Baur PD-SGS User manual

BAUR GmbH ▪Raiffeisenstr. 8 ▪6832 Sulz, Austria

T +43 5522 4941-0 ▪F +43 5522 4941-3 ▪www.baur.eu ▪headoffice@baur.at

User manual

Handheld

Online PD Detector

PD-SGS

(supervisor)

© 2018

All rights reserved.

Reproduction, circulation in any form whatsoever, publishing on online services or Internet, as well as

duplication on data carriers, even in extracts or with changed format is allowed only with prior written

permission of BAUR GmbH, A-6832 Sulz / Austria.

We reserve the right in the interests of our customers to make amendments as a result of further

technical development. Illustrations, descriptions and scope of supply are therefore not binding.

The names of products and companies are the trademarks or brand names of the relevant companies.

PD-SGS Table of c ontents

822-162-1 iii / 46

Table of contents

1General.......................................................................................................... 5

1.1 Using this manual ................................................................................ 5

1.2 Structure of safety instructions ............................................................ 5

1.3 Symbols used ...................................................................................... 7

1.4 Note on the screenshots and graphics used ....................................... 7

1.5 Warranty .............................................................................................. 7

1.6 After Sales Service .............................................................................. 7

2For your safety............................................................................................. 8

2.1 Instructions for the user ....................................................................... 8

2.2 Intended use ........................................................................................ 8

2.3 Avoid dangers, take safety measures.................................................. 9

2.3.1 Dangers when working with high voltage during online

measurements ..................................................................... 10

2.4 Special personal protection equipment.............................................. 12

3Product information .................................................................................. 13

3.1 PD-SGS ............................................................................................. 13

3.2 Partial discharge ................................................................................ 13

3.2.1 Radiated energy................................................................... 14

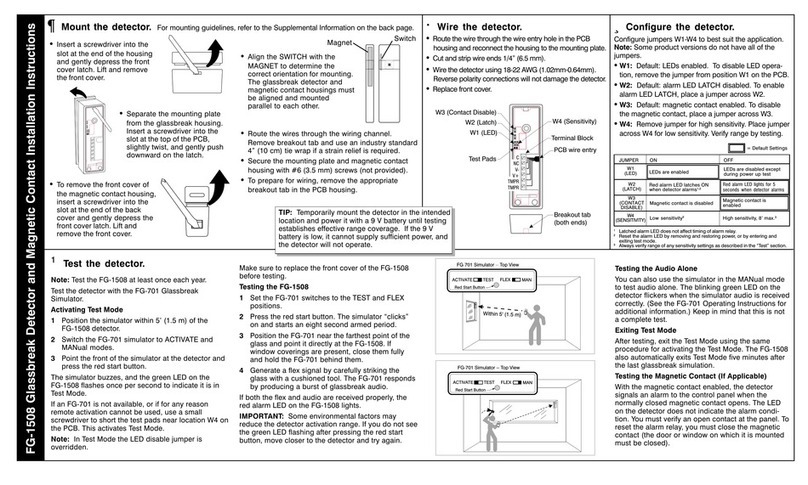

3.3 Full illustration .................................................................................... 14

4PD-SGS overview....................................................................................... 15

4.1 PD-SGS outline.................................................................................. 15

4.2 PD-SGS Input/Output ........................................................................ 15

5Transient Earth Voltage (TEV).................................................................. 16

5.1 Capacitive Coupler sensor................................................................. 16

5.2 Specification....................................................................................... 16

6Acoustic Emission (AE) ............................................................................ 17

6.1 Surface Tracking................................................................................ 17

6.2 Acoustic sensor.................................................................................. 17

6.3 Specification....................................................................................... 17

7Operational control.................................................................................... 18

7.1 Control buttons................................................................................... 18

7.2 On/Off button ..................................................................................... 18

7.3 Battery level indication ....................................................................... 19

7.4 MODE button ..................................................................................... 19

Table of c ontents PD-SGS

iv

/ 46 822-162-1

7.4.1 TEV mode ............................................................................ 19

7.4.2 TEV noise detection ............................................................. 20

7.4.3 AE mode .............................................................................. 20

7.5 Display ............................................................................................... 21

7.5.1 Level display ........................................................................ 21

7.5.2 Trend display........................................................................ 22

7.5.3 Setting the volume ............................................................... 23

8Charging the device .................................................................................. 24

9Checking the PD-SGS function ................................................................ 25

9.1 Function tester PD-FT........................................................................ 25

9.2 Checking the TEV function ................................................................ 26

9.3 Checking the AE function .................................................................. 27

10 Surveying switchgear panels for PD – TEV ............................................ 28

10.1 Examples for checking TEV activity levels ........................................ 29

11 Surveying switchgear panels for PD – AE .............................................. 31

12 Parabolic reflector (optional).................................................................... 32

12.1 Assembling and commissioning ........................................................ 33

12.2 Using the parabolic reflector .............................................................. 34

12.3 Maintenance and Servicing ............................................................... 35

12.4 Calibration.......................................................................................... 35

12.5 Laser pointer extension kit (optional)................................................. 36

13 Disposing of the device ............................................................................ 37

14 Technical data............................................................................................ 38

15 Delivery includes and Options ................................................................. 40

16 Declaration of conformity ......................................................................... 41

17 Appendix .................................................................................................... 42

18 Index............................................................................................................ 44

PD-SGS General

822-162-1 5 / 46

1.1 Using this manual

This user manual contains all necessary information that is needed for the commissioning

and operation of the described product.

Read this user manual completely before operating the product for the first time.

Consider this user manual to be a part of the product and store it in an easily accessible

location.

If this user manual is lost, please contact BAUR GmbH or your nearest BAUR

representative (http://www.baur.eu/baur-worldwide).

Applicable documents

If the PD-SGS is delivered together with the optional parabolic reflector and the laser pointer

extension kit, this user manual must be applied only with the user manuals of all components

comprised.

1.2 Structure of safety instructions

The safety instructions in this user manual are presented as follows:

Danger

symbol

SIGNAL WORD

Type of danger and its source

Possible consequences of violation.

Measure to prevent the danger.

1 G

ENERAL

General PD-SGS

6

/ 46 822-162-1

If a dangerous situation could arise at a specific step, the safety instruction is displayed

immediately before this dangerous step and is shown as follows:

SIGNAL WORD

Type of danger and its source

Possible consequences of violation.

Measure to prevent the danger.

Danger levels

Signal words in the safety instructions specify the danger levels.

DANGER Will lead to severe injuries or death.

WARNING May lead to severe injuries or death.

CAUTION May lead to light to moderate injuries.

NOTICE May lead to material damage.

Danger symbols

General danger

Risk of electric shock

Risk of falling

PD-SGS General

822-162-1 7 / 46

1.3 Symbols used

Symbol Meaning

You are prompted for an action.

1.

2.

...

Perform the actions in this sequence.

a.

b.

...

If an operation consists of several operating steps, specify these

with "a, b, c".

Perform the operating steps in this sequence.

1

2

...

Numbering in the legend

List

Indicates extensive information on the topic in the corresponding

user manuals.

1.4 Note on the screenshots and graphics used

The screenshots and graphics used are intended to illustrate the procedure and may

therefore differ slightly from the actual state.

1.5 Warranty

For warranty claims, please contact BAUR GmbH or your local BAUR representative

(http://www.baur.eu/baur-worldwide). Warranty is cancelled in case of misuse.

1.6 After Sales Service

For questions contact BAUR GmbH or your BAUR representative (http://www.baur.eu/baur-

worldwide).

BAUR GmbH

Raiffeisenstraße 8

A-6832 Sulz / Austria

service@baur.at

www.baur.eu

For your safety PD-SGS

8

/ 46 822-162-1

All BAUR devices and systems are reliable and are manufactured as per state-of-the-art

technology. The individual parts and the finished devices are subject to continuous testing by

our qualified personnel as part of our quality assurance system. Each device is fully tested

before delivery.

However, the operational safety and reliability in practice can be achieved only when all

necessary measures have been taken. The responsible body1and operator2of the device or

system are responsible for planning these measures and monitoring their implementation.

Before operating the device or system you should read and understand this user manual and

the user manuals of all integrated devices.

2.1 Instructions for the user

The product may be operated only by authorised and trained electrical engineers. An

electrical engineer is a person who owing to his professional education (electrical

engineering), knowledge, experience and acquaintance with the applicable standards and

regulations can assess the tasks assigned to him and detect possible dangers.

In addition, the user must have:

Knowledge of the technical equipment and operation of the PD-SGS

Knowledge of the testing and measurement procedures

Knowledge of plant engineering (cable types, switchgear, etc.).

2.2 Intended use

The BAUR handheld online PD detector PD-SGS is used to conduct rapid initial tests for PD

activities on live switchgear.

If the device is used without observing this condition, safe operation cannot be guaranteed.

The operator or user is liable for any damage to persons and property resulting from

incorrect operation.

Proper use also includes

Compliance with all instructions in this user manual,

Compliance with the technical data and connection requirements given on the rating

plate and in the user manual,

Compliance with the inspection and maintenance tasks.

1Responsible body is the person or group that is responsible for the safe operation of the device and its

maintenance (EN 61010, 3.5.12).

2Operator is the person who uses the device for its intended purpose (according to the definition of user in

compliance with EN 61010, 3.5.11).

2 F

OR YOUR SAFETY

PD-SGS For your safety

822-162-1 9 / 46

2.3 Avoid dangers, take safety measures

When operating the PD-SGS observe the following rules and guidelines:

Accident prevention and environment protection rules applicable for your country

Safety instructions and regulations of the country where the PD-SGS is being used

(according to the latest version)

EU/EFTA countries: EN 50110 “Operation of electrical installations”

Other countries: the standard for operating electrical systems applicable for your country

If necessary, other national and international standards and guidelines in accordance

with the latest applicable version

Local safety and accident prevention regulations

Liability insurance association regulations (if any).

Technically secure state of the device

Safety, function and availability depend on the proper condition of the device. Upgrades,

modifications or alterations to the product are prohibited.

Operate the device only in a technically perfect condition.

In the case of damage and/or malfunction, immediately stop the device, identify

accordingly and have the faults rectified by appropriately qualified and authorised

personnel.

Comply with the inspection and maintenance conditions.

Use only accessories and original spare parts recommended by BAUR. The use of spare

parts, accessories and optional extras that are not tested and approved by BAUR could

adversely affect the safety, function and characteristics of the product.

Never take apart the device. The device does not contain any components that could be

serviced or repaired by the user.

Do not operate under damp or humid conditions

Condensation can form in devices and systems due to temperature fluctuations and high air

humidity, which in some components can lead to leakage currents and flashovers.

Maximum danger arises when relatively high air humidity and temperature fluctuations occur

consecutively, e.g. which is the case when storing the device in an unheated room or when

placed outdoors. Then when the device is exposed to a high ambient temperature, the cold

surfaces of the device cool the air in the immediate vicinity, which leads to the formation of

condensation, even inside the device.

Therefore, two factors are crucial:

The higher the relative air humidity, the faster the dew point is reached and water is

condensed.

The higher the temperature difference between the surfaces and the ambient air, the

more likely condensation will occur.

To prevent condensation, always temper the device and system before and during

measurements to minimise the risk of condensation.

For your safety PD-SGS

10

/ 46 822-162-1

Working in dangerous environment: working at height

If performing connection and measurement tasks at workplaces that are more than 1 m

above ground, special safety measures must be taken to prevent falls from height occurring.

DANGER

Danger of falling while working at heights

Danger to life, risk of injury due to fall

Secure workplaces posing risk of falling with safety devices (e.g.

railings, platforms, scaffolds, frameworks).

Cover or block places where there is danger of falling or tripping.

Tasks performed at heights must be supervised by a second

person.

2.3.1 Dangers when working with high voltage during online measurements

A PD test with the PD-SGS is carried out on a live test object. Personnel need to pay special

attention and must be very careful while working with high electric voltage.

During the preparation and while performing the measurement, the user can come close to

live parts. Consequently, there is danger of touching the active parts directly or indirectly.

Commissioning and operation of the PD-SGS are permitted only in compliance with

EN 50110 (EU/EFTA countries) or with standards applicable in your country. Also observe

the applicable national and local accident prevention regulations.

PD-SGS For your safety

822-162-1 11 / 46

DANGER

Working in the vicinity of adjacent live parts

Danger to life or risk of injury due to electric shock

Before commencing work, the responsible body or operator must

assess the danger for the specific working conditions. Protective

measures are based on the risk assessment and must be followed

at the workplace.

Only accredited personnel with appropriate Health and Safety

training should use the equipment.

Do not use the equipment if it is damaged, or its safety is impaired

in any way.

Inspect and test all earthing and signal cables for continuity.

The user should have read and understood the appropriate

equipment manuals.

Always select the appropriate sensor and sensor connection for the

application.

When taking the measurement, protection must be guaranteed for

all plant parts, either

through safety devices, insulating cover material

or by adhering to the necessary safety distances. Safety

distances depend on the voltage level, plant model, personnel

qualification and available space. In this regard, comply with

EN 50110 or the applicable standards in your country as well

as the relevant national and local accident prevention

regulations.

The device has been designed for use only on the earthed, outer

surface of metal-clad equipment and the earthed/neutral

connections of cables/switchgear.

Under no circumstances should the sensors be connected to the

high-voltage terminals of HV plant under test.

Do not disturb or interfere with the high-voltage equipment in any

way.

Working in the vicinity of open cables or faulty systems is forbidden.

Notify the responsible authorities immediately.

Never take the safety devices out of operation. It is forbidden to

bypass the safety devices.

Keep the measurement tasks as short as possible.

Use suitable personal protection equipment to protect against

electric hazards.

To assess the local conditions adequately, provide sufficient

lighting at the work place.

For your safety PD-SGS

12

/ 46 822-162-1

Guaranteeing immediate measures in case of danger

The device may be connected and operated only if a second person with visual and auditory

contact to the tester is present and is in the position to detect possible dangers and to act

immediately and appropriately.

Access

The test engineers shall only enter the customer’s switchyard or substation after they have

received permission from an authorised person appointed by the plant owner. If in doubt

about any matter the plant owner’s high-voltage safety rules should be consulted by the test

engineers who will carry out the testing.

Visual inspection of substation

On entry to the test area a visual inspection of the area should be carried out by the test

engineers. This should enable the operator to identify any potential hazards in the area and

to assess both the type of equipment to be tested and the method of doing so. Only when

this visual inspection has been completed can the equipment be set-up for testing.

2.4 Special personal protection equipment

Personal protection equipment based on the risk assessment for the relevant working

conditions are part of the PD-SGS safety concept.

Observe the national safety regulations and your company’s working and operating

instructions.

Depending on the conditions of the work place, use the following safety equipment:

Protection against electrostatic charging, crushing,

slipping and other accidents: Safety hood

Protection against electrical hazards (arcing fault): Certified safety clothing

Hard hat with visor

Insulating protective gloves

LV HRC fuse handle with sleeve

Protection against noise: Ear protection

Protection against dangers from road traffic: High visibility vest according to EN 471

(Protection class 2) or according to the

applicable standards in your country for

high visibility clothing for commercial use.

No high visibility vest during tasks with

risk of arcs!

Hand protection: Safety gloves

PD-SGS Product information

822-162-1 13 / 46

3.1 PD-SGS

The BAUR handheld online PD detector PD-SGS is a first level partial discharge (PD)

detection device designed for use in distribution voltage substations. It enables network

operators to carry out simple routine tests that will identify discharge activity in switchgear

and accessories.

The battery-operated portable device has a live display that shows a quantified level of

detected PD activity. A colour-coded traffic light system indicates when detected levels

exceed the pre-set thresholds.

The PD-SGS has a built-in TEV sensor for capacitive coupling to switchgear and a built-in

ultrasonic sensor for detection of surface discharge and tracking. Headphones are also

supplied to help the user when working in noisy environment.

The PD-SGS is supplied with a battery-operated function tester PD-FT that should be used

to verify the correct operation of the device before use.

The PD-SGS is a non-intrusive test device therefore PD can be identified and located whilst

the equipment remains live.

3.2 Partial discharge

Partial discharge (PD) is an electrical discharge that does not completely bridge the space

between two conducting electrodes. The discharge may be in a gas filled void in a solid

insulating material, in a gas bubble in a liquid insulator or around an electrode in a gas.

When partial discharge occurs in a gas, it is usually known as corona.

Partial discharge is generally accepted as the predominant cause of long term degradation

and eventual failure of electrical insulation. As a result, its measurement is standard as part

of the factory testing of most types of high-voltage equipment. In-service monitoring of

equipment for PD gives an advance warning of pending insulation failure. This allows a plant

operator to take remedial action during planned outages.

Partial discharge often occurs under normal working conditions, gradually deteriorating the

dielectric until it can no longer withstand the electrical stress and fails. By detecting this PD

activity while the equipment is in operation, failure can be avoided.

3 P

RODUCT INFORMATION

Product information PD-SGS

14

/ 46 822-162-1

3.2.1 Radiated energy

A PD event will radiate energy in different forms and this energy can be picked up by the

PD-SGS in order to detect the source and locate it.

Electromagnetic radiation

PD creates electromagnetic (EM) radiation that dissipates in all directions away from the

source. Metal components, for instance the panels around switchgear, will pick up this

radiation and small voltages called Transient Earth Voltages (TEVs) are induced on the

surface. These very high frequency signals will be picked up by the PD-SGS and indicate

that there is a PD source nearby.

Acoustic radiation

Partial discharge also generates acoustic energy across a wide band of frequencies. This

acoustic energy can be detected in the ultrasonic range when there is a ‘line of sight’

between the PD source and the detecting sensor. Sharp points, for instance on air insulated

cable terminations, are typical sources of corona that will produce acoustic emission. Cast

insulators are prone to surface tracking where electrical stress across the insulator’s surface

causes discharge, and deteriorates the insulator surface and creates carbon tracks. This can

lead to flashover and failure of the equipment.

3.3 Full illustration

1 Transport case

2 Handheld online PD detector PD-SGS

3 PD-SGS power supply / charger

4 Function tester PD-FT

5 Stereo headphones

PD-SGS PD-S GS overview

822-162-1 15 / 46

4.1 PD-SGS outline

The PD-SGS has a tough ABS enclosure with rubber protective covering around the PD

sensors. Both built-in PD sensors are mounted at the front of the device so that they can be

easily directed at the inspection point. The PD-SGS is controlled with two membrane

switches on the front panel and a trigger button underneath. An OLED type screen is used

for function control and providing both text and graphical output information to the user. In

addition the PD-SGS has an audio output through both a built-in speaker and pluggable

headphones.

The unit is powered by a lithium-ion rechargeable battery giving a life of over 12 hours of

use. The software has intelligent power management prolonging battery life.

4.2 PD-SGS Input/Output

The PD-SGS has an input and output as detailed in the tables below:

Front panel Type

Display OLED display

6 x PD level LEDs

Control button MODE Membrane switch

On/Off button Membrane switch

Side panels Type

Headphone socket 3.5 mm jack

External AE sensor 3.5 mm jack

Handle Type

Trigger button Push button

Power charge socket 2.1 mm DC power

4 PD-SGS

OVERVIEW

Trans ient E arth V oltage (TE V ) PD-SGS

16

/ 46 822-162-1

Partial discharge activity inside a metal-clad high-voltage plant induces small voltage

impulses called Transient Earth Voltages on the surface of the metal cladding. These TEVs

travel around the cladding surface to the outside of the gear where they can be picked up

using capacitively coupled transducers.

The TEV signals emerge at the joins between the metal panels and it is at these points that

the highest readings are generally detected.

Figure: PD pulse propagation in AIS panels

5.1 Capacitive Coupler sensor

The built-in Capacitive Coupler sensor detects TEVs as they pass over the cladding of the

high-voltage plant. The very fast transient signals are detected by the PD-SGS and their

magnitude is measured and displayed.

5.2 Specification

Specification

Sensor Capacitive

Measurement range 0 – 80 dBmV

Frequency range 20 MHz – 200 MHz

Resolution 1 dB

Accuracy ±1 dB

5 T

RANSIENT

E

ARTH

V

OLTAGE

(TEV)

PD-SGS Acous tic E mis sion (AE )

822-162-1 17 / 46

Acoustic emission is ultrasonic energy that is emitted by discharges on electrical insulating

surfaces or sometimes called Surface Tracking.

6.1 Surface Tracking

Surface Tracking is the formation of a permanent conducting path across an insulator

surface. Usually the conducting path results from degradation of the insulation. Tracking

most readily occurs when the insulation is a carbon based compound.

A high-voltage plant is often very difficult to clean, so dirt and contaminants can build up over

time. In the presence of moisture, these contaminating layers give rise to leakage current

over the insulator surface. This heats the surface and through evaporation causes

interruption in the moisture film. Large potential differences are generated over the gaps in

the moisture film and small sparks can bridge the gaps. Heat from the sparks causes

carbonisation of the insulation and leads to the formation of permanent carbon tracks on the

surface. Under such conditions this process will develop over time and eventually lead to

flashover and full breakdown of the insulation.

6.2 Acoustic sensor

The ultrasonic acoustic sensor is designed for use on air-insulated terminations where there

is a clear sound path between the electrically stressed insulation and the probe. The sensor

is extremely sensitive when pointed directly at the discharge source.

The transducer is embedded into the rubber moulded cover at the front of the device so it

can be easily directed towards the parts of electrical plant where tracking may occur.

6.3 Specification

Specification

Measurement range -6 to +70 dBµV

Resolution 1 dB

Accuracy ±1 dB

Convertor sensitivity -65 dB (0 dB = 1 V/µbarrms sound pressure

level)

Convertor average frequency 40 kHz ± 1 kHz

6 A

COUSTIC

E

MISSION

(AE)

Operational control PD-SGS

18

/ 46 822-162-1

7.1 Control buttons

The PD-SGS is controlled by three buttons on the device as shown below:

1 MODE button

2 On/Off button

3 TRIGGER button

7.2 On/Off button

The On/Off button is used to turn the PD-SGS on and off.

Note that the On/Off button should be pressed and held down for two seconds before the

power is switched.

7 O

PERATIONAL CONTROL

PD-SGS Operational control

822-162-1 19 / 46

7.3 Battery level indication

The remaining charge in the battery is indicated by the small icon in the bottom right-hand

side of the display screen.

1 Battery level indication

7.4 MODE button

The MODE button is used to toggle the device between TEV mode and AE mode. The

MODE button should be pressed briefly in order to switch between the two modes.

7.4.1 TEV mode

In TEV mode, the device measures and displays the magnitude of TEV signals detected.

The measured value is shown in dBmV such that 0 dB = 1 mV. The relationship between

detected signal magnitude in dB and mV is shown in the table below:

mV dB

1 0

2 6

5 14

10 20

20 26

35 31

50 34

100 40

1 000 60

10 000 80

Operational control PD-SGS

20

/ 46 822-162-1

7.4.2 TEV noise detection

In TEV mode, the PD-SGS can identify HF signals that are from a noise source and are not

PD. When noise is detected, the display will alternate between the dB level recorded and the

indication Noise as shown in the figure below:

The noise detection algorithm is only applied to signals with a magnitude greater than 20 dB

as noise signals below this level are relatively common.

It should be noted that when high noise is detected, it can mask genuine PD. It is advisable

to use more sophisticated PD detection devices that can detect PD even in the presence of

high noise.

7.4.3 AE mode

In AE mode, the device measures and displays the magnitude of ultrasonic acoustic signals

detected. The measured value is shown in dBµV such that 0 dB = 1 µV. The relationship

between detected signal magnitude in dB and µV is shown in the table below:

µV dB

0.5 -6

1 0

2 6

5 14

10 20

20 26

35 31

50 34

100 40

1 000 60

3 100 70

Table of contents