Bayrol Flockmatic Vario User manual

Flockmatic Vario

Version 2.1

GB

Operating manual

Flocculant dosing pump

3

Index

1GENERAL SAFETY INSTRUCTIONS.......................................................................................................4

2OVERVIEW ................................................................................................................................................ 5

3OPERATION .............................................................................................................................................. 5

3.1 Button functions.................................................................................................................................... 5

3.2 Operating states ....................................................................................................................................5

3.3 Menu structure.......................................................................................................................................6

3.4 Menu items............................................................................................................................................. 6

4INSTALLATION AND MAINTENANCE..................................................................................................... 7

4.1 Safety instructions for installation and mintenance tasks................................................................ 7

4.2 Mounting................................................................................................................................................. 7

4.3 Electrical connection............................................................................................................................. 7

4.4 Replacing the device fuse ....................................................................................................................7

4.5 Installation in the circulation system .................................................................................................. 8

4.6 Maintenance...........................................................................................................................................8

4.6.1 14-day maintenance............................................................................................................................8

4.6.2 Yearly maintenance.............................................................................................................................8

4.6.3 Cleaning ..............................................................................................................................................8

4.6.4 Hose replacement Flockmatic Vario ...................................................................................................8

4.7 Winter care ............................................................................................................................................. 9

4.8 Decommissioning..................................................................................................................................9

5TECHNICAL DATA.................................................................................................................................... 9

6SPARE PARTS..........................................................................................................................................9

4

1General safety instructions

This operating manual contains basic instructions that must be

complied with for installation, commissioning, operation, and

maintenance. Consequently this operating manual must always

be read by the fitter as well as the responsible owner prior to

installation and commissioning, and must be accessible to

every user of the device. In addition, all other safety

instructions in this document must be strictly complied with.

Read and comply with all instructions.

To reduce the danger of injury, do not allow children to use this

product.

Dangers due to failure to comply with the safety

instructions

Failure to comply with the safety instructions can result in

hazards for personnel as well as for the environment and the

device.

Failure to comply with the safety instructions can result in loss

of all claims for damage compensation.

DANGER!

Inadequate qualification of personnel

Dangers due to inadequate qualification of

personnel!

Possible consequence: Death or severe injury,

significant damage to material assets.

The system owner must ensure compliance

with the required qualifications.

All activities must only be carried out by

personnel who are qualified to perform such

activities.

Access to the system must be prevented for

inadequately qualified personnel..

IMPORTANT NOTE!

Compliance with the applicable accident

prevention regulations and the other statutory

regulations and the generally acknowledged

safety regulations must be ensured by the system

owner!

IMPORTANT NOTE!

Only liquid flocculants from the company

BAYROL may be dosed with the Flockmatic

Vario. The use of flocculants or other products

from other manufacturers results in loss of all

damage compensation claims!

DANGER!

Compliance with the protection rating

After tasks on the Flockmatic Vario, if the housing

or individual cable glands are not properly closed,

so that a reliable seal is ensured, moisture can

penetrate into the device.

Possible consequences: Damage or

destruction of the Flockmatic Vario,

malfunctions.

After all tasks performed on the device,

ensure a safe seal..

5

2Overview

The Flockmatic Vario is a high quality peristaltic pump for

dosing of liquid flocculants in the circulation circuit of a

swimming pool.

The swimming pool must be equipped with an adequately

dimensioned sand filter system.

3Operation

The Flockmatic Vario is operated via the two-row display with 2

x 16 characters and the membrane pushbuttons.

3.1 Button functions

Button

Function

Switches from the basic view to the menu

structure.

-Switches from the menu structure back

to basic view.

-Switches from one menu item to the

next higher menu item.

-When exiting an input menu the

selected settings are not applied.

-Opens the input menu of a menu item.

-Confirms the changed settings in an

input menu.

and

-Navigates between the individual menu

items.

-Changes the setting values in the input

menu.

3.2 Operating states

Status

Description

Off

The display is switched off, the pump does

not display, the filling level of the canister

for flocculent is not evaluated, and no

input can be made. The green LED

flashes at intervals of approx. 2 sec.

Activate the button for approximately

1 second to switch on the device; the

device is in operating status Off.

On

The green LED flashes briefly at

intervals of approx. 2 sec, the display is

switched on and inputs can be made.

Briefly activate the button to switch

the device to automatic mode.

Dosing

The green LED is illuminated

continuously. The display is switched on

and inputs can be made.

If the filling level of the canister for

flocculent is low, an alarm will be

triggered.

Fast vacuum function:

With this function the air can be quickly

removed from the suction and pressure

hose. For this, the dosing pump is

switched on manually with the

button for approximately one minute with

full capacity. Subsequent pushing of the

button switches off the pump as

needed before one minute elapses.

6

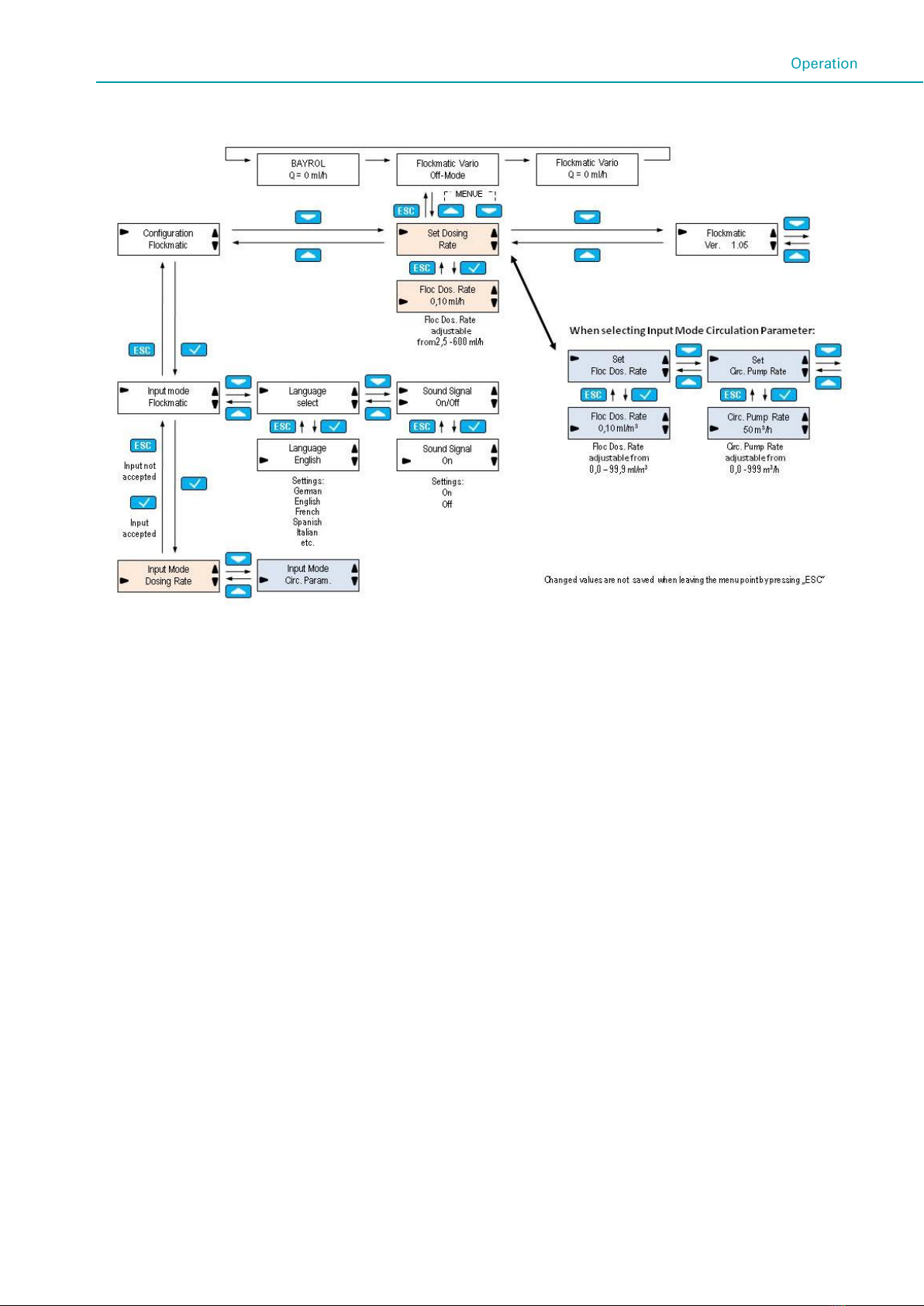

3.3 Menu structure

3.4 Menu items

Basic view:

In the basic view the momentary delivery capacity is displayed,

and in operating status Off, the current mode is displayed.

Flockmatic configuration:

Input mode - delivery capacity

There are 2 possibilities for entering the delivery capacity:

1. Input mode dosing capacity

If this input mode is selected the delivery capacity is

entered directly in ml/h (from 2.5 - 600 ml/h)

2. Input mode - circulation parameters

If this input mode is selected the delivery capacity is

calculated based on the two parameters "dosing

quantity" and "circulation" that must be input.

The necessary dosing quantity of flocculent per m3of

circulation capacity depends on the concentration of

the flocculent used.

The circulation capacity is set in accordance with the

circulation pump used.

Available languages

The device can be configured for multiple languages.

Acoustic signal

The acoustic signal that is triggered when the filling level

of the canister for flocculent is low, can be activated or

deactivated. The visual alarm signal will always be output

regardless of this setting.

Output of the alarm via the PoolManager®/Analyt

(only devices with colour display):

If an alarm should not be output via the Flockmatic Vario,

but rather should be output via one of the devices cited,

then the BNC connector of the suction lance is connected

directly to the control device. In this case the input on the

Flockmatic Vario must be bypassed with a BNC

terminating connector.

In this case the Flockmatic Vario must be connected via

the module in the PoolManager®/Analyt that is provided for

this purpose.

See the PoolManager®/Analyt manual for more

information on connection and configuration.

7

4Installation and maintenance

4.1 Safety instructions for installation

and mintenance tasks

DANGER!

Danger due to electric shock

The Flockmatic Vario is energised as soon as

voltage is applied on the mains input. Contact

with energised parts can result in electric shock.

Possible consequence: Serious or fatal

health impairment, damage to material

assets

Installation and maintenance tasks on the

device must always be executed in de-

energised status.

When performing tasks safeguard the

device from being switched on!

Only connect cables in de-energized status.

A safety device that is independent of the

pump should always be present .

The valid country-specific safety regulations

must be complied with.

Directly after completing the tasks, all safety

devices and protective devices must be

reattached, i.e. must be rendered functional.

Failure to comply with the safety instructions

can result in defects of the device and life-

threatening danger, with the consequence

of loss of warranty.

4.2 Mounting

Level, vertical surface.

The free area surrounding the device must be large enough

to ensure that trouble-free operation and maintenance are

possible. The cover must always be removable.

Pump housing vertical, hose connections downwards.

The display of the regulator should be approximately at eye

level.

Below the device, at least 20 cm of free space is required

for installation of the hoses.

There must be no parts that are sensitive to moisture below

the device.

A wet room earth contact electrical outlet with continuous

current at a maximum distance of 1.5 m.

All hoses and cables must be laid out in such a manner that

they are kink-free and free of abrasion.

No hose line should be longer than 5 m

The hoses must not be routed directly over heat-conducting

pipes or systems.

Direct sunlight, thermal radiation, the effects of frost and

moisture must be avoided.

Ensure adequate aeration.

Ensure that measures are in place in the event of a leak in

the pump or the dosing hoses (e.g. defined discharge,

collecting container).

The base plate can be used as a drilling template by

holding it at the intended location and marking the location

of the bores on the wall..

4.3 Electrical connection

The Flockmatic Vario has been designed and built in

accordance with the applicable guidelines. Prior to leaving the

plant the product was carefully tested and it left the plant in

faultless condition.

Safe operation is only possible if all instructions contained in

this manual and the generally applicable guidelines are

complied with.

The supply voltage for the device must not exceed 240 V/50

Hz. The permitted operating temperature is 5 to 45ºC, the

permitted humidity is 0-90%.

As is customary for all electrical connections, ensure that all

plug connections are protected against water.

IMPORTANT NOTE

Ensure that the Flockmatic Vario is only

supplied with power when the circulation pump

is running!

4.4 Replacing the device fuse

If the device is subjected to an unusual operating state, this can

cause a fuse to trip; in this case the fuse must be replaced.

IMPORTANT NOTE

Always identify what caused the fuse to trip.

Always ensure that the cause is completely

eliminated before placing the Flockmatic Vario

is service again.

Replacing a fuse:

Disconnect the Flockmatic Vario from the power supply.

Remove the pressure and suction hose.

Take the cover off of the rotor.

Pull off the blue housing frame from the front.

Open the housing by unscrewing the 4 Phillips head

screws.

Pull off the upper part of the housing from the front.

Turn the cover of the black fuse holder a quarter turn to the

left and pull the fuse up and out.

Insert a new (1 A/250 V MT) fuse.

Assembly is executed in the reverse sequence.

8

4.5 Installation in the circulation system

Install the Flockmatic Vario in the circulation system as follows.

1 Flockmatic Vario

2 Quickflock fluid

3 Heat exchanger

4 Filter

5 Injection after the circulation pump

6 Filter pump

7 Injection before circulation pump

(recommended if counter pressure is higher than 0.8 bar)

Connect the suction hose (connection to the canister) on the

left connection of the pump, connect the pressure hose

(connection to the injection nozzle) on the right connection of

the pump.

IMPORTANT NOTE

For all hose and mounting connections, ensure

that these connections do not leak.

Liability is excluded if there are leaks!

4.6 Maintenance

Some parts of the Flockmatic Vario are subject to wear due to

chemical and mechanical stress. Thus regular inspection is

required for safe, long-term operation. Regular preventive

maintenance of the system protects against unscheduled

interruptions of operation.

4.6.1 14-day maintenance

Visual inspection of all dosing lines and the dosing hose

for leaks, replace if necessary

4.6.2 Yearly maintenance

Visual inspection of all dosing lines, replace if necessary

Replacement of the hose of the dosing pump

4.6.3 Cleaning

Clean the surfaces of the device with a soft lint-free cloth as

needed. To do this only use a little water, if necessary

IMPORTANT NOTE

Do not use aggressive cleaners

4.6.4 Hose replacement Flockmatic Vario

NOTE

Never grease the hose!

NOTE

Only use original spare pump hoses!

DANGER!

Danger due to chemicals

When pulling off the pump hose, corrosive

product residues can escape.

Possible consequence: Serious health

impairment (acid burns) and damage to

material assets

Always empty the pump hose and supply

lines first.

If necessary wear protective goggles and

protective gloves and protect the

surroundings against escaping product

residues with a cloth.

DANGER!

Danger due to rotating parts

The rotor of the dosing pump can start-up

abruptly.

Possible consequence: Danger of crushing

for fingers!

Ensure that the dosing pump remains

disconnected from the operating voltage while

replacing the hose (unplug the mains plug)!

The hose of the dosing pump is replaced without dismounting

the rotor.

Remove the emptied suction and pressure hoses from the

hose holder. To do this open the blue clamping screws.

Take the transparent cover 1 off of the pump.

Take off the blue cover 2 of the rotor.

Turn rotor 3 in such a manner that the flat side points to

the left and is vertical.

Pull the hose holder 4 out of its holder and lift it on the left

side.

Now turn the rotor 3 clockwise and follow with the hose

lifted until it is completely free.

Proceed in the reverse sequence for mounting.

The hose only, or the hose together with the hose holder can

be replaced.

9

We recommend replacing the hose together with the hose

holder. (Replacement hose set)

Art.-no.

Description

127402

Replacement hose Flockmatic / Vario S

127403

Replacement hose set Flockmatic / Vario S

NOTE

If only the hose is replaced, you must strictly

ensure the following when mounting the hose

Firm seat of the hose on the nozzles.

The hose must not be fitted on twisted under

any circumstances.

You must ensure that the hose connectors

are firmly seated..

4.7 Winter care

For brief interruption of use (e.g. several days) no special

measures are required.

For longer interruptions of operation that extend over several

weeks, as in the case of winter care the following tasks must be

executed:

Remove the suction lance from the canister and rinse it with

water.

Seal the delivery container, store it in a cool and dry

location and protect against UV radiation.

Rinse the hose pump with water.

Take the dosing hose out of the pump.

Flush all hoses with water and empty them completely.

After the winter season, all components must be examined to

determine that they are functional. All dismounted parts must

be remounted at their intended position. Check the settings of

the Flockmatic Vario.

4.8 Decommissioning

If the device will be disposed of after its service life, it must be

flushed out and the water drained. The device has been

manufactured in accordance with the provisions of the ROHS

Directive and the Waste Electrical and Electronic Equipment

Directive. It does not belong in domestic waste.

Take the device to a suitable and appropriate collection point.

5Technical data

Parameter

Value

Supply voltage

230VAC

Power consumption

max. 20VA

Ambient temperature

min.5 - max. 45°C

Delivery capacity

2,5 –600ml/h

Counterpressure

max. 3 bar

Protection class -

housing

P65

Dimensions

(without mounting plate):

approx. 93 x 150 x 130 mm

(WxHxD)

6Spare parts

Art.-No.

Picture

Description

127 450

Flockmatic Vario

172 130

Suction fitting, rigid PR

127403

Replacement hose set

Flockmatic / Vario S

127402

Pump hose Flockmatic /

Vario S

100 509

PE dosing hose 6x4X1

(10 m)

171 207

Injection nozzle, 0.5 bar

Table of contents

Popular Swimming Pool Pump manuals by other brands

Polygroup

Polygroup SUMMER WAVES ST1100 owner's manual

NOVARDEN

NOVARDEN NSH35s Installation and user manual

Dankoff Solar Products

Dankoff Solar Products SunCentric P instruction manual

Badu Tec

Badu Tec Eco Touch Series Original installation and operating manual

Pentair

Pentair SWIMMEY Series installation guide

Hayward

Hayward TriStar Waterfall owner's manual