Bartington Mag585 User manual

BARTINGTON INSTRUMENTS

Page 2 of 16

Table of Contents

1. Legal notices 4

1.1. Copyright 4

1.2. Trademarks 4

1.3. Warranty and Terms & Conditions 4

2. How to use this manual 4

2.1. Symbols glossary 4

3. Safe use 5

4. Introduction to the Mag585 and Mag592 5

4.1. Vector measurements and conventions 5

5. Installing the Mag585 and Mag592 6

5.1. Siting the magnetometer (environment recommendations) 6

5.2. Connection recommendations 7

5.2.1. Connector pin allocation 7

5.2.2. Interface 7

5.2.3. Power supplies 7

5.3. Pre-installation tests 7

5.4. Mounting recommendations 8

5.5. Post installation testing 8

6. Using the Mag585 and Mag592 8

6.1. Cabling 8

6.2. Connecting power 9

6.3. Electromagnetic compatibility 9

6.4. Performance 9

6.4.1. Signal processing 9

6.5. Magnetic hysteresis 10

6.6. Environmental precautions 10

7. Troubleshooting 10

BARTINGTON INSTRUMENTS

Page 3 of 16

8. Care and maintenance 11

8.1. Cleaning the Mag585 and Mag592 11

8.2. Calibration 11

9. Storage and transport 12

10. End of life disposal 12

10.1. Waste Electrical and Electronic Equipment (WEEE) Regulations 12

Appendix 1: Use of Alternative Power Supplies 12

A1.1. Signal/power ground 13

A1.2. Recommended connection method 14

BARTINGTON INSTRUMENTS

Page 4 of 16

1. Legal notices

1.1. Copyright

The copyright of this document is the property of Bartington Instruments Ltd.

1.2. Trademarks

Bartington® is a trademark of Bartington Instruments Ltd in Australia, Canada, China, the

European Community, India, Japan, the countries of the Madrid Agreement & Protocol™, Norway

and the United States of America.

1.3. Warranty and Terms & Conditions

This document should be read in conjunction with the Terms & Conditions for the Supply of

Goods and Services, which also describe the terms of warranty. They are available at www.

bartington.com/terms-and-conditions.html.

Bartington Instruments reserves the right to change any part of the design of these products

without prior notice.

2. How to use this manual

This document describes the installation, operation and maintenance of the Mag585 and Mag592

Magnetic Field Sensors.

Take the time to get well acquainted with your purchase by reading this manual. Knowing and

understanding your sensor will ensure you experience the most reliable operation.

When service or maintenance is required, contact the Bartington Instruments service team.

Technical specifications for these products can be found in the appropriate product brochures on

the product pages of the Bartington Instruments website:

www.bartington.com/mag585-low-radiation-three-axis-magnetic-field-sensor.html

www.bartington.com/mag592-low-radiation-single-axis-magnetic-field-sensor.html

2.1. Symbols glossary

The following symbols used within this manual call your attention to specific types of

information:

BARTINGTON INSTRUMENTS

Page 5 of 16

WARNING: Indicates a situation in which serious bodily injury or death could result if the

warning is ignored.

Caution: Indicates a situation in which bodily injury or damage to your instrument, or both,

could result if the caution is ignored.

Identifies items that must be disposed of safely to prevent unnecessary damage to the

environment.

Note: Provides useful supporting information on how to make better use of your purchase.

3. Safe use

WARNING: These products are not qualified for use in explosive atmospheres or life

support systems. Consult Bartington Instruments for advice.

4. Introduction to the Mag585 and Mag592

The Mag585 is a magnetometer consisting of three feedback stabilised fluxgate sensors

arranged along X, Y and Z axes. Each axis provides a highly linear magnetic response with low

hysteresis and low cross talk between axes.

The Mag592 is a single axis equivalent, providing precision measurements of the intensity of

static and slowly varying magnetic fields in one direction.

The Mag585 and Mag592 are cost effective sensors suitable for many general purpose

applications. High stability circuitry ensures that a minimum of ten years’ service should be

expected.

The sensors have no power supply or data processing abilities of their own and must always be

connected to a power supply to be able to operate.

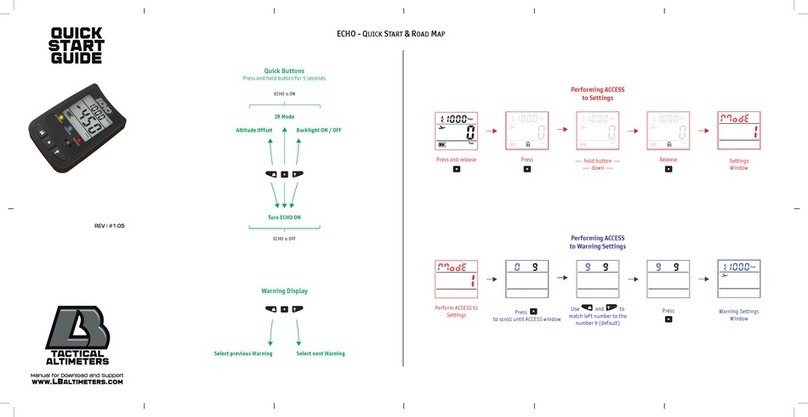

4.1. Vector measurements and conventions

The Mag585 produces three independent analogue output voltages in response to the magnitude

and direction of the orthogonal components of a magnetic field. A ‘right-hand’ co-ordinate

system is adopted (Figure 1). In this system, the X, Y and Z axis correspond to the thumb, first

and second finger respectively of the right hand. By convention, the magnetometer should be

installed so that the X axis is arranged to point north, the Y axis to point east and the Z axis to

point down.

BARTINGTON INSTRUMENTS

Page 6 of 16

Figure 1. Illustration of the Right Hand Rule

The centres of the three vector sensors are superimposed. Each orientation is denoted on the

magnetometer’s label. The point of each vector arrow indicates the positive direction of each

axis.

5. Installing the Mag585 and Mag592

5.1. Siting the magnetometer (environment recommendations)

Note: Site the magnetometer several metres from any magnetic base rock to avoid

compromising measurements.

Note: Site the magnetometer several tens of metres from very large ferromagnetic objects

that could create fields exceeding the measuring range of the sensor.

Note: Avoid siting the sensor near any ferromagnetic objects that may be subjected to the

effects of magnetic hysteresis, which would affect the sensor in an unpredictable manner.

Note: Conduct a magnetic evaluation of any proposed installation site to establish that

it is free from magnetic contaminants. Carry out such an evaluation using total field or

resonance magnetometers.

North

+X

Thumb

Down

+Z

2nd Finger

East

+Y

1st Finger

BARTINGTON INSTRUMENTS

Page 7 of 16

5.2. Connection recommendations

5.2.1. Connector pin allocation

The connector pin or cable colour allocation for the connection to each package type is shown on

the appropriate outline drawing on the product page.

5.2.2. Interface

X, Y and Z outputs are protected against short circuit to 0V.

Caution: Short circuits from output to either power rail may result in permanent damage to

the sensor. Limit the power supply current to 100mA to minimise risk of damage caused by

incorrect connection.

The analogue outputs for the X, Y and Z axes are buffered to give a low output impedance,

enabling the unit to be operated over long cables and interfaced to low impedance data

acquisition systems.

5.2.3. Power supplies

The Bartington PSU1, Magmeter, SCU1 and Spectramag-6 are ideal power supply units.

Alternatively, users may wish to provide their own power supply. Refer to Appendix 1 for further

information.

5.3. Pre-installation tests

Prior to the installation of the system, the magnetometer, cable and power supply must be fully

tested to ensure correct function as follows:

Caution: Take care to avoid bending or otherwise damaging the contacts whilst conducting

the tests.

Caution: Carefully check for correct connection before applying power. Applying incorrect

polarity or power to output connections may cause irreparable damage to the sensor.

1. Test the cables for continuity (using an electrical continuity tester or ohmmeter).

a. Test the cables end to end at the connectors to ensure that the correct pins have been

allocated to the conductors and that there are no open or high resistance circuits.

a. Test the cables at the connectors to ensure that there are no short circuits between the

conductors.

2. Check the power supply output voltage using a voltmeter. Refer to the product brochure for

the required values.

BARTINGTON INSTRUMENTS

Page 8 of 16

Caution: Switch off the power supply before connecting to the Mag585 and Mag592.

3. Connect the magnetometer to the cable connector.

4. Connect the power supply to the other cable connector.

5. Switch on the power supply and wait until the magnetometer has stabilised.

5.4. Mounting recommendations

Each magnetometer has a set of mounting holes to allow attachment to a stable base of fixture.

Refer to the mechanical drawings on the product page for details.

5.5. Post installation testing

1. Site the magnetometer and install the power supply and cabling.

2. Switch on the power supply and wait until the magnetometer has stabilised.

3. Confirm no magnetic objects are moving in the vicinity.

4. Monitor the sensor outputs.

5. Confirm that the sum of the measured magnetic field vectors is similar to the expected local

earth field.

6. Using the Mag585 and Mag592

6.1. Cabling

Note: The connecting cable to the sensor should be an eight-core screened cable. Two

cores will be used for positive and negative power supply lines, three cores for output

signals, one core for signal common and one for power supply ground. The screen should

be connected to supply ground at the supply end only. The capacitance between cores

should be less than 200pF per metre. A cable with individually shielded cores should be

considered for long cable applications.

Note: Leads are susceptible to EM interference and should be screened wherever possible.

Note: The length of the cable is limited by the voltage drop in the power supply lines

and the capacitance between the cores. For this reason the cable should be limited to a

maximum length of 600 metres.

BARTINGTON INSTRUMENTS

Page 9 of 16

Bartington Instruments can supply cables for connection of the sensor to the PSU1, Magmeter,

SCU1 and Spectramag-6.

6.2. Connecting power

Caution: Check that the polarity of the supply is correct. The power supply should

be connected to the sensor before the supply is energised as this prevents high

surge currents which could cause damage. Apply the positive and negative supplies

simultaneously and avoid leaving the sensor connected to one polarity only.

6.3. Electromagnetic compatibility

Note: The Mag585 and Mag592 are not shielded for immunity from, or emission of,

electromagnetic fields. Any shield placed around the sensor will limit the bandwidth of the

sensor response. The emissions generated are at a low level with a primary frequency of

12.8kHz, being the frequency of the energising field of the sensor. The sensor is required to

respond to magnetic fields within the specified frequency band.

Note: Ensure that the sensor is not operated in areas where a high electromagnetic field

exists, even if the frequency is above the bandwidth of the sensor, as false information may

appear due to aliasing. This effect is seen in data acquisition systems when the frequency

of sampling is lower than the frequency of the signal which is being sampled. It may

produce apparent signals at lower frequencies than the noise, which may be within the

frequency band of the sensor. Similarly, do not place the sensor near to any equipment

which may be affected by the fields produced by the sensor excitation.

6.4. Performance

6.4.1. Signal processing

For different applications it may be necessary to process the signal from the sensor in different

ways.

a. In order to increase the sensitivity of the recording system, it may be necessary to back-

off the earth’s field and amplify only the changes in the field from the current value. This

requires a high-pass filter, which could be a simple capacitively coupled arrangement or a

multi-pole filter to provide a steep roll-off characteristic. These features are all present in

the SCU1 signal conditioning unit.

The output from all fluxgate sensors will contain noise from the driving electronics. For

the Mag585 and Mag592 this noise is at 12.8kHz, which is well above the bandwidth of the

sensors. Where low noise operation is required, a filter should always be provided to reject

the noise which lies outside the band of interest.

BARTINGTON INSTRUMENTS

Page 10 of 16

b. When the sensor output is digitized, it may be necessary to include an analogue, low-pass

anti-alias filter to prevent the creation of in-band noise by mixing the 12.8kHz excitation

frequency with the sampling clock frequency of the digitizer.

The level of unwanted breakthrough at 12.8kHz has been minimized in the Mag585 and

Mag592 but may still cause an apparently raised noise level when sampled at low sampling

frequencies without further analogue filtering.

c. In applications such as surveillance and magnetic signature monitoring it may be required

to remove both the DC standing field and all AC noise and pick-up above a set frequency. The

band of interest will be, say, 0.01 to 10Hz and a band pass filter can be used to provide the

required signal.

The Magmeter and PSU1 power supply units, which can be used with all sensors, contain

three low pass filters with a -3dB point at 10kHz together with three high pass filters with a

-3dB point at 0.1Hz.

The SCU1 signal conditioning unit provides filters with independent control of the low and

high pass filter sections, together with offset and gain control for the output of each axis.

6.5. Magnetic hysteresis

The Mag585 and Mag592 are designed to have an extremely low magnetic hysteresis. However,

Bartington Instruments recommends your magnetometer is not subjected to magnetic fields

greater than its stated measuring range for extended periods as this could alter the DC offset. If

this occurs, the offset will exhibit drift as it returns to its original offset specification.

Caution: Subjecting the magnetometer to fields in excess of 2 x the nominal range may

cause inaccuracy in future measurements. Degaussing the magnetometer can reverse

such an effect.

6.6. Environmental precautions

Refer to the product brochure for maximum environmental electrical and mechanical ratings.

Caution: Exceeding the maximum ratings may cause irreparable damage to your sensor.

7. Troubleshooting

The Mag585 and Mag592 are unlikely to suffer any defects in normal use. The most likely causes

of failure, and their solutions, are detailed in the following table:

BARTINGTON INSTRUMENTS

Page 11 of 16

Cause of failure Solution

Power supply Check the power supply as detailed in Pre-Installation Tests.

Cables Check the cables as detailed in Pre-Installation Tests.

Power Input If no fault can be found in the power supply or cables, ensure

the cable length is not too long, causing excessive voltage drop

between the power supply and magnetometer. Refer to the

specifications defined in the product brochure.

Magnetometer In the event of any apparent malfunction, email service@

bartington.com or telephone the Bartington Instruments service

team on +44 (0)1993 706565. Attempted repair or opening of the

casing by users may invalidate the warranty.

A re-calibration service is available which is traceable to

international standards.

For information about disposal of the damaged unit, refer to End of

Life Disposal.

8. Care and maintenance

8.1. Cleaning the Mag585 and Mag592

Use water and mild soap to remove grime from external enclosures.

Caution: Never use chemicals, such as solvents, when cleaning the Mag585 and Mag592.

Caution: Take particular care when cleaning around electrical connections. Bent or

damaged pins may cause the magnetometer to malfunction.

8.2. Calibration

Return the Mag585 and Mag592 to Bartington Instruments for calibration at the recommended

intervals. Refer to the Calibration Certificate for further details.

BARTINGTON INSTRUMENTS

Page 12 of 16

9. Storage and transport

Your sensor is a precision electronic instrument and should be treated as such.

Note: Avoid exposing this instrument to shocks or continuous vibration.

Note: Store only within the temperature range specified in the product brochure.

Note: Do not expose this instrument to strong magnetic fields while being stored.

10. End of life disposal

This product should not be disposed of in domestic or municipal waste. For information about

disposing of your sensor safely, check local regulations for disposal of electrical / electronic

products.

10.1. Waste Electrical and Electronic Equipment (WEEE) Regulations

This sensor complies fully with Restriction of the Use of Certain Hazardous Substances in

Electrical and Electronic Equipment (RoHS) and WEEE Regulations current at the time of

printing.

Appendix 1: Use of Alternative Power Supplies

Bartington Instruments power supplies provide the most suitable methods for connecting to

and operating your sensor. If you have decided to use an alternative then the information in this

Appendix is important.

Caution: Failure to follow these instructions may result in incorrect sensor readings and in

some circumstances may cause irreparable damage to your sensor, power supply, or both.

Power supplies should normally provide ±12V. For the lowest noise applications, ripple in the

output should be in the mV region. The nominal current requirements are +45mA and -18mA

with an additional current in proportion to the measured field. The additional current is 1.4mA

per 100μT per axis and will be drawn from the positive or negative supply, depending on the

direction of the field.

The maximum output voltage swing from the sensor will always be less than the supply voltage.

In the temperature range -40°C to +70°C, and with an external load of 10kΩ, the maximum

output voltage will be less than each supply voltage by up to 2V. All parameters, other than the

output voltage range, remain unaffected for supply voltage changes in the range from ±8 to ±15V.

BARTINGTON INSTRUMENTS

Page 13 of 16

The current drain is independent of the power supply voltage, and the unit will operate with

input voltages down to ±8V. As the output voltage swing is limited to 2V less than the supply

voltage, for a supply of ±8V the output will operate normally with any output between +6V and

-6V, representing a field of 0.6 of the full scale value in each direction. The scaling factor and

linearity will remain at the normal value up to this saturation point. The output will remain at

the saturation level if the field is increased beyond this point. Asymmetric supplies may be used,

provided that the minimum and maximum voltages are not exceeded for either polarity.

A1.1. Signal/power ground

The two signal/power ground conductors are connected to a common point within the sensor.

The power supply common (power 0V) should be connected to only one of them, which becomes

the power ground. The other conductor becomes the signal ground and is used as the 0V output

from the sensor. Each signal is then measured between the X, Y and Z output conductors and the

signal ground output. In this way, the signal ground carries no power supply currents.

The minimum current in the power ground conductor is approximately 25mA. On long cables,

this will give rise to an appreciable potential difference between the power supply end and

the sensor end of the power ground conductor. The use of separate power and signal ground

conductors will ensure that this voltage is not included in the voltage measured between the

signal outputs and the signal ground.

BARTINGTON INSTRUMENTS

Page 14 of 16

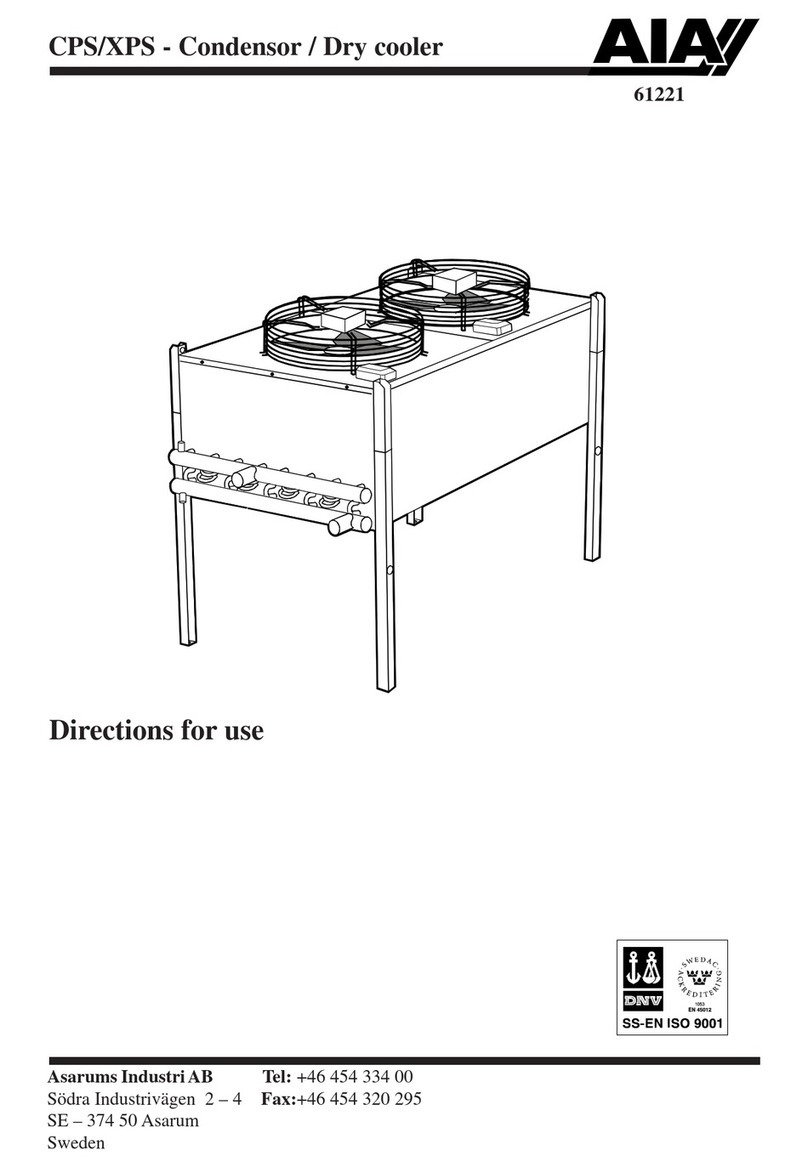

A1.2. Recommended connection method

Figure 2. Ideal connection method.

Key to Figure 2:

1 Sensor 5 Signal Ground

2 Host 6 Power Ground

3 Host Power Supply 7 Ground

4 Host Local 0V

Figure 2 illustrates the recommended connection method for users who do not wish to use

Bartington Instruments’ power supplies.

Note: Using this method is essential when using cables over 10m.

The schematic shows signal and power grounds separated at the Host end. The Host is fitted

with buffer amplifiers configured as Instrumentation Amplifiers (IA), which have two high

impedance inputs, one connected to X, Y or Z and the other to signal ground. An IA produces an

output that is the voltage difference of its input referenced to a local 0V. This 0V reference may be

significantly different to either of the two input voltages to the IA (indicated by VCM in Figure 2).

Consult the manufacturer’s data for the part chosen, to ensure the common-mode range is not

exceeded.

BARTINGTON INSTRUMENTS

Page 15 of 16

In this configuration there is a voltage drop due to the cable’s resistance along the power ground.

Typical current is 25mA and the resistance of a 100m, 24 AWG cable is 5Ω, resulting in a drop

of 0.125V. Thus the reference point for the X, Y and Z outputs is 0.125V difference to the Host

0V, which is the source of power for the sensor. However, no current flows in the signal ground

conductor because the IAs have very high input impedance and no voltage is dropped in the 5Ω

resistance of either signal ground or X, Y and Z conductors.

Connecting sensors using this method means that the sensor outputs are accurately read by the

IAs, which then refer them accurately back to the 0V of the Host equipment.

Bartington Instruments Limited

5, 10 & 11 Thorney Leys Business Park

Witney, Oxford, OX28 4GE, England

T: +44 (0)1993 706565

E: sales@bartington.com

F: +44 (0)1993 774813

The specifications of the products described in this brochure

are subject to change without prior notice. Bartington® is a

registered trademark of Bartington Instruments Ltd.

www.bartington.com

OM1679/1

This manual suits for next models

1

Table of contents

Other Bartington Accessories manuals