BAUMOT BA5000 User manual

Operating Manual

DPF Cleaning System

I innovative exhaust aftertreatment

2

02/11/2010 Germany: +49 (0)2361 / 30 231 – 0; Switzerland: +41 (0)44 / 954 80 7 - 0

Table of contents

1. Information for Customers………………………………………………………………………………………….. 3

1.1. General Information………………………………………………………………………………………………... 3

1.2. Guarantee and Liability……………………………………………………………………………………………. 3

1.3. Symbols Used………………………………………………………………………………………………………. 3

2. Safety Information…………………………………………………………………………………………………….. 4

2.1. General Safety Instructions……………………………………………………………………………………….. 4

2.1.1. Safety Instructions for Operation……………………………………………………………………………….. 4

2.1.2. Safety Check Before Start-up…………………………………………………………………………………... 5

2.1.3. Safety Instructions for Maintenance and Repair……………………………………………………………… 5

2.2. Safety and Protective Equipment, Excerpt from the Danger Assessment…………………………………... 5

2.3. Installation and Assembly…………………………………………………………………………………………. 5

3. Technical Data…………………………………………………………………………………………………………. 6

4. General Description…………………………………………………………………………………………………... 6

4.1. Intended Use……………………………………………………………………………………………………….. 6

4.2. Assembly Procedure (Short Description)………………………………………………………………………... 6

5. Description of Machine Components……………………………………………………………………………... 7

5.1. Machine Overview…………………………………………………………………………………………………. 7

5.2. Overview of Safety Devices…………………………………………………………………………….………… 7

5.3. Control………………………………………………………………………………………………………………. 8

5.4. Electric Field Sensors……………………………………………………………………………………………… 8

5.5. Operator’s Console………………………………………………………………………………………………… 8

5.6. Cleaning Chamber…………………………………………………………………………………………………. 8

5.7. Cleaning Apparatus………………………………………………………………………………………………... 9

5.8. Adapter Ring Insertion…………………………………………………………………………………………….. 9

5.9. Start-up……………………………………………………………………………………………………………… 9

5.9.1. First Steps………………………………………………………………………………………………………… 9

5.9.2. EMERGENCY STOP Acknowledgement…………………………………………………............................ 9

5.9.3. Suction Start-up………………………………………………………………………………………………….. 9

5.9.4. Inserting Filters…………………………………………………………………………………………………. 10

5.9.5. Switching on Automatic Operation …………………………………………………………………………… 10

5.9.6. Premature Shut-off of Automatic Operation…………………………………………………………………. 10

5.9.7. Removing Filters……………………………………………………………………………………………...... 10

5.9.8. Setup instructions for pressure switch…………………………………………..………………………….... 11

5.9.9 Setting the pressure switch…………………………………………………………………………………….. 11

6. Malfunction Description……………………………………………………………………………………………. 12

7. Service…………………………………………………………………………………………………………………. 12

7.1. Maintenance and Lubrication Instructions……………………………………………………………………... 12

8. Disposal……………………………………………………………………………………………………………….. 13

Addresses………………………………………………………………………………………………………………... 14

3

02/11/2010 Germany: +49 (0)2361 / 30 231 – 0; Switzerland: +41 (0)44 / 954 80 7 - 0

1. Information for Customers

1.1 General Information

This operator’s manual is part of the user information when the machine is brought into circulation. It describes

the setup, operation and basic maintenance procedure of the machine mentioned above.

It must be kept such that it is accessible to the operator and users in a readable format at any time. When the

machine is moved to a different location, the operating manual must accompany it as it is part of the machine.

The operating manual contains important information on how to operate the machine safely, correctly, and

efficiently. Observing the manual helps to prevent dangers, avoid repair costs and down time, and increases the

reliability and service life of the machine.

The entire operating manual must be read and applied by everyone who is instructed to work with the machine.

The machine may only be switched on and operated by trained and responsible operating personnel.

The operator of the machine must make the user manual accessible to users and make sure that they have read

and understood it. Only then may the machine be put into operation.

The operator is required to observe all operating and safety instructions given in this operating manual as well as

all such legal instructions.

The respective operating manual of any devices and equipment purchased from the manufacturer of the machine

must be observed.

1.2 Guarantee and Liability

The general guarantee and liability for this machine is 24 months for single-shift operation. Parts that

are subject to wear are excluded. The guarantee of the supplier applies to purchased parts.

The guarantee and liability in the event of bodily injury and property damage are excluded if they are attributable

to the following causes:

Improper use of the machine

Improper operation and maintenance of the machine

Operating the machine with defective, improperly installed, or non-functional safety and protective

equipment

Operating the machine with defective or not completely functional parts and assemblies

Non-observance of the operating manual in all details

Unauthorized structural changes or changes to the performance data

Improperly executed repairs

Force majeure

Interventions and changes to the machine and machine systems that are not authorized by us, in particular to

electrical, mechanical, hydraulic and pneumatic components may result in the cancellation of the declaration of

conformity and loss of the CE mark.

1.3 Symbols Used

Warning of danger

Warning of danger of crushing

4

02/11/2010 Germany: +49 (0)2361 / 30 231 – 0; Switzerland: +41 (0)44 / 954 80 7 - 0

Wear protective mask

Observe instructions unconditionally

Open flame of any type and smoking forbidden

Do not eat near the machine

Maintenance

Manual cleaning

2. Safety Information

2.1 General Safety Instructions

Read the operating manual carefully before starting up the machine!

Independent of the description in this operating manual, safety and accident prevention regulations apply to the

operation of the machine.

The respective safety instructions of any devices and equipment purchased from the manufacturer of the

machine must be observed.

The existence and operation of protective equipment must be checked before production begins.

Safety and protective equipment may not be removed or disabled. In the event of malfunctions or faults in the

machine that have an adverse effect on safety, they must be eliminated immediately.

This machine may only be used by employees who have been instructed to do so by their supervisors and are

familiar with its operation.

Responsibilities must be clearly established and defined. Observe the statutory minimum age!

2.1.1 Safety Instructions for Operation

For reasons of safety, we point out in particular observance of the points given in the following.

The machine may not be used to clean any filters that contain explosive, combustible and oily dusts,

dust/air mixtures and hybrid mixtures.

The machine must have an explosion protected design for explosive dust-air mixtures. There are special

regulations for this.

In order to keep the danger to persons and the machine to a minimum, it is not permitted

to work with hot objects, use open flames of any type or to smoke in the cleaning

chamber and in the area around the machine.

The operating temperature as well as the filter temperature must not exceed 70°C when inserting a filter.

Eating close to the machine is also not permitted.

5

02/11/2010 Germany: +49 (0)2361 / 30 231 – 0; Switzerland: +41 (0)44 / 954 80 7 - 0

2.1.2 Safety Check Before Start-up

The following safety checks must be performed before operating the machine:

Check the side panels and covers to make sure they are in place and tight.

Check the protective doors to make sure they work and seal when closed. The doors must be opened for

this. Now, it must not be possible to switch on the machine.

Check the emergency stop apparatus by pressing the emergency stop switch and opening the protective

doors. Here, the voltage and the air to the machine must be cut off. It is only possible to start up again

after the emergency connection is acknowledged.

The suction system must be connected. Please make sure that the suction hose is attached to the

machine.

The machine may only be operated with the suction system switched on.

Remove all filters and items from the machine.

2.1.3 Safety Instructions for Maintenance and Repair

Before starting service or maintenance work, shut off the power supply to the machine. The power and

air can be cut off by unplugging the power and air connecting line.

Only qualified technicians may perform work on electric machines and devices that are under voltage. (See DIN

VDE 0105 or IEC 364)

Please note: It is necessary to wear protective masks when cleaning the machine.

2.2 Safety and Protective Equipment, Excerpt from the Danger Assessment

Besides general and mechanical components, a dangerous part of the machine is the automatic cleaning of the

filter.

To reduce the danger, the machine has been encapsulated and equipped with monitored protective doors at the

access points.

Emergency stop switches have been installed for fast and safe shutdown of the machine components in a

dangerous situation.

2.3 Installation and Assembly

The machine is a mobile utensil that is mounted on rollers. As a result, it is possible to adapt the device

optimally to the work area by pushing it there.

It is also possible to transport the machine with the help of a pallet lifter or stacker. Here, make sure that there is

enough support area on the forks under the device’s traverse.

Please note: There is a danger of tipping when pushing and transporting the machine.

The setup site must be sufficiently firm, horizontal and dry.

The surrounding temperature must not deviate from the temperature given in the technical data.

The machine is connected to the utilities network by means of the device’s plug connector for power and a quick-

release coupling for the air.

Independent of this description, installation manuals of the manufacturers of purchased parts must be observed.

(See suction description.)

6

02/11/2010 Germany: +49 (0)2361 / 30 231 – 0; Switzerland: +41 (0)44 / 954 80 7 - 0

3. Technical Data

Machine number:

Year of construction:…………………. 2010

Net weight:……………………………... 120 kg

Machine dimensions:

Depth…………………………………….700 mm

Width……………………………………. 1160 mm

Height:………………………………….. 1890 mm

Operating pressure:…………………… 6 bar

Voltage:………………………………….230V

Frequency:……………………………... 50 Hz

Series fuse:…………………………….. 16A

Power consumption:………………….. 200 W

Control voltage:………………………... 24V / DC

Auxiliary power:………………………...air 6 bar, dehumidified not oiled, humidity level > 1%, constant air

pressure, Connector: NW 7.2 nipple plug-in

Ambient temperature:………………….0 – 35° C

Cabinet temperature:…………………..0 – 35° C

Operating noise:………………………..> 75 db

Note: The machine pressure must be 6 bar. If there is not enough air pressure, the machine may have

operating problems.

4. General Description

Machine description

4.1 Intended Use

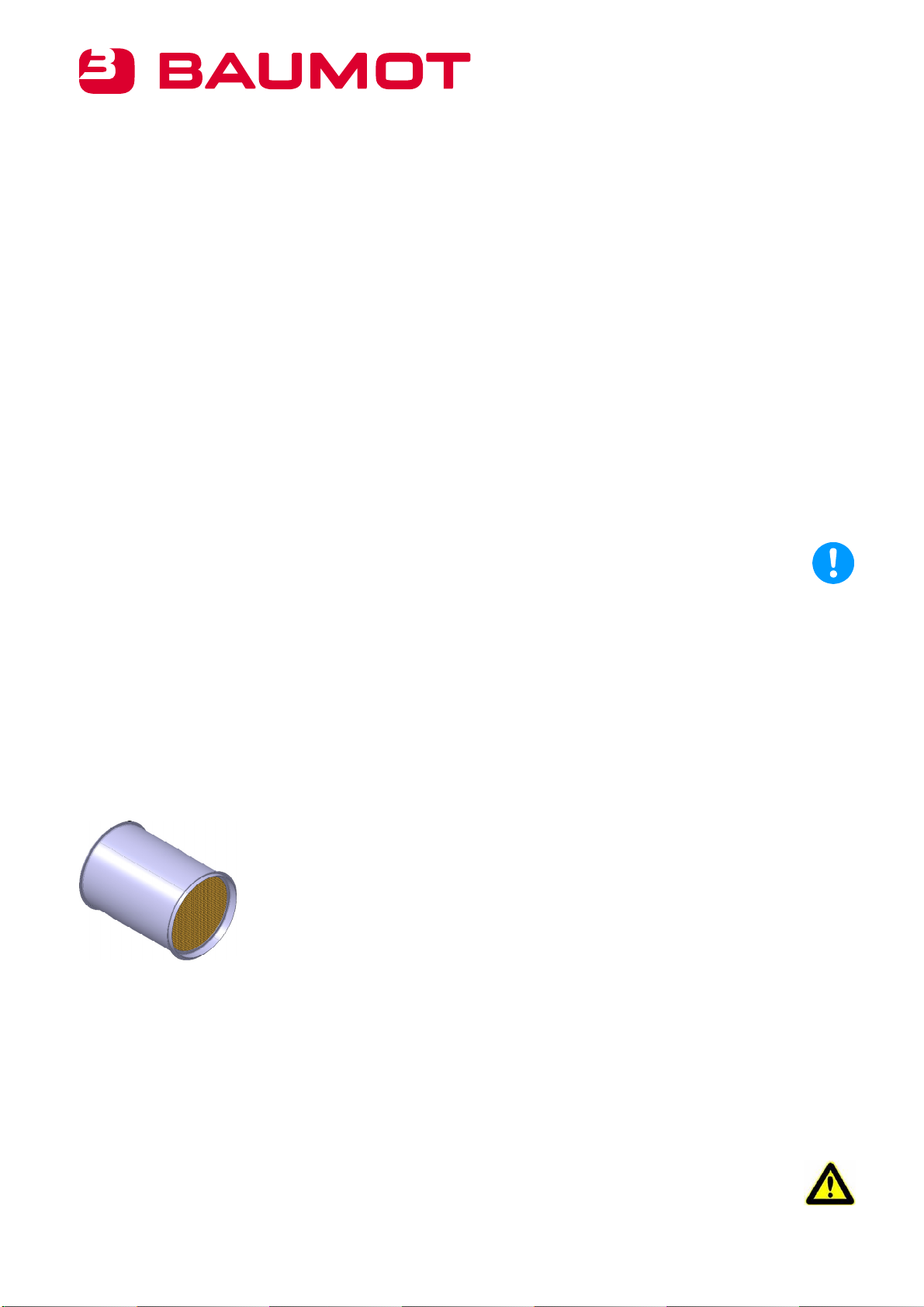

The design of the unit is based on the Baumot filter design. However, it can also clean filters from almost all other

manufacturers.

Below is an example of the filter that is blown out in the cleaning system.

Observation of this operating manual is also part of proper use.

It is not permitted to use any type of cleaning agents.

4.2 Assembly Procedure (Short Description)

The machine consists of the machine body with the cleaning chamber, the automatic cleaner, the swiveling

device as well as the protective covers and protective doors. There is also an industrial vacuum cleaner on the

side.

(The industrial vacuum cleaner is not part of the machine.)

Please note: It is absolutely mandatory to extract the filter particles with the help of an industrial

vacuum cleaner during the cleaning process.

7

02/11/2010 Germany: +49 (0)2361 / 30 231 – 0; Switzerland: +41 (0)44 / 954 80 7 - 0

Procedure

First of all, the suction is switched on. Then, the filter insert is placed in the correct position in the cleaning

chamber by opening the protective doors. The emergency stop device is acknowledged using the "Reset"

button. Afterwards, the machine can be switched on using the “Start” button.

The “ ” light indicates that the machine is in operation.

The cleaning process stops when the “Stop” button is pressed or the cleaning time has ended. The filter

can be removed from the machine.

5. Description of Machine Components

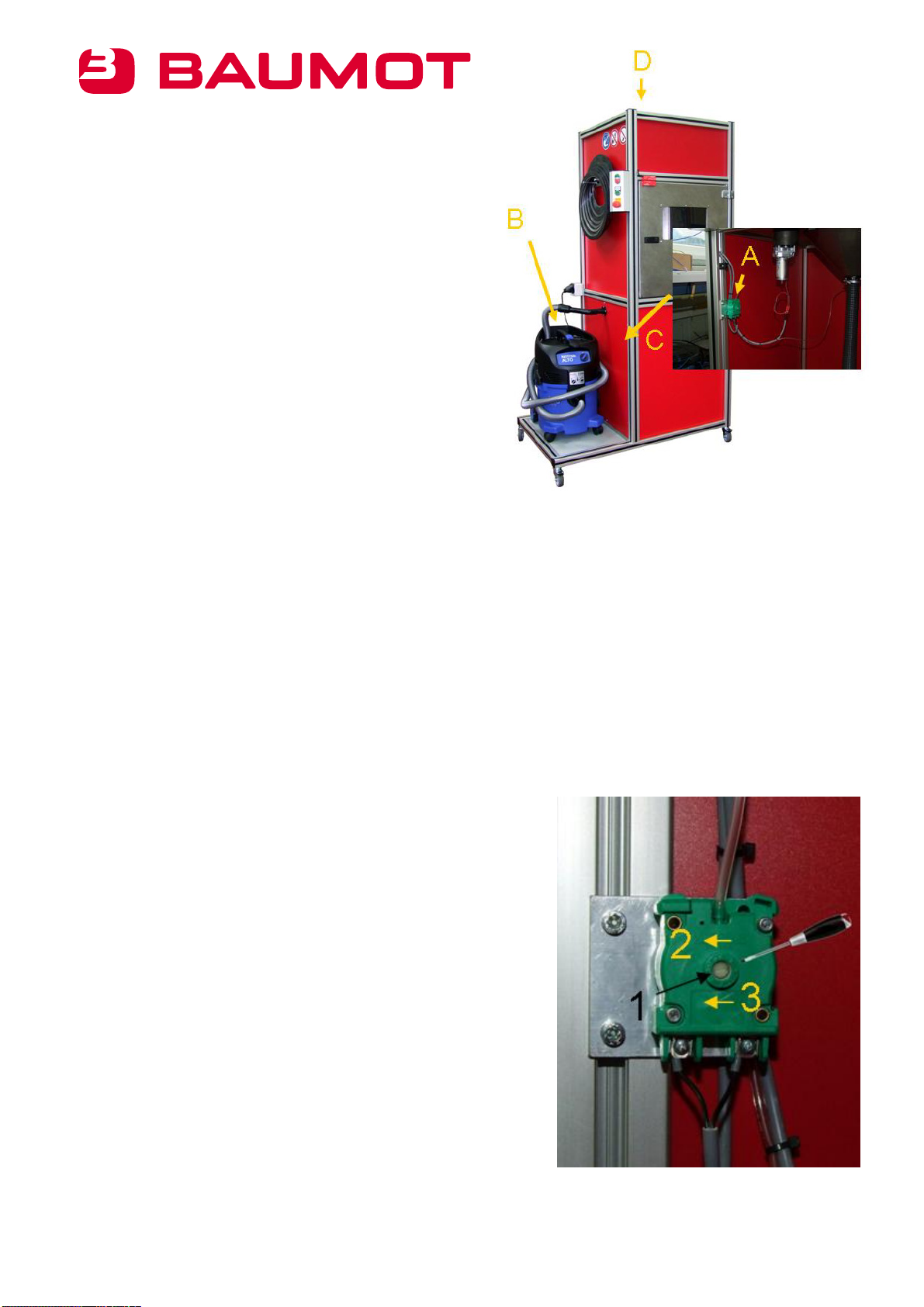

5.1 Machine Overview

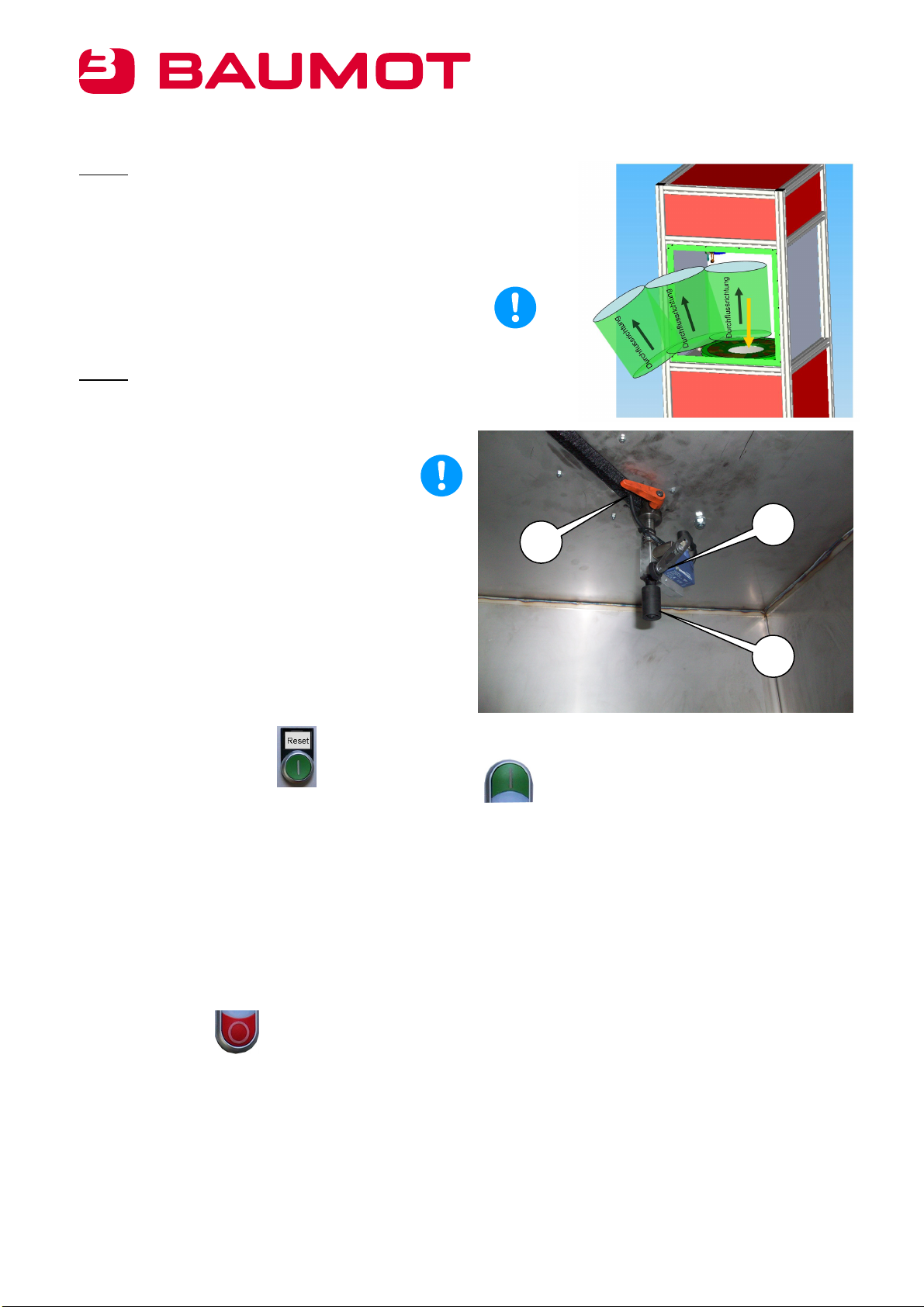

5.2 Overview of Safety Devices

Machine housing

Operator’s console

Adapter rings

Cleaning chamber

Emergency stop

Suction connector

Area for suction system

Rollers

Protective doors

Protective doors

Door safety switch

8

02/11/2010 Germany: +49 (0)2361 / 30 231 – 0; Switzerland: +41 (0)44 / 954 80 7 - 0

1

2

3

5.3 Control

Main equipment cabinet

One part of the control elements for the machine process is located in the lower section of the cleaning

machine. The fuses, motor protection, PLC controller, protection for motors, clamps and safety relays

are here.

5.4 Electric Field Sensors

All the machine’s sensors such as the limit switch, buttons and safety relays, for example, are connected to the

PLC controller. The switching statuses of the sensors are shown on the sensors or the PLC.

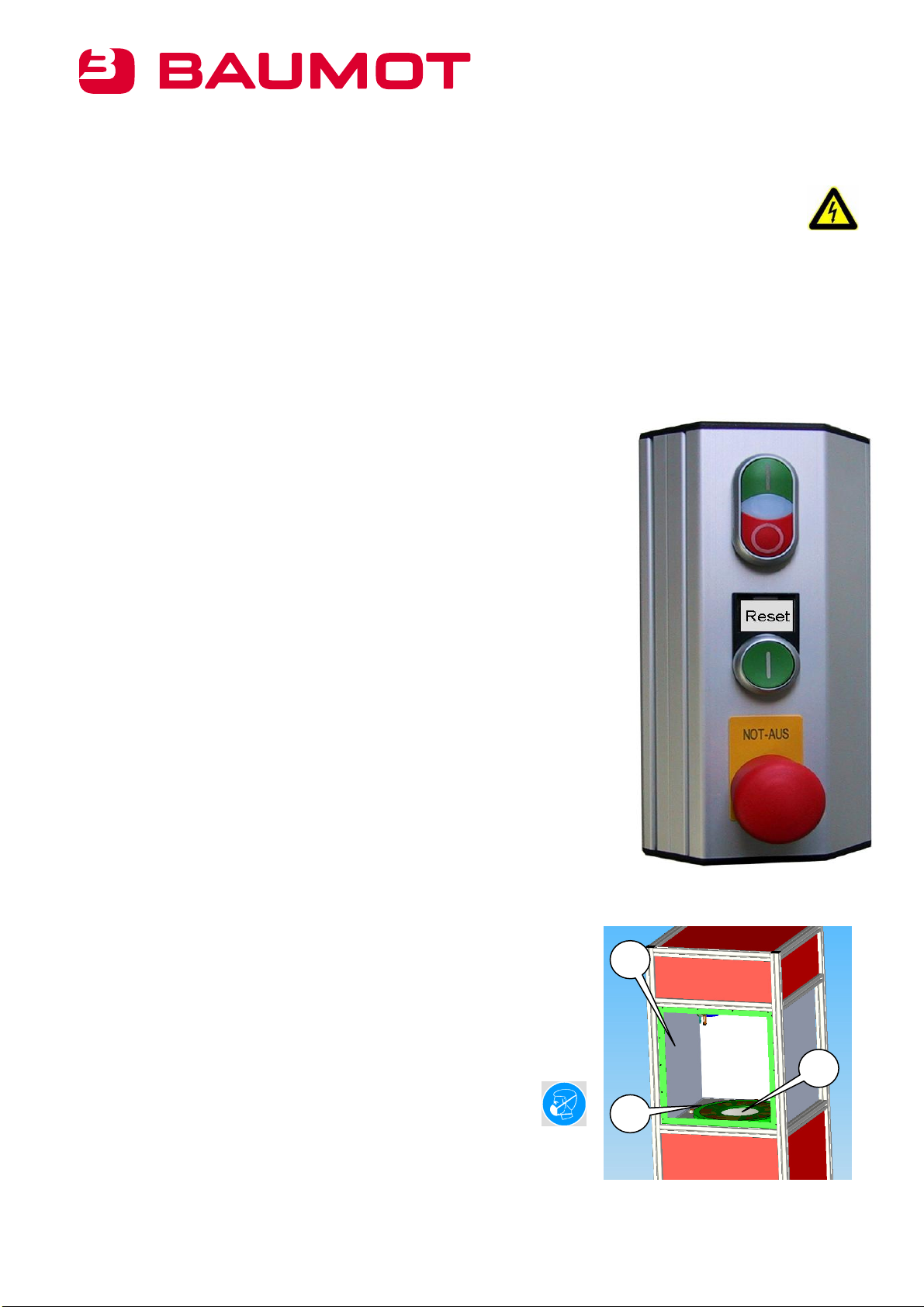

5.5 Operator’s Console

The machine’s operator’s console fulfils the following functions:

1) Button/lamp combination

The machine is switched on and off with this.

Among other things, the integrated signal light (white field) indicates the

following:

Solid light – machine is running without any problems

Flashing – Machine malfunction

The lamp flashes if the emergency stop relay has been triggered and the

“On” switch is pressed at the same time.

2) Emergency stop reset switch

The emergency stop reset switch is used to acknowledge the emergency off

relay after it has been triggered.

3) Emergency stop switch

The emergency stop switch can be used to stop dangerous movements in

the event of danger.

Please note: The cylinder may still be under pressure even if the emergency

stop button has been pressed. The emergency stop switch is not a repair

switch!!!

5.6 Cleaning Chamber

The filter chamber consists of a closed stainless steel container (1) that

forms a tight seal with the protective doors.

The slewing ring (2) with the extraction funnel (3) are located in the base

area.

The chamber and the slewing ring must be cleaned occasionally. This

can be done with the industrial vacuum cleaner.

Please note: A protective mask must be worn while cleaning.

If cleaning cloths are used, then they must be disposed of properly after

cleaning.

2

3

1

9

02/11/2010 Germany: +49 (0)2361 / 30 231 – 0; Switzerland: +41 (0)44 / 954 80 7 - 0

5.7 Cleaning Apparatus

The cleaning apparatus is needed for blowing out the

filter. The apparatus consists of the oscillator rod with

the drive cylinder, the clamping unit for the nozzle rod

(1) as well as the limit switch for the oscillation (2).

The cleaning nozzle (3) is located on the cleaning rod.

The brush (4) prevents dust from escaping from the

cleaning chamber. It must be replaced when necessary.

5.8 Adapter Ring Insertion

The adapter rings are used to compensate for the

different filter diameters above the suction funnel.

Here, the adapter ring must be inserted flush into the

slew ring from above (arrow). The adapter ring must

seal evenly with the slewing ring.

Please note: An incorrectly inserted adapter

ring can lead to damage to the cleaning

apparatus.

5.9 Start-up

5.9.1 First Steps

Install the matching adapter rings.

Connect the device’s plug connector and air connector. (check air pressure)

Plug in the industrial vacuum cleaner and mount the suction hose.

Remove all objects or parts from the machine.

Perform a functional test of all safety devices.

5.9.2 Emergency Stop Acknowledgement

Close the protective doors and release the emergency stop switch by pulling out the

emergency off button.

Press the “Reset” button on the operator’s console.

5.9.3 Suction Start-up

Insert the suction unit into the “suction connector” on the cleaning unit.

Insert the suction tube into the suction supports on the cleaning unit.

Switch on the suction unit (see suction unit operator's manual).

4

1

2

3

10

02/11/2010 Germany: +49 (0)2361 / 30 231 – 0; Switzerland: +41 (0)44 / 954 80 7 - 0

1

3

2

5.9.4 Inserting Filters

Step 1: Insert the filter

After opening the machine’s door, the filter must be

placed on the adapter ring in the correct position.

To do this, it is placed on the adapter ring from the top

(yellow arrow) such that its edge encloses the edge of

the funnel area.

Please note: The filter must be inserted opposite to its

direction of flow.

Step 2: Setting the cleaning nozzle

The nozzle rod locking device (1) must be disengaged

to adjust the cleaning nozzle, and the cleaning nozzle

(2) lowered to the top filter rim.

Please note: The nozzle head must not touch

the rim.

The actuating roller of the limit switch for the oscillation

(3) is actuated by the filter rim and that way limits the

oscillation path of the cleaning nozzle. The oscillation

path is limited by the drive cylinder for a filter without a

filter rim.

5.9.5 Switching on Automatic Operation

Close the protective doors.

Acknowledge the emergency stop switch using

the “Reset” button.

Press the “Start” button on the operator’s console.

The control lamp on the operator’s console starts to illuminate. The cleaning nozzle is pressurized with air and

the oscillation starts.

Automatic operation switches off after 30 minutes. The protective doors can be opened and the filter removed.

It is possible to restart the machine immediately.

5.9.6 Premature Shut-off of Automatic Operation

The “Stop” button can be used at any time to stop automatic operation. Automatic operation is switched off by

pressing the “Stop” button. The process time is reset.

5.9.7 Removing Filters

The filter is removed in the reverse order to inserting it.

Disengage the nozzle rod locking device.

Raise the cleaning nozzle.

Remove the filter.

11

02/11/2010 Germany: +49 (0)2361 / 30 231 – 0; Switzerland: +41 (0)44 / 954 80 7 - 0

5.9.8 Setup instructions for pressure wave switch DW

3 S-100, type AL2-14, MR-D Industriegeräte GmbH

The BA 5000 cleaning unit is equipped with a DW 3S-100

pressure wave switch (A). The pressure wave switch is

used to monitor the exhaust air of the connected industrial

vacuum cleaner (B). It is located behind panel (C) in the

unit.

The signals of the pressure wave switch are evaluated by

the PLC control. If the suction performance (negative

pressure) is too low, the signal on input 7 of the PLC control

drops.

The unit switches off after a monitoring period. This

malfunction can be confirmed only by restarting the unit.

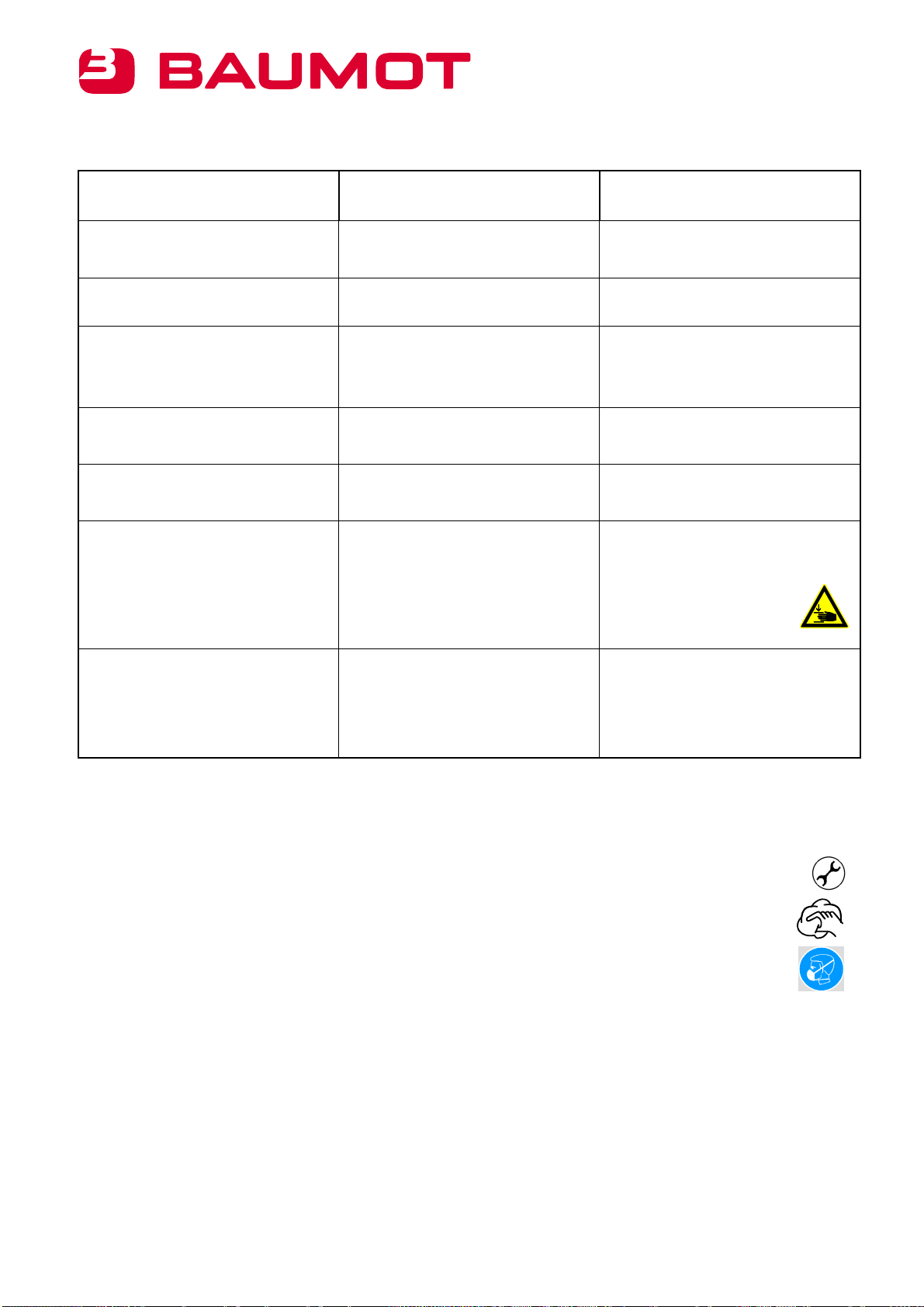

5.9.9 Setting the pressure switch

Preparation

Pull the plug of the industrial vacuum cleaner out of the outlet on the cleaning device and plug it into an

external outlet. (Keep the vacuum cleaner off.)

Open the top cover of the cleaning device (D); this is where the PLC control is located.

Connect the cleaning device to the external power supply (the PLC is supplied with power).

Open the cover (C) to access the pressure switch (A).

Setting the pressure switch

Insert the screwdriver into the plastic setting screw (1) and

turn it anticlockwise until it stops (2).

Switch the industrial vacuum cleaner on.

Caution:

The industrial vacuum cleaner’s filter insert must be clean; a filter

must not be in the unit.

Turn the plastic setting screw slowly clockwise until input 7

on the PLC lights up.

Continue to turn the screw until you have attained the

desired setting range (~ 5 division marks).

Switch the industrial vacuum cleaner off. Input 7 on the

PLC goes out.

The adjustment of the pressure switch is complete. The covers can

be reattached.

12

02/11/2010 Germany: +49 (0)2361 / 30 231 – 0; Switzerland: +41 (0)44 / 954 80 7 - 0

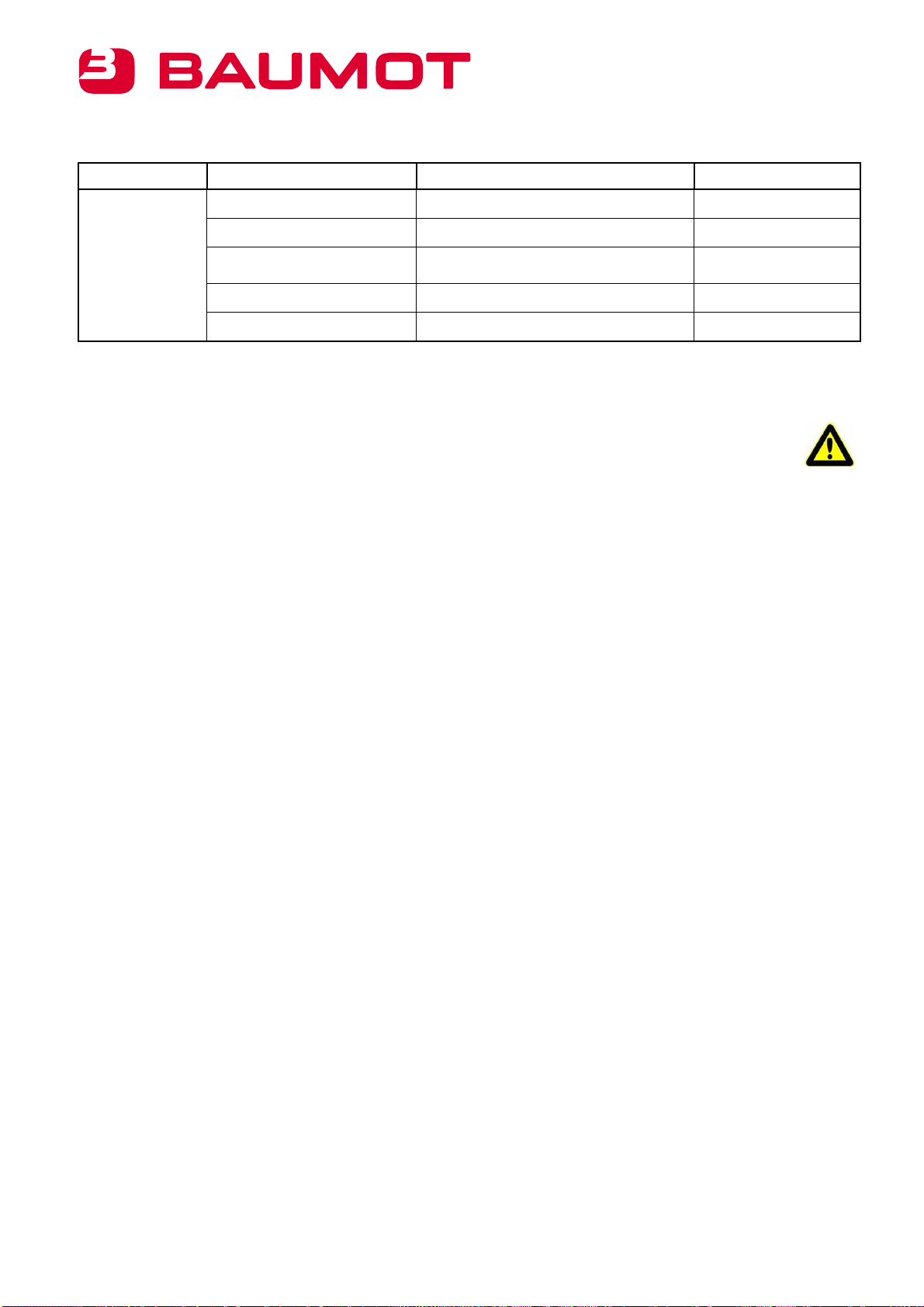

6. Malfunction Description

Malfunction Possible cause Remedial measures

System has no voltage

Connection line not

plugged in

Fuse has tripped

Plug in the connection line

Inform an electrician

System cannot be acknowledged Emergency stop pressed

Doors not closed

Check emergency off and

door switches

Cleaning result is not

adequate

Air pressure too low

Blowing nozzle clogged

Nozzle not set low enough

Check air pressure

Clean blowing nozzle

Check nozzle setting

Filter particles are escaping

Cleaning apparatus sealing

brushes leaky

Door seal faulty

Clean or replace the

sealing brushes

Check door seal

Slewing ring does not turn Motor fuse tripped

Slewing ring stuck

Inform an electrician

Check slewing ring

mechanics

Cleaning apparatus does not

oscillate

Air pressure too low

Swiveling cylinder faulty or

stuck

Check air pressure

Check swiveling cylinder

Please note: The cylinder

may be

under pressure. Danger

of crushing.

No, or too little,

suction

Suction turned off or faulty

Filter clogged

Suction tube leaky

Wrong adapter rings

installed

Check suction system

Clean filter

Check suction tubes

Check adapter rings

7. Service

7.1 Maintenance and Lubrication Instructions

The maintenance and lubrication instructions here do not replace the specifications of the manufacturer

in the respective operating instructions.

Defective parts must be replaced without delay.

The machine should be cleaned with an industrial vacuum cleaner or a cloth.

Do not use compressed air!!!

Switch off the power supplies before maintenance. To do this, the power and air lines must be separated from

the utility network.

13

02/11/2010 Germany: +49 (0)2361 / 30 231 – 0; Switzerland: +41 (0)44 / 954 80 7 - 0

Maintenance plan: Table 1

Name Task Time period

Machine

Machine body Cleaning and inspection Every shift

Construction Tighten the screw connections ¼ yearly

Rotating mechanism with

slewing ring Clean Daily

Cleaning apparatus Clean Weekly

Oscillator seal Clean As required

The bearings and cylinder are maintenance-free.

8. Disposal

Please note: Separate the machine from the power and air network before disposal.

Disassembly procedure:

Remove the power and air lines.

Professionally remove the operating supplies.

Disassemble the machine.

Take the plastic parts to plastic recycling.

Take the metal parts to metal recycling.

Take the electronic assemblies and connection lines to special waste or to electronics waste.

I innovative exhaust aftertreatment

Contact

Netherlands

Baumot Nederland BV

Aarplein 24

NL-2406 BZ Alphen aan den Rijn

Tel.: +31 (0) 6 555 127 80

Fax: +31 (0) 172 493 109

Denmark / Sweden

Norway / Finland / Iceland

Baumot Nordic Apsv

Motorgangen 13

DK-2690 Karlslunde

Tel.: +45 46 40 03 00

Fax: +45 46 40 03 08

Italy

Baumot Italien S.r.l.

Via Del Tecchione, 24/B

I-20098 San Giuliano Milanese (MI)

Tel.: +39 02 982 828 73

Fax: +39 02 980 468 55

Czech Republic

Baumot s.r.o

Spolková 11

CZ-60200 Brno

Tel.: +42 (0) 5 - 452 146 51

Fax: +42 (0) 5 - 452 146 53

Switzerland

Baumot AG

Allmendstrasse 11

CH-8320 Fehraltorf

Tel.: +41 (0) 44 - 954 80 70

Fax: +41 (0) 44 - 954 34 36

USA

Baumot North America, LLC

2118 Wilshire Blvd., #255

Santa Monica

CA 90403-5784

Tel.: +1-323 393 0162

Tel.: +1-951 934 5436

Germany

Baumot Deutschland GmbH

Zentrale Deutschland

Mainstraße 2-6

D-45663 Recklinghausen

Tel.: +49 (0) 2361 - 30 231 0

Fax: +49 (0) 2361 - 30 231 69

Austria

Baumot GmbH

Hirschvogelstrasse 7/15

A-1200 Wien

Tel.: +43 (0) 2262-75 662-0

Fax: +43 (0) 2262-75 662-70

England / GB

Baumot UK Ltd.

1-9 Barton Road

Walter Eaton

Milton Keynes, NK2 3HU

United Kingdom

Tel.: +44 (0) 1908 82 11 03

Fax: +44 (0) 1908 82 11 04

02/11/2010

Table of contents