TABLE OF CONTENTS

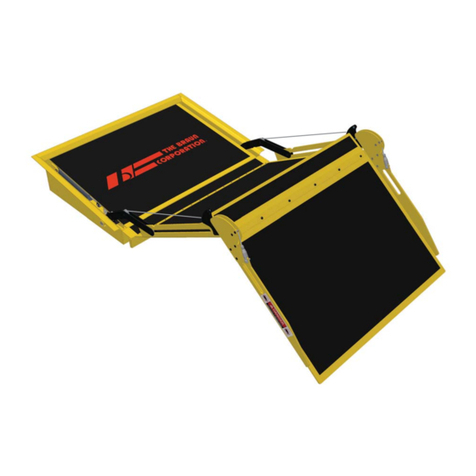

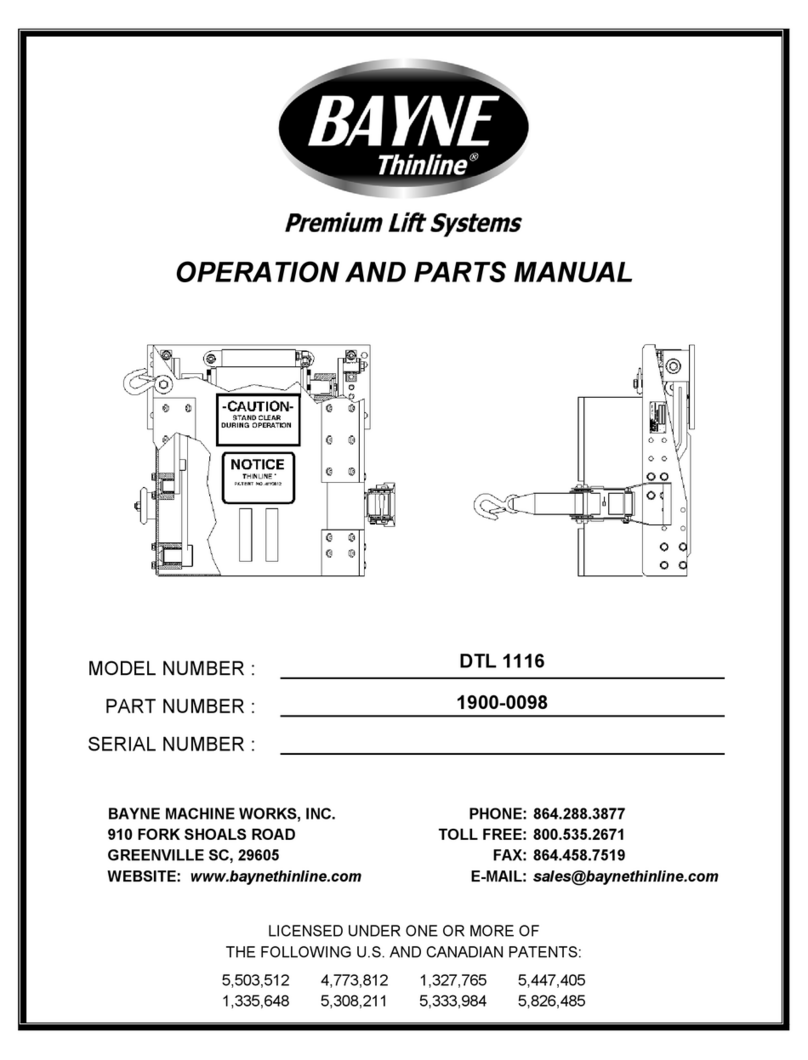

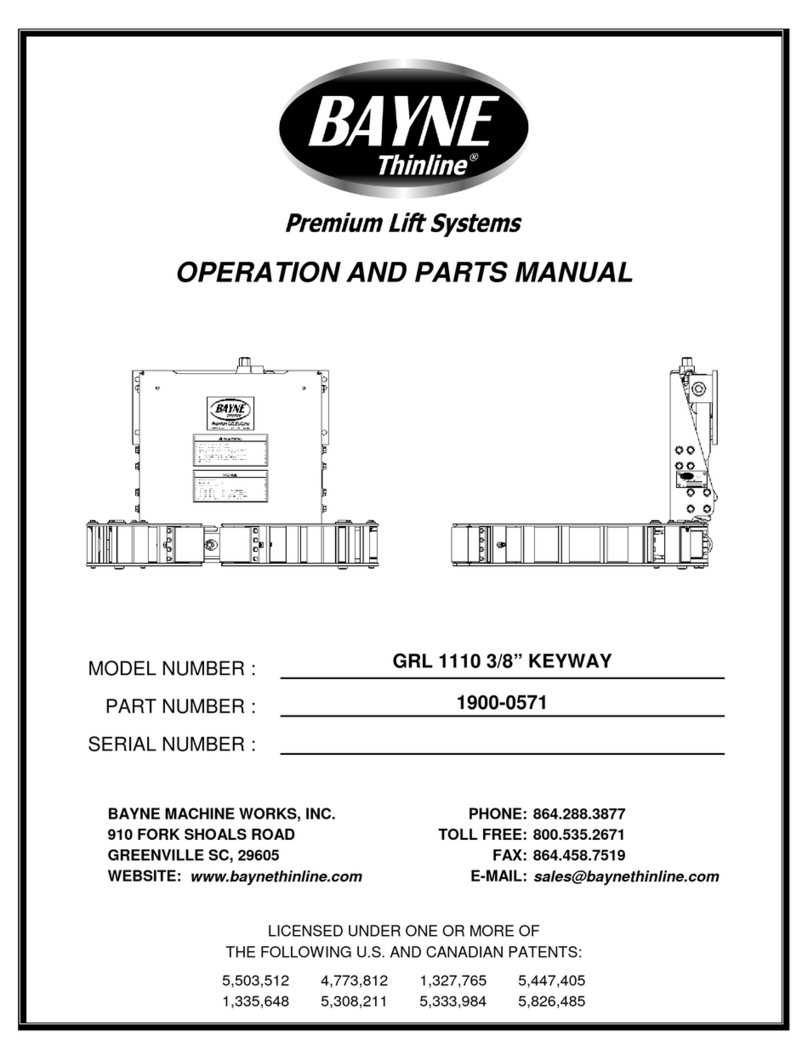

GRL 1110

Printed in U.S.A.

Copyright 2016, Bayne Premium Lift Systems

Issued August 2016

Revision No: 003

........................................................................................................................................................................................2Specifications

........................................................................................................................................................................................4Installation Instructions

........................................................................................................................................................................................7Operation Instructions

........................................................................................................................................................................................8Maintenance Instructions

........................................................................................................................................................................................9Actuator Assembly Instructions

........................................................................................................................................................................................20Troubleshooting Chart

........................................................................................................................................................................................21Appendix A - Assembly Drawings and Part Numbers

........................................................................................................................................................................................221900-0560 - GRL 1110 Lifter Assembly

........................................................................................................................................................................................254800-0272 - GRL Faceplate Weldment

........................................................................................................................................................................................264800-0277 - GRL Clamp Arm Link Weldment

........................................................................................................................................................................................274800-0060 - GRL Clamp Arm Assembly

........................................................................................................................................................................................286065-2710 - GRL Control Valve

........................................................................................................................................................................................293112-1044 - GRL Clamp Cylinder Assembly

........................................................................................................................................................................................302000-1230 - Torque Bearing Assembly

........................................................................................................................................................................................312000-1338 - Lower Idler Bearing Assembly

........................................................................................................................................................................................322000-1335 - Upper Idler Bearing Assembly

........................................................................................................................................................................................33H5900001 - GRL Series Specifications

........................................................................................................................................................................................356900-0733 - Hydraulic Schematic

...................................................................................................................................................................... 37

Index