4

INSTALLATION, OPERATIONS AND MAINTENANCE MANUAL

General information

This manual contains procedures for receiving,

handling, storage, equipment installation,

operation, and maintenance and service of

ReliaGear LV SG low voltage switchgear.

Notice: The personnel responsible for installing,

operating, and servicing this equipment should

be thoroughly familiar with the contents of

this manual.

Before any installation work is performed,

thoroughly read and understand the material in this

instruction manual and the drawings furnished

with the equipment. The As-built documentation

shipped with the equipment includes the Summary,

Front View, Elementary Diagram, and Connection

Diagram. This material is located in a forward

compartment tagged "INSTRUCTIONS IN THIS

COMPARTMENT." The documentation provides all

of the information necessary for installation of the

switchgear. When requesting information from

ABB, include the complete data appearing on the

equipment nameplate, requisition number,

summary number, and elementary diagram

number. The nameplate is located in

the lower left, front corner of the lineup.

When requesting information concerning any

specific item furnished with the switchgear, refer

to that item by description, part number, its

location within this manual, and any applicable

drawing number. Any material external to the

equipment, which may be required to meet local

codes (such as mats, screens, railings, etc.), is not

furnished by ABB.

If there are any questions or requirements not

covered in this manual or in the accompanying

drawings, please contact your ABB

sales representative.

Introduction

Instruction book arrangement

Information and procedures in this instruction

book are divided as follows:

Introduction: gives a brief account of the

equipment's function and provides for general

information, and applicable data for the equipment

and its components.

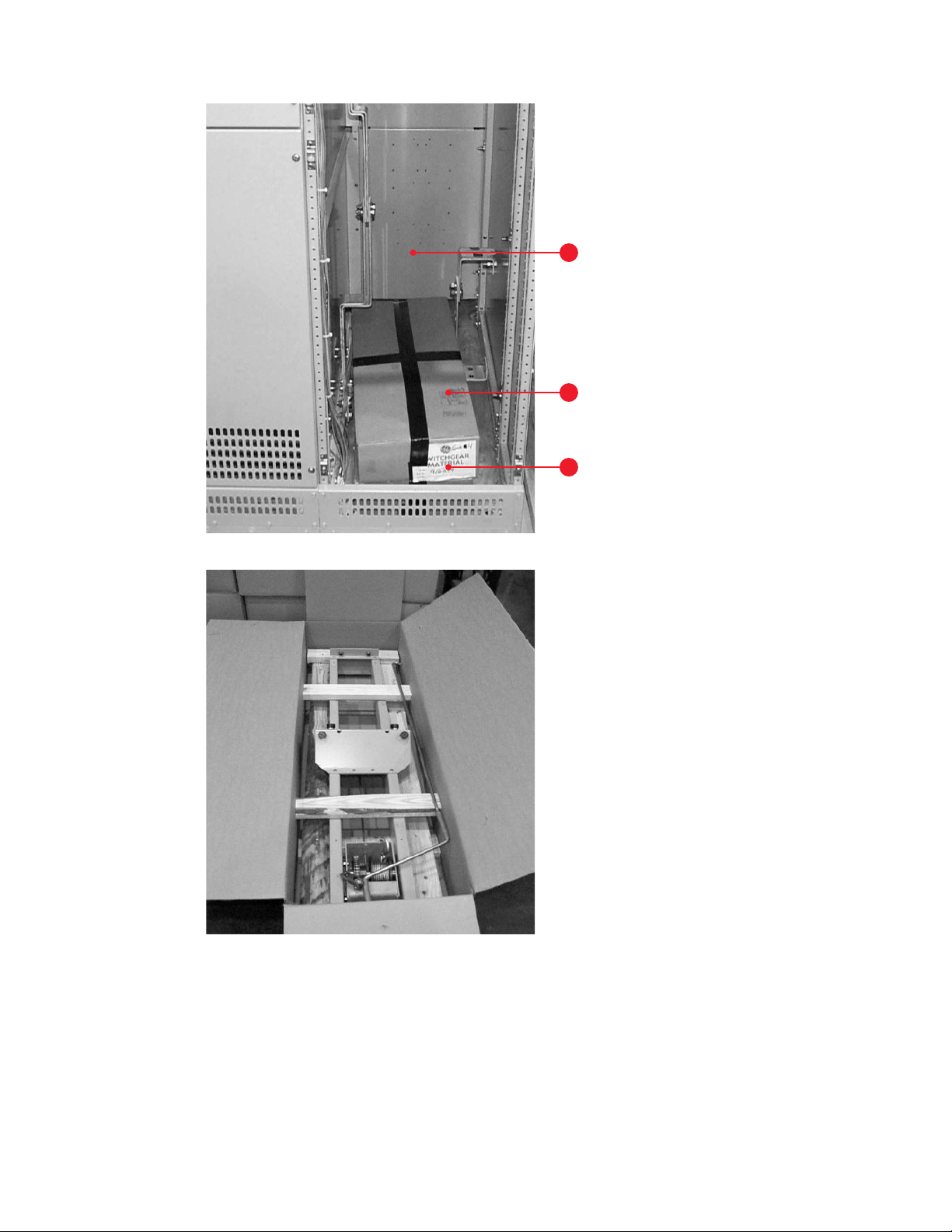

Receiving, handling and storage: describes

procedures required for receiving and handling the

equipment and how to prepare it for

short-or long-term storage.

Switchgear description: describes the ReliaGear LV

SG low voltage switchgear and its various

components. Included are the section enclosure,

breaker compartment, circuit breakers, instrument

panels and instrument compartments, bus bar

arrangement, incoming cable and busway, ground

and neutral bus, outdoor equipment, and auxiliary

section. This section also explains how the

electrical and mechanical components perform

their assigned functions.

Equipment installation: provides the information

needed prior to installation, site location and

foundation requirements, and how to anchor

the equipment properly and safely. It also covers

installation of peripheral equipment and includes

information on electrical connections and

mechanical construction.

Installing and removing circuit breakers: gives

a step-by-step procedure for lifting the breaker

from the floor, installing it on draw-out rails, and

moving it into the connected position.

A further procedure is given to withdraw a breaker,

remove it from the draw-out rails, and lower it to

the floor. Also included is a description of the

rejection system provided to avoid the inadvertent

use of an incorrect breaker

in a breaker compartment.

DANGER

WARNING

CAUTION

NOTICE