Rigging the fixture

Caution!

1. The installations must be carried out by an authorized dealer or trained professional.

2. Unit may cause severe injures if you have doubts concerning the safety do not install.

3. Unit is to be 24inches away from flammable materials (decoration material)

4. Use high quality installation equipment to hang unit.

When rigging a unit it is very important that you follow common safety procedures. Rigging requires extensive experi-

ence including but not limited to calculating working loads, material being used and periodic safety inspections. If you

lack these qualifications, do not attempt the installation yourself, instead use a professional structural rigger.

When rigging the unit always be secured with a secondary safety attachment. The installation location of the projector

has got to be built in the way that it can hold 10 times the weight for 1 hour with out any harming. Installation should be

checked at least one time a year by a skilled person.

Rigging the fixture

Caution!

1. The installations must be carried out by an authorized dealer or trained professional.

2. Unit may cause severe injures if you have doubts concerning the safety do not install.

3. Unit is to be 24inches away from flammable materials (decoration material)

4. Use high quality installation equipment to hang unit.

When rigging a unit it is very important that you follow common safety procedures. Rigging requires extensive experi-

ence including but not limited to calculating working loads, material being used and periodic safety inspections. If you

lack these qualifications, do not attempt the installation yourself, instead use a professional structural rigger.

When rigging the unit always be secured with a secondary safety attachment. The installation location of the projector

has got to be built in the way that it can hold 10 times the weight for 1 hour with out any harming. Installation should be

checked at least one time a year by a skilled person.

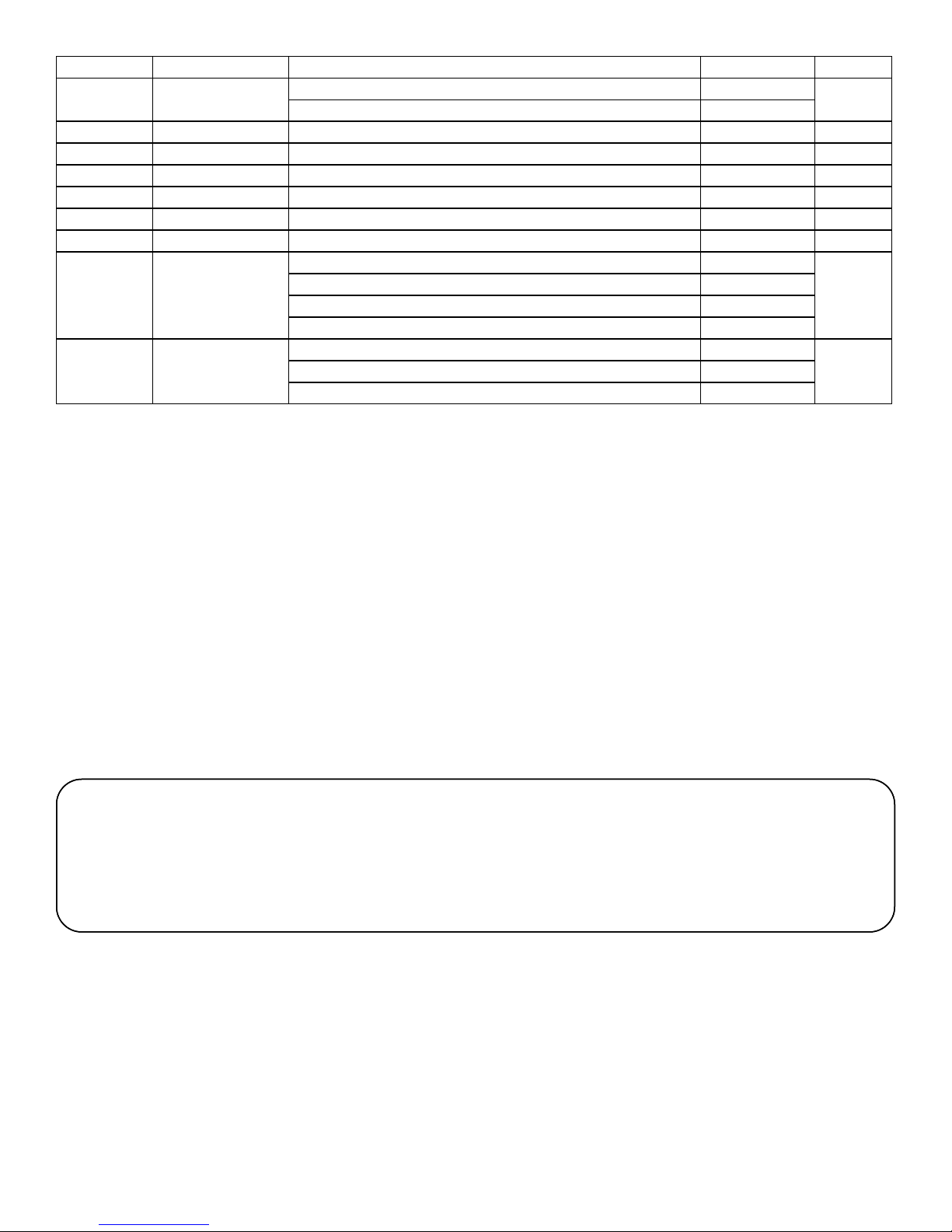

7No Function No Function 0-255 0

8Frost No Function 0-127 0

Frost (clear to frost) 128-255

9Focus Focus 0-255 0

10 Pan Pan Course 0-255 128

11 Pan Fine Pan Fine 0-255 128

12 Tilt Tilt Course 0-255 128

13 Tilt Fine Tilt Fine 0-255 128

14 Pan & Tilt Speed Pan & Tilt Speed (Fast to Slow) 0-255 0

No Function 0-26

15 Reset Lamp Reset 26-76 0

Pan Tilt Reset ]77-127

All Reset 128-255

No Function 0-9

16 Lamp Control Lamp OFF (hold for 3 seconds) 10-100 0

Lamp ON (hold for 3 seconds) 101-255

10