covering or carpet and the floor is of

a type that is likely to be covered in

such a way in the future then the

distance from the base of the

fireplace opening in the wall to the

floor level should be increased to at

least 160mm. The minimum shelf

height will have to be taken from the

base of the fireplace opening.

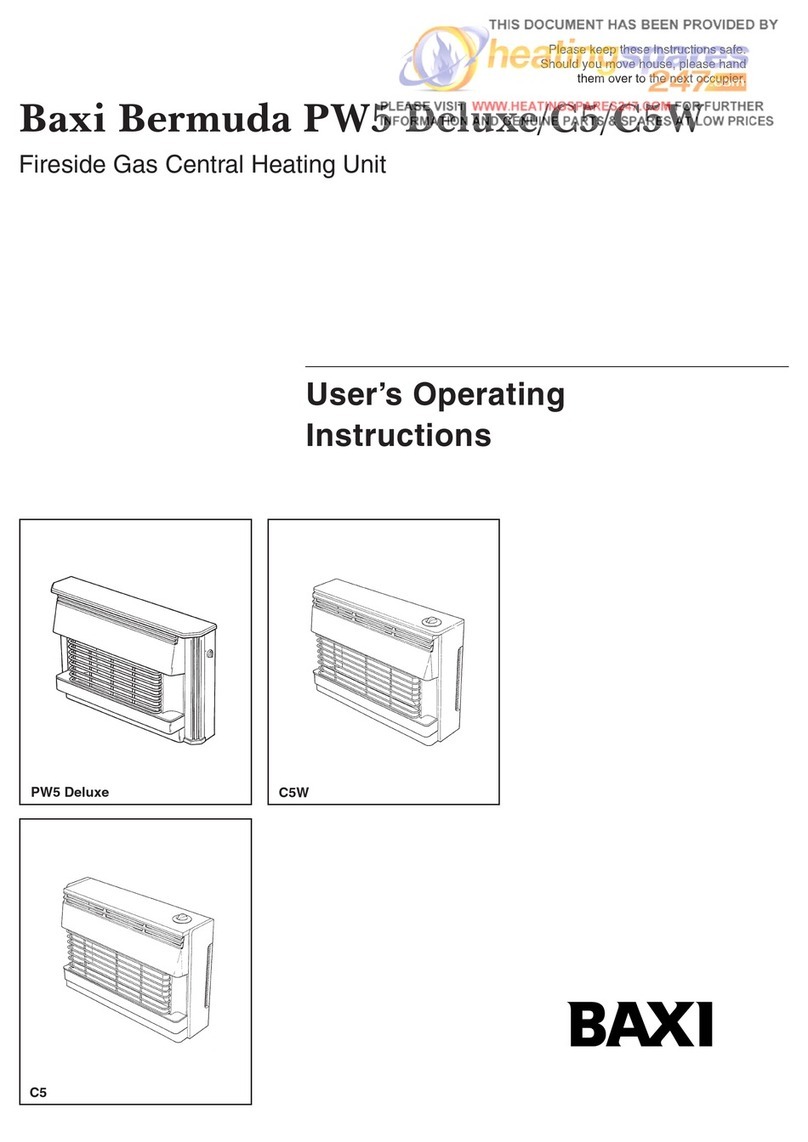

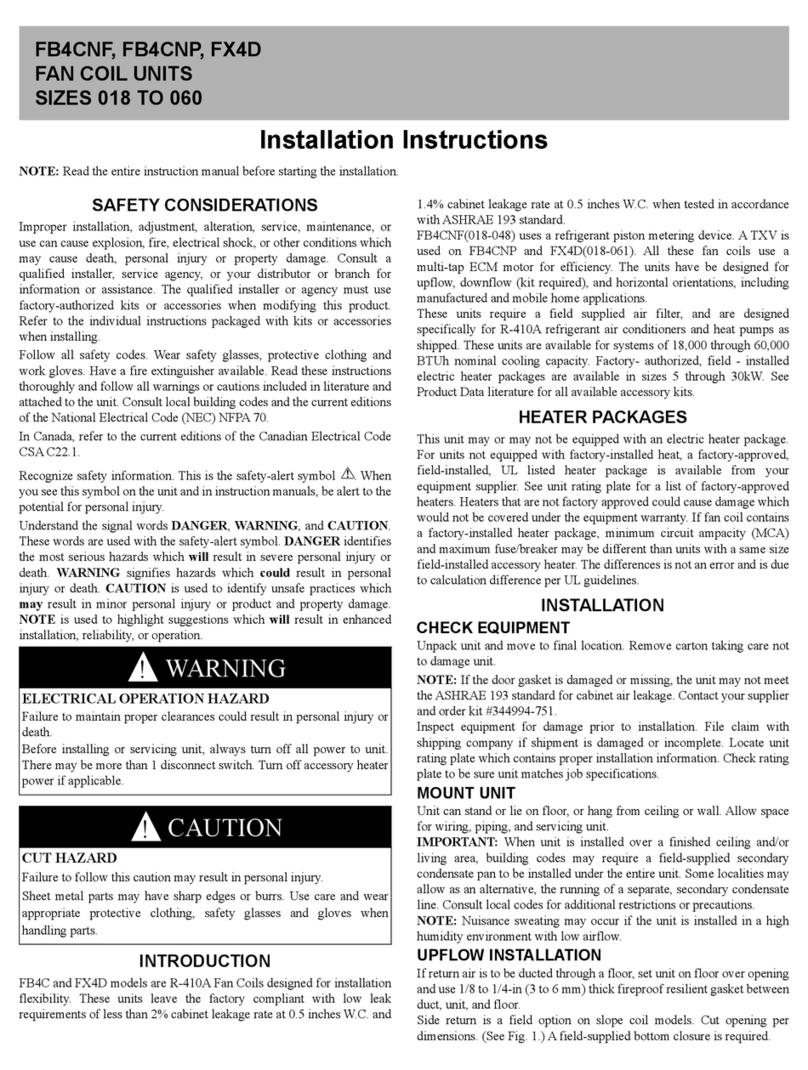

4.2.2 To a fireplace incorporating a

metal flue box complying with the

constructional requirements of

BS 715 and BS EN 1856 Part 1. The

dimensions of the flue box must

conform to those shown in figure 2.

4.2.3 A precast concrete or clay flue

block system conforming to BS EN

1858 or BS 1289 with dimensions as

in figure 3 or using a 05654K1 spacer

kit. (Installation Instructions part

number 3003095). The current versions of BS1289 and BS EN 1858 recommend that

there should be an air space or insulation between the flue blocks and the plaster

because heat transfer may cause cracking on directly plastered flues. However, generally

this appliance is suitable for installations under all circumstances unless there is a

history of cracking problems.

Remember that faults such as cracking may be caused by poorly built and restrictive

flues, e.g. mortar extrusions, too many bends, flue heights below three metres,

restrictive terminations etc (See figure 3).

4.2.4 If the fireplace opening is greater than the acceptable dimensions given in this

guide, do not use the back of a fire surround or marble to reduce the opening. This may

cause cracking of the surround back or marble.

4.3 Suitable flues and minimum flue sizes are as follows: -

It should be noted that, as with many appliances, sharp bends or horizontal runs in

metal flues at the top of the system can be a cause of problems in these types of

installation.

! 225mm x 225mm conventional brick flue.

! 175mm diameter lined brick or stone flue.

!

200mm diameter factory made insulated flue manufactured to the current edition of

BS EN 1859 or BS 4543.

! 175mm diameter flue pipe. See BS6461 Part 1 for suitable materials.

Page 9

INSTALLER GUIDE

© Baxi Heating U.K. Limited 2006.

Figure 2. Metal flue box