ZDK 250 135/155Contents

3www.zepro.com

Contents

1 Important information ..................................................................................... 5

1.1 Attention! ................................................................................................ 5

1.2 Technical support.................................................................................... 5

1.3 Identication ........................................................................................... 6

1.4 CE marking............................................................................................. 6

1.5 Product approval ................................................................................... 6

1.6 Hydraulic oil ............................................................................................ 6

1.7 Guarantee............................................................................................... 6

1.8 Repainting .............................................................................................. 7

1.9 Battery maintenance............................................................................... 7

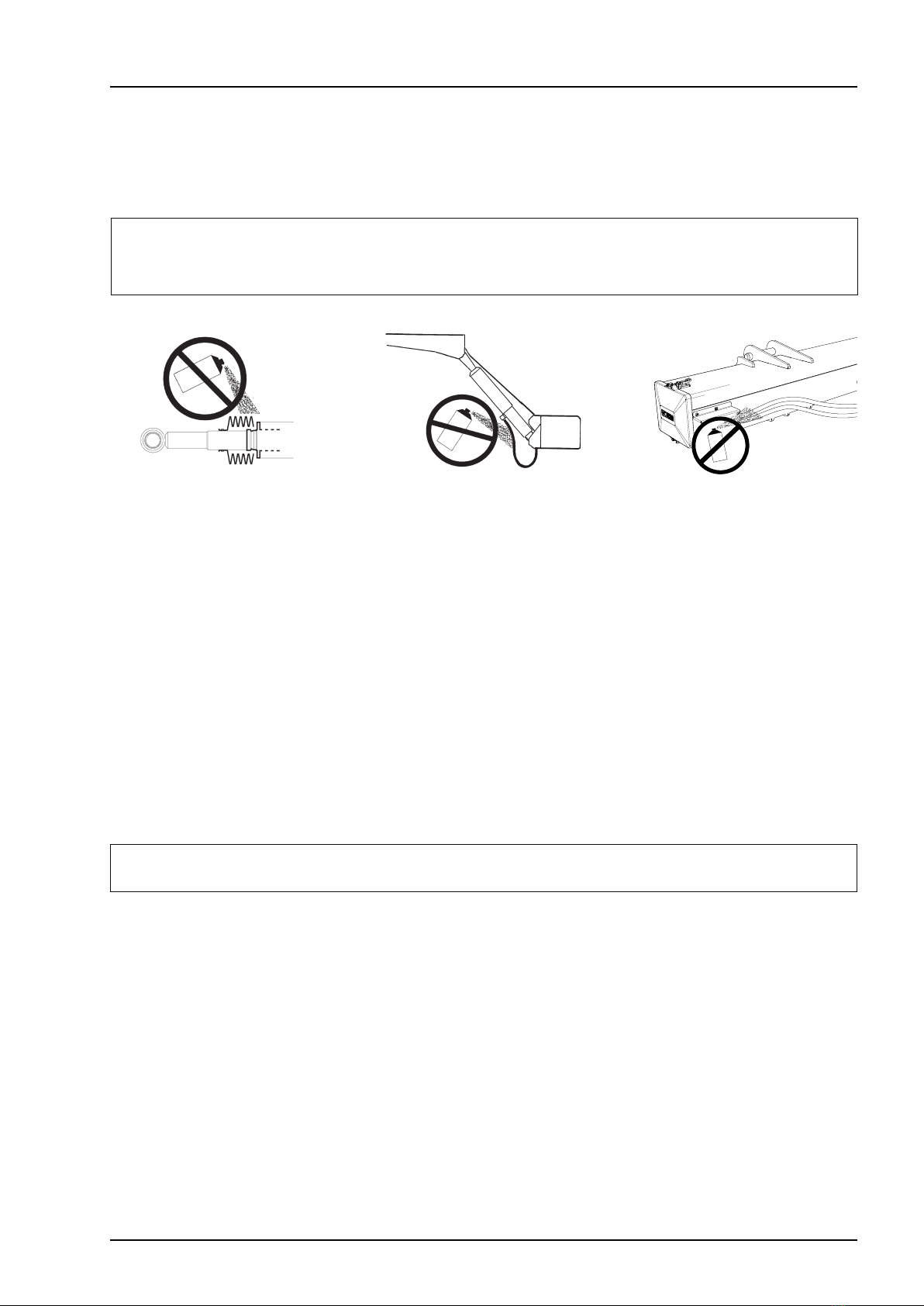

2 Safety rules ....................................................................................................... 8

2.1 Moving parts - free movement................................................................ 8

2.2 Connection of third-party equipment is forbidden................................... 8

2.3 Installation .............................................................................................. 8

3 Before installation ............................................................................................ 9

3.1 Vehicle chassis requirements................................................................. 9

3.2 Statutory dimensions .............................................................................. 9

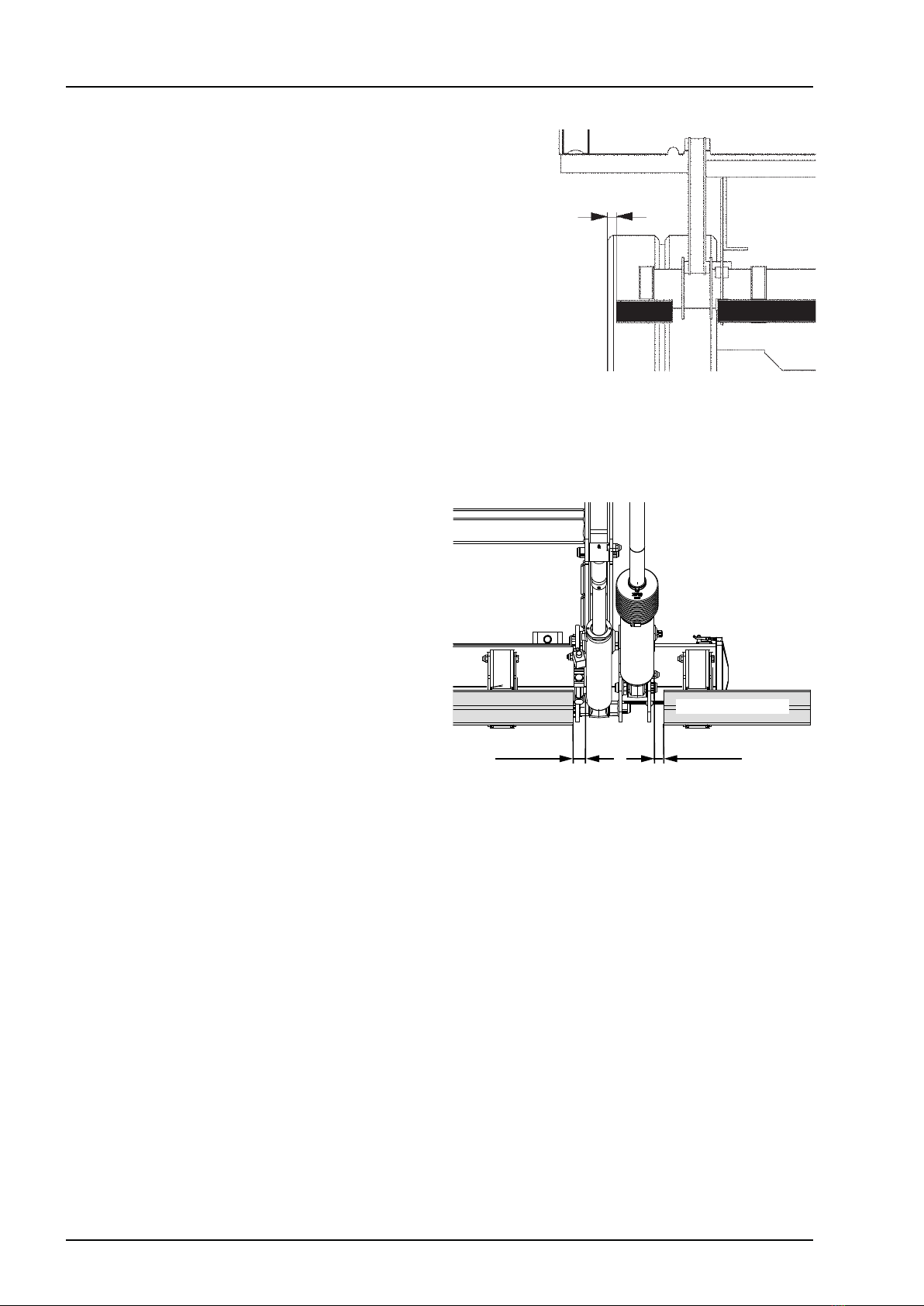

3.3 Calculating the installed dimensions .................................................... 11

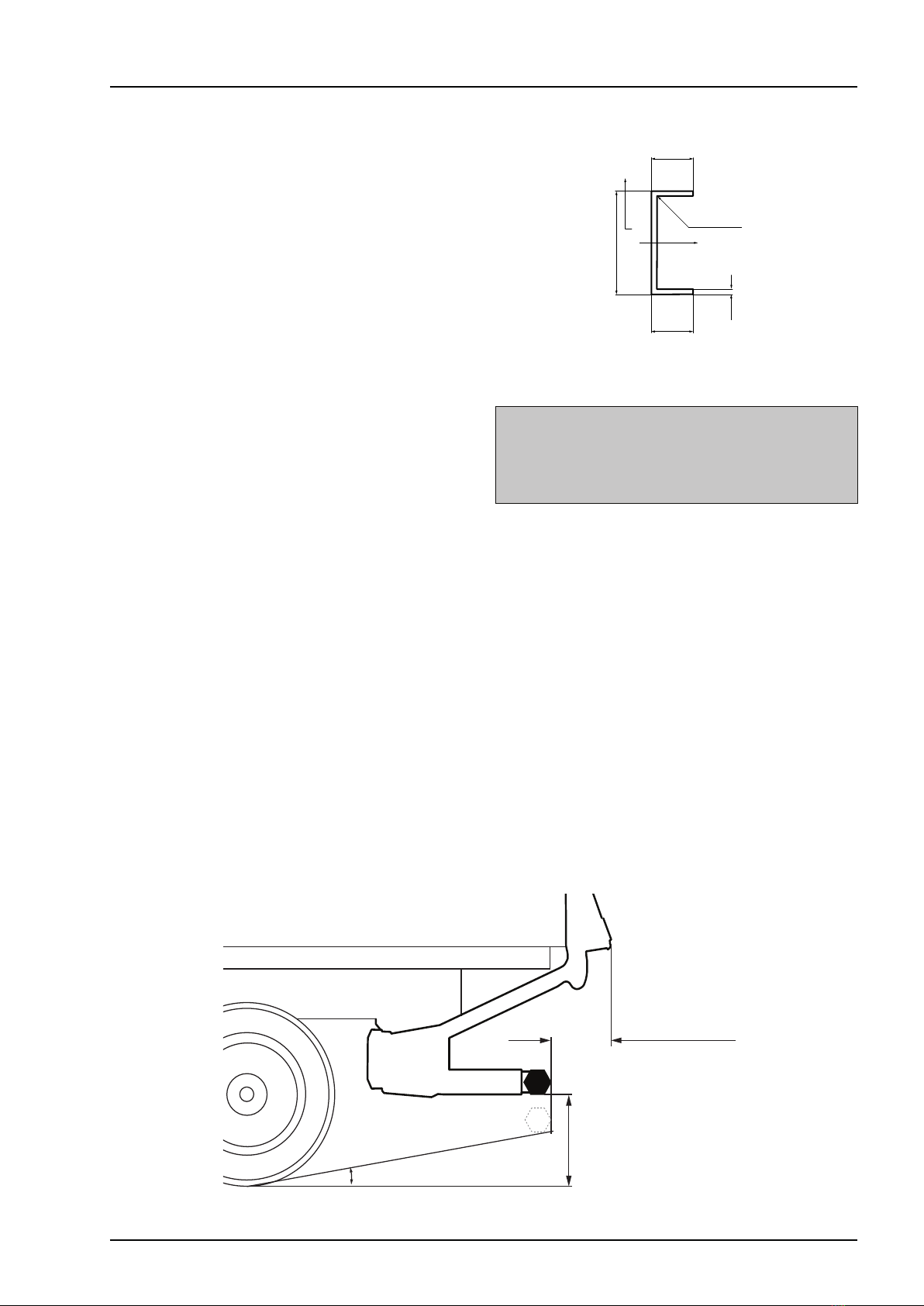

3.4 Rear member cut-outs.......................................................................... 14

3.5 Prepare the tail lift................................................................................. 15

3.6 Temporary connection .......................................................................... 17

4 Installation ..................................................................................................... 20

4.1 Platform ................................................................................................ 23

4.2 Armstops .............................................................................................. 28

4.3 Sealing strip (horizontal)....................................................................... 29

4.4 Sealing strip (vertical) ........................................................................... 29

4.5 Purging the cylinders ............................................................................ 31

4.6 Angle sensor / Inclinometer.................................................................. 32

4.7 Controllers ............................................................................................ 34

5 Cable routing ................................................................................................. 36

5.1 General................................................................................................. 36

5.2 Sizing electrical systems ...................................................................... 37

5.3 Main power cable, earth cable, main fuse and main switch ................. 38

5.4 Control power cable.............................................................................. 40

5.5 Open platform alarm............................................................................. 40

5.6 Foot controller / Warning lights............................................................. 40

6 Connection...................................................................................................... 41

6.1 Cable grommet ..................................................................................... 41

6.2 Connection ........................................................................................... 42

7 Powering up the tail lift.................................................................................. 50