Set up instructions for the 714XLT

Baumfolder Corporation P.O. Box 728 1660 Campbell Rd, Sidney, Ohio USA 45365 Copyright © 2002

Phone 1-800-543-6107 or 1-937-492-1281 Fax 1-937-492-7280 email: Baumfolder@baumfolder.com

Time to set up a job…..

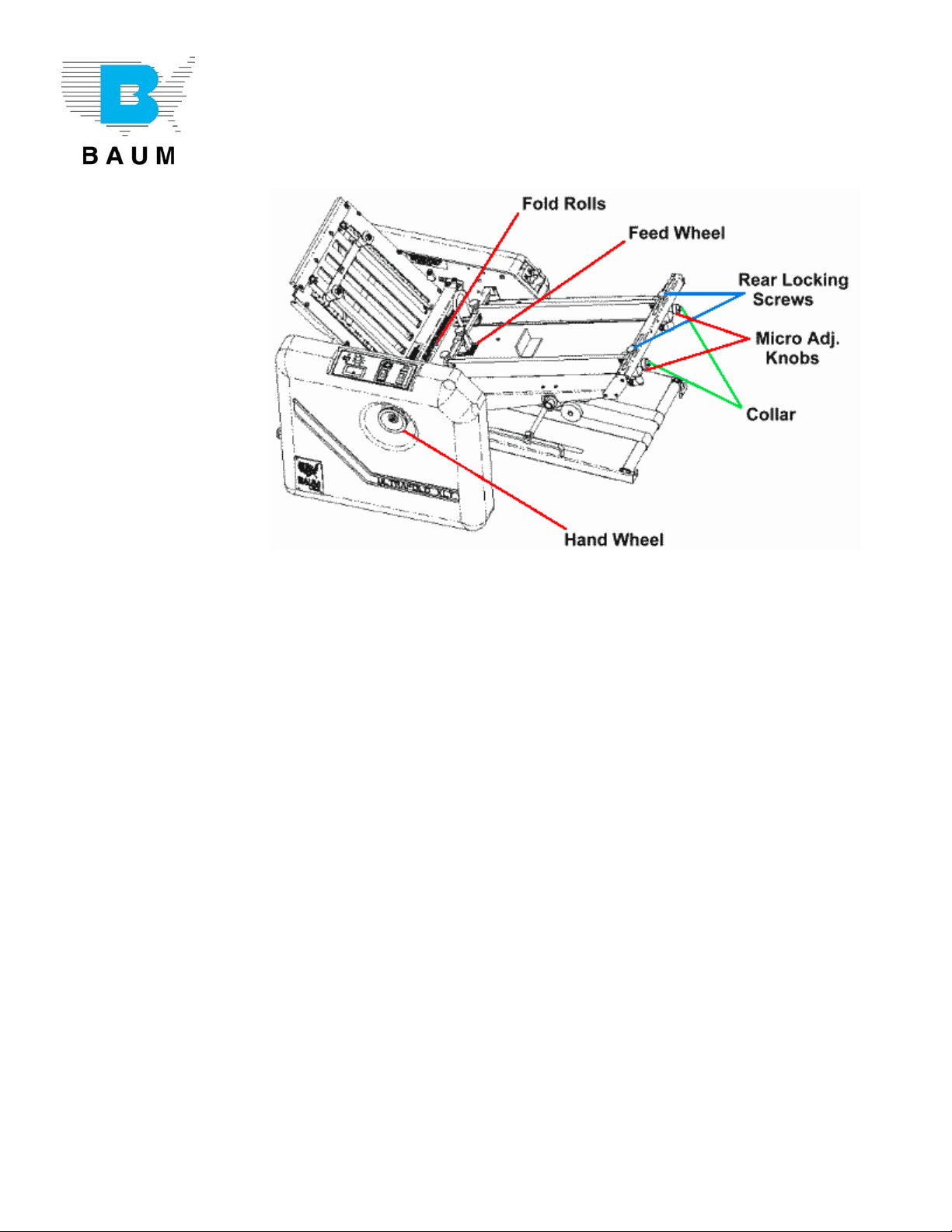

We are now ready to set up a job on the folder. Ask your customer for a sample of the job he/she wants

to run. This will give you, the sheet size and type fold. Let’s take for example an 8 ½ “ x 11” letter fold.

The example shown is with the header folded in.

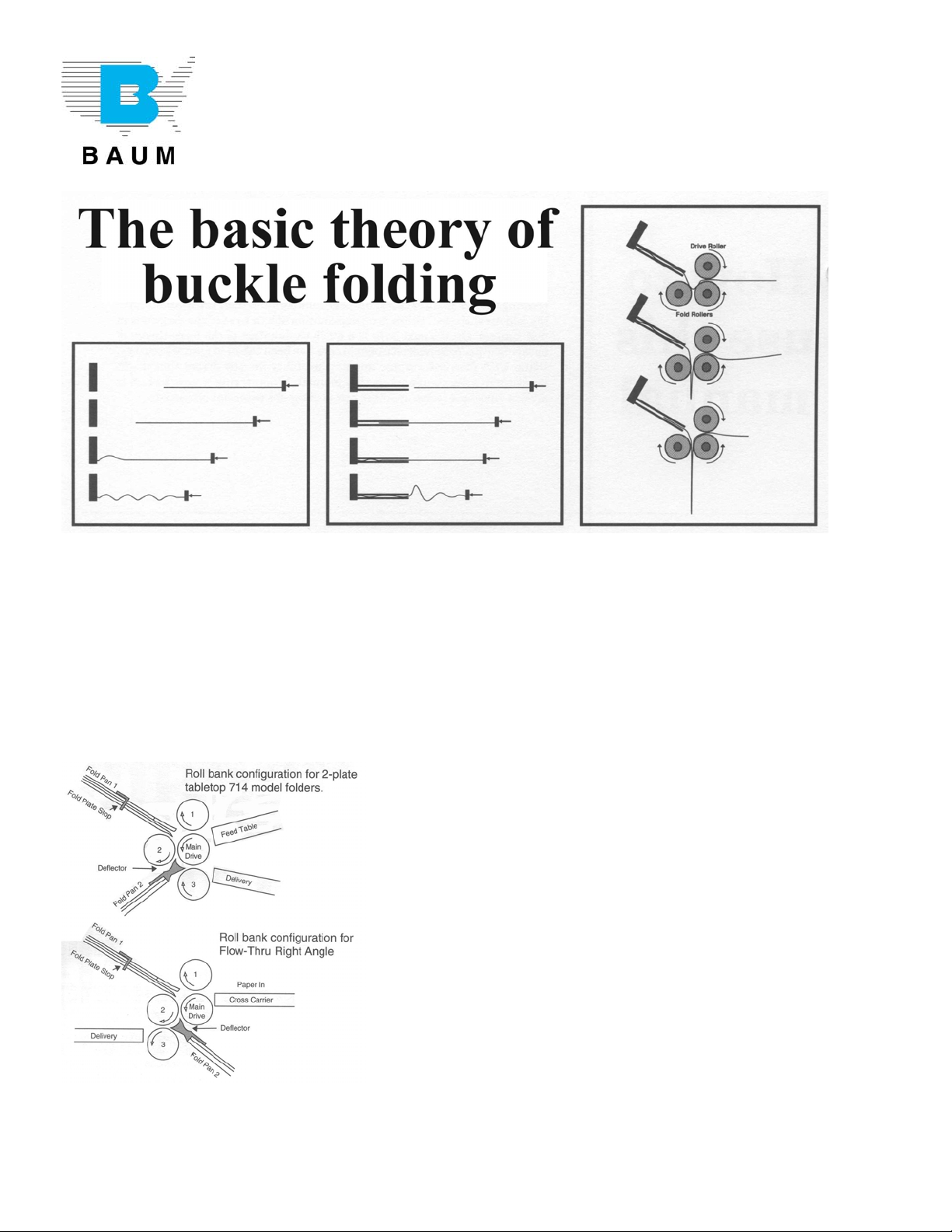

1. Loosen the locking screws on the feeder side guides. Turn the

knobs on the back of the Side guides and set them on 8 ½ on the

scale, actual 4 ½ “ from the center of the feeder. Lay a sheet of

paper you are running between the guides and it should slide down

but not have very much movement side to side. This is the key to

good folding. IF THE GUIDES ARE TOO TIGHT, IT WILL NOT

FEED WELL. If the guides are to loose, the fold will vary. If a fold

is always crooked, usually the cause is that the side guides are not

square with the number one fold roller. See appendix A for

correction. Set the magnetized angle stop at the back of the sheet.

2. Insert two thickness of paper between the caliper tab and the

sucker wheel. Turn the gap knob counter-clockwise to tighten or

clockwise to loosen. Set the gap knob until there is a slight drag on the

paper. Remove the paper and the correct gap is now set. When you load

the feeder, the printing will be up.

3. The front blow will normally be set properly. If not, it should be set so it

separates the bottom sheets. The adjustment knob on the side of the

feeder is to set the blow in the side guide and front blow. Turn the knob to

the right to obtain more blow on the right side and front of the feed table.

Turn the knob to the left to obtain more blow on the left and reduce the

front blow.

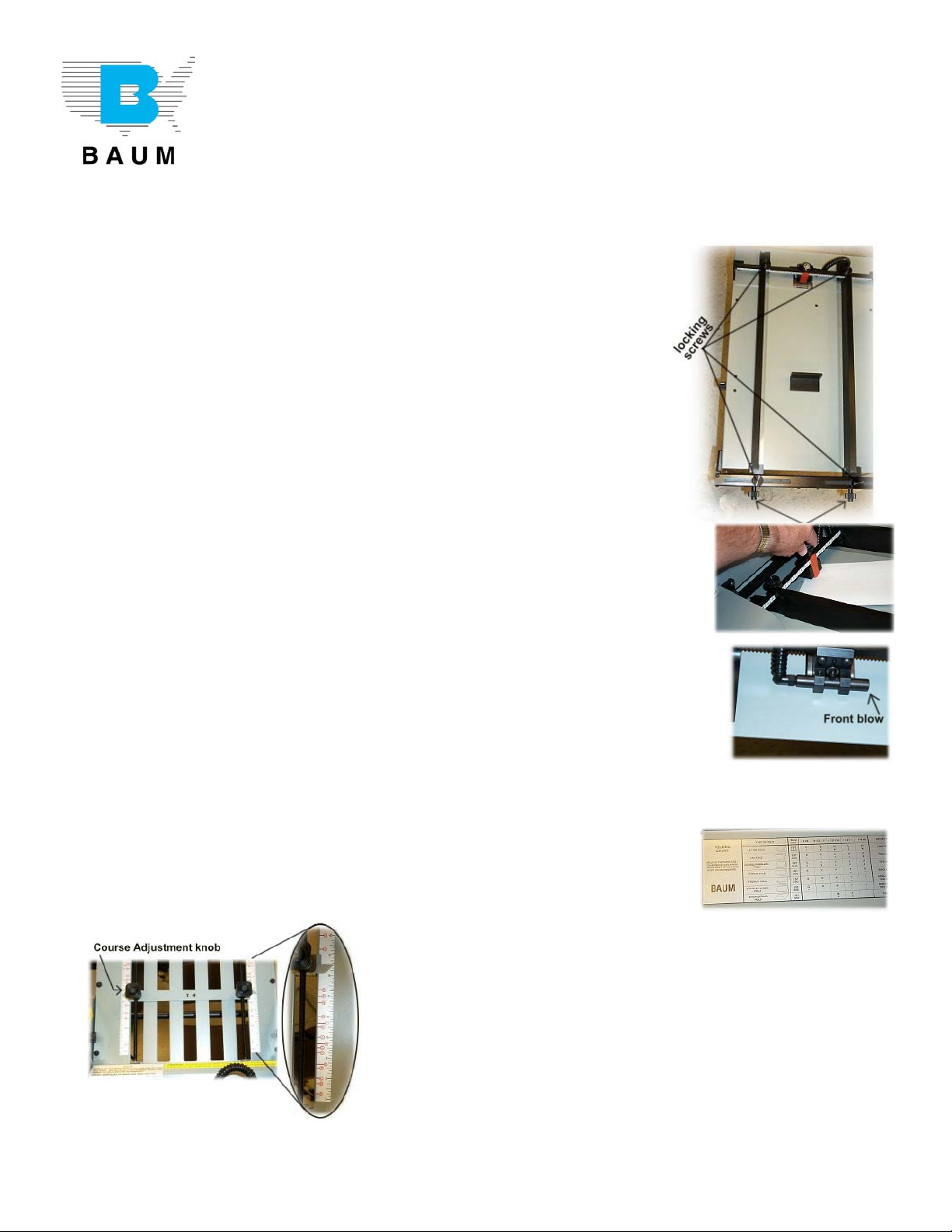

4. Look on the folding chart on the stacker tray and locate 8 ½ x 11, fifth column over and letter fold

second line down. It shows the first fold plate is set on E, and the

second fold plate is set on E. On the fold plates approximately 3 ½ “

from the nose of the fold plate are the letter E (on both sides,) in a red

circle with a line from it. Depress the course adjustment knobs and

move the paper stop until it is on or close to the red line out

from the letter E. At the end away from the rolls of the

adjustment rods are micro adjustment knobs. You can move

these knobs to align the paper stops on the red line. Both fold

plates should have the open end toward the fold rollers and

the deflector away from the fold rollers. Both fold plate stops

are adjusted the same way.

(continued)