2.0 Flushing & Filling the System

5

2.2 Completing the System fill of the Solar Pump

Station with Controller

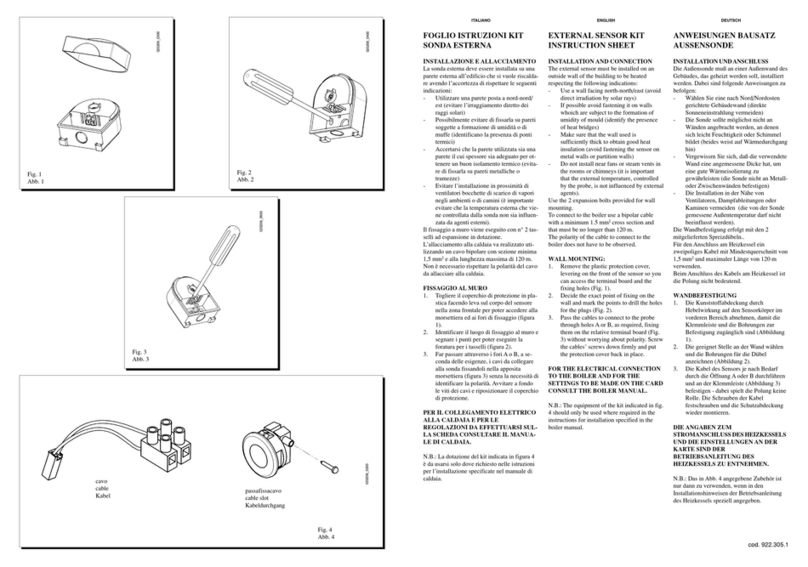

1. Connect the filling pump to the solar pump station with

controller, on the fill and drain valve on the safety group (Fig. 2

item1) and connect the drain hose to the fill and drain valve on

the flow meter, (Fig. 2 item 2) and check that the valves are

closed. Ensure the drain hose is installed as prescribed earlier.

2.Turn the left hand isolating valve (Fig. 2, item 4) to 45°

anticlockwise and the flow meter adjusting screw (Fig. 2, item 6)

to off.

3. Fully open the fill and drain valves on the safety group (Fig. 2,

item 1 & 2)

4.Turn the slot of the adjusting screw (Fig. 2, item 3) in the return

so the slot is vertical to open the non return valve

5.The handle on the Multifit Electric Pump outlet should be

turned to the closed position.

6. Switch on the pump, and open the pump outlet lever slowly.

Only open the pump outlet sufficiently to ensure the system can

be filled, and that over pressurisation of the circuit does not

occur.

7. The transfer fluid level should be monitored during the fill

procedure. If the fluid level gets near the bottom of the suction

hose, approximately 1 litre is left in the container, it will be

necessary to stop the fill procedure, close items 1 and 2

(Fig. 2), switch off the pump and replenish the transfer fluid

before repeating from step 1 again. (If the level gets below this,

the pump is liable to damage and air will be introduced into the

system.)

8. During the fill process air bubbles may be seen behind the glass

window of the flow meter (Fig. 2 item 7 ), the air should gradually

reduce until there is a clear flow of fluid.The fill process should be

run for several minutes to ensure the system is flushed of debris

and all air is removed.The debris should be caught within the

inline filter of the drain tube. Debris accumulation can be cleaned

out from the filter at a later date on the Multifit Electric Pump.

9. Continue filling at the fill valve on the safety group (Fig. 2, item

1) until the system pressure reaches 2 bar.

10. Once the master pump station leg of the system is filled and a

pressure of 2 bar achieved, close the drain valve (Fig. 2 item 2),

switch off the pump, close the valves (Fig. 2 items 1 & 2). Check

for leaks.

11.Turn the left hand isolating valve (Fig. 2, item 4) back 45°

clockwise until the dot on the bezel is back at 12 o’clock

12.Turn the non return back to open (Fig. 2, item 3)(12 o’clock).

13.Turn the flow meter adjusting screw (Fig. 2, item 6) until it is

fully open on both pump stations (12 o’clock).

For step by step guide to operating the controller, refer to

commissioning instructions section 3 (Part No. 5130227).

Ensure collectors temperatures are cool before this process.

14.Turn on the power to the solar controller.This should display

the information screen.

15. Key the left button (Fig. 2a item 3) once to enter the main

menu screen.The ‘i’ icon will flash (See section 3.0 of the

commissioning booklet 5130227 for a description of the solar

controller button functions)

Fig. 2

1 (Fill Valve)

2 (Drain Valve)

3

4

5

6

Key - Item Identification

1 Safety Group incorporating Pressure Relief

2 Drain with Isolation Connection Point

3 Non Return Valve Screw

4 Combined Isolation Valve with Integral Thermometer

5 Right Hand Isolation Valve with Integral Thermometer

6 Flow Meter Adjustment Screw

7 Flow Meter

Outlet Lever to restrict

& close flow

Open position

7

45°

In-Line

Filter

On Off