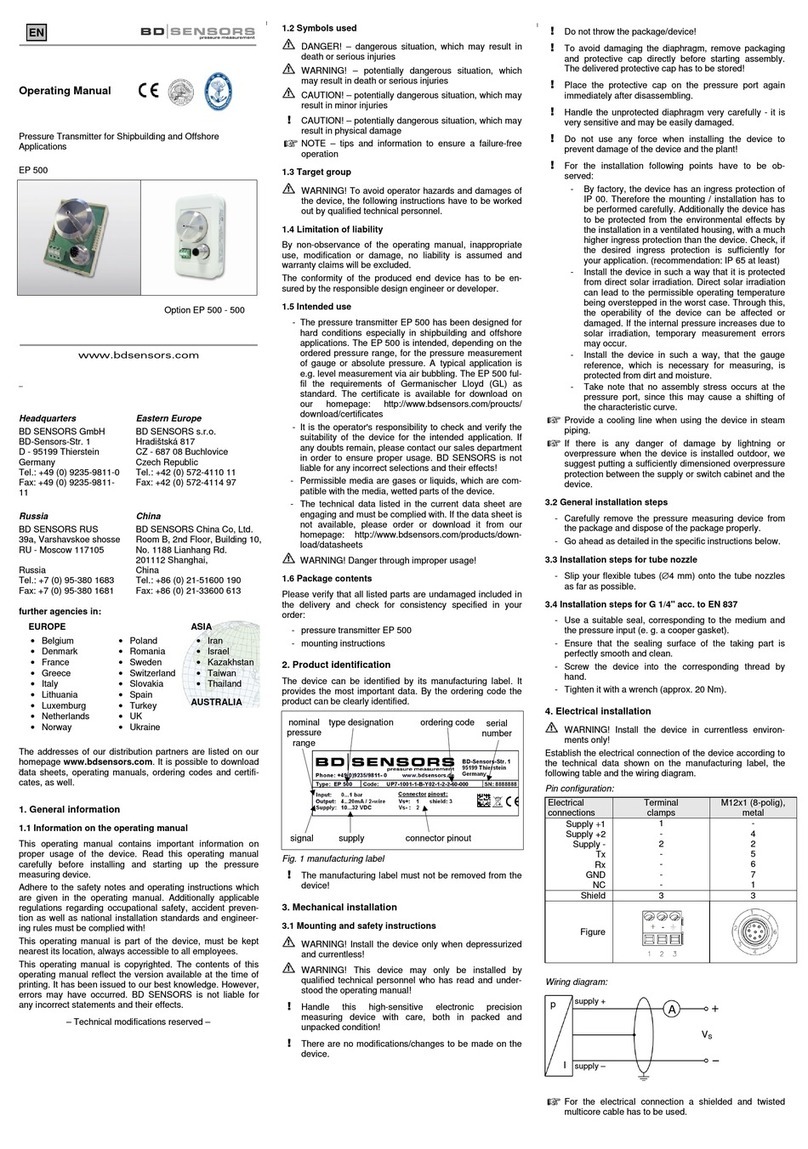

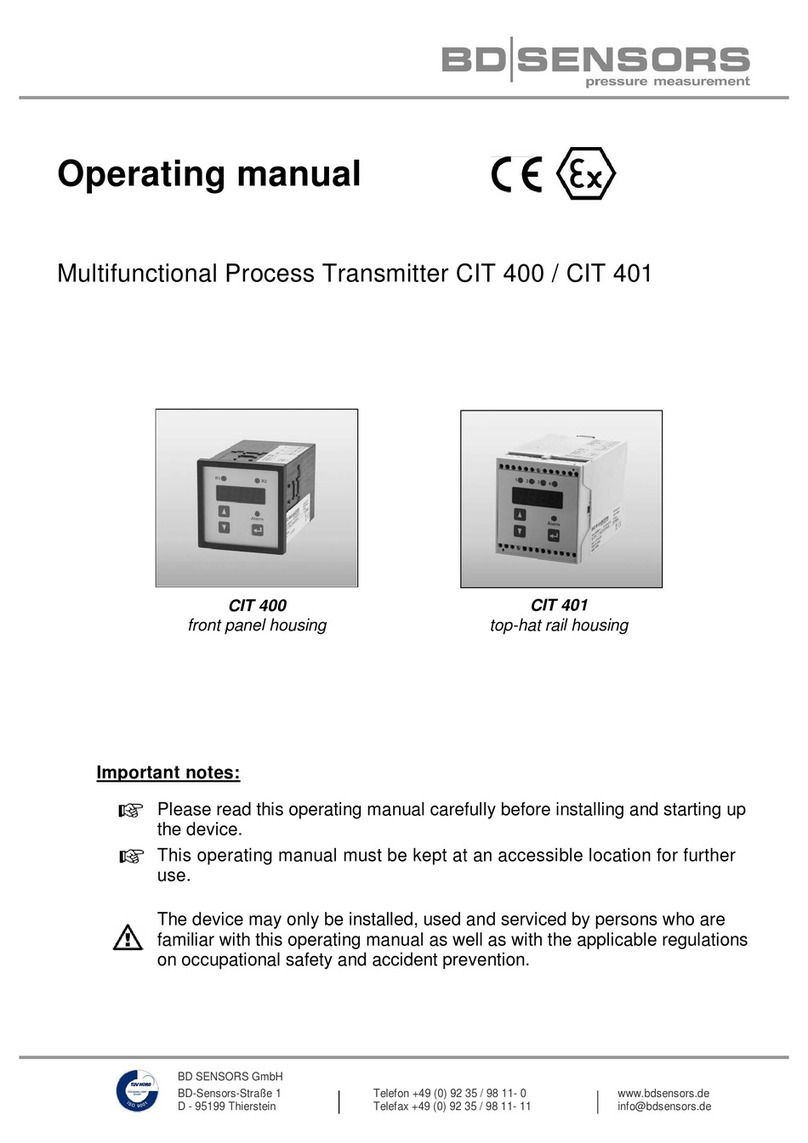

Operating Manual

Industrial pressure transmitter DMK / DMP,

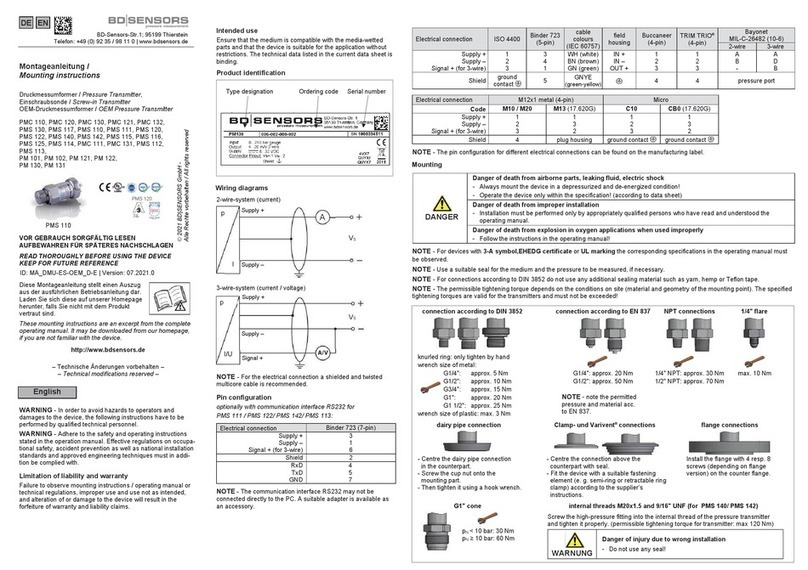

screw-in transmitter LMK / LMP and

OEM pressure transmitter

DMK 331, DMK 331 P, DMK 351, DMK 351 P, DMP 311,

DMP 320, DMP 321, DMP 331, DMP 331i, DMP 331 P,

DMP 331 Pi, DMP 333, DMP 333i, DMP 334, DMP 334i,

DMP 335, DMP 335P, DMP 339, DMP 343,

LMK 331, LMK 351, LMP 331, LMP 331i,

17.6XX, 17.6XX G, 18.6XX, 18.6XX G,

26.6XX, 26.6XX G, 30.6XX, 30.6XX G

BD SENSORS GmbH

BD-Sensors-Str. 1

D - 95199 Thierstein

Germany

Tel.: +49 (0) 9235-9811-0

Fax: +49 (0) 9235-9811-11

BD SENSORS s.r.o.

Hradištská 817

CZ - 687 08 Buchlovice

Czech Republic

Tel.: +42 (0) 572-4110 11

Fax: +42 (0) 572-4114 97

Russia

BD SENSORS RUS

39a, Varshavskoe shosse

RU - Moscow 117105

Russia

Tel.: +7 (0) 95-380 1683

Fax: +7 (0) 95-380 1681

China

BD SENSORS China Co, Ltd.

Room B, 2nd Floor, Building 10,

No. 1188 Lianhang Rd.

201112 Shanghai,

China

Tel.: +86 (0) 21-51600 190

Fax: +86 (0) 21-33600 613

The addresses of our distribution partners are listed on our

homepage www.bdsensors.com. It is possible to download

data sheets, operating manuals, ordering codes and certifi-

cates, as well.

1. General information

1.1 Information on the operating manual

This operating manual contains important information on

proper usage of the device. Read this operating manual

carefully before installing and starting up the pressure meas-

uring device.

Adhere to the safety notes and operating instructions which

are given in the operating manual. Additionally applicable

regulations regarding occupational safety, accident preven-

tion as well as national installation standards and engineering

rules must be complied with!

This operating manual is part of the device, must be kept

nearest its location, always accessible to all employees.

– Technical modifications reserved –

1.2 Symbols used

DANGER! – dangerous situation, which may result in

death or serious injuries

WARNING! – potentially dangerous situation, which may

result in death or serious injuries

CAUTION! – potentially dangerous situation, which may

result in minor injuries

!CAUTION! – potentially dangerous situation, which may

result in physical damage

NOTE – tips and information to ensure a failure-free

operation

1.3 Target group

WARNING! To avoid operator hazards and damages of

the device, the following instructions have to be worked

out by qualified technical personnel.

1.4 Limitation of liability

By non-observance of the operating manual, inappropri-

ate use, modification or damage, no liability is assumed

and warranty claims will be excluded.

1.5 Intended use

- The pressure transmitter DMK/DMP and OEM-

pressure transmitter have, according to the type, been

developed for applications in overpressure and vacuum

as well as for absolute pressure measurement. The

screw-in transmitters LMK/LMP have been particularly

developed for level and process measurement. It is the

operator's responsibility to check and verify the suitability

of the device for the intended application. If any doubts

remain, please contact our sales department in order to

ensure proper usage. BD SENSORS is not liable for any

incorrect selections and their effects!

!Permissible media are gases or liquids, which are com-

patible with the media wetted parts described in the data

sheet. In addition it has to be ensured, that this medium

is compatible with the media wetted parts.

!The technical data listed in the current data sheet are

engaging. If the data sheet is not available, please order

or download it from our homepage.

(http://www.bdsensors.com)

WARNING! Danger through improper usage!

1.6 Package contents

Please verify that all listed parts are undamaged included in

the delivery and check for consistency specified in your order:

- pressure transmitter or screw-in transmitter

- for mechanical pressure ports DIN 3852: o-ring

(pre-assembled)

- mounting instructions

- with option SIL2 version:

Functional Safety Manual, Functional Safety Data

Sheet

1.7 UL – Approval (for devices with UL-identification)

The UL – Approval was done with respect to U.S. standards

norms which also correspond with the applicable Canadian

standards norms for safety.

Note the following points, so that devices fulfils the demands

of UL approval:

- The transmitter shall be supplied by Limited Energy

Source (per UL 61010) or NEC Class 2 Power Source.

- maximum operating voltage: see technical data

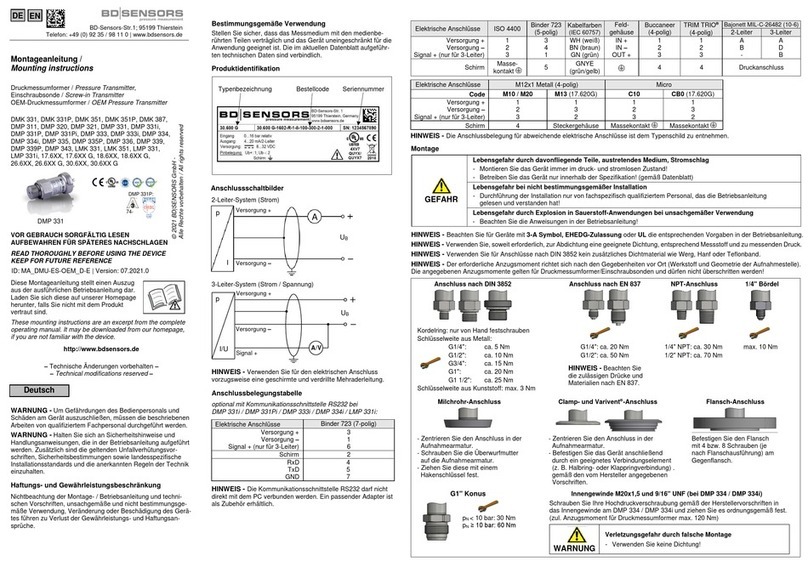

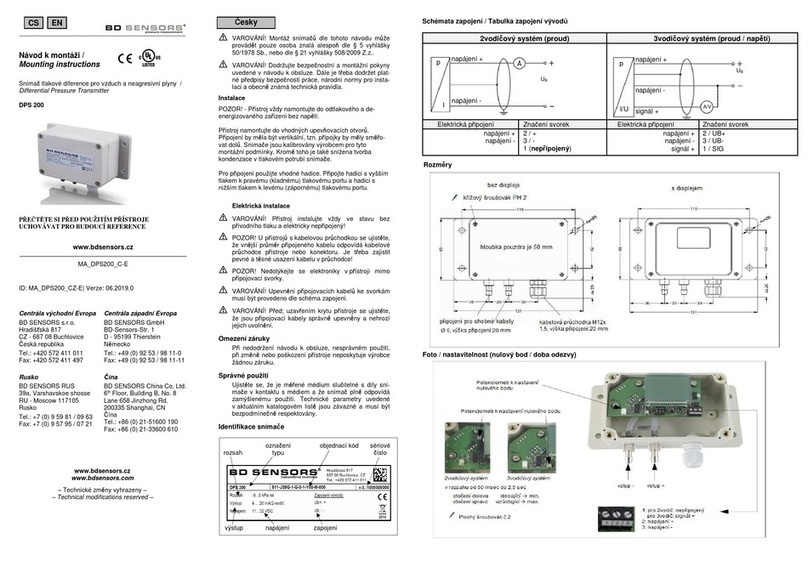

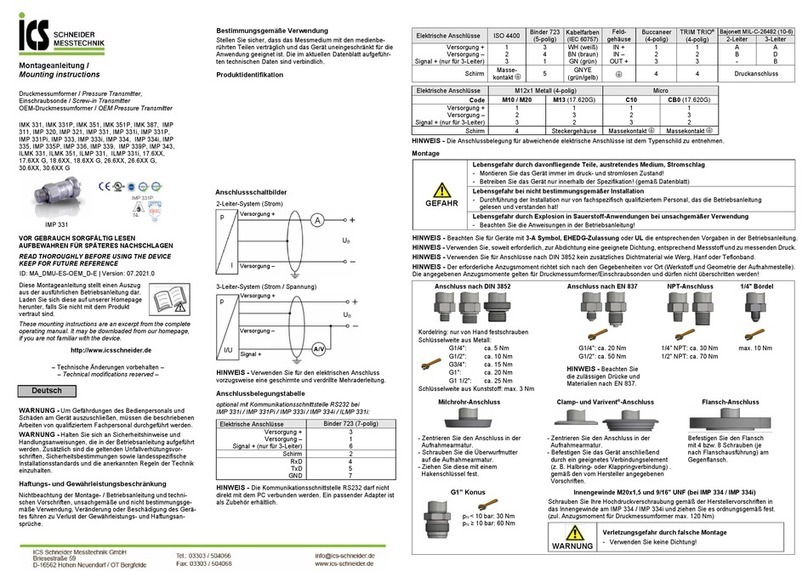

2. Product identification

The device can be identified by its manufacturing label. It

provides the most important data. By the ordering code the

product can be clearly identified.

!The manufacturing label must not be removed from the

device!

3. Mechanical installation

3.1 Mounting and safety instructions

WARNING! Install the device only when depressurized

and currentless!

WARNING! This device may only be installed by quali-

fied technical personnel who has read and understood

the operating manual!

Oxygen

DANGER! When used improperly, special versions of

devices suitable for oxygen applications may explode!

To ensure a usage without danger, the following points

must be adhered to:

- Make sure that your device has been ordered as a

special version for oxygen applications and that it

has been delivered conformably. You can check

this easily by reading the manufacturing label (see

figure 1). If your ordering code ends with the num-

bers "007", your device is suitable for the oxygen

application.

- When being dispatched the device is packed into a

plastic bag to keep it from impurity. The indication

label with the text "Device for oxygen, unpack only

directly before assembling" has to be observed!

Furthermore any skin contact must be avoided dur-

ing unpacking and installing the device, so that no

fatty residue remains on the device!

- For installing the respective regulations for explo-

sion protection have to be fulfilled. Please check if

an ATEX-approval is necessary for the application

in addition to the acceptability for oxygen. (the de-

livered device has no ATEX-approval)

- Consider that the entire construction must corre-

spond to the standards of BAM (DIN 19247).

- For oxygen applications over 25 bar are recom-

mended pressure transmitter without seals.

- Transmitters with o-rings of 70 EPDM 281:

permissible maximum values: 15 bar/ 60° C and

10 bar/ 60 up to 90°C.

- Transmitters with o-rings of FKM Vi 567:

permissible maximum values: 15 bar/ 60° C.

!Handle this high-sensitive electronic precision

measuring device with care, both in packed and

unpacked condition!

!There are no modifications/changes to be made on the

device.

!Do not throw the package/device!

!To avoid damaging the diaphragm, remove packaging

and protective cap directly before starting assembly. The

delivered protective cap has to be stored!

!Place the protective cap on the pressure port again

immediately after disassembling.

!Handle the unprotected diaphragm very carefully - it is

very sensitive and may be easily damaged.

!Do not use any force when installing the device to pre-

vent damage of the device and the plant!

!For installations outdoor and in damp areas following

these instructions:

- To prevent moisture admission in the plug the de-

vice should be installed electrically after mounting,

at once. Otherwise a moisture admission has to be

blocked e.g. by using a suitable protection cap.

(The ingress protection in the data sheet is valid for

the connected device.)

- Choose an assembly position, which allows the

flow-off of splashed water and condensation. Avoid

permanent fluid at sealing surfaces!

- When using a cable gland or outlet device, turn the

outgoing cable downwards. If the cable has to be

turned upwards, then point it downward so the

moisture can drain.

- Install the device in such a way that it is protected

from direct solar irradiation. Direct solar irradiation

can lead to the permissible operating temperature

being overstepped in the worst case. By this the

operability of the device can be affected or dam-

aged. If the internal pressure increases due to solar

irradiation, measurement errors may be caused.

!For devices with gauge reference in the housing (small

hole next to the electrical connection), install the device

in such a way, that the gauge reference is protected

from dirt and moisture. Should the device be exposed to

fluid admission, the functionality will be blocked by the

gauge reference. An exact measurement in this condi-

tion is not possible. Furthermore this can lead to dam-

ages on the device.

Take note that no inadmissibly high mechanical stresses

occur at the pressure port as a result of the installation,

since this may cause a shifting of the characteristic

curve or to the demage. This is especially important for

very small pressure ranges as well as for devices with a

pressure port made of plastic.

In hydraulic systems, position the device in such a way

that the pressure port points upward (ventilation).

Provide a cooling line when using the device in steam

piping.

If there is any danger of damage by lightning or

overpressure when the device is installed outdoor, we

suggest putting a sufficiently dimensioned overpressure

protection between the supply or switch cabinet and the

device.

If the device is installed with the pressure connection up,

it has to be made sure that no liquid drain off at the

case. Humidity and dirt can block the relative cover in

the case and it could lead to malfunctions through this.

Dust and dirt must be removed from the edge of the

thread connection of the electrical connection if required.

3.2 General installation steps

- Carefully remove the pressure measuring device from

the package and dispose of the package properly.

- Go ahead as detailed in the specific instructions below.

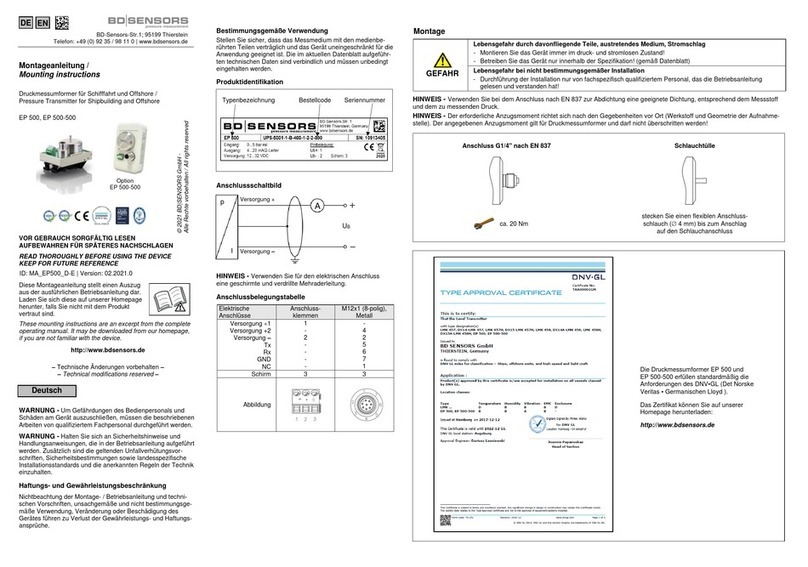

3.3 Installation steps for DIN 3852

DO NOT USE ANY ADDITIONAL SEALING MATERI-

ALS, LIKE YARN, HEMP OR TEFLON TAPE!

- Check to ensure the proper groove fitting of the o-ring

and additionally to ensure no damage to the o-ring.

- Ensure that the sealing surface of the taking part is per-

fectly smooth and clean. (RZ 3.2)

- Screw the device into the corresponding thread by hand.

- If you have a device with a knurled ring, the transmitter

has to be screwed in by hand only.

- Devices with a spanner flat have to be tightened with an

open-end wrench (wrench size of steel: G1/4": approx. 5

Nm; G1/2": approx. 10 Nm; G3/4": approx. 15 Nm; G1":

approx. 20 Nm; G1 1/2": approx. 25 Nm; wrench size of

plastic: max. 3 Nm).

- The indicated tightening torques must not be

exceeded!

Fig. 1 manufacturing label

pressure

range

number