FG-1508 Glassbreak Detector and Magnetic Contact Supplemental nformation

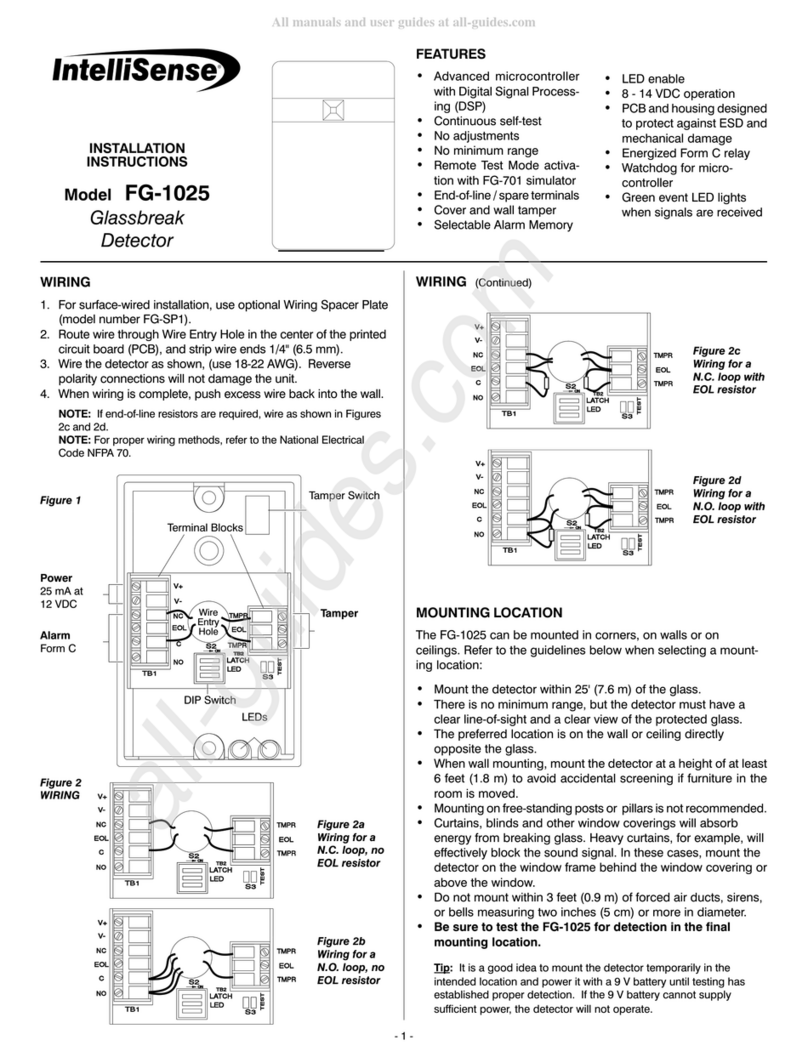

Protected glass:

Minimum size for all types is 11" (28 cm) square. Glass must be framed in

the wall of the room or mounted in a barrier of 36" (0.9 m) minimum width.

1 Protected only if both glass plates are bro en.

2 Coated glass with security films, including films for solar protection, up to 12

mil. thic may be used. Film Technologies, Inc.s GLASS GARD® GLL 1200 has

been evaluated with this product by Underwriters Laboratories Inc. at

IntelliSenses request.

3 Underwriters Laboratories of Canada has investigated the use of the coating

referred to on note 2 for plate and tempered glass.

MPORTANT: The FG-1508 must be connected to a UL listed power supply

or UL listed control unit capable of providing a minimum of four hours of

standby power.

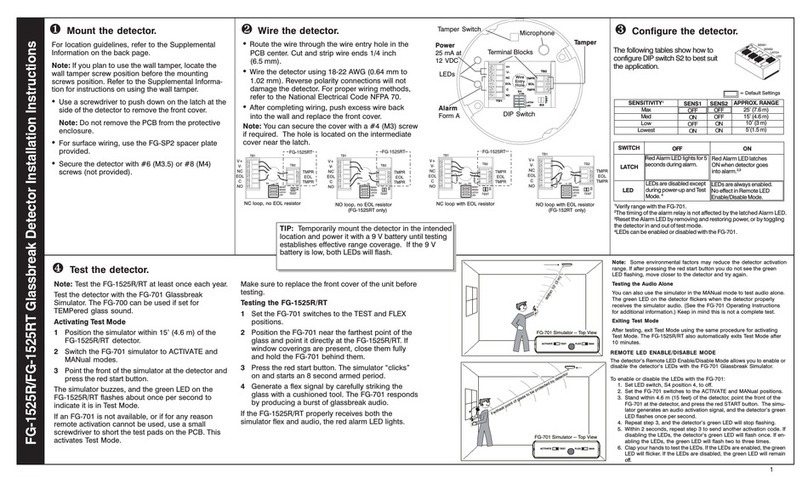

LED ND CATORS

The two LEDs shining through the front cover indicate the detector's

operational status. The following table summarizes the LED opera-

tion when the LEDs are enabled.

REMOTE LED ENABLE/D SABLE MODE

The detectors Remote LED Enable/Disable Mode allows you to

enable or disable the detectors LEDs with the FG-701 Glassbrea

Simulator.

To enable or disable the LEDs with the FG-701:

1Position jumper W1 to OFF.

2Set the FG-701 switches to the ACTIVATE and MANual positions.

3Stand within 5 (1.5 m) of the detector, point the front of the

FG-701 at the detector, and press the red start button. The

simulator generates an audio activation signal, and the detectors

green LED flashes once per second.

4Repeat step 3, and the detectors green LED stops flashing.

5Within 2 seconds, repeat step 3 to send another activation code. If

you disable the LEDs, the detectors green LED flashes once. If

you enable the LEDs, the green LED flashes 2 to 3 times.

6Clap your hands to test the LEDs. If the LEDs are enabled, the

green LED flic ers. If the LEDs are disabled, the green LED

remains off.

MOUNT NG GU DEL NES

The FG-1508 detects framed glass bro en by an impact sufficient to

ma e a hole.

•Mount the FG-1508 (indoors only) on doors, window frames, walls,

ceilings, and in corners.

•Mount within 8 (2.4 m) of the glass.

•The detector must have a direct line-of-sight to the glass with no

obstructions.

•When wall mounting, mount the detector a minimum of 6 (1.8 m)

high.

•Do not mount within 3 (0.9 m) of forced air ducts, sirens, or bells

measuring 2 (5 cm) or more in diameter.

•If the magnetic contact is enabled, the glassbrea housing must

be mounted less than 1(2.5 cm) from the magnet housing.

Maximizing Detection

•Minimize range to the glass. Do not install beyond the maximum

specified range, even if testing indicates greater range.

•Mounting on freestanding posts and pillars is not recommended.

•The FG-1508 detects through window blinds and light drapes. For

heavy window coverings, mount the unit on the window frame

behind the covering. Test the location thoroughly whenever

window coverings are present.

•Verify all installations bac to the panel to be sure the protection

loop is intact.

Minimizing the Chance of False Alarms

•Avoid installing in rooms with high-level noise sources, such as air

compressors, bells, and power tools if those sources can be active

when the detector can signal an alarm.

•Magnetically susceptible materials affect the range of the contact

gap. If using the magnetic contact, be sure to test the gap thor-

oughly when the unit is mounted on iron or steel surfaces.

•Test false alarm immunity by activating any nown noise sources

in the room.

SELF-TESTS

The FG-1508 automatically performs a series of self-tests during

power-up. If any self-test fails, the detector signals trouble by

flashing the LEDs alternately once per second. Always return the

detector for repair if there is any indication of trouble, even if the

trouble is temporary.

SPEC F CAT ONS

Range:

8 (2.4 m) maximum

4 (1.2 m) maximum (

for lowest UL setting

)

No minimum range

Alarm relay:

Form A, 250 mA maximum

25 VDC maximum

Alarm duration:

5 seconds (unaffected by alarm LED

latching)

Tamper switch:

Cover tamper 25 mA maximum

24 VDC maximum

Power requirements:

6 - 18 VDC; 13 mA typical at

12 VDC, 22 mA max.;

AC Ripple: 4 Volts pea -to-pea at

nominal 12 VDC

Operating temperature:

14° to 122°F (-10° to 50°C)

Storage: -4° to 122° F (-20° to 50° C)

RF immunity:

30 V/m, 10 MHz - 1000 MHz

ESD immunity:

10 V, Discharges of either polarity to

exposed surfaces

Magnetic contact:

Ma e gap 0.9 (2.3 cm) minimum

Brea gap 2.2 (5.6 cm) maximum

Dimensions:

Glassbrea housing:

4-9/16 x 15/16 x 1-1/4

(11.6 cm x 2.3 cm x 3.2 cm)

Magnet housing:

4-9/16 x 15/16 x 1/2

(11.6 cm x 2.3 cm x 1.3 cm)

Weight:

2.9 oz., (81 g)

Pac aged product: 3.8 oz., (108 g)

Accessories:

FG-701 Glassbrea Simulator

Approvals/listings:

FCC / IC verified

CE

C-Tic

UL Listed

ULC Listed

FCC Notice: This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can radiate

radio frequency energy, and if not installed and used in accordance with the instructions may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures: 1) Reorient or relocate the receiving antenna, 2)

Increase the separation between the equipment and receiver, 3) Connect the equipment into an outlet on a

circuit different from that to which the receiver is connected. The installer can also consult an experienced

radio/television technician for additional suggestions, if necessary.

Normal OFF OFF

Normal, event detected Flic er OFF

Normal, event detected and Flic er Flash 5 seconds

alarm in memory

Normal, brea detected OFF ON 5 seconds

Normal, alarm latched OFF ON continuously

Power up self-test ON 1 second ON 1 second

Trouble detected Flash ON/OFF Flash OFF/ON

Low voltage Flash ON/OFF Flash ON/OFF

Test Mode Flash once per second OFF

Test Mode, event detected Flic er OFF

Test Mode, alarm Flash once per second ON 5 seconds

Condition Green LED Red LED

TH CKNESS

Type Minimum Maximum

Plate 3/32" (2 mm) 3/8" (10 mm)

Tempered 1/8" (3 mm) 3/8" (10 mm)

Laminated11/8" (3 mm) 9/16" (14 mm)

Wired 1/4" (6 mm) 1/4" (6 mm)

Coated2, 3 1/8" (3 mm) 1/4" (6 mm)

Sealed Insulating11/8" (3 mm) 1/4" (6 mm)

© 2001 IntelliSense®•IntelliSenseisaregistered trademark of Honeywell, Inc.

• All other trademarks are the properties of their respective owners. • All rights reserved.

5-051-626-01RevD