The addresses of our distribution partners are listed on our

homepage www.bdsensors.com. It is possible to download

data sheets, operating manuals, ordering codes and certifi-

cates, as well.

1. General information

1.1 Information on the operating manual

This operating manual contains important information on

proper usage of the device. Read this operating manual care-

fully before installing and starting up the pressure measuring

device.

Adhere to the safety notes and operating instructions which

are given in the operating manual. Additionally applicable reg-

ulations regarding occupational safety, accident prevention as

well as national installation standards and engineering rules

must be complied with!

This operating manual is part of the device, must be kept near-

est its location, always accessible to all employees.

This operating manual is copyrighted. The contents of this op-

erating manual reflect the version available at the time of print-

ing. BD SENSORS is not liable for any incorrect statements

and their effects.

–Technical modifications reserved –

1.2 Symbols used

DANGER! –dangerous situation, which may result in

death or serious injuries

WARNING! –potentially dangerous situation, which may

result in death or serious injuries

CAUTION! –potentially dangerous situation, which may

result in minor injuries

!CAUTION! –potentially dangerous situation, which may

result in physical damage

NOTE –tips and information to ensure a failure-free

operation

1.3 Target group

WARNING! To avoid operator hazards and damages of

the device, the following instructions have to be worked

out by qualified technical personnel.

1.4 Limitation of liability

By non-observance of the operating manual, inappropri-

ate use, modification or damage, no liability is assumed

and warranty claims will be excluded.

1.5 Intended use

- The pressure transmitter DMP 303 / DMP 304 has been

especially designed for the overpressure measuring.

- It is the operator's responsibility to check and verify the

suitability of the device for the intended application. If any

doubts remain, please contact our sales department in or-

der to ensure proper usage. BD SENSORS is not liable

for any incorrect selections and their effects!

- Permissible media are gases or liquids, which are com-

patible with the media wetted parts described in the data

sheet. In addition it has to be ensured, that this medium

is compatible with the media wetted parts. For questions

please contact our sales team!

- The technical data listed in the current data sheet are en-

gaging. If the data sheet is not available, please order or

download it from our homepage.

(http://www.bdsensors.com)

WARNING! Danger through improper usage!

1.6 Package contents

Please verify that all listed parts are undamaged included in

the delivery and check for consistency specified in your order:

- pressure transmitter

- mounting instructions

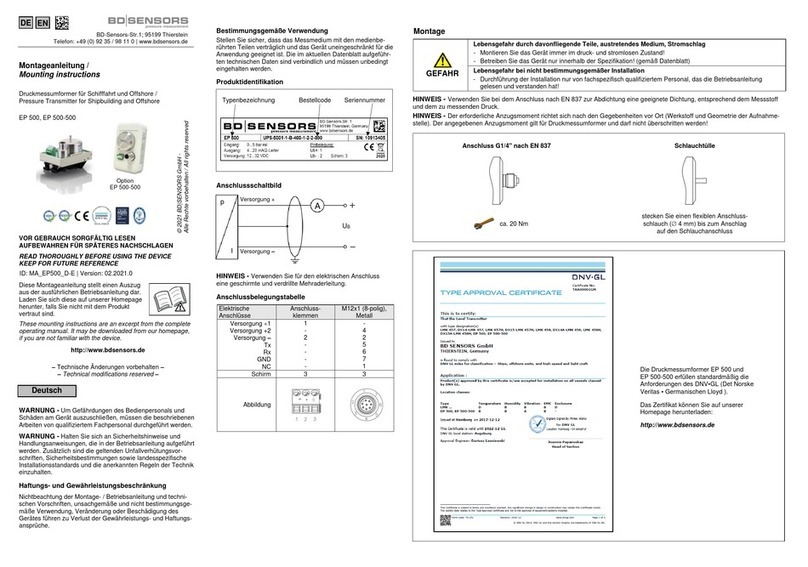

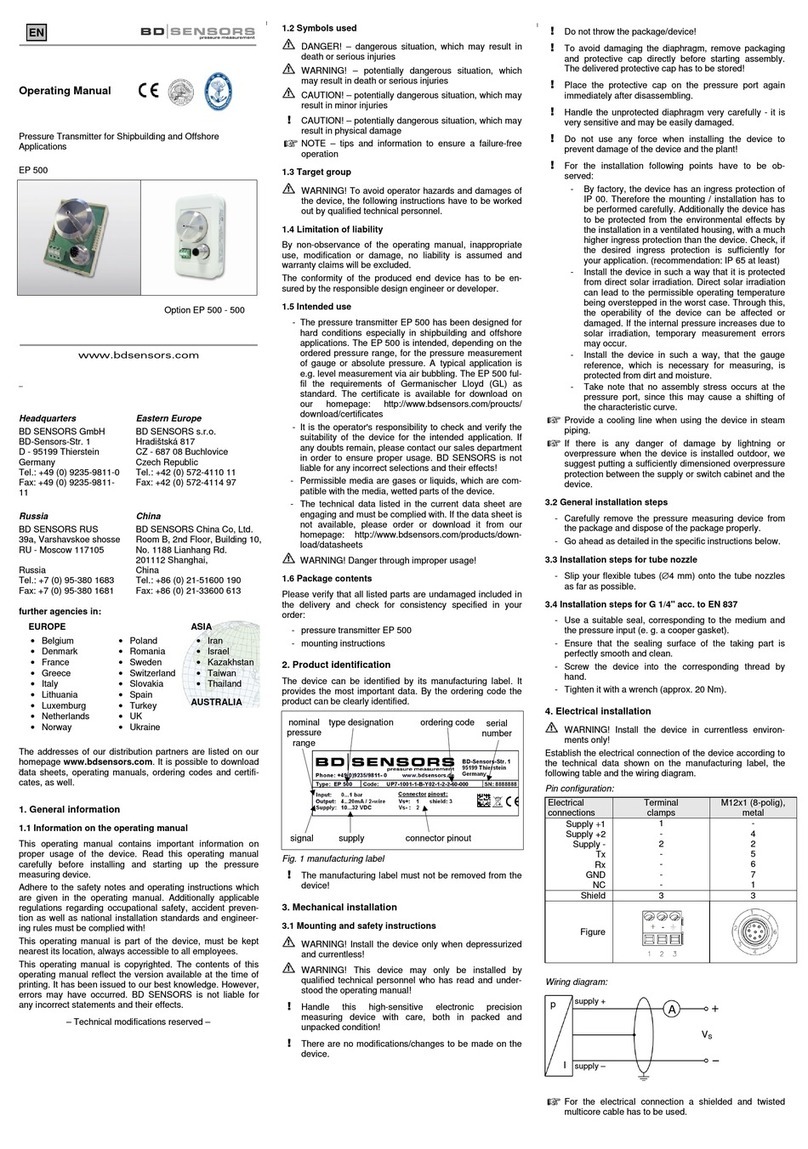

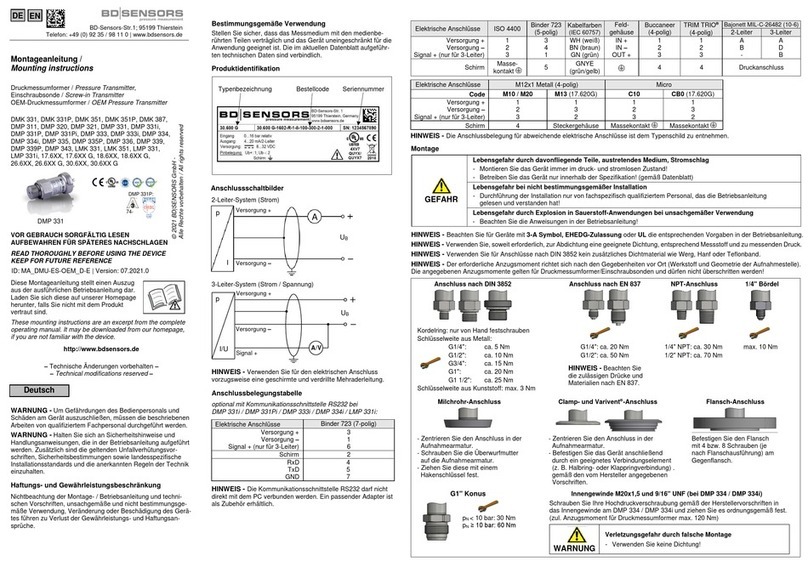

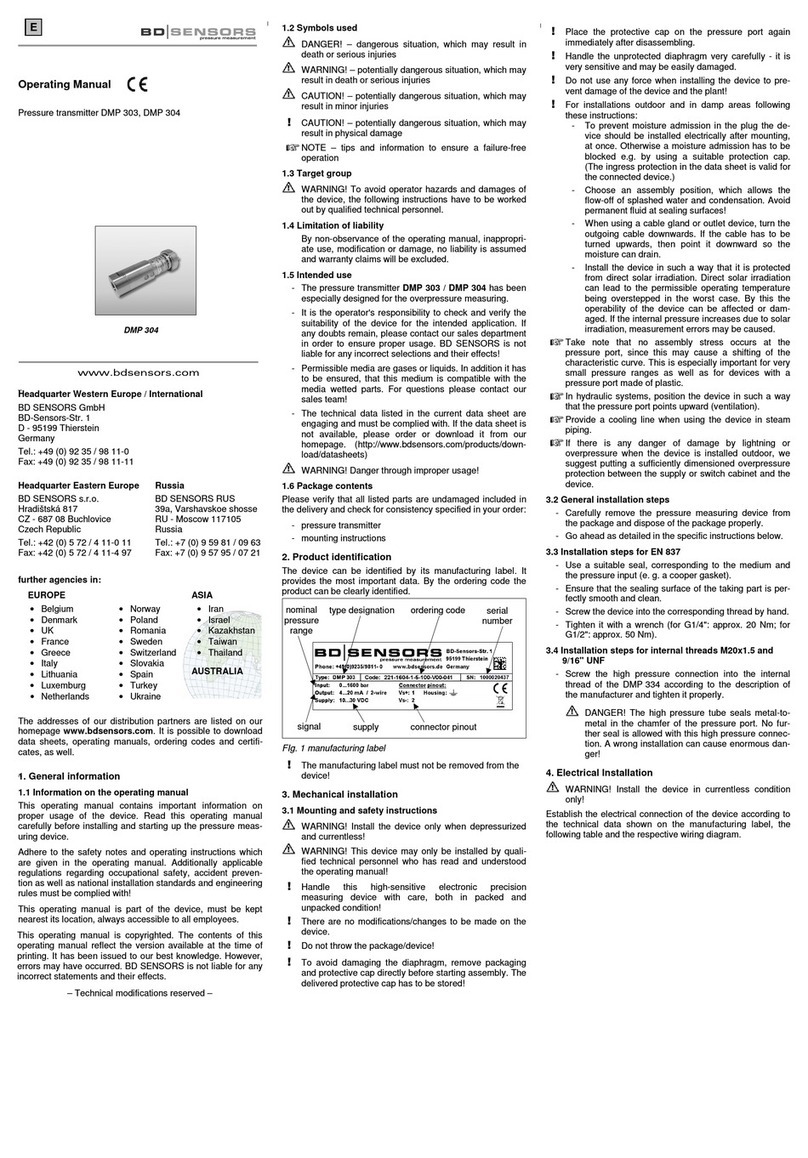

2. Product identification

The device can be identified by its manufacturing label. It pro-

vides the most important data. By the ordering code the prod-

uct can be clearly identified.

FIg. 1 manufacturing label- example

!The manufacturing label must not be removed from the

device!

3. Mechanical installation

3.1 Mounting and safety instructions

WARNING! Install the device only when depressurized

and currentless!

WARNING! This device may only be installed by qualified

technical personnel who has read and understood the op-

erating manual!

!Handle this high-sensitive electronic precision measuring

device with care, both in packed and unpacked condition!

!There are no modifications/changes to be made on the

device.

!Do not throw the package/device!

!To avoid damaging the diaphragm, remove packaging

and protective cap directly before starting assembly. The

delivered protective cap has to be stored!

!Place the protective cap on the pressure port again

immediately after disassembling.

!Handle the unprotected diaphragm very carefully - it is

very sensitive and may be easily damaged.

!Do not use any force when installing the device to prevent

damage of the device and the plant!

!For installations outdoor and in damp areas following

these instructions:

- To prevent moisture admission in the plug the device

should be installed electrically after mounting, at

once. Otherwise a moisture admission has to be

blocked e.g. by using a suitable protection cap. (The

ingress protection in the data sheet is valid for the

connected device.)

- Choose an assembly position, which allows the flow-

off of splashed water and condensation. Avoid per-

manent fluid at sealing surfaces!

- When using a cable gland or outlet device, turn the

outgoing cable downwards. If the cable has to be

turned upwards, then point it downward so the mois-

ture can drain.

- Install the device in such a way that it is protected

from direct solar irradiation. Direct solar irradiation

can lead to the permissible operating temperature

being overstepped in the worst case. By this the op-

erability of the device can be affected or damaged. If

the internal pressure increases due to solar irradia-

tion, measurement errors may be caused.

Take note that no inadmissibly high mechanical stresses

occur at the pressure port as a result of the installation,

since this may cause a shifting of the characteristic curve

or to the demage. This is especially important for very

small pressure ranges as well as for devices with a

pressure port made of plastic.

In hydraulic systems, position the device in such a way

that the pressure port points upward (ventilation).

Provide a cooling line when using the device in steam

piping.

If there is any danger of damage by lightning or

overpressure when the device is installed outdoor, we

suggest putting a sufficiently dimensioned overpressure

protection between the supply or switch cabinet and the

device.

3.2 General installation steps

- Carefully remove the pressure measuring device from the

package and dispose of the package properly.

- Go ahead as detailed in the specific instructions below.

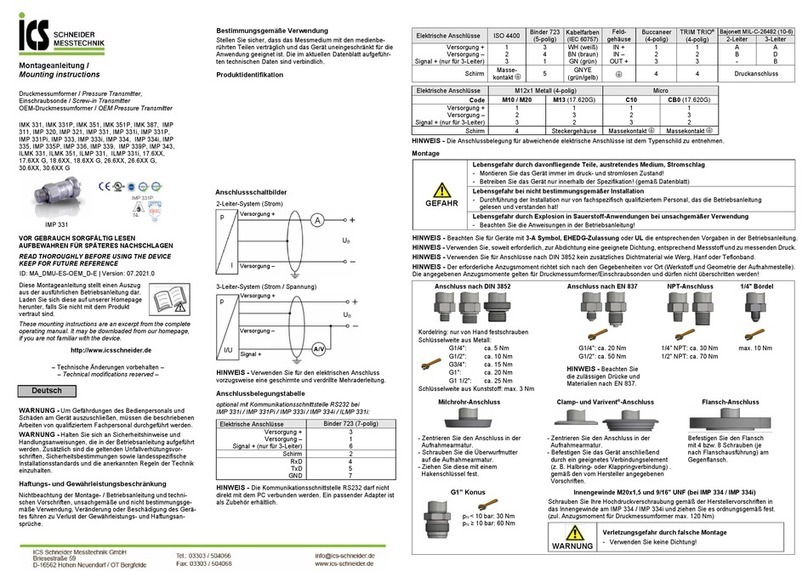

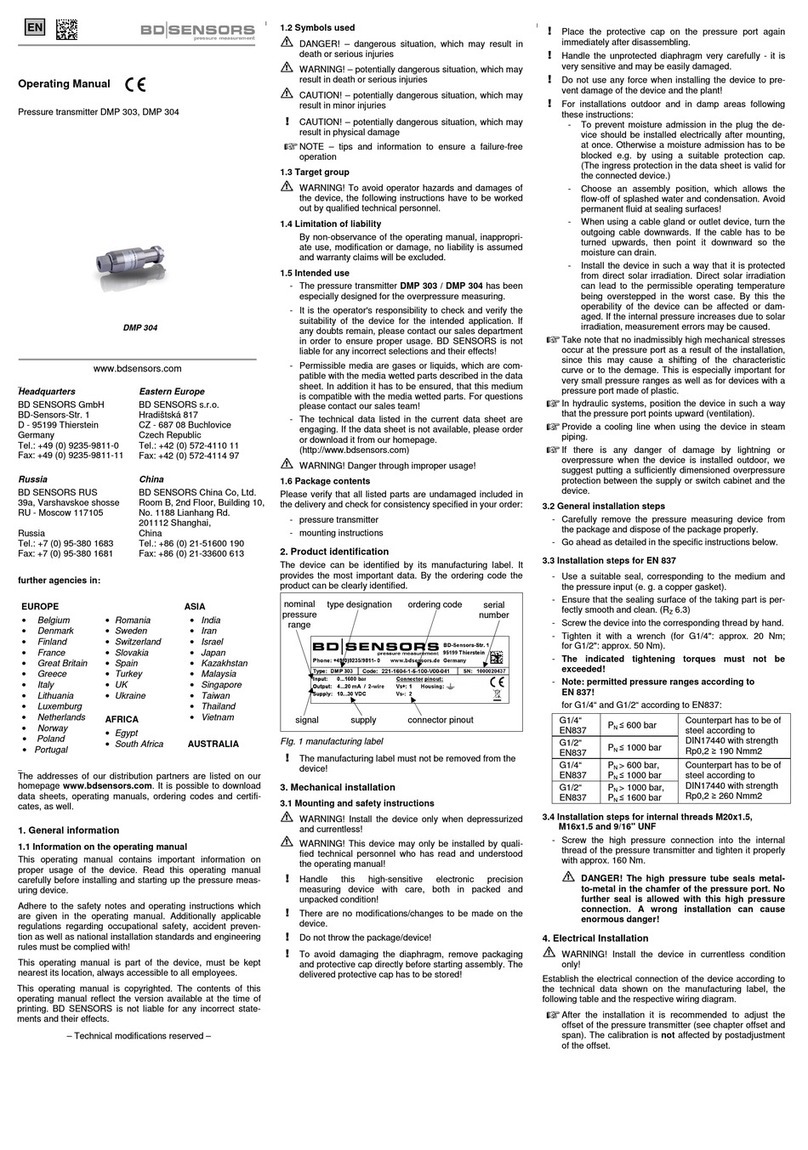

3.3 Installation steps for EN 837

- Use a suitable seal, corresponding to the medium and the

pressure input (e. g. a copper gasket).

- Ensure that the sealing surface of the taking part is per-

fectly smooth and clean. (RZ6.3)

- Screw the device into the corresponding thread by hand.

- Tighten it with a wrench (for G1/4": approx. 20 Nm;

for G1/2": approx. 50 Nm).

- The indicated tightening torques must not be

exceeded!

- Observe the permitted pressures and materials for

G1/4“ and G1/2“ according to EN837: