Bartell Global B424 User manual

WALK-BEHIND TROWELS

B424 –B430 –BC436 –BC446 –B436 –B446 –MEGA-T B446

OWNER’S MANUAL

www.BARTELLGLOBAL

Doc. # OI-B19001

Orig. Rel. –08/2016

Curr Rev. - 03

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

2

www.BARTELLGLOBAL.com

Bartell Morrison Inc.

170 Traders Blvd E

Mississauga, Ontario, Canada

L4Z 1W7

Tel: (647) 953-4100

Fax: (647) 953-4101

Bartell Morrison USA LLC

200 Commerce Drive, Unit A

Freehold, NJ, USA

07728

Tel: (848) 225-8100

Fax: (848) 225-8101

SPE International Ltd

Honeyholes Lane

Dunholme, Lincoln, England

LN2 3SU

Tel: 01673 860709

Fax: 01673 861119

Innovatech

4701 Allmond Ave

Louisville, Kentucky, USA

40209

Tel: (425) 405-9100

Fax: (425) 405-9101

ORIGINAL LANGUAGE OPERATING MANUAL FOR

BARTELL WALK-BEHIND POWER TROWELS

© 2019 Bartell Morrison Inc.

No part of this work may be reproduced or transmitted in any form or by any means, electronic

or mechanical, including photocopying and recording, or by any information storage or retrieval

system without the prior written permission of Bartell Morrison Inc. unless such copying is

permitted by federal copyright laws.

REV.

DATE

DESCRIPTION

APPROVED BY:

1

18/08/17

Updated Service Intervals, Removed Electric Trowel,

Address Change, Oil bath oil change procedure added

AN

2

02/18

Added Tie down recommendations in transporting

section, Folding handle procedure

AN

3

02/19

Updated Oil Recommendations

AN

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

3

SAFETY PRECAUTIONS

DANGER

EXPLOSION HAZARD

Never operate the machine in an explosive

atmosphere, near combustible materials, or

where ventilation does not clear exhaust fumes.

WARNING

BURN HAZARD

Never come into contact with the engine or

muffler when engine is operating or shortly after it

is turned off. Serious burns may occur.

CAUTION

ROTATING HAZARD

Never place hands or feet inside safety guard

rings. Serious injury will result from contact with

rotating blades.

CAUTION

MOVING PARTS

Before starting the machine, ensure that all

guards and safety devices are in place and

functioning properly.

ATTENTION

READ OWNER’S MANUAL

Read and understand owner’s manual before

using this machine. Failure to follow operating

instructions could result in serious injury or death.

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

4

Personal Protective Equipment (PPE)

Hearing Protection

Wear earplugs or ear muffs to protect hearing

from potentially damaging noise levels

Eye Protection

Wear eye protection to protect eyes from blowing

dust, splattering concrete, and other foreign

objects

Safety Footwear

Wear safety footwear to protect feet from falling

objects, compression and punctures or cuts from

surrounding and below

Hand Protection

Protect exposed skin surfaces when working with

fresh concrete to avoid skin irritation or chemical

burns

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

5

This Page Intentionally Left Blank

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

6

TABLE OF CONTENTS

QUALITY ASSURANCE/ MACHINE BREAK IN 7

WALK-BEHIND TROWEL WARRANTY 8

ROUTINE SERVICE INTERVALS 9

ROUTINE SERVICE INTERVALS 10

OPERATING SAFETY PRECAUTIONS 11

SAFETY PRECAUTIONS 11

ASSEMBLY INSTRUCTIONS (B424, B430 EDGER) 12

ASSEMBLY INSTRUCTIONS (BC436, BC446, B436, B446, MEGA-T) 12

OPERATION INSTRUCTIONS 15

OPERATION (FLOATING)15

OPERATION (FINISHING)15

STARTING PROCEDURE: WARM CLIMATE 16

STARTING PROCEDURE: COLD CLIMATE 16

STOPPING PROCEDURE 16

LUBRICATION 17

STORAGE 18

MAINTENANCE 18

FOLDING HANDLE 19

TRANSPORTING 20

TROWEL ARM ADJUSTMENT FIXTURE 21

ADJUSTMENT PROCEDURE 21

TROWEL ARM ADJUSTMENT SCREW 22

TROUBLESHOOTING 23

TECHNICAL INFORMATION 25

B424 EDGER &B430 EDGER 25

B436 &B446 WALK-BEHIND TROWEL 25

DECLARATION OF CONFORMITY 26

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

7

QUALITY ASSURANCE/ MACHINE BREAK IN

The Bartell Walk-Behind Power Trowel is the product of extensive engineering

development designed to give long life and unmatched performance. The Walk-Behind Power

Trowels are Shipped Partially Assembled, and only require filling with fuel and a brief check of

lubricant levels in preparation for operation.

You can help ensure that your Power Trowel will perform at top levels by observing a

simple routing on first use. Consider that your new Power Trowel is like a new car. Just as you

would break in a new car to the road or any new machine to the job, you should start gradually

and build up to full use. Learn what your machine can do and how it will respond. Refer to the

engine manufacturer’s manual for run-in times. Full throttle and control may be used after this

time period, as allowed by material. This will serve to further break in the machine on your

specific application, as well as provide you with additional practice using the machine.

We thank you for the confidence you have placed in us by purchasing a Bartell Walk-

Behind Trowel and wish you many years of satisfied use.

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

8

WALK-BEHIND TROWEL WARRANTY

All products sold by Bartell Morrison Inc. and Bartell Morrison (USA) LLC (the “Company”) are

warranted against defects in materials and/or workmanship; excluding normal wear on wearing

components and components covered by a separate original manufacturer’s warranty, for a

period of 12 months (BC436, BC446) or 36 months (B424, B430, B436, B446, B446 Mega-T)

from the date of sale to the original end user purchaser provided that certain conditions have

been met.

Conditions

1. The equipment serial number has been registered with the Company or its approved

dealers, distributors, representatives or agents.

2. The equipment has been operated in an appropriate manner by qualified individuals.

3. The equipment has been properly maintained as per the instructions included in the Owner’s

Manual.

4. All claims for warranty must be filed on proper forms and include the serial number of the

equipment along with proof of purchase.

Any evidence of failure to meet these conditions may result in a denial of the warranty claim.

Consideration of warranty claims will be at the sole discretion of the Company, or its authorized

dealers, distributors, representatives or agents.

The Company may, at its discretion, request that the equipment to be considered for warranty

be returned at the owner’s expense to an authorized repair facility for inspection.

Under this warranty we may, at our discretion, repair or replace a part or the whole of the

defective component or equipment.

Our Warranty coverage is limited to the cost to repair or replace the defective portion of the

equipment and a reasonable (as determined by the Company) amount of labour to conduct the

repair or replacement. Under no circumstances shall the Company be liable for any additional

or exceptional costs beyond the cost to repair or replace the defective portion of the equipment.

The Company shall not be held accountable for; costs associated with travel to inspect or repair

defective equipment, costs for transporting defective equipment to or from an authorized repair

facility, costs incurred to repair or replace the defective equipment at any facility other than one

authorized by the Company or ancillary damage caused by or as a result of the defective

equipment.

Under no circumstances shall equipment be returned to the Company or its authorized dealers,

distributors, representatives or agents without the approval of the Company as evidenced by a

Returned Goods Number. To obtain a Returned Goods Number contact the factory or your

authorized dealer, distributor, representative or agent.

This warranty is for the sole benefit of the original end user purchaser and is not transferable to

any other company or person.

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

9

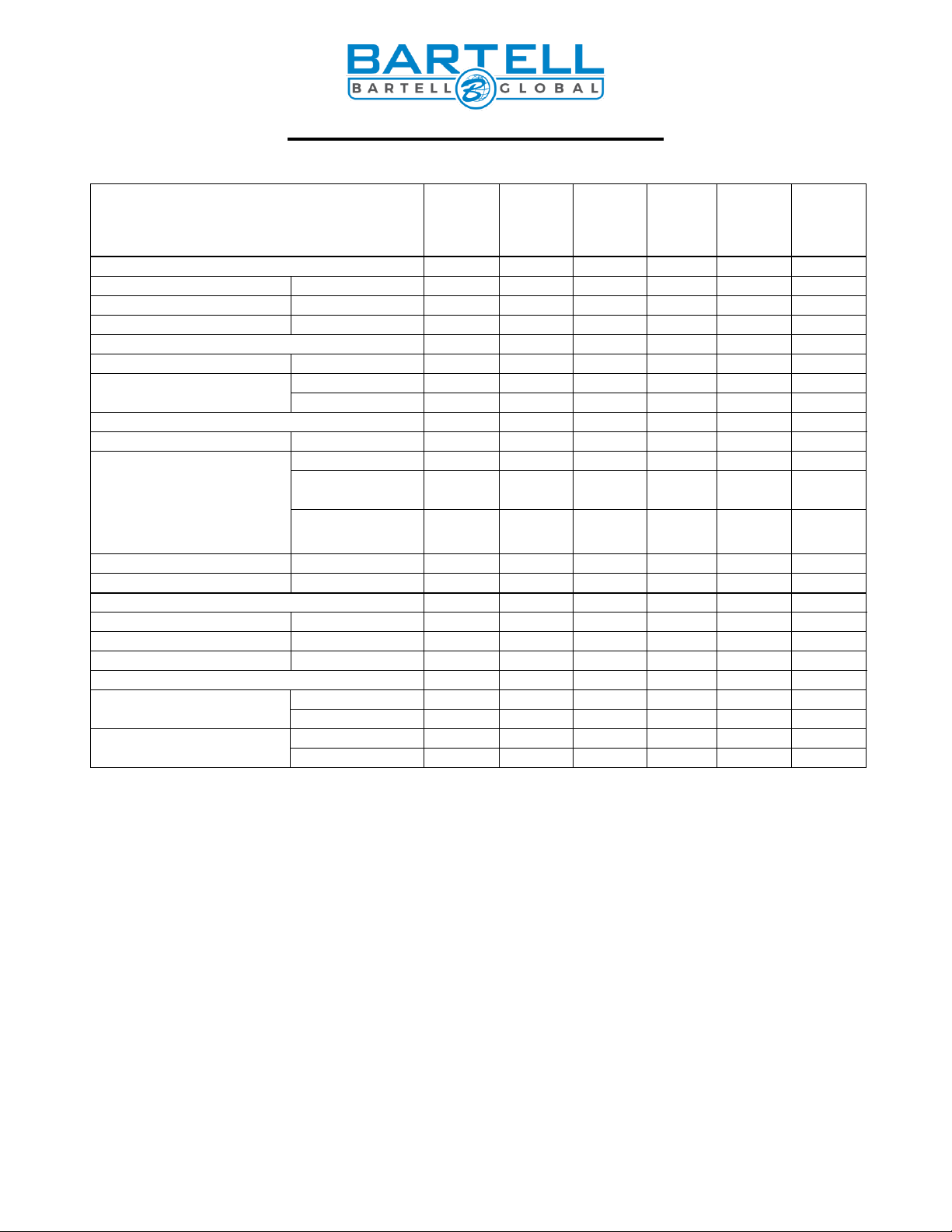

ROUTINE SERVICE INTERVALS

Routine Service Intervals

Each

Use

After

1.5

months

or 50

hrs

Each 3

months

or 100

hrs

Each 6

months

or 200

hrs

Each 9

months

or 300 hrs

Each 12

months

or 400 hrs

General Inspection:

Guards

Check

o

o

o

o

o

o

Warning stickers

Check

o

o

o

o

o

o

Test run:

Check operation

o

o

o

o

o

Controls:

Safety switch operation

Check

o

o

o

o

o

o

Pitch control

Check

o

o

o

o

o

o

Lubricate

o

o

o

o

o

Drive Train:

Clutch / Pulley

operation

Check

o

o

o

o

o

o

Spider plate assembly

Check

o

o

o

o

o

o

Grease

(B436/446)

o

o

o

o

o

o

Lubricate

(B424/430)

o

o

o

o

o

V-Belt

Check

o

o

o

o

o

o

Blades

Check

o

o

o

o

o

o

Gearbox:

Gearbox oil

Check Level

o

Change

o

o

Gearbox breathers

Check operation

o

Engine:

Engine oil (2)

Check Level

o

Change

o

o

o

Air Cleaner (2)

Check –Clean

(1)

o (1)

o

Replace

o

o

o

o

(1) Service more frequently in dusty areas

(2) Refer to engine owner’s manual for servicing instructions and a detailed maintenance

schedule. Some items should be serviced by your servicing dealer, unless you have the

proper tools and are mechanically proficient. Refer to the Honda shop manual for service

procedures

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

10

ROUTINE SERVICE INTERVALS

Due to the nature and environment of use, Power Trowels could be exposed to severe

operating conditions. Some general maintenance guidelines will extend the useful life of your

trowel.

•The initial service for your power trowel should be performed after 25 hours of use, at

which time your mechanic (or authorized repair shop) should complete all of the

recommended checks in the schedule above.

•Regular service according to the schedule above will prolong the life of the Power Trowel

and prevent expensive repairs.

•Keeping your Power Trowel clean and free from debris is the single most important

regular maintenance operation, over and above the checks in the service schedule

above, that can be performed. After each use your Power Trowel should be cleaned to

remove any dust and debris from the undercarriage and surrounding components. Use

of a power washer will make clean up quick and easy, especially if a non-stick coating

was applied prior to use.

•In the Service Schedule above, items that should be checked, replaced or adjusted are

indicated by “o” in the appropriate column. Not all Power Trowel models include the

same features and options and as such not all service operations may have to be

performed. For ease of recording place a checkmark (√) through the “o” when the item

is complete. If an item is not required or not completed place an “x” through the “o” in the

box.

•All Power Trowels have governed engine speed of 3600 rpm. See engine manufacturer’s

manual for exact specifications. Care should be used when making any adjustments to

the Power Trowel not to change the governed speed.

•Failure to have your Power Trowel regularly serviced and properly maintained in

accordance with the manufacturer’s instructions will lead to premature failure and void

the warranty.

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

11

OPERATING SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

•Always keep unauthorized, inexperienced, untrained people away from this machine.

•Rotating and moving parts will cause injury if contacted. Make sure guards are in place.

Keep hands and feet away from moving parts.

•Fuel the machine only when the engine is stopped, using all necessary safety

precautions.

•The engine must always be stopped before attempting any repair or adjustments.

Ignition switch should be off.

•Be careful when working around pipes or ducts protruding from the floor or slab edges.

If the trowel blades hit such obstacles, damage to the machine or possible operator

injury may result.

•When starting the machine, do not exceed 1/3 throttle position. A higher setting may

cause the centrifugal clutch to engage and the handle to rotate.

•Be careful not to come in contact with the muffler when the engine is hot, serious burns

may result!

•Over time, the blades will form a sharp edge. Be careful when handling the old blades.

DANGER: Never operate the machine in an explosive atmosphere, near combustible

materials or where ventilation does not clear exhaust fumes. Repair fuel leaks

immediately. Refer to your engine owner’s manual for more safety instructions.

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

12

ASSEMBLY INSTRUCTIONS (B424, B430 EDGER)

Folding handle version: Your new Bartell Edger Power Trowel has been shipped to you fully

assembled. All you need to do is remove the locking pin, unfold the handle and re-insert the

locking pin.

Rigid handle version:

Remove any shipping or packing materials. On Euro models, be sure to remove and discard

the band securing the safety/stop switch on the handles. This serves only to facilitate shipping

and is not intended to be a permanent feature.

When removing the machine from the carton, be careful to use the handles to lift the unit from

the carton. NEVER LIFT THE MACHINE BY THE RING OR DISC. Filling the fuel tank and a

brief check of lubricant levels in preparation for operation is required.

ASSEMBLY INSTRUCTIONS (BC436, BC446, B436, B446, MEGA-T)

Your new Bartell Walk-Behind Power Trowel has been shipped to you partially assembled.

Filling the fuel tank and a brief check of lubricant levels in preparation for operation is required.

To complete the assembly for all Bartell Walk-Behind trowels, the following instructions will be

helpful.

IMPORTANT: Before running machine, ensure that engine idles properly and that the

safety-switch shuts off the engine.

Step 1: Trowel shown with handle

separate. (Fig. 1)

Step 2: Lay handle on ring to prepare for assembly. (Fig. 2 and 3)

Fig. 1

Fig. 3

Fig. 2

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

13

Step 3: Install pitch control

cable to yoke and install

locknut loosely (Fig. 4). If

needed, turn pitch control knob

counter-clockwise until the

stop screw is at the lowest

position (Fig. 5).

Step 4: Lift and install handle to position using the supplied four sets of

lockwashers and nuts. Do not torque greater than 18ft-lb. At the yoke;

tighten the locknut for pitch control cable (Fig. 6). If the cable is too loose or

tight, the pitch control range position can be moved by changing the

position of the stop screw (Fig. 5). The factory default is the middle position.

Turn the pitch control knob completely clockwise and check for maximum

pitch possible. This is possible when the clearance between the yoke and

underside of the gearbox is enough to pass a business card through.

Step 5: Unwrap throttle control and engine safety

shut-off wires to prepare for their assembly. (Fig. 7

and 8)

Step 6: Remove air filter cover and

air filter. (Fig. 9)

Step 7: Check for free moving

engine throttle control lever

and loosen pivot nut if

necessary (Fig. 10)

Step 8: Push handle throttle lever

all the way forward for idle position

(Fig. 11). If necessary, the tension

screw can be adjusted for smooth

operation while holding throttle

position.

Step 9: Install the throttle

control wire into the throttle

control lever. (Fig. 12)

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Fig. 10

Fig. 11

Fig. 12

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

14

Step 10: Secure the wire to the

cable clamp while pushing with

slight pressure forward. (Fig. 13)

Step 11: Check operation of

throttle control lever. (Fig. 11

and 14)

Step 12: Reinstall air filter and

cover (Fig. 15)

Step 13: Route engine safety shut-off wire around

engine and install. There are two types that may be

available with the machines. (Fig. 16 and 17)

Step 14: Wrap and secure engine safety

shut-off wire. (Fig. 18)

Step 15: Refer to Owner’s Manual before

operating the trowel.

Fig. 13

Fig. 14

Fig. 15

Fig. 16

Fig. 17

Fig. 18

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

15

OPERATION INSTRUCTIONS

OPERATION (Floating)

When the slab has set sufficiently firm that the operator’s footprint leaves a very slight

depression on the surface of the slab, it is ready for the floating operation.

Guiding the machine on the slab is very simple, a slight upward lift of the handle causes the

machine to travel to the left. Holding the handle in the neutral position, will slowly cause the

machine to spin in one spot. Slight downward pressure on the handle causes the machine to

travel to the right. Best results are obtained by covering approximately 4” on each turn. In other

words, let the machine move right or left, backwards or forwards, approximately 4” with each

revolution of the trowels. To fill a hole or cut down a hump, move the unit back and forth over

the problem area.

Under normal operating conditions the machine should cover as much as 1000 sq. ft. in about

15 minutes. It is recommended that a slight tension on the trowel control cable, (but not a

definite tilt), during the floating operation will cause the machine to operate much smoother.

After the floated slab has set sufficiently, it is ready for the finishing operation.

OPERATION (Finishing)

When starting the finishing operation, never set the trowels up over 1/4” pitch. This is important.

Guiding the machine on the slab is very simple, a slight upward lift of the handle causes the

machine to travel to the left. Holding the handle in the neutral position, will slowly cause the

machine to spin in one spot. Slight downward pressure on the handle causes the machine to

travel to the right. Best results are obtained by covering approximately 4” on each turn. In other

words, let the machine move right or left, backwards or forwards, approximately 4” with each

revolution of the trowels. To fill a hole or cut down a hump, move the unit back and forth over

the problem area.

After the first pass over the slab, the waiting time between operations is determined in the same

manner as if you were hand troweling. To repeat; the entire application and action of the

troweling machine in regard to getting on the slab, and the correct pitch of the trowels, is

determined in the same manner as would be used by a cement finisher when troweling by

hand.

CAUTION: Do not let the machine stand in one spot on the soft cement. Lift from the

slab when the floating operation is complete.

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

16

STARTING PROCEDURE: WARM CLIMATE

1. Open fuel valve on gas tank, the fuel valve lever should be in the ON position.

2. Set choke lever to closed position.

3. Throttle should be in fast idle position (Approx 1/3rd throttle)

4. Ensure the on/off switch on the engine is in the ON position. The centrifugal switch on

the handle should be in the run/on position. *Euro version: make sure safety switch is

engaged.

5. Start engine using the recoil start. Lightly pull on starter grip until resistance is felt, then

pull quickly and return grip to starting position.

6. Open choke slightly to prevent flooding.

7. Move choke to “Open” or “Run” position when engine is warm.

8. Using remote throttle lever on the handle increase throttle to maximum operation

position (3600 rpm).

STARTING PROCEDURE: COLD CLIMATE

Follow same procedure as above but allow longer warm-up period –3 to 5 minutes. In cold

weather, oil is much heavier to move and requires more time to work its way into the moving

parts. If maximum power is not attained, allow further warm-up time.

STOPPING PROCEDURE

1. Throttle engine down to idle.

2. Turn on/off switch to off position.

3. Turn fuel valve lever to off position.

Fill fuel tank with clean gasoline, use safety approved gas containers. DO NOT

MIX OIL WITH GASOLINE –USE UNLEADED GAS ONLY.

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

17

LUBRICATION

1. ENGINE OIL

The long life and successful operation of any piece

of machinery is dependent on frequent and

thorough lubrication. Before using the trowel,

always check your engine for oil. Use proper engine oil as recommended in the engine

manufacturer’s manual. Fill crankcase to levels as recommended.

2. SPIDER PLATE - GREASE

There are 4 (four) grease fittings on the spider plate, each must be greased daily. THE

SPIDER PLATE MUST BE GREASED EVERY TIME MACHINE IS USED.

3. SPIDER PLATE –OIL BATH (B424/B430 Edger only)

The trowel arm on the spider plate does not require lubrication to be added every use.

However, the oil in the oil bath spider plate should be checked periodically and topped

up or changed if necessary.

4. HOW TO CHANGE OIL IN THE OIL BATH SPIDER PLATE (B424/B430 Edger only)

Step 1. First remove the set screw that holds the trowel arm into the spider plate

Step 2. Add oil through the set screw hole. Very little oil is needed.

Step 3. While rotating the trowel arm throughout its pitch direction, pull the trowel arm

about half to three quarters of the way out of the spider plate. This should be done about

half dozen times. Doing this releases any pressure that may have built up in the

chamber that holds the arm and the oil. The pressure will release through the oil grooves

and through the vacant bolt hole. Add oil if necessary.

Step 4. Push the trowel arm back into its proper location and re-install the set screw. The

trowel arm should move freely.

Step 5. Steps 1 to 4 should be repeated for remaining trowel arms.

5. GEARBOX (Except B424/B430 Edger)

Check the oil level sight plug on the gearbox daily to ensure the oil is half way on the site

glass. Top up with Agma 8 compounded gear oil only. Gearbox capacity 16 oz. to 19 oz.

(473ml. To 562ml.) Example: Esso/Exxon Cylesstic TK680, AGMA 8 or ISO 680

6. TO CHANGE GEARBOX OIL (Except B424/B430 Edger)

Place a pan beneath the drain plug to catch the oil. Remove the drain plug and the filler

plug from the gearbox. After the oil has drained completely, replace the drain plug and

tighten. Fill gearbox through the filler plug with 16 oz. to 19 oz. (473ml to 526ml) of

Agma 8 or ISO 680 compound gear oil. Replace the filler and tighten.

7. GEARBOX (B424/B430 Edger)

Check for oil leaks around gearbox. If necessary, remove drain plug from back of

gearbox to drain and refill with 10.1 oz. (0.3 L) of Shell Tivela Compound A or similar.

NOTE: THE LUBRICATION SYSTEM SHOULD BE CHECKED AT LEAST ONCE

PER MONTH TO ENSURE THAT THE UNIT IS FUNCTIONING PROPERLY.

ENGINE OIL SPECIFICATIONS

All seasons: SAE 10W-30

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

18

STORAGE

The following steps should be taken to prepare your walk-behind trowel for extended storage.

1. Clean the exterior surfaces of the trowel.

2. Close fuel shut off valve.

3. Siphon excess gasoline from tank.

4. Start engine until it stops from lack of fuel. This will use up all the fuel in the carburetor

and prevent formation of deposits due to evaporation of fuel.

5. Store the unit in an upright position in a cool, dry, well ventilated area.

6. Refer to the engine manual for more information.

MAINTENANCE

Maintaining your Walk-Behind Power Trowel will ensure long life to the machine and its

components.

AIR CLEANER - Keep air filter clean at all times. Refer to engine manual.

LUBRICATION –Check engine oil regularly. Use proper engine oil as recommended. See

previous chart. Fill crankcase to levels as recommended in manufacture’s engine manual.

SPARK PLUG –Check and clean spark plugs regularly. A fouled or dirty spark plug causes

hard starting and poor engine performance. Set spark plug gap to recommended clearance.

Refer to engine manual.

BELT TENSION –IMPORTANT! When the engine is switched off, and the machine has

stopped, the normal belt play should be loose. This is due to the clutch type. When the

machine is running at full throttle, the clutch will close in, which tightens the belt causing the

gearbox to engage. When adjusting the belt make sure that the clutch is in alignment with

the follower pulley. Secure belt guard. Tighten all engine mount bolts, and tighten lock nuts.

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

19

FOLDING HANDLE

FOLDING PROCEDURE

To avoid damage to the folding handle or the pitch cable please follow the instructions below.

1. Turn the fine pitch knob counter clockwise to remove pitch from the blades.

2. Once the blades are flat, keep turning the knob counter clockwise until the stop screw

bottoms out in the slot. (see Fig 19)

3. Now that the cable has enough slack, remove the locking screw by turning it counter

clockwise and fold the handle slowly. Damage may occur if handle is dropped into

folding position.

4. Reinsert the locking screw when the handle is in the folded position, turn the locking

screw clockwise to secure in place. (See Fig 20)

5. Your handle is now folded and ready for transportation or storage.

UNFOLDING PROCEDURE

6. Follow the folding procedure but in reverse to return the handle into operating position.

Fig 19

Fig 20

IMPORTANT: IF THERE IS NOT ENOUGH SLACK IN THE PITCH CABLE, THE CABLE

WILL GET DAMAGED WHEN FOLDING. MAKE SURE THERE IS AS MUCH SLACK AS

POSSIBLE BY TURNING THE PITCH KNOB COUNTER CLOCKWISE COMPLETELY.

WALK-BEHIND TROWELS OI –B19001

OWNER’S MANUAL

20

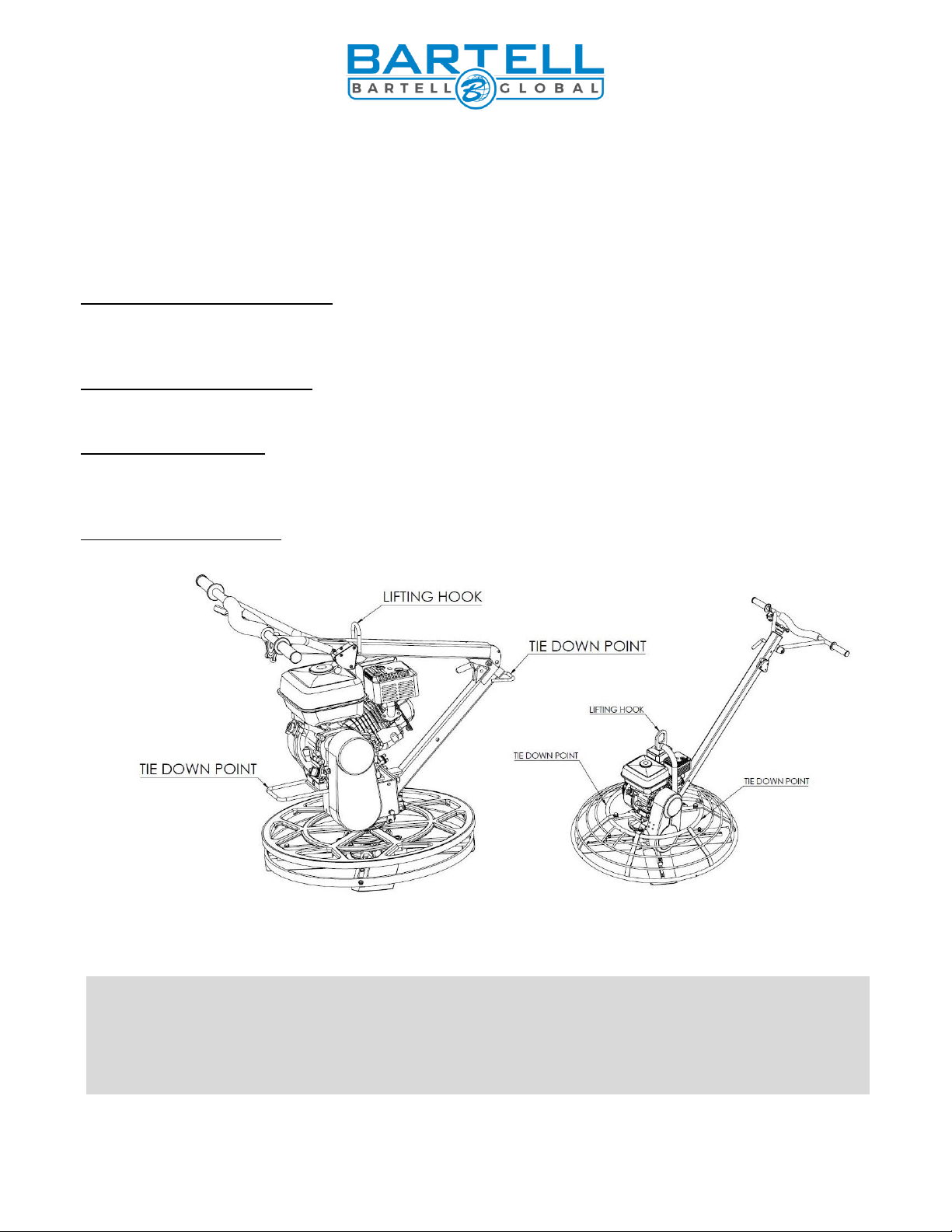

TRANSPORTING

When transporting the trowel by human effort (carrying, sliding, etc.), always keep the handle

folded (if equipped) and the blades fully un-pitched to prevent damage to the pitch control

system.

When lifting from above via a crane, forklift, etc. always use the hoist hook. The hoist hook is an

optional feature that can be mounted to the engine or a feature built in to the folding handles.

Recommended Tie Down Points

Edger Trowel w/folding handle –Always make sure handle is folded and lock pin is installed

while transporting. The front carry handle and the rear carry handle can be used as tie down

points.

Edger Trowel w/rigid handle –The front carry handle and base of the handle can be used as tie

down points. Wrap the tie down strap around the base of the handle for best results.

B436 w/folding handle –Always make sure handle is folded and lock pin is installed while

transporting. The top ring of the guard ring and the rear carry handle can be used as tie down

points.

B436/446 w/rigid handle –Use the top ring of the guard ring as a tie down point. Use 2-4 tie

downs space evenly apart for best results

EDGER TROWEL CAUTION: Never lift the trowel by the rotating ring; use the hoist

hook or handle provided on the trowel.

ALL TROWEL CAUTION: Remove the float disc when lifting machine more than

100cm (40”). The floating disc is loosely secure, so it may fall off.

Trowel recommended tie down locations and over head lifting points

This manual suits for next models

6

Table of contents

Other Bartell Global Trowel manuals

Popular Trowel manuals by other brands

Norton

Norton MTA 36 Operating instructions and spare parts list

Beton Trowel

Beton Trowel BT120H270 instruction manual

MULTIQUIP

MULTIQUIP Whiteman STXD6i Operation manual

MULTIQUIP

MULTIQUIP hhn34tvdtcsl4 Operation manual

Isoplam

Isoplam L030001 User manual and spare parts list

Flextool

Flextool PORTATROWEL FPT30 operating instructions