Bavis TransTrax Manual

Captive Carrier TransTrax®

Installation and Service Manual

Utilizing BavSonic Audio

E. F. Bavis & Associates, Inc.

201 Grandin Road

Maineville, Ohio 45039

(513) 677-0500

Copyright 2011 E. F. Bavis & Associates, Inc. Revised 3/24/2011

All Rights Reserved P/N 00655011

Captive Carrier TransTrax®

Table of Contents

Overview..............................................................................................................................1

Typical Diagram....................................................................................................................... 3

Installation................................................................................................................................ 4

Airlock Assembly........................................................................................................ 7

Ceiling Trims............................................................................................................... 7

Power Connection........................................................................................................ 8

Installing Tape ............................................................................................................. 8

Wiring ......................................................................................................................... 9

Shift Point Adjustment ................................................................................................ 9

Autocycler .............................................................................................................................. 10

Track Preparation................................................................................................................... 11

Customer Mounting ............................................................................................................... 12

Mounting Block Diagram ...................................................................................................... 13

Audio Adjustment.................................................................................................................. 14

Troubleshooting the TransTrax®........................................................................................... 15

Maintaining the TransTrax®.................................................................................................. 17

User Instructions..................................................................................................................... 18

Shift Point Diagram................................................................................................................ 19

Wiring Diagram...................................................................................................................... 20

Radius & Trim Diagram ........................................................................................................ 21

Tools Necessary for Installation ............................................................................................ 22

TransTrax® Shipping Manifest ............................................................................................ 23

1

Captive Carrier TransTrax®

Overview

The TransTrax®Captive Carrier is a mechanical, positive drive conveyor system kit intended for

the conveyance of pharmacy prescriptions and documents between customers and pharmacists at

drive-thru pharmacy lanes. For ease of use by customers, the door of the carrier car opens and

shuts automatically. The closing of the door is accomplished by spring force. The opening motion

is accomplished when a lever on the bottom of the carrier contacts the inside or outside stabilizers.

Inside the carrier is a spring-loaded bail to keep the receipts and small bags from falling or blowing

out of the carrier. Note that the carrier inverts during its travel. Whatever is inserted into the

carrier flips upside down when it is delivered.

This kit features one piece extruded architectural grade aluminum tubing that has a satin anodized

finish. The tubing can be, using a power miter box with the proper blade installed, cut and spliced

to suit dimensions dictated by varying site conditions. The system is sold as a complete kit ready

to install at a site. The standard kit allows for a maximum tubing centerline-to-centerline distance

of 23'11". Minimum distance is 3'11". Maximum overall height is 16'. Longer, shorter and/or

taller sites can be accommodated. Please consult the factory for assistance and pricing.

(Note; With factory assistance, the minimum horizontal distance from center line to center line

of the vertical tube is 32 inches, maximum horizontal distance from center line to center line of

the vertical tube is 33 feet, 10 inches. Maximum vertical height from the top of the horizontal

tube to the drive surface or finished floor, whichever is the greater, is 16 feet.)

The TransTrax®must be run in an overhead configuration. It was not designed to accommodate

"Downsend" configurations. If there is a need for this type of configuration at a given site, we

suggest that you consider a product from our Autoveyorproduct line. Please contact us for more

details on this product line.

In order to provide the greatest speed and safety of operation, the TransTrax®operates at two

different speeds. The carrier travels at slow speed when it is exposed to either the customer or

pharmacist. Then it travels at a much higher speed when in the horizontal section of the track

when the carrier is not exposed to people. This model features a proven system of distance

monitoring to control shift points versus less sophisticated "time based" systems. In addition, the

Captive Carrier system features a mechanical brake to prevent the CARRIER from coasting

when the system is off.

The Captive Carrier features dual stopping heights: high for vehicles such as vans and trucks, low

for cars. There are two (high and low) premium weatherproof buttons for send. The stopping

height is determined by pressing the appropriate CAR or TRUCK buttons when sending the

CARRIER out to the customer. The system allows one move from car to truck or vice versa; then

the CARRIER must be recalled.

Customer audio components, including wiring harness, microphone, speaker and two call buttons

are included with the TransTrax®.

The weight capacity of the system is conservatively rated at one pound. There are safeguards built

into the system which prevent catastrophic failure should the carrier be overloaded.

2

This system is intrinsically safe in that the mechanical power levels at the moving parts (carriage

and carrier) are below 40 lbs. of force when accessible by the users. The electrical power levels at

all locations other than the INSIDE VERTICAL STANDOFF are intrinsically safe in that they are at

NEC Class II levels (24vdc 100 VAC) or lower.

The TransTrax®has been reviewed by a third party for safety and suitability for the given

application. Please review the label applied to the machine for details concerning this review.

Please note that the intrinsically safe power level does require that the system be smooth running

without any extra drag induced by poor fitups, misalignment at joints in the tubing and other

installation related problems, or it simply won't run properly.

Each part in the kit contains a PSA label with the part name and number attached to it. Please read

over this manual before installation to familiarize you with the different components and where they

are used in the system.

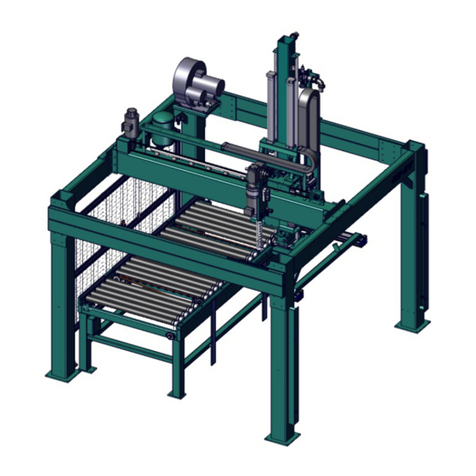

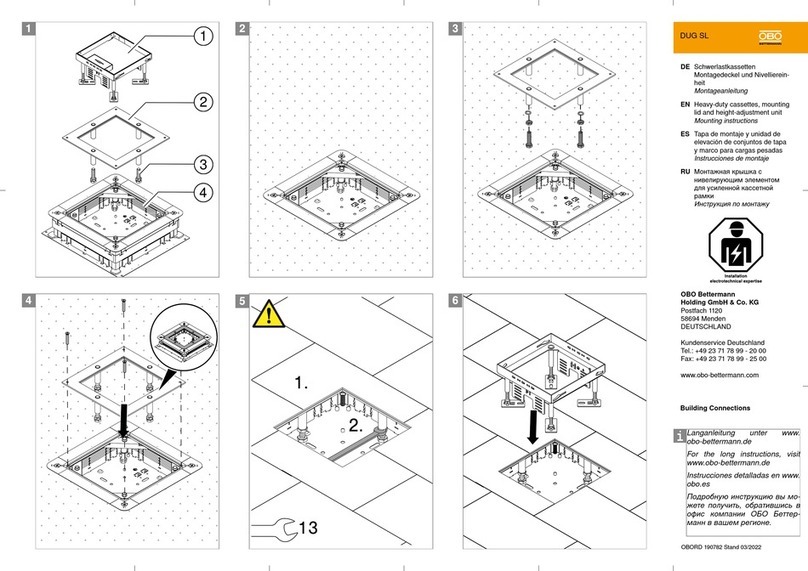

A schematic of an installed TransTrax®system identifying major components by part number

follows.

If there are questions about any of the following, contact the Technical Service Department at (513) 677-

0500.

Note: Shipping manifest can be found on Page 23; a listing of required tools on Page 22.

3

16

12

13

14

38

163

4

163

4

24

16

CEILING TRIM EXTENSION

CEILING TRIM

OPENING FOR CEILING TRIM

CUT ISLAND HEIGHT OFF

BOTTOM OF TRACK

46

WALL ROUGH OPENING

CLEAR CHANNEL

183

4

163

4

12

16 X 16

CLEAR CHANNEL

24

R12

HARDENED

TT RADIUS

04016333

CEILING TRIM

04021224

CEILING LINE

110 VAC 20 AMP OUTLET

92" FROM FLOOR

CENTERED TO TRACK

INSIDE VERTICAL

ASSEMBLY

04013596 CC CARRIER

04059991

HARDENED

TT RADIUS

04016333

CEILING TRIM

04021224

CUSTOMER VERTICAL

ASSEMBLY

04015596

12

SEE PAGE 21

FOR MINIMUM

REQUIREMENTS

HORIZONTAL SECTION

04005591

12

4

Installation

Installation Overview:

The process of installing a TransTrax®into a building consists of first mounting the inside vertical,

attaching the radius, adding the horizontal section, attaching the customer radius, and then

mounting the customer end. All horizontal wiring cables are designed to run inside the tubing.

After the tubing is installed, the AIRLOCK ASSEMBLY and CEILING TRIMS are mounted. The

electrical connection is then made. The final aspect of the assembly process consists of feeding the

DRIVE TAPE into the machine, and adjusting the electronic motor control.

The inside vertical unit, customer vertical unit and carrier are all tested as a unit in the factory. Do

not mix and match components when installing a multiple lane job.

The following detailed description provides step by step details of this process, as well as

important notes and cautions. Read these details carefully before attempting to install the

TransTrax®.

Installation Procedures:

The first part of the TransTrax®Kit is a completely assembled INSIDE VERTICAL UNIT. The

System Electronics are housed in the WALL STANDOFF portion of the INSIDE VERTICAL UNIT.

The WALL STANDOFF sides open outward to expose the back. The WALL STANDOFF BACK

needs to be mounted securely to the wall.

CAUTION: The WALL STANDOFF supports the entire weight of the INSIDE VERTICAL UNIT.

Do not just use molly bolts or similar type mounts into the drywall. Make certain that the fasteners

and mounting surface are adequate to fully support this component and the forces that occur during

operation.

The bottom of the INSIDE VERTICAL UNIT should be positioned 46” off the inside floor. If the

vision window frame obstructs the placement of the WALL STANDOFF, it can be repositioned up

to 6” higher on the VERTICAL TUBING by removing its associated screws and placing it at the

higher position.

5

Cutting TransTrax®Tube:

The TransTrax®system uses a proprietary aluminum extrusion. This extrusion must be cut

using carbide tipped circular saw blade in a power miter box. No other way of cutting the

tube is acceptable.

Many have tried to use an abrasive blade installed in a power miter box to cut the tube. Do

not use this method as it will yield cuts that will not function properly. Further, since the

cuts must be made dead square, a good quality miter box is the only acceptable way to

make the cuts.

If you have any questions regarding the proper method of cutting the tubing, please contact

the factory. Cutting the tube properly is key to making the system function properly.

The INSIDE VERTICAL EXTENSION should be cut to a dimension that will allow the FORMED

RADIUS to exit the building via the 16" x 24" clearance hole in the wall. The INSIDE VERTICAL

EXTENSION must then be deburred and the tape slot chamfered1.

NOTE: The area of the TAPE SLOT where the tubes are joined must actually be CHAMFERED

on both tubes and on the top and bottom track and not just deburred to allow the tape to pass

easily in the event of a slight misalignment. Inspect the factory prepared ends for an example.

The factory prefers to use a conical rotary cutter in a high speed grinding tool such as a Dremel.

1 Fig. 1

6

Connect the HORIZONTAL WIRING CABLES To the inside vertical assembly and through all

other tubing, as the unit is assembled. Sometimes “fishing” the wiring cable through the tubing

can be a challenge due to the screws, etc. We have found that a “fish tape” made from a scrap

section of tape does a great job. Just attach one end of the harness to a 10-12’ length of tape with

electrical tape and push the tape through the tube. The cable can then be easily pulled through

using the tape to push the tape through the tube. The cable can then be easily pulled through using

the tape to pull the cable. Attach the tubing to the INSIDE VERTICAL UNIT using two of the

extruded internal SPLICE PLATES². Be careful when running screws into the tubing not to nick

or cut any of the wires.

The FORMED RADIUS needs to be attached to the INSIDE VERTICAL EXTENSION using the

extruded internal SPLICE PLATES³.

CAUTION: The FORMED RADII are not designed to be cut. They were designed to be

used as is. Any modifications to this component will void the warranty and will likely yield

less than acceptable operation.

The CUSTOMER VERTICAL UNIT is completely assembled and designed for installation at a site

with no elevation difference from the lane to the island. Measure the distance from the lane to the

island and cut this amount off of the bottom of the CUSTOMER VERTICAL UNIT. It mounts to

the island with a CUSTOMER BASE UNIT. The CUSTOMER BASE UNIT mounts to the island

via two 3/8" holes (Note: base unit to island fasteners not provided) and to the CUSTOMER

VERTICAL TUBING via two self-drilling screws4. The CUSTOMER VERTICAL UNIT is 120"

tall. It needs to be cut to length which will allow the HORIZONTAL TUBING to be plumb

horizontally after the FORMED RADIUS is attached to it. Be sure to deburr and chamfer each end

of the tubing5before proceeding.

CAUTION: When cutting off the top of the customer unit, make sure that the vertical cable

from the customer unit is pulled back down the customer tube to prevent cutting the cable.

_______________________

2Fig. 2

3Fig. 2

4Fig. 3

5Fig. 1

7

The FORMED RADIUS needs to be attached to the CUSTOMER VERTICAL UNIT using the

extruded internal SPLICE PLATES6.

The HORIZONTAL TUBING needs to be cut to a dimension which will allow both of the vertical

units to be plumb vertically after it is installed to the FORMED RADII. Be sure to deburr and

chamfer each end of the tubing1 before proceeding.

Airlock Assembly:

The AIRLOCK ASSEMBLY is a two-piece design. Attach the AIRLOCK BOTTOM using the self

drilling screws provided8 . Note the alignment tabs on this part that center it on the tube. The

notched end goes on the radius. Install the AIRLOCK TOP to the BOTTOM. Fill the area between

the AIRLOCK ASSEMBLY and the 16" x 24" opening with insulating material and cover with

drywall, sheathing board or other appropriate material.

Ceiling Trims:

Secure the CEILING TRIM halves together around the TransTrax®tube with the #8-32 hardware

provided. Holes must be predrilled with the short 9/64" bit provided in the installation accessories

to prevent drilling into and damaging wiring. Attach the ceiling trim to the tubing of the

TransTrax®with the #8x1/4" self-tapping screws provided. These screws do not protrude into the

tubing greatly simplifying running the wiring. Note: The trim must be on the vertical section of

tubing, not the radius. If it is necessary to attach the trim to the ceiling, it will be necessary to drill

holes for this purpose, as there are no holes provided for this. Test the machine to insure that there

is nothing preventing the car from traveling through the flaps.

NOTE: CEILING TRIMS are designed to be mounted on the vertical tube and are not designed

to be mounted on the FORMED RADIUS. When installing trims, make sure that the CAR moves

freely through the trim and does not rub or bump the sides of this component.

Note that six 1" angled reinforcement plates are included in the installation accessories of each

TransTrax®. These are intended to be used when installing the ceiling trims and airlocks when it is

not possible to get fasteners in from the bottom of the tube or the sides. Simply attach the angle to

the airlock bottom or ceiling trim back and then the side of the tube.

_______________________

6Fig. 2

7Fig. 2

8See Drawing on page 3

8

Power Connection:

The AC Line connection is at the top of the INSIDE VERTICAL STANDOFF. Connection method

should comply with all authorities having jurisdiction, (i.e. National, State or Local Electrical

Codes). A 1/2" knockout is provided on a single gang box cover. Removing the cover will reveal

three leads for termination.

The white wire is the neutral.

The black wire is the hot. (Single phase 120vac)

Green is for ground.

NOTE: To reduce the risk of shock hazard of both line voltage and static, the ground must be

connected to a good earth ground.

The wiring can be enclosed in flexible metallic or nonmetallic conduit. If a cord connection is

acceptable, one is provided in the kit complete with a romex connector. NOTE: On the supplied

cord the ribbed wire is the neutral connection and the smooth wire is the HOT. Please reduce the

cord to a minimum length before connecting. Do not use an extension cord for permanent wiring

and do not run the cord through or conceal in walls, ceilings and or other permanent fixtures.

Press the POWER BUTTON once. The LED above it should come on indicating that the unit has

power. Pressing it again should toggle the power off.

Installing Tape:

NOTE: The AC power must be on to install the tape as this machine has a mechanical brake

that requires power to release.

Remove the CUSTOMER SPEAKER PANEL. Feed the TAPE into the tape slot at the CUSTOMER

SPEAKER OPENING insuring that it pushes smoothly all the way into the power unit of the

INSIDE VERTICAL UNIT. Cut the tape two feet longer than this dimension. Remove the tape and

dress the ends9. Attach the CARRIER to the TAPE10. Before reinserting the prepared tape with

CARRIER attached, take a section of the discarded tape (two feet will do) with square cut ends and

run it through the system by hand with a screwdriver. If any rough spots or obstructions exist,

correct them before proceeding. Reinsert the TAPE into the tape slot. At the INSIDE VERTICAL

UNIT, Press and hold the brake release while inserting the tape. Note that the LED comes on.

_____________________

9Fig.5

10Fig.6

9

Engage the tape with a small screwdriver pushing firmly down, without damaging the tape,

consistently, but slowly, allowing the tape to engage the gear, wrap around and feed into the tape

return slot. Do this until the magnet block of the CARRIER is engaging the upper black non-

contact switch on the CUSTOMER VERTICAL UNIT. Replace the CUSTOMER SPEAKER

PANEL.

Carefully jog the car inside and back outside while checking that there is nothing obstructing or

binding the car. Release the switch back to the normal position.

With the power on, pressing the "RECALL" button should cause the CARRIER to come in. By

pressing the "CAR" button, the CARRIER should go out to the lower car stop position. By

pressing the "TRUCK" button, the CARRIER should go out to the higher truck stop position.

Note that the microprocessor control will only allow one move between car and truck or truck and

car before it will require the car to be recalled inside. If the carrier does not run, or does not run

smoothly, please consult the factory for assistance.

Wiring:

The wiring for the TransTrax®is connectorized and is enclosed within the tubing of the machine.

The vertical cable extends through the top of the vertical assemblies and connects with the

horizontal cable. The horizontal cable is identical on both ends and cannot be installed backwards.

After you have connected the audio horizontal harness, wrap both ends of the strain relief boot

with the electrical tape provided.

NOTE: A version of this unit dated before 05/2003 has the horizontal harness running directly to

the outside base audio board and inside to the audio console.

Power Drive Adjustment:

Open the hinged INSIDE STANDOFF LEFT COVER11 to get access to the MOTOR CONTROL

BOARD. The shift point adjustments are next. There are three adjustments, SEND, RECALL and

HIGH. SEND adjusts when the carrier shifts from low into high speed when the CARRIER is

sent from inside to customer. RECALL adjusts when the CARRIER shifts from low into high

speed when the CARRIER is sent from customer to inside. HIGH adjusts how long the

CARRIER stays in high speed.

The CARRIER should be in low speed when traveling through the AIRLOCK, RADII and in sight

of users. It should be in high speed only in the HORIZONTAL section. If the car is in high speed

in the radii, the CARRIER may flip out of the car. Adjust the SEND pot so that when the

CARRIER is traveling from the inside to customer, it shifts into HIGH SPEED after it comes out

of the AIRLOCK. Adjust the HIGH pot so that the CARRIER shifts back into low before it enters

the CUSTOMER FORMED RADIUS. Adjust the RECALL pot so that when the CARRIER is

traveling from the customer to the inside, it shifts into HIGH SPEED after it comes out of the

CUSTOMER FORMED RADIUS. Observe that the CARRIER shifts back into slow before it

enters the AIRLOCK. Readjust as necessary so that the CARRIER is in high speed only in the

HORIZONTAL SECTION but not in the AIRLOCK or FORMED RADII.

_____________________

11See Drawing on Page 3 for location of Standoff

10

Note: The shift points are controlled by a microprocessor that is monitoring the rotation of the

sprocket shaft and the settings should not vary due to speed, that is monitoring the rotation of the

sprocket shaft and the settings should not vary due to speed, voltage, temperature, age of machine,

etc. Position 1 of dip switch DS1 controls the range of the adjustment for the high speed.

On=Long, Off=Short.12

If there is a problem with a carrier missing a switch, check to see what the gap between the switch

and the magnet is. Anything over 1/8" and the potential for missing switches exists. This can

sometimes be adjusted by loosening the black carrier stabilizers and pulling in the side opposite the

stop switch, pushing back the side with the stop switch or a combination of both. Note that the

carrier has to have some clearance to the stabilizers to prevent it from binding.

A run limit timer is factory preset at 45 seconds. If the CARRIER is obstructed during its travel,

the motor will shut down after this delay. If more or less time is needed, please consult the factory

for assistance.

Close and secure INSIDE STANDOFF LEFT COVER.

Autocycler

The Captive Carrier® is equipped with an autocycler that can be activated to run the carrier in and

out. This is useful to check the unit for proper operation after installation or service.

The procedure for doing this is as follows

1. Recall the car to the inside stop.

2. Turn the power off using the breaker located on the bottom of the black standoff.

3. Press and hold the car and truck buttons on the inside control panel while turning

the breaker back on.

4. When the car starts moving, release the car and truck buttons

To turn off the autocycler, press the power button on the inside control panel and turn off the

unit.

To resume normal operating procedure, press the power button and turn the unit on.

___________________________

12See Drawing on Page 18 for Dip Switch Settings

11

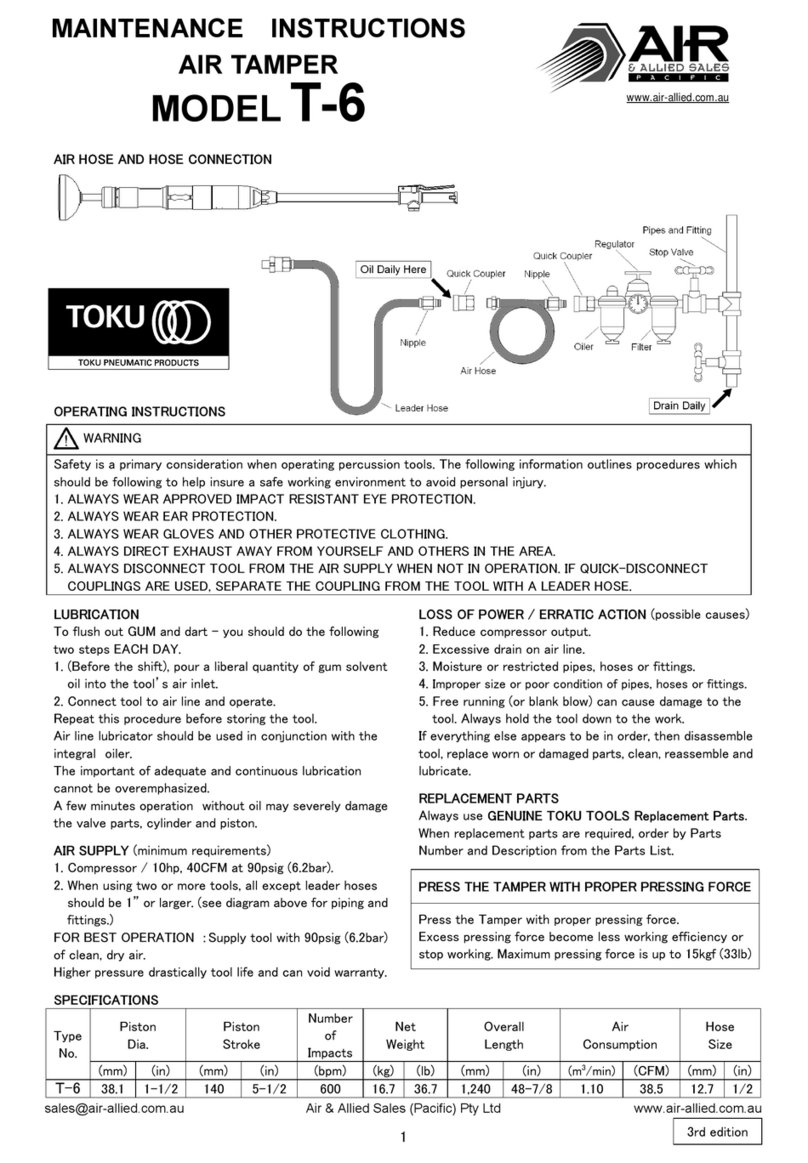

9/64” DRILL BIT

12

Customer Mounting

FASTEN TO ISLAND WITH

CONCRETE ANCHOR BOLTS

(NOT SUPPLIED)

USE SHEET METAL SCREWS TO

ATTACH TUBE TO ANCHOR BRACKET

TRIM AND THEN REMOVE

BURR FROM CUT EDGES

TAPE PREPARATION

TAPE-FINISH END

(BOTH ENDS OF TAPE)

TAPE-CLEANING END

USE ONLY FOR CLEANING BEFORE THE NEW TAPE

IS INSTALLED, THEN RESHAPE TO FINISH END.

13

Grey CC Carrier Hole Spacing

UNITS BUILT

AFTER 4/04

1 HOLE

#8-32 X 1-1/4" TRUSS HEAD

WITH LOCKING PATCH

#8-32 X 15/16" TRUSS HEAD

WITH LOCKING PATCH

1 HOLE

25 HOLES

BOTTOM VIEW

5 HOLES TAPE BLOCK

Red CC Carrier Hole Spacing

14

Audio Adjustment

This unit has the BavSonic audio system. There is one NA Base Audio Board located on the

back of the customer speaker panel assembly, inside the weatherproof enclosure. Please see

diagram below. This NA Base Audio Board adjusts the outgoing volume of the audio to the

customer by turning the gain pot.

15

Troubleshooting the TransTrax®

This section assumes that the machine in question has been inspected for loose, damaged or

missing parts, tape, belts, wiring, etc.

If the unit has a connector board located behind the customer speaker panel, remove the connecting

and audio wires from the connector board and hardwire together matching color to color.

NOTHING WORKS:

Check the circuit breaker on the bottom of the Teller Unit Standoff. Reset it by toggling it off and

back on. Nothing still works, check to insure that there is 110 VAC power coming into the

machine. If there is no AC Power, have an electrician restore power to the machine. If there is

power, check the fuse marked F1. If it is blown replace it with a 10A fast blow fuse. If the fuse

blows again, replace the control board. If nothing still works, please consult the factory.

POWER ON LED WON'T COME ON OR GO OFF:

Check the LED marked PWR while pressing the POWER SWITCH. The PWR LED should only

be on while the switch is depressed. If the PWR LED is on all the time, replace the INSIDE

SWITCH ASSEMBLY. If the PWR LED does not come on, check the switch on the brake control

board to insure that it is in the normal position. If the PWR LED still will not come on replace the

INSIDE SWITCH ASSEMBLY. If the PWR LED still does not come on replace the control board.

CARRIER WON'T RUN IN WHEN RECALL BUTTON IS DEPRESSED:

This presumes that the carrier will run out. Check the LED marked T-L, inside limit. It should not

be on. If it is, replace the INSIDE STOP SWITCH. If it is not, press the button marked recall.

When the recall button is depressed, the LED marked RCL, recall, should be on. If it does not

come on, replace the INSIDE SWITCH ASSEMBLY. If it does come on, replace the CONTROL

BOARD.

CARRIER WON'T RUN IN WHEN CUSTOMER START BUTTON IS DEPRESSED:

This presumes that the carrier will run out. Check the LED marked T-L, inside limit. It should not

be on. If it is, replace the INSIDE STOP SWITCH. If it is not, press the customer start button.

When the button is depressed, the LED marked RCL, recall, should be on. If it does not come on,

replace the CUSTOMER START SWITCH. If it does come on, replace the CONTROL BOARD.

CARRIER WON'T RUN OUT WHEN THE CAR BUTTON IS DEPRESSED:

This presumes that the carrier will run in. Check the LED marked C-L, customer limit. It should

not be on. If it is, replace the CAR STOP SWITCH. If it is not, press the inside button marked

CAR. When the button is depressed, the LED marked SND, send, should be on. If it does not

come on, replace the INSIDE SWITCH ASSEMBLY. If it does come on, replace the CONTROL

BOARD.

CARRIER WON'T RUN OUT WHEN THE TRUCK BUTTON IS DEPRESSED:

This presumes that the carrier will run in. Check the LED marked TR-L, truck limit. It should not

be on. If it is, replace the TRUCK STOP SWITCH. If it is not, press the inside button marked

TRUCK. When the button is depressed, the LED marked TRK, truck send, should be on. If it

does not come on, replace the INSIDE SWITCH ASSEMBLY. If it does come on, replace the

CONTROL BOARD.

16

CARRIER WON'T RUN EITHER DIRECTION:

This presumes that the power LED works properly. If it does not, go to the paragraph on

"NOTHING WORKS". First replace the MOTOR FUSE. Replace it only with an AGC10 fuse.

This is a U.L. listed fuse rated for 120vac. Do not use fuses rated for only 32vac. If the carrier

does not run, proceed to the paragraph "CARRIER WON'T RUN IN WHEN INSIDE RECALL

BUTTON IS DEPRESSED". If the carrier still won’t run, replace the DRIVE ASSEMBLY

CARRIER WON'T SHIFT INTO HIGH SPEED:

Adjust the speed shift points as instructed on page 9. If the carrier will still not run in high speed,

monitor the voltage to the motor at the connections to the motor in the power module. Note:

These connections are fully insulated quick connects; however, there is room to carefully slip

meter leads into them sufficient to make contact for measuring purposes. The motor must be

connected for this test. Run the carrier. The voltage should be approximately 36vdc in slow and

88vdc in high. If the voltage changes and the speed don’t, inspect the machine for anything

causing excessive drag such as damaged tape, bows, sags or misalignment in the track or bad

bearings in the surround. If the voltage doesn't change, observe the CHAIN LED. This LED

should flash on twice for each revolution of the motor. If it does not, check SJ1 connection on the

control board. If connection is O.K., replace the DRIVE ASSEMBLY. If it still does not, replace

the CONTROL BOARD.

CARRIER IS IN HIGH SPEED IN THE VERTICAL SECTIONS:

Adjust the speed shift points as instructed on page 9.

CARRIER OVERRUNS STOP POSITION ON INSIDE END:

First, insure that the carrier is traveling in the slow speed in the vertical section. Check to insure

that the gap between the magnet and the black switch is 1/8" or less. With the carrier at the stop

position and the magnet positioned on one of the stop switches, check the LED labeled T-L. It

should be on. If it is not, replace the SWITCH; if it is still not on, replace the CONTROL BOARD.

CARRIER OVERRUNS THE CAR & TRUCK STOP POSITIONS ON THE CUSTOMER

END:

First, insure that the carrier is traveling in the slow speed in the vertical section. Check to insure

that the gap between the magnet and the black switch is 1/8" or less. With the carrier at the stop

position and the magnet positioned on one of the stop switches, check the LED labeled T-L. It

should be on. If it is not, replace the SWITCH; if it is still not on, replace the CONTROL BOARD.

RELAYS AND BRAKE CLICK; MOTOR WON’T RUN:

There is a brake interlock switch, which prevents the motor from running unless the brake fully releases.

Check J11 connection on the Control Board. If you still experience this problem, please consult the

factory.

Table of contents

Other Bavis Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Watts

Watts FGD Series installation manual

Grouw!

Grouw! 50799 instruction manual

Durst

Durst Rho P10 200 operating instructions

Ortlinghaus

Ortlinghaus TPI 1140 EN Translation of original operating manual

Keba

Keba KeTop T50VGA user manual

Eaton

Eaton AirFlex TLC 5004 Installation, operation and maintenance manual

Showa Denki

Showa Denki Mistresa CRG Series Operation Manual & Cautions

Loepfe

Loepfe YARNMASTER 3N1 FITTING INSTRUCTION

OBO Bettermann

OBO Bettermann DUG SL Mounting instructions

Bauer

Bauer BG 24 H instruction manual

Master

Master MB Bucker 500 Instructions for use and maintenance

Air & Allied Sales

Air & Allied Sales TOKU T-6 Maintenance Instruction