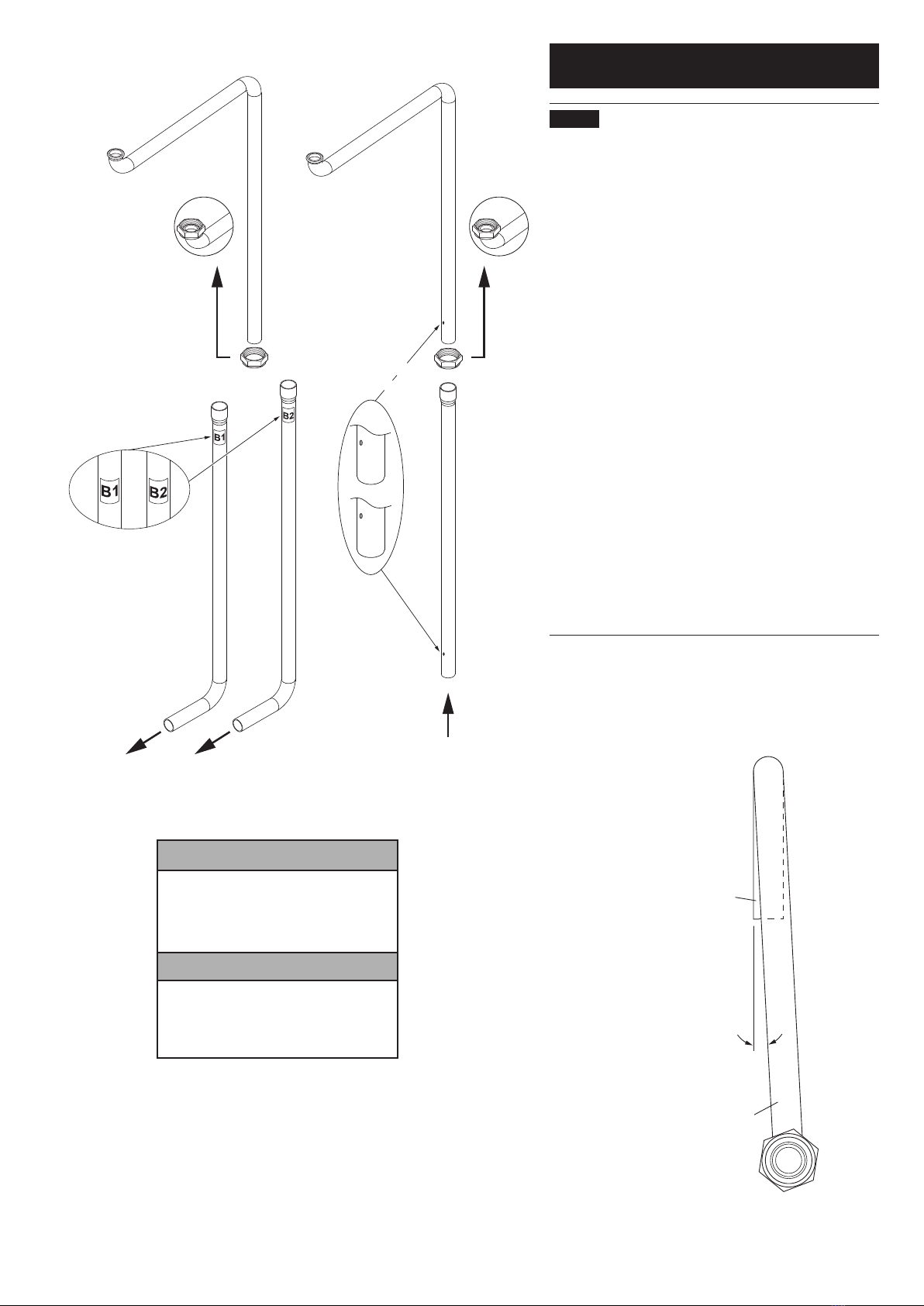

9

4.0 Installation

4.3 Installation - Horizontal Direct Rear Flue

7210434

IMPORTANT: Follow the Installation & Servicing

Instructions supplied with the boiler to the point at

which the wall plate is tted, but do not mark the ue

position. The Assure FGHR must be tted on a at

vertical surface.

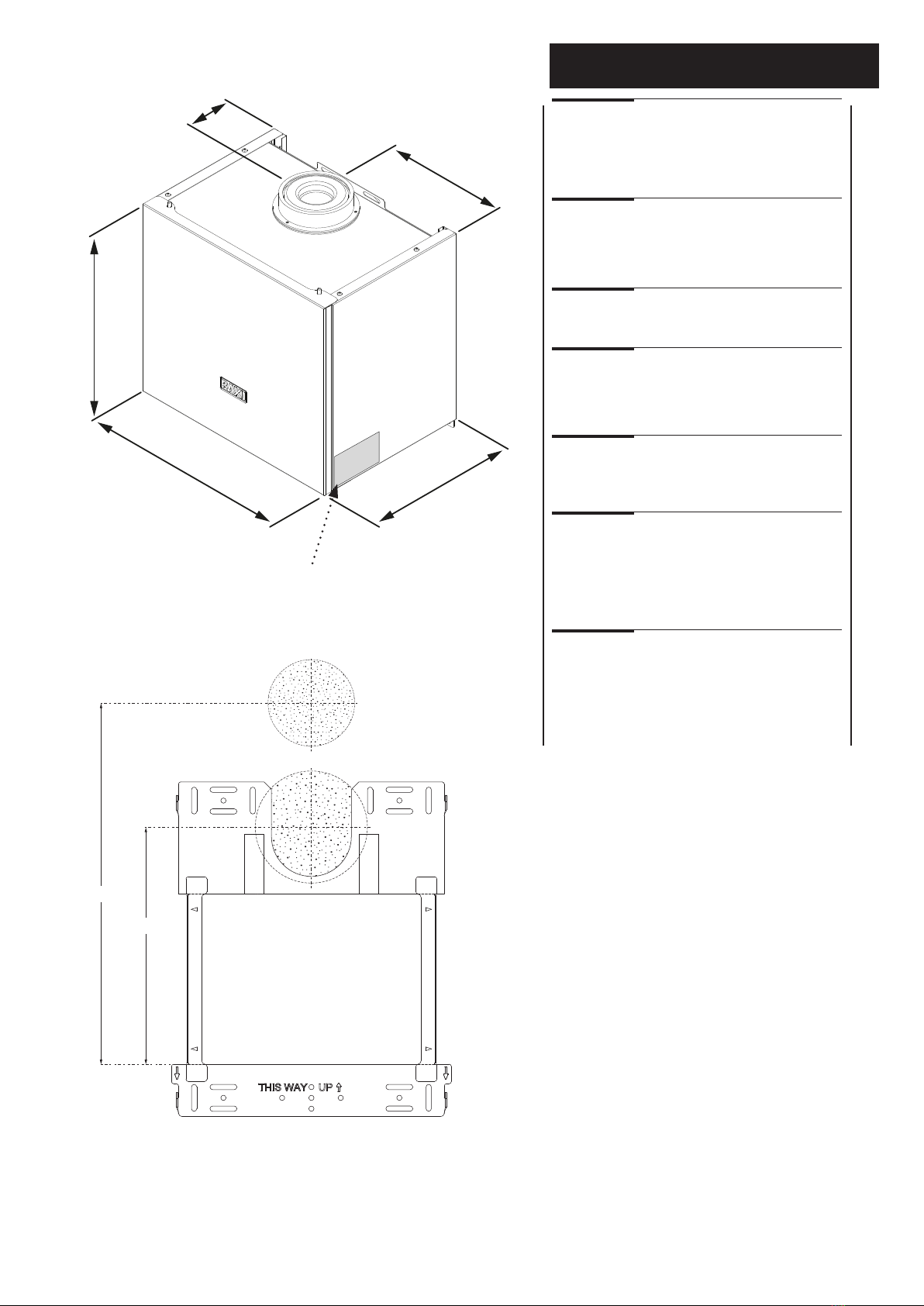

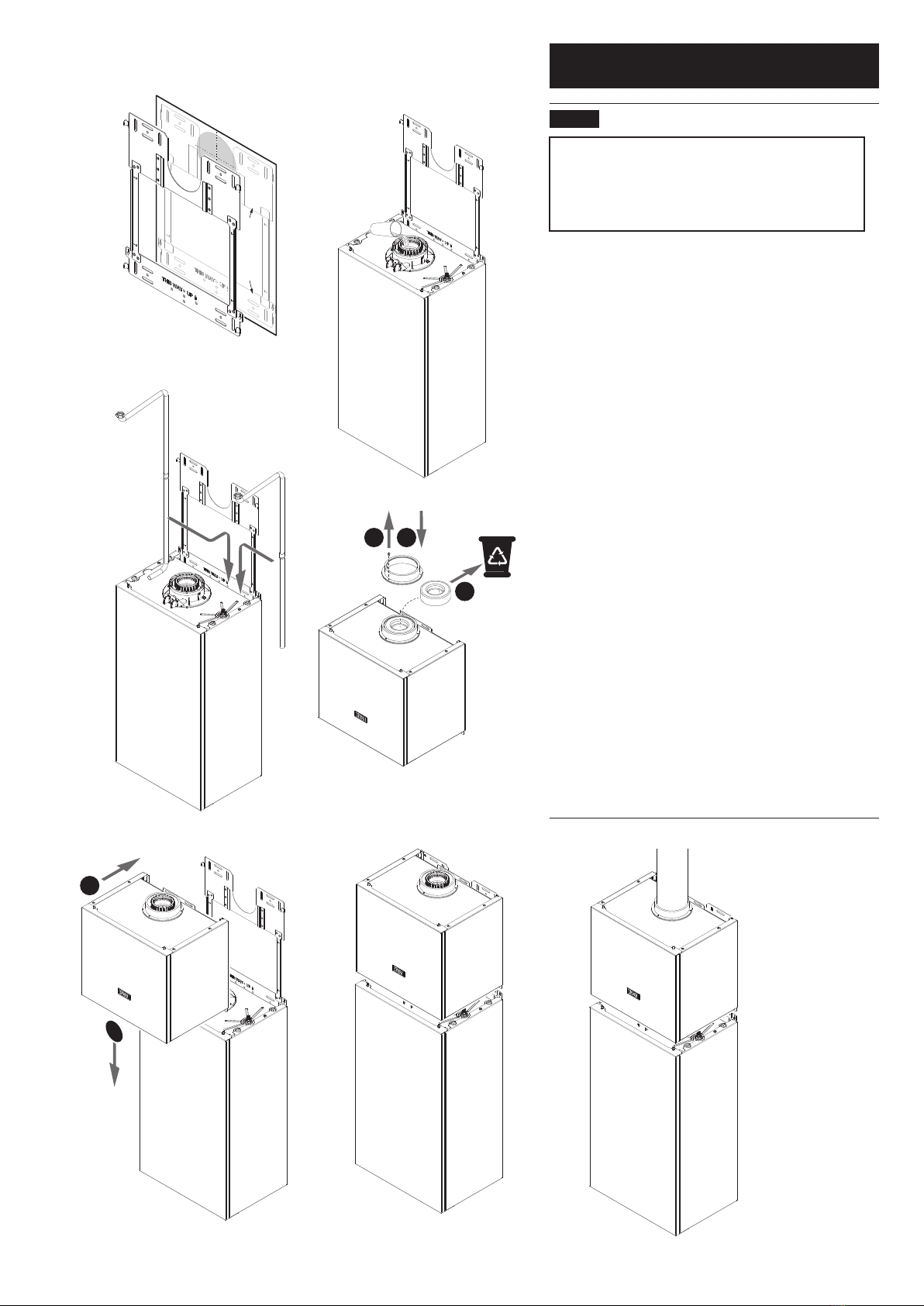

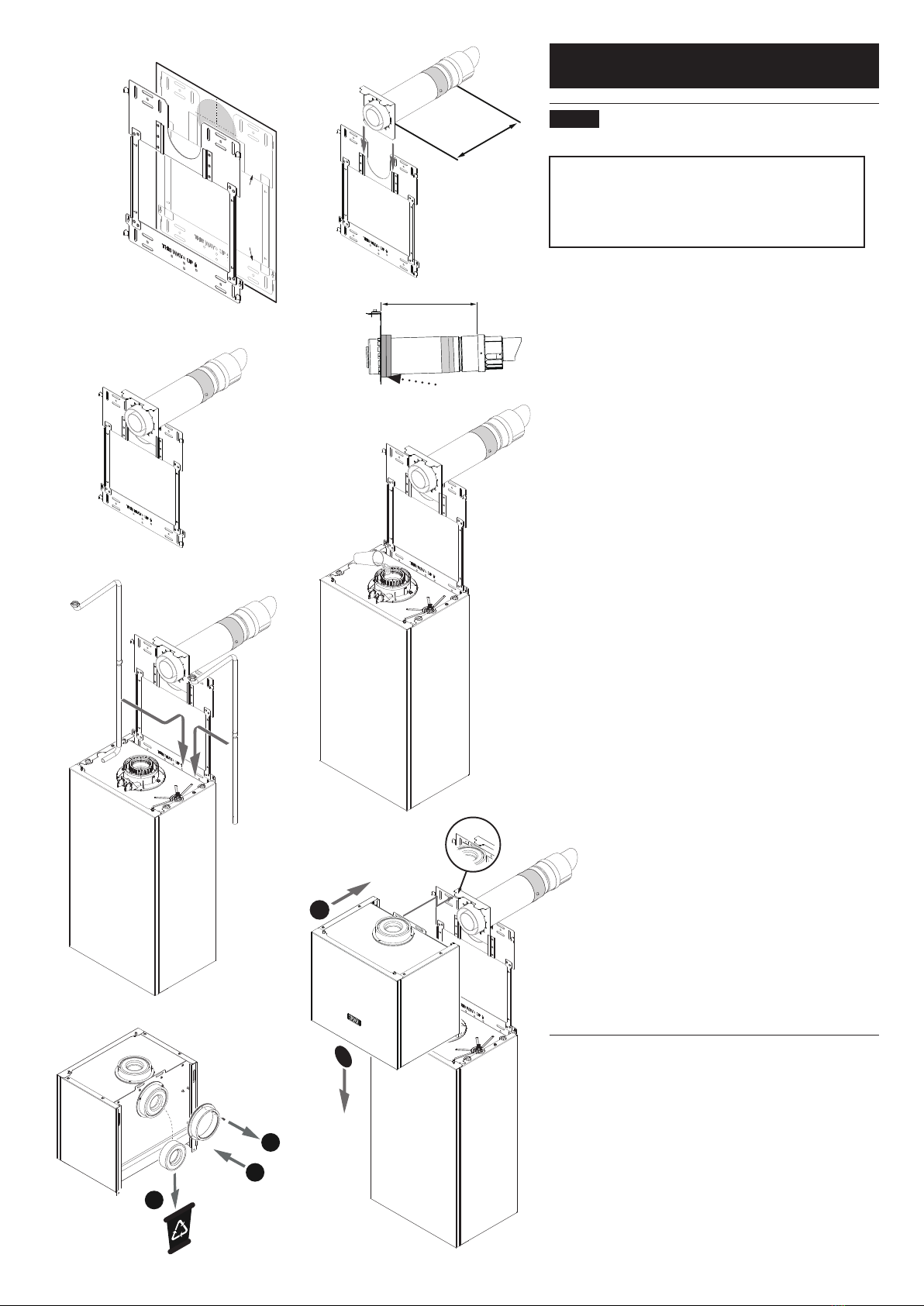

1. Align the Assure FGHR template on the wall (Fig. 16)

and mark the positions of suitable xing points on the

upper and lower plates of the wall frame.

2. Drill & plug the xing points. Cut the hole for the ue

Ø150 mm. Measure the wall thickness and add 17 mm.

Adjust the telescopic ue to length after locating and

securing it in the sliding collar with the screws supplied.

Tape and secure the ue (Fig. 17).

3. Apply the self-adhesive foam from kit 7215374 to the

rear face of the sliding collar (Fig. 18). Wrap the foam

around the ue twice. Engage the ue & collar in the

channels on the frame (Fig. 19).

4. Insert the ue into the Ø150 mm hole and secure the

frame assembly to the wall, ensuring the ue is uppermost

in the hole by pushing up the sliding collar. Hang the boiler

on the lower plate (Fig. 20). Prime the boiler trap by

pouring 300 ml of clean cold water into the central spigot.

Do not allow any water to spill into the air chamber.

5. After identifying the FGHR inlet and ow pipes (Fig. 21),

manoeuvre them into place behind the boiler.

6. Undo the screws securing the rear ue adaptor and

remove the adaptor. Retain the screws & adaptor for reuse.

Extract the blanking cap and discard, recycling where

possible. Ret the adaptor and secure with the screws

previously removed (Fig. 22).

7. The Assure FGHR can now be tted (Fig. 23). Locate

the slots in the rear of the FGHR on the tabs of the

ue collar & upper plate. Lower the FGHR to engage

the ue connection on the underside with the boiler

adaptor, taking care to not displace the seals.

8. As the FGHR is lowered the ue & collar assembly

will slide down the channels to the lowest position.

9. Connect the ow & inlet pipes to the ttings on the

underside of the FGHR unit ensuring that the sealing

washers are in place.

10. Continue with the installation and commissioning of

the boiler.

Rear Flue - Drill Hole Ø125mm

Upper Plate

Lower Plate

Fig. 16

Template

Upper Plate

Lower Plate

Fig. 17

Wall

Thickness

+17 mm

Flue in Sliding

Collar

Wall Thickness +17 mm

Foam Seal

Fig. 18

Fig. 19

Fig. 20

Fig. 21

1

3

2

1

2

Flow Pipe

Inlet

Pipe

Keep Flue

Uppermost in

Hole

Priming

Fig. 22

Fig. 23

Locate Slots in

FGHR on Tabs

Direct Rear Flue

tted to FGHR