ROUTINE SERVICE INTERNALS

BR1570

Due to the nature and environment of use, plate compactors could be exposed to severe operating

conditions. Some general maintenance guidelines will extend the useful life of your machine.

•

•

•

•

•

•

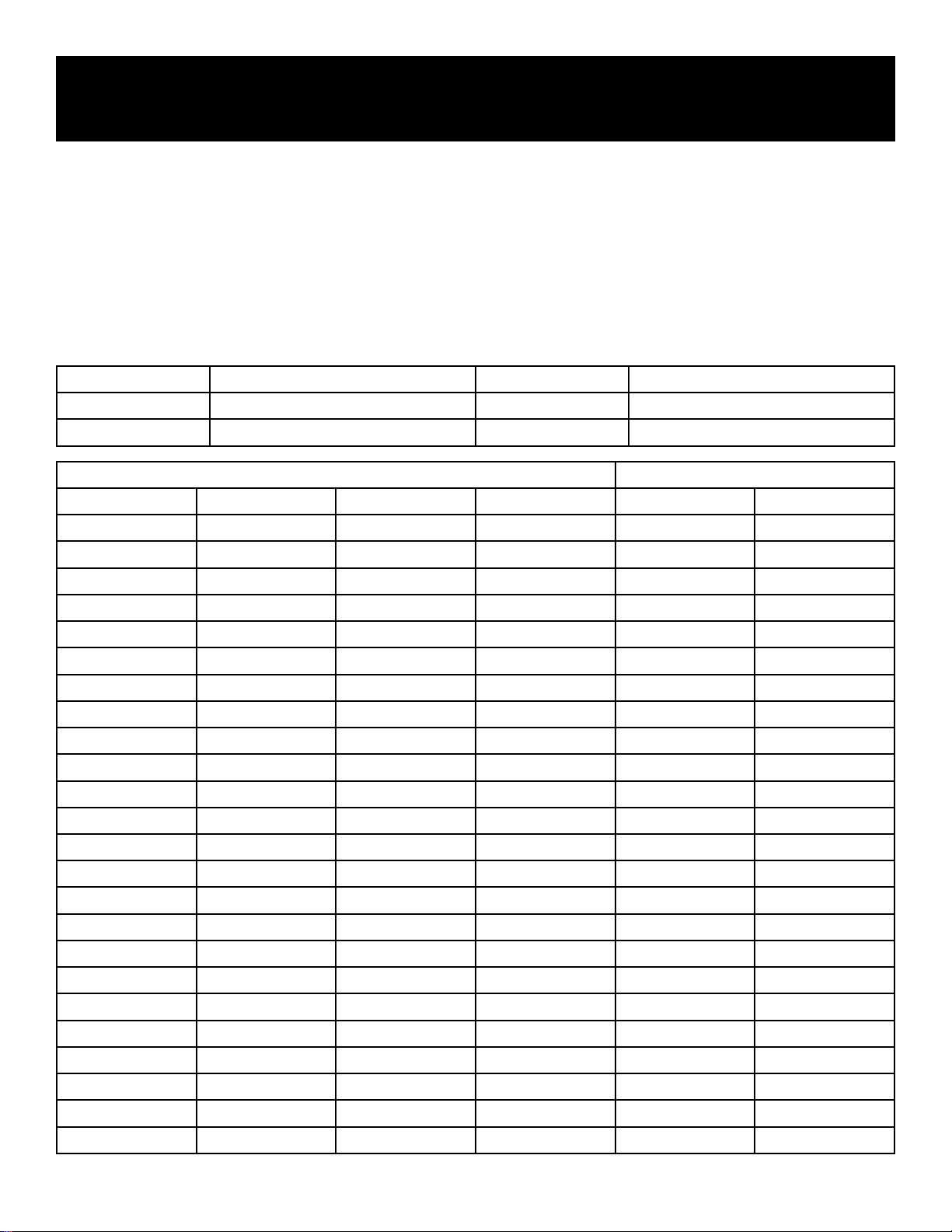

The initial service for your compactor should be performed after 25 hours of use, at which time

your mechanic (or authorized repair shop) should complete all of the recommended checks in

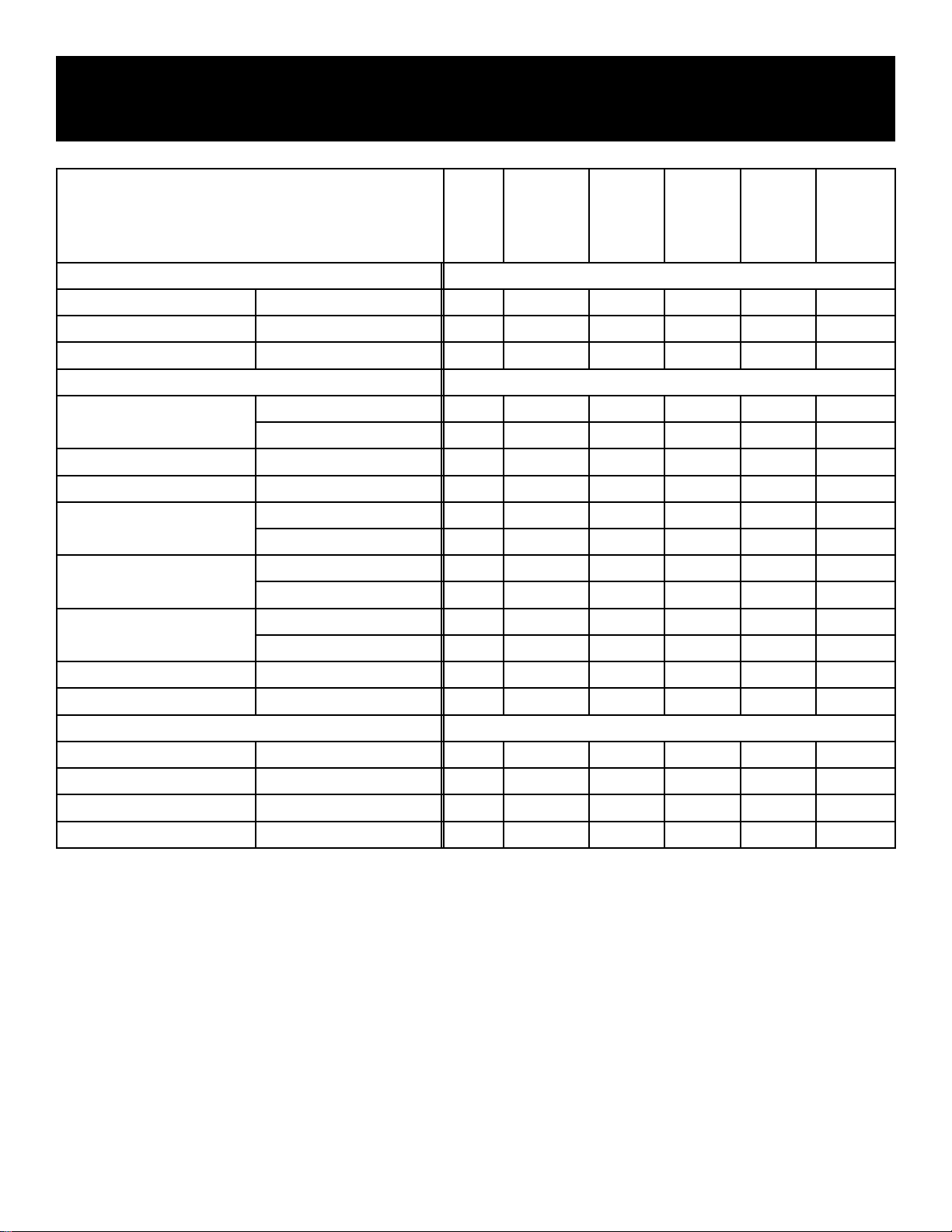

the schedule above. The chart on page 6 (six) is handy for keeping a record of the maintenance

performed and the parts used for servicing your compactor.

Regular service according to the schedule above will prolong the life of the plate compactor and

prevent expensive repairs.

Keeping your plate compactor clean and free from debris is the single most important regular

maintenance operation, over and above the checks in the service schedule above, that can be

performed. After each use your compactor should be cleaned to remove any dust and debris from

the undercarriage and surrounding components. Use of a power washer will make clean up

quick and easy, especially if a non-stick coating was applied prior to use.

In the Service Schedule above, items that should be checked, replaced or adjusted are indicated

by “o” in the appropriate column. Not all plate compactor models include the same features and

options and as such not all service operations may have to be performed. For ease of recording

place a checkmark through the “o” when the item is complete. If an item is not required or not

completed place an “x” through the “o” in the box.

All compactors have governed engine speed of 3600 rpm. See engine manufacturer’s manual for

exact specifications. Care should be used when making any adjustments to the compactor not to

change the governed speed. Running the engine at lower rpm’s will result in a decrease of com-

paction force and lower travel speed. It will create excessive “out-of-synch” vibrations resulting in

poor compaction, maneuverability, excessive wear to the machine, and discomfort to the operator.

Failure to have your vibratory plate compactor regularly serviced and properly maintained in ac-

cordance with the manufacturer’s instructions will lead to premature failure and void the warranty.

10