BEAMEX PGM User manual

© Copyright 2001, 2004, 2006, 2008

BEAMEX OY AB

Ristisuonraitti 10

FIN-68600 PIETARSAARI

FINLAND

Phone +358 - 10 - 5505000

Fax +358 - 10 - 5505404

Internet http://www.beamex.com

Beamex Inc

2270 NW Parkway

Suite 165

Marietta, GA 30067

U.S.A.

Phone 800 888-9892,

+1-770-951-1927

Fax +1-770-951-1928

Beamex Limited

Newtown Grange Farm Business Park

Desford Road

NEWTOWN UNTHANK

Leicestershire LE9 9FL

United Kingdom

Phone 01455 821 920

Fax 01455 821 923

Representative:

INSTRUCTION MANUAL

CALIBRATION PRESSURE PUMP

MODEL PGM

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

A T IO N P U M P

/ 1 0 0 0 0 p s i

S S U R E 7 0 0 b a r

s s r e s e r v o i r

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

WARNINGS

Read the instruction manual carefully prior to setting up and using the

pressure pump. The pressure built up internally during use can be

very high.

Do not generate higher pressures than 20 bar (300 psig).

Higher pressures may damage the pump.

Only personnel with good experience and knowledge of high pressure

are allowed to work with the pressure pump. Incorrect use may result

in damage to the pump, the instrument connected to the pump and/or

personal injury.

Ensure that all connections are made correctly and that the hose and

the connectors are intact. Do not use faulty hoses or connectors.

Do not connect the pump to a high pressure source.

Use only the connectors provided with the pump. Impurities from

wrong materials may plug the pump.

Dear user,

We have made every effort to ensure the accuracy of the contents of this

manual. Should any errors be detected, we would greatly appreciate to re-

ceive suggestions to improve the quality of the contents of this manual.

The above not withstanding, we can assume no responsibility for any errors

in this manual or their eventual consequences.

We reserve rights to make modifications to this manual without any further

notice.

For more detailed technical data about the Calibration Pressure Pump,

model PGM, please contact the manufacturer.

8801300/UEPGM/000528

APPLICATION EXAMPLES

Pressure

instrument

T/C, Low V 4-w meas

R, RTD

3 & 4-w m eas

V,I, +24V IMEAS/SINK

V,HA RT®

Low V

MEAS& IOUTPUT

GEN

SENSOR M EAS URE & SIMU LA TE

ET E

T/C INT.RJ

T/C OR EXT

WIRESONLY

?

2

1

0

3

4

5

6

7

8

9

DCBA

2-w xmtr

MULTIFUNCTION CALIBRATOR Pressure

pump

Calibrator

06.10.2000 11:49

Input

Error

1.00

Output

Gauge

bar

8.0310

0.28 % of s pan

0.4982

+

0

-0% 50% 100%

Pressur e [P1: INT6C ]

Current [E: M eas]

mA

Pause Readings

Accept

Desired Inp ut Value 0.5000

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V,I, +24V IMEAS/SINK

V,HA RT®

Low V

MEAS& IOUTPUT

GEN

SENSOR M EA SURE & SIM ULA TE

ET E

T / C IN T . R J

T/C OR EXT

WIRESONLY

?

2

1

0

3

4

5

6

7

8

9

DCBA

2-w xmtr

M UL T IF U N CT IO N C A L IB R A T O R Calibrator Pressure

pump

Pressure

instrument

06.10.2000 11:49

Input

Error

1.00

Output

Gauge

bar

8.0310

0.28 % of s pan

0.4982

+

0

-0% 50% 100%

Pressure [P1: INT6C]

C u rre n t [E : M e a s]

mA

Pause Readings

Accept

D es ire d In pu t V a lue 0.5 0 00

(plugged)

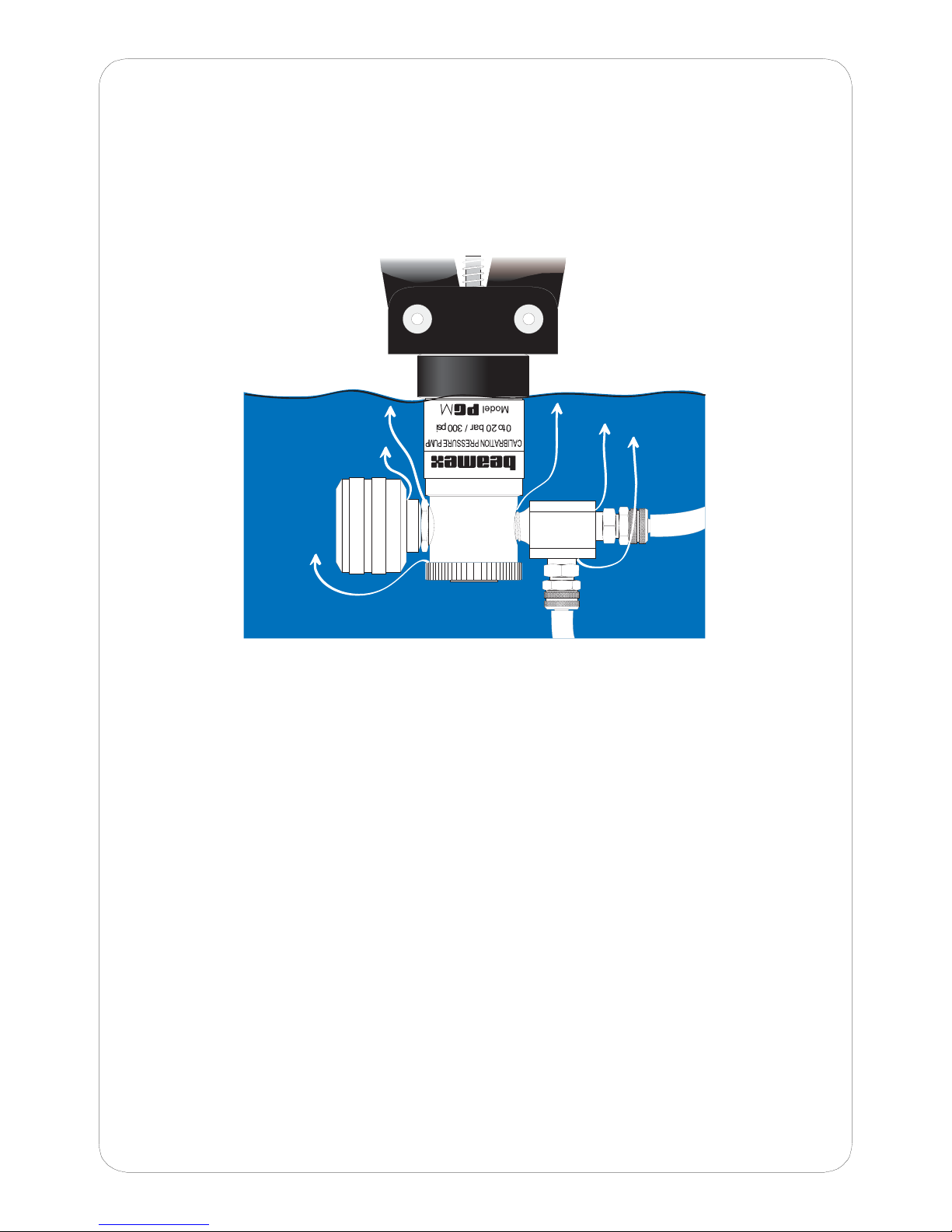

3.2 Leak Testing the Pump

If you suspect that the pump is leaking, immerse the top of the pressurized

pump in water. The most likely leakage points are shown in the following

picture. Where applicable, use sealant glue to stop the leakage.

V o u m e c o n n e c t o r

i s e a k i n g

V o u m e p i s t o n

s e a i s

e a k i n g

O u t p u t c o n n e c t o r

i s e a k i n g

V e n t v a v e

s e a i s e a k i n g

Note. Do not sink PGM any deeper than as shown in the picture. Otherwise

you might get water into the pump.

4 SPECIFICATIONS

Weight 0.4 kg approx. 0.9 lb

Dimensions Height 223 mm approx. 8

3/4"

Width 117 mm approx. 4 3/4"

Depth 38 mm approx. 1 1/2"

Pressure range 0 to 20 bar 0 to 300 psi

Pressure media Dry clean air or other clean, inert,

non-toxic, non-corrosive gases

Outlet connectors Two 1/8" NPT female.

CONTENTS

1 DESCRIPTION...................................................................................2

1.1 Standard Accessories ..................................................................2

1.2 Optional Accessories and Spare Parts.........................................2

2 OPERATION......................................................................................3

2.1 Practical Notes.............................................................................4

3 TROUBLESHOOTING/MAINTENANCE ...........................................4

3.1 Seal Replacement........................................................................4

3.1.1 Main Piston Seal.......................................................................5

3.1.2 Fine Control Seal ......................................................................5

3.1.3 Release Valve Seal...................................................................5

3.1.4 Replacing the Check Valve Seal...............................................5

3.2 Leak Testing the Pump ................................................................7

4 SPECIFICATIONS.............................................................................7

i

F i n e c o n t r o l

C o n n e c t o r s

f o r p r e s s u r e

m e a s u r e m e n t

h o s e s

M a i n p i s t o n h a n d l e s

R e l e a s e v a l v e

Screw for fastening

the cylinder block

Cylinder collar

1.5 mm hex screw

Fine control seal

Release valve seal

Check valve seal

Main piston lock ring

2.0 mm hex screw

Release valve stemRelease valve hand wheel

Main piston

NOTE! Using PGMwith seals not supplied by Beamex is at your own

risk. The warranty is no longer valid when using other seals

than the ones supplied by Beamex.

ch

3.1.1 Main Piston Seals

The main piston is assembled using special methods so it must be changed

as one component.

Remove the cylinder block from the main piston handles by opening the

three screws hidden under the cylinder collar. Rotate the cylinder unit until

the screws are visible one by one in the collar’s hole. When all screws are

loosened, pull the cylinder unit apart from the handle

Too loosen the piston, open the lock ring (see picture). Replace the piston

and reassemble.

3.1.2 Fine Control Seal

The variable volume is disassembled by opening the three 1.5 mm

hexagonal screws holding the retaining collar. Open the volume unit by

turning the knob counterclockwise.

After replacing the o-ring or after carrying out other reparative actions

grease the seal with pressure proof grease (e.g. Esso Nebula EP). When

reassembling, use a suitable sealant to avoid leakage (e.g. Locktite 572).

3.1.3 Release Valve Seal

Detach the release valve hand wheel from the release valve stem by

opening the 2 mm hexagonal screw. Turn the hand wheel upside down (the

stop pin pointing upwards) and fix it back to the release valve stem. Rotate

the had wheel counterclockwise to remove the release valve stem. Now the

release valve seal is visible.

Note that both the check valve spring and the check valve itself are

disassembled at the same time. Be careful not to damage or drop them

while replacing the release valve seal.

When reassembling, apply silicon oil on the vent valve stem and the

release valve seal.

3.1.4 Replacing the Check Valve Seal

The procedure is exactly the same as when replacing the release valve

seal (see the description above) but this time you also need to remove the

check valve spring and the check valve.

Replace the check valve seal, apply silicon oil and reassemble.

1 DESCRIPTION

The PGM calibration pressure pump is designed to manually generate

pressure up to 20 bar (300 psi) for quick and accurate calibration of

pressure gauges, transducers and other pressure measuring instruments.

1.1 Standard Accessories

The standard accessories are as follows:

∗Service seal kit for PGM.

∗Opening tool (hex wrench)

∗Output adapters:

•G 1/8” male 60°int. cone

•2 connectors for 1/8” ID hose

•2 connectors for 1/8” ID / 1/4" OD hose with nut

•Plug

∗This Instruction Manual.

2.2 Optional Accessories and Spare Parts

The optional accessories are as follows:

∗Carrying case

∗T-tubing set with connectors

∗1.5 m / 4.9” hose

∗Service seal kit for PGM.

gd

2 OPERATION

READ THE WARNINGS PRESENTED IN THIS MANUAL BEFORE

OPERATING THE PRESSURE PUMP.

1. Connect the instrument to be tested to the Pressure Measurement

Hose and attach it to the pump. Be sure that all the output connectors

are properly plugged or connected to an instrument to avoid leakage.

2. Adjust the fine control to "mid-travel".

3. Ensure the pressure release valve is closed (turn fully clockwise, but

keep in mind that excessive force may damage the seals).

4. Operate the handles several times to raise the pressure close to the

required value.

5. Do the final adjustment with the variable volume. If necessary, wait with

the adjustment until the temperature has stabilized (see chapter

2.1 Practical notes).

6. Repeat steps 4 and 5 until the highest calibration point is reached.

7. To decrease the pressure, open the release valve slightly.

Follow the decreasing of the pressure e.g. with the help of the

calibrator’s display. Close the release valve when the pressure is a little

above the required level.

8. Use the variable volume to set the exact pressure. Again, if necessary,

wait with the adjustment until the temperature has stabilized.

9. Repeat steps 7 and 8 until all of the decreasing calibration points are

done.

Small gauge pressures as well as negative pressures may be generated

using only the variable volume. The negative pressure is restricted to

approx. 150 mbar (then the force of the vacuum is equal to the force of the

volume piston’s spring).

2.1 Practical Notes

When increasing the pressure, the temperature of the air inside the system

rises on account of thermodynamic phenomena. When the temperature

returns to the level of the environment, the generated pressure may slightly

fall.

Respectively, when the pressure decreases, the air cools down. So when

the temperature again rises to the level of the environment, a slight in-

crease in the pressure may occur.

The temperature change depends (among other things) on the volume of

the system and the pressure change created by the user. Thus the effect of

the phenomenon varies for each calibration and even for each calibration

step.

Another phenomenom that affects the pressure is the flexibility of the hoses

used in the measurement system. When the pressure increases, the hoses

stretch, thus slightly altering the volume of the measurement system.

3 TROUBLESHOOTING/MAINTENANCE

If the pump assembly fails to indicate a pressure increase after consider-

able pumping action, the following items should be examined:

•Check to assure that the connections between the pump, the hose end

and the attached instrument(s) are tight and repeat operating instruc-

tions items 3 and 4. Check to assure that all the unused output connec-

tors are properly plugged.

If a pressure increase still cannot be obtained, it’s possible that one or more

of the seals and/or the check valve on the main piston is leaking and needs

to be replaced.

3.1 Seal Replacement

Depending on the frequency of use, the Main Piston Seals (and others) will

eventually need replacing. Although the replacement seals are an optional

accessory, the same instructions for fitting the seals are included in this

manual as in the replacement package.

fe

2 OPERATION

READ THE WARNINGS PRESENTED IN THIS MANUAL BEFORE

OPERATING THE PRESSURE PUMP.

1. Connect the instrument to be tested to the Pressure Measurement

Hose and attach it to the pump. Be sure that all the output connectors

are properly plugged or connected to an instrument to avoid leakage.

2. Adjust the fine control to "mid-travel".

3. Ensure the pressure release valve is closed (turn fully clockwise, but

keep in mind that excessive force may damage the seals).

4. Operate the handles several times to raise the pressure close to the

required value.

5. Do the final adjustment with the variable volume. If necessary, wait with

the adjustment until the temperature has stabilized (see chapter

2.1 Practical notes).

6. Repeat steps 4 and 5 until the highest calibration point is reached.

7. To decrease the pressure, open the release valve slightly.

Follow the decreasing of the pressure e.g. with the help of the

calibrator’s display. Close the release valve when the pressure is a little

above the required level.

8. Use the variable volume to set the exact pressure. Again, if necessary,

wait with the adjustment until the temperature has stabilized.

9. Repeat steps 7 and 8 until all of the decreasing calibration points are

done.

Small gauge pressures as well as negative pressures may be generated

using only the variable volume. The negative pressure is restricted to

approx. 150 mbar (then the force of the vacuum is equal to the force of the

volume piston’s spring).

2.1 Practical Notes

When increasing the pressure, the temperature of the air inside the system

rises on account of thermodynamic phenomena. When the temperature

returns to the level of the environment, the generated pressure may slightly

fall.

Respectively, when the pressure decreases, the air cools down. So when

the temperature again rises to the level of the environment, a slight in-

crease in the pressure may occur.

The temperature change depends (among other things) on the volume of

the system and the pressure change created by the user. Thus the effect of

the phenomenon varies for each calibration and even for each calibration

step.

Another phenomenom that affects the pressure is the flexibility of the hoses

used in the measurement system. When the pressure increases, the hoses

stretch, thus slightly altering the volume of the measurement system.

3 TROUBLESHOOTING/MAINTENANCE

If the pump assembly fails to indicate a pressure increase after consider-

able pumping action, the following items should be examined:

•Check to assure that the connections between the pump, the hose end

and the attached instrument(s) are tight and repeat operating instruc-

tions items 3 and 4. Check to assure that all the unused output connec-

tors are properly plugged.

If a pressure increase still cannot be obtained, it’s possible that one or more

of the seals and/or the check valve on the main piston is leaking and needs

to be replaced.

3.1 Seal Replacement

Depending on the frequency of use, the Main Piston Seals (and others) will

eventually need replacing. Although the replacement seals are an optional

accessory, the same instructions for fitting the seals are included in this

manual as in the replacement package.

fe

3.1.1 Main Piston Seals

The main piston is assembled using special methods so it must be changed

as one component.

Remove the cylinder block from the main piston handles by opening the

three screws hidden under the cylinder collar. Rotate the cylinder unit until

the screws are visible one by one in the collar’s hole. When all screws are

loosened, pull the cylinder unit apart from the handle

Too loosen the piston, open the lock ring (see picture). Replace the piston

and reassemble.

3.1.2 Fine Control Seal

The variable volume is disassembled by opening the three 1.5 mm

hexagonal screws holding the retaining collar. Open the volume unit by

turning the knob counterclockwise.

After replacing the o-ring or after carrying out other reparative actions

grease the seal with pressure proof grease (e.g. Esso Nebula EP). When

reassembling, use a suitable sealant to avoid leakage (e.g. Locktite 572).

3.1.3 Release Valve Seal

Detach the release valve hand wheel from the release valve stem by

opening the 2 mm hexagonal screw. Turn the hand wheel upside down (the

stop pin pointing upwards) and fix it back to the release valve stem. Rotate

the had wheel counterclockwise to remove the release valve stem. Now the

release valve seal is visible.

Note that both the check valve spring and the check valve itself are

disassembled at the same time. Be careful not to damage or drop them

while replacing the release valve seal.

When reassembling, apply silicon oil on the vent valve stem and the

release valve seal.

3.1.4 Replacing the Check Valve Seal

The procedure is exactly the same as when replacing the release valve

seal (see the description above) but this time you also need to remove the

check valve spring and the check valve.

Replace the check valve seal, apply silicon oil and reassemble.

1 DESCRIPTION

The PGM calibration pressure pump is designed to manually generate

pressure up to 20 bar (300 psi) for quick and accurate calibration of

pressure gauges, transducers and other pressure measuring instruments.

1.1 Standard Accessories

The standard accessories are as follows:

∗Service seal kit for PGM.

∗Opening tool (hex wrench)

∗Output adapters:

•G 1/8” male 60°int. cone

•2 connectors for 1/8” ID hose

•2 connectors for 1/8” ID / 1/4" OD hose with nut

•Plug

∗This Instruction Manual.

2.2 Optional Accessories and Spare Parts

The optional accessories are as follows:

∗Carrying case

∗T-tubing set with connectors

∗1.5 m / 4.9” hose

∗Service seal kit for PGM.

gd

F i n e c o n t r o l

C o n n e c t o r s

f o r p r e s s u r e

m e a s u r e m e n t

h o s e s

M a i n p i s t o n h a n d l e s

R e l e a s e v a l v e

Screw for fastening

the cylinder block

Cylinder collar

1.5 mm hex screw

Fine control seal

Release valve seal

Check valve seal

Main piston lock ring

2.0 mm hex screw

Release valve stemRelease valve hand wheel

Main piston

NOTE! Using PGMwith seals not supplied by Beamex is at your own

risk. The warranty is no longer valid when using other seals

than the ones supplied by Beamex.

ch

3.2 Leak Testing the Pump

If you suspect that the pump is leaking, immerse the top of the pressurized

pump in water. The most likely leakage points are shown in the following

picture. Where applicable, use sealant glue to stop the leakage.

V o u m e c o n n e c t o r

i s e a k i n g

V o u m e p i s t o n

s e a i s

e a k i n g

O u t p u t c o n n e c t o r

i s e a k i n g

V e n t v a v e

s e a i s e a k i n g

Note. Do not sink PGM any deeper than as shown in the picture. Otherwise

you might get water into the pump.

4 SPECIFICATIONS

Weight 0.4 kg approx. 0.9 lb

Dimensions Height 223 mm approx. 8

3/4"

Width 117 mm approx. 4 3/4"

Depth 38 mm approx. 1 1/2"

Pressure range 0 to 20 bar 0 to 300 psi

Pressure media Dry clean air or other clean, inert,

non-toxic, non-corrosive gases

Outlet connectors Two 1/8" NPT female.

CONTENTS

1 DESCRIPTION...................................................................................2

1.1 Standard Accessories ..................................................................2

1.2 Optional Accessories and Spare Parts.........................................2

2 OPERATION......................................................................................3

2.1 Practical Notes.............................................................................4

3 TROUBLESHOOTING/MAINTENANCE ...........................................4

3.1 Seal Replacement........................................................................4

3.1.1 Main Piston Seal.......................................................................5

3.1.2 Fine Control Seal ......................................................................5

3.1.3 Release Valve Seal...................................................................5

3.1.4 Replacing the Check Valve Seal...............................................5

3.2 Leak Testing the Pump ................................................................7

4 SPECIFICATIONS.............................................................................7

i

WARNINGS

Read the instruction manual carefully prior to setting up and using the

pressure pump. The pressure built up internally during use can be

very high.

Do not generate higher pressures than 20 bar (300 psig).

Higher pressures may damage the pump.

Only personnel with good experience and knowledge of high pressure

are allowed to work with the pressure pump. Incorrect use may result

in damage to the pump, the instrument connected to the pump and/or

personal injury.

Ensure that all connections are made correctly and that the hose and

the connectors are intact. Do not use faulty hoses or connectors.

Do not connect the pump to a high pressure source.

Use only the connectors provided with the pump. Impurities from

wrong materials may plug the pump.

Dear user,

We have made every effort to ensure the accuracy of the contents of this

manual. Should any errors be detected, we would greatly appreciate to re-

ceive suggestions to improve the quality of the contents of this manual.

The above not withstanding, we can assume no responsibility for any errors

in this manual or their eventual consequences.

We reserve rights to make modifications to this manual without any further

notice.

For more detailed technical data about the Calibration Pressure Pump,

model PGM, please contact the manufacturer.

8801300/UEPGM/000528

APPLICATION EXAMPLES

Pressure

instrument

T/C, Low V 4-w meas

R, RTD

3 & 4-w m eas

V,I, +24V IMEAS/SINK

V,HA RT®

Low V

MEAS& IOUTPUT

GEN

SENSOR M EAS URE & SIMU LA TE

ET E

T/C INT.RJ

T/C OR EXT

WIRESONLY

?

2

1

0

3

4

5

6

7

8

9

DCBA

2-w xmtr

MULTIFUNCTION CALIBRATOR Pressure

pump

Calibrator

06.10.2000 11:49

Input

Error

1.00

Output

Gauge

bar

8.0310

0.28 % of s pan

0.4982

+

0

-0% 50% 100%

Pressur e [P1: INT6C ]

Current [E: M eas]

mA

Pause Readings

Accept

Desired Inp ut Value 0.5000

T/C, Low V 4-w meas

R, RTD

3 & 4-w meas

V,I, +24V IMEAS/SINK

V,HA RT®

Low V

MEAS& IOUTPUT

GEN

SENSOR M EA SURE & SIM ULA TE

ET E

T / C IN T . R J

T/C OR EXT

WIRESONLY

?

2

1

0

3

4

5

6

7

8

9

DCBA

2-w xmtr

M UL T IF U N CT IO N C A L IB R A T O R Calibrator Pressure

pump

Pressure

instrument

06.10.2000 11:49

Input

Error

1.00

Output

Gauge

bar

8.0310

0.28 % of s pan

0.4982

+

0

-0% 50% 100%

Pressure [P1: INT6C]

C u rre n t [E : M e a s]

mA

Pause Readings

Accept

D es ire d In pu t V a lue 0.5 0 00

(plugged)

© Copyright 2001, 2004, 2006, 2008

BEAMEX OY AB

Ristisuonraitti 10

FIN-68600 PIETARSAARI

FINLAND

Phone +358 - 10 - 5505000

Fax +358 - 10 - 5505404

Internet http://www.beamex.com

Beamex Inc

2270 NW Parkway

Suite 165

Marietta, GA 30067

U.S.A.

Phone 800 888-9892,

+1-770-951-1927

Fax +1-770-951-1928

Beamex Limited

Newtown Grange Farm Business Park

Desford Road

NEWTOWN UNTHANK

Leicestershire LE9 9FL

United Kingdom

Phone 01455 821 920

Fax 01455 821 923

Representative:

INSTRUCTION MANUAL

CALIBRATION PRESSURE PUMP

MODEL PGM

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

A T IO N P U M P

/ 1 0 0 0 0 p s i

S S U R E 7 0 0 b a r

s s r e s e r v o i r

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L IC C A L I B R A T IO N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u ri z e g a s s r e s e r v o ir

Table of contents

Other BEAMEX Water Pump manuals

Popular Water Pump manuals by other brands

Alcatel

Alcatel 2033 instruction manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 81 2D11-B Installation, operation and maintenance manual

Batavia

Batavia MAXX Series operating instructions

North American Solar Solutions

North American Solar Solutions NASS 500 manual

Pentair

Pentair JUNG PUMPEN U3K /2 instruction manual

Homa

Homa C240W Original instruction manual

GORMAN-RUPP

GORMAN-RUPP PA6D60-4045T-SU Installation, operation and maintenance manual

Pompetravaini

Pompetravaini TCK Series INTEGRATIVE NOTES TO THE OPERATING MANUAL

BorMann

BorMann PRO BGB1000 user manual

WilTec

WilTec 50199-50220 Operation manual

Gardena

Gardena GP 3000/4 Operator's manual

Xylem

Xylem Flojet G55 Series Installation and operation manual