Operating Instructions

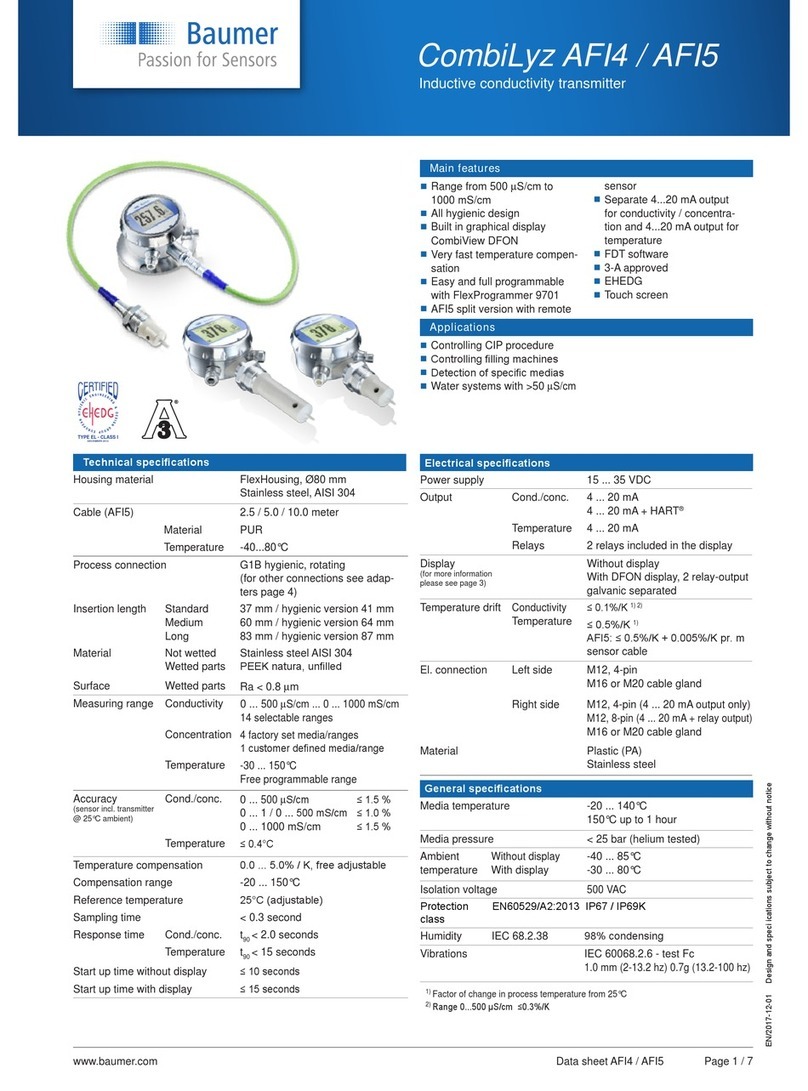

Pressure measurement

CombiPress™ PFMH/N

Fully welded pressure transmitter with touch screen

Type plate / Typenschild / Plaque d‘identication

PFMx-xx.xxxx.xxxxx.xxxxx.xxxx

Matr.:12345678

S/N.:8200 Date.: 2018-08-15

Made in Denmark www.Baumer.com

Runetoften 19 DK-8210 Aarhus V

Cell Range.: -0.345...400.00 Bar Rel

In. U.: 10...35V Out I 4...20mA HART

Zone 0: -20°C ˜ Tamb ˜ 60°C

Other zones: 40°C ˜ Tamb ˜ 85°C

IP67

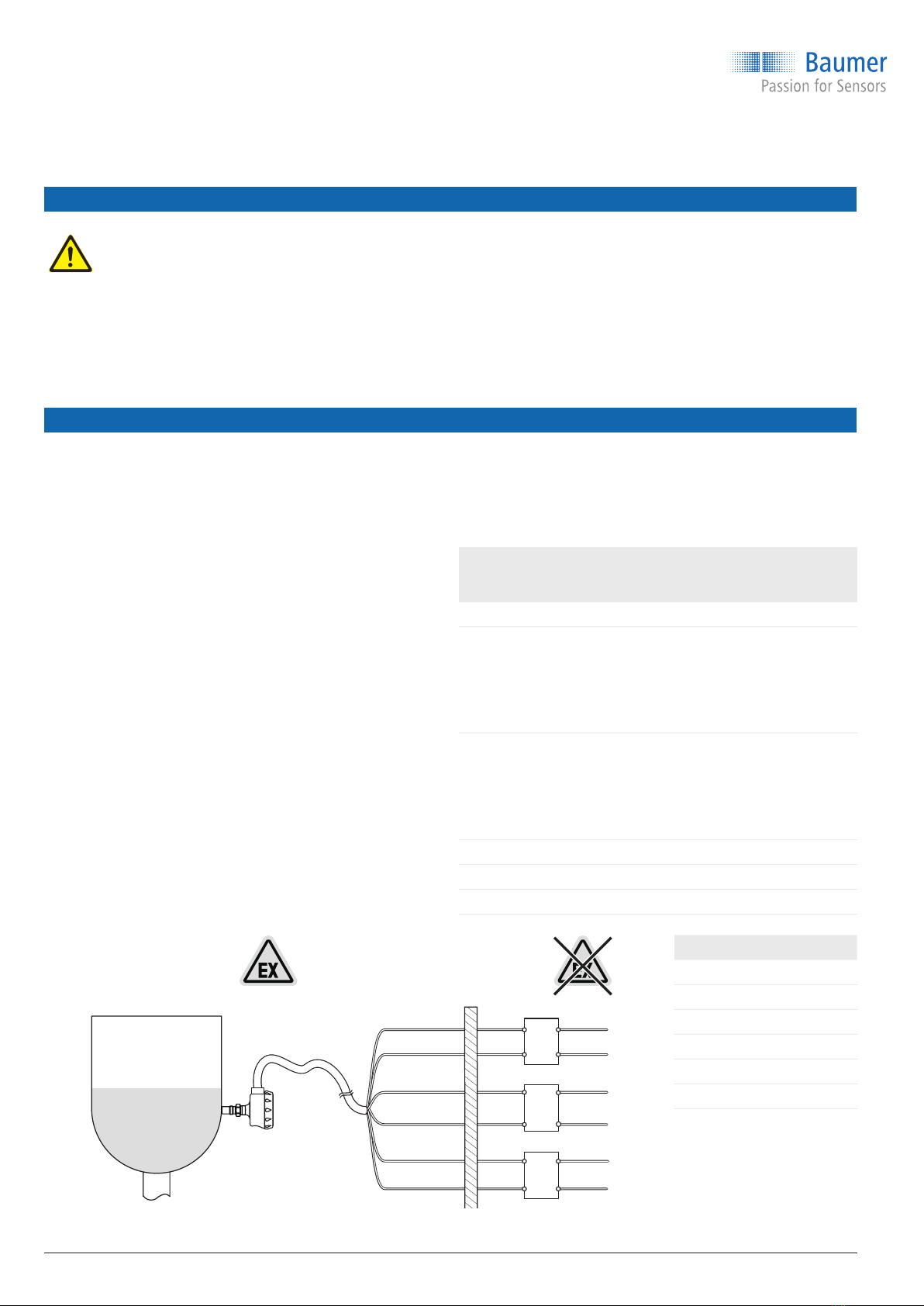

TÜV 13 ATEX 113125X

II 1G Ex ia IIC T6 Ga

II 1D Ex ia IIIC T100°C Da

Ui ˜ 30VDC II ˜ 0,1A Pi ˜ 0,75W

Ci=40nF Li=10°

PFMx-xx.xxxx.xxxxx.xxxxx.xxxx

Matr.:12345678

S/N.:8200 Date.: 2018-08-15

Made in Denmark www.Baumer.com

Runetoften 19 DK-8210 Aarhus V

Type Type of sensor

Matr. Material number

S/N Serial number

Date Date of manufacture

Cell range Pressure range of measuring cell

In Power supply

Out Output signal

Tamb Ambient temperature

IP Degree of protection

ATEX Explosion protection, type-specic

Tag Tag number, costumer-specic

Do not dispose of in household waste

Conformity with EU directives

Approvals, type-specic

Version Sensortyp

Matr. Materialnummer

S/N Seriennummer

Date Herstellungsdatum

Cell range Druckbereich Messzelle

In Speisung

Out Ausgangssignal

Tamb Umgebungstemperatur

IP Schutzart

ATEX Explosionsschutz, typspezisch

Tag Kennnummer, kundenspezisch

Nicht im Hausmüll entsorgen

Konformität mit EU-Richtlinien

Zulassungen, typspezisch

Version Type de capteur

Matr. Réf. mat.

S/N Numéro de série

Date Date de fabrication

Cell range Plage de pression de la cellule de

mesure

In Alimentation

Out Signal de sortie

Tamb Température ambiante

IP Indice de protection

ATEX Protection contre les explosions, selon

le type

Tag Identiant, spécique au client

Ne pas jeter avec les ordures

ménagères

Conformité avec les directives

européennes

Autorisations, selon le type

2 / 48