication of the Wave Length

(1)In the entering mode or programming mode, these keys serve to enter

numerical values.

Trigger the sensor equalizing (see section 4.2)

Call up the history setup (see section 4.3.5.1)

Switch from online graphic mode to history graphic mode (see section 4.3)

(2) If these two keys are not labelled with F1 and F2 at your measuring de-

vice, this does not mean its functional range is restricted. The function of

the keys is available anyhow.

Display of warnings and error messages

Call up the programming mode (see section 5.2)

Selection keys (see section 5.3),

Switch between the display modes (see section 4.3)

Change the cursor position in entry fields (see section 5.4.3)

(1)

VOL%

1

PPM

2

DT

3

FP

4

MC

5

VP

-

CH1

6

CH2

7

CH3

8

TT

9

SP

0

WL

,

(2)

F1

F2

HELP

PROG

System description

1-6

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

The four keys to the right of the display are not labelled. Depending on the

operating status of the measurement system, different functions are as-

signed to them. The current function is marked by a symbol next to the key

in the display (for the meaning of the symbols see section 5.1).

In several operating situations is the current function of the F1 and F2 keys

as well as the four keys to the right of the display only displayed when touch-

ing one of these keys.

When the function is displayed you can start the function by touching this

key.

System description

1-7

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

1.3.1.2 Display

A graphic display screen designed as a touch-screen is used for display

purposes.

Some functions are operated by means of key functions located on the dis-

play screen in dependence on the situation.

System description

1-8

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

1.3.2 Interfaces

Polychromator

Channel boards Analog/Digital I/O Ex

Relay module

Power supply module

CPU module

Interface module

Channel 1

Channel 2

Channel 3

Current output Ex i

Temperature sensor (PT100)

Pressure sensor (4...20 mA)

CO2-sensor (4...20 mA)

COM

USB

Relay outputs see section 1.4.7

3x Current output

System description

1-9

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

System description

1-10

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

Interface

module

System description

1-11

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

1.4 Technical data

1.4.1 Evaluation unit F 5673

Evaluation unit

Display ranges

(not the measuring range)

Measurement variable

Lower range limit

Upper range limit

Vol% [%]

0

100

PPM [ppm]

0

25000

DT [°C,°F,K]

-100

100

FP [°C,°F,K]

-100

100

MC [mg/m3],

[lb/MMscF]

0

30000

VP [hPa]

0

250

TT [°C,°F,K]

-50

100

SP [bar,PSI,..]

0

250

WL [nm]

780

830

Auxiliary variables

The temperature (TT) at the measuring point is measured via a sensor inte-

grated in the humidity sensor or entered by hand. The pressure (SP) is

measured via a 4...20 mA signal from an external pressure transmitter or

entered by hand. CO2-content (0...100%) is measured via a 4...20 mA-

signal or entered by hand.

Measurement channels

1, 2 or 3

Measuring rate

Max. 3 measurements / minute per channel

Inputs per measurement channel

- Light waveguide port for optical humidity sensor

- 9-pole D-SUB plug for data memory with sensor characteristic

- Clamp-type terminal for PT 100 measurement sensor in sensor head

- Clamp-type terminal for signal from a pressure transmitter for absolute

pressure (4...20 mA)

- Clamp-type terminal for CO2content (4...20 mA)

all inputs Ex ia, galvanically isolated

Analog outputs per measurement

channel

Clamp-type terminal 0/4...20 mA, EEx ia, galvanically isolated

Source and sink

Resolution 0.0003 mA

Max. load: 500 Ω

Accuracy: 0.03 mA

Temperature drift: <0.001 mA/ °C

Interfaces

RS 232, modbus, profibus

Display

Graphic display 320 x 240 dots

Keyboard

Red backlit touch-screen

Auxiliary energy

DC 10...36 V max. 60 W (Si 6.3 A T)

AC 100...240 V max. 110 VA (Si 3.15 A MT)

Ambient conditions

Permissible working temperature: 0...+50 °C

Permissible storage temperature: -20...+60 C

Climatic category: IWI according to DIN 40040

Dimensions (WxHxD)

483 x 192 x 212

Approvals

ATEX, CSA, GOST

Weight

approx. 8.5 kg

System description

1-12

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

1.4.2 CPU plug-in unit type 5673-113

Electrical data

Operating voltage CPU

5.5 V ±2 %

Power consumption

800 mA

Fuse of battery

3.5 A

Interfaces

USB 2.0 Host

OHCI

Ethernet

100 MBit

Serial interfaces

5x up to 115200 Bit/s, 3.3 V LVTTL

2x up to 460800 Bit/s, 3.3 V LVTTL

Elektronics

Realtime clock

32.768 kHz (battery buffered)

Ambient conditions

Operating temperature

- 10 … + 50 °C

Storage temperature

- 20 … + 70 °C

Climatic class

JWF in accordance with DIN 40040

Protection type

IP00 in accordance with DIN 40050

1.4.3 Power supply plug-in unit DC 10..36V

type 5673-108

Electrical data

Input voltage

DC 10...36 V, fuse 6.3 A (T)

Output voltage

5,5 V 3.2 A short-circuit-proof

24 V 1.2 A short-circuit-proof

10 V max. 100 mA

Maximum output power

60 W

Ambient conditions

Operating temperature

- 10 … + 50 °C

Storage temperature

- 20 … + 70 °C

1.4.4 Power supply plug-in unit AC 100..240V

type 5673-109

Electrical data

Input voltage

AC 100...240 V, fuse 3.15 A (MT)

Output voltage

5.5 V 3.2 A short-circuit-proof

24 V 1.2 A short-circuit-proof

10 V max. 100 mA

Maximum output power

110 VA

Ambient conditions

Operating temperature

- 10 … + 50 °C

Storage temperature

- 20 … + 70 °C

System description

1-13

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

1.4.5 Analog I/O Ex type 5673-114

Electrical data

Operating voltage for CPU

DC 5.5 V ± 2 % 200 mA, fuse 400 mA

Operating voltage for sensor supply

DC 24 V ± 5 %, max. 480 mA, fuse 1 A

PT-100 [EEx ia]

Type

Pt-100 (4 wires), l 1 mA -50...+100 °C

Resolution

0.005 °C (16 bit)

Separation

galvanically isolated

Analog Output [EEx ia]

Current range

0/4-20 mA

resolution

0.0003 mA

Separation

galvanically isolated

Sampling

Max. 10 /s

Aktive

Load max. 500 Ω

Passive

Umax :36 V, Umin at 20 mA: 8 V

Analog Input [EEx ia]

Quantity

2

Input current

4...20 mA

Resolution

0.005 mA

Separation

galvanically isolated

Sampling

Max. 10 /s

output voltage V+1 and V+2

DC 24 V ±10% max. 30 mA, short-circuit-proof

Ambient conditions

Operating temperature

- 10 … + 50 °C

Storage temperature

- 20 … + 70 °C

System description

1-14

HYGROPHIL® F 5673 Operating manual, Software version 1.8.x, 387896MDHEN(14.06.2013)

To the cables of the analog inputs IN1, IN2 and to the cable of the analog

output OUT Source must be fixed ferrite noise filters (order no. 275368) (see

section 3.2).

Analog I/O Ex

Type 5673-114

Shield

Shield

Shield

Shield

Shield

EMC:

This manual suits for next models

1

Table of contents

Other BARTEC BENKE Measuring Instrument manuals

BARTEC BENKE

BARTEC BENKE VISC-4 User manual

BARTEC BENKE

BARTEC BENKE HYGROPHIL H 4230-12 Ex Zone II User manual

BARTEC BENKE

BARTEC BENKE CFPP-4.2 User manual

BARTEC BENKE

BARTEC BENKE HYGROPHIL HCDT Series User manual

BARTEC BENKE

BARTEC BENKE A Series User manual

BARTEC BENKE

BARTEC BENKE DPA-4.5 User manual

BARTEC BENKE

BARTEC BENKE RVP-4 User manual

BARTEC BENKE

BARTEC BENKE VOLUTANK PETRO 3003 User manual