BEAMEX PGPH User manual

INSTRUCTION MANUAL

HIGH PRESSURE PNEUMATIC PUMP

MODEL PGPH

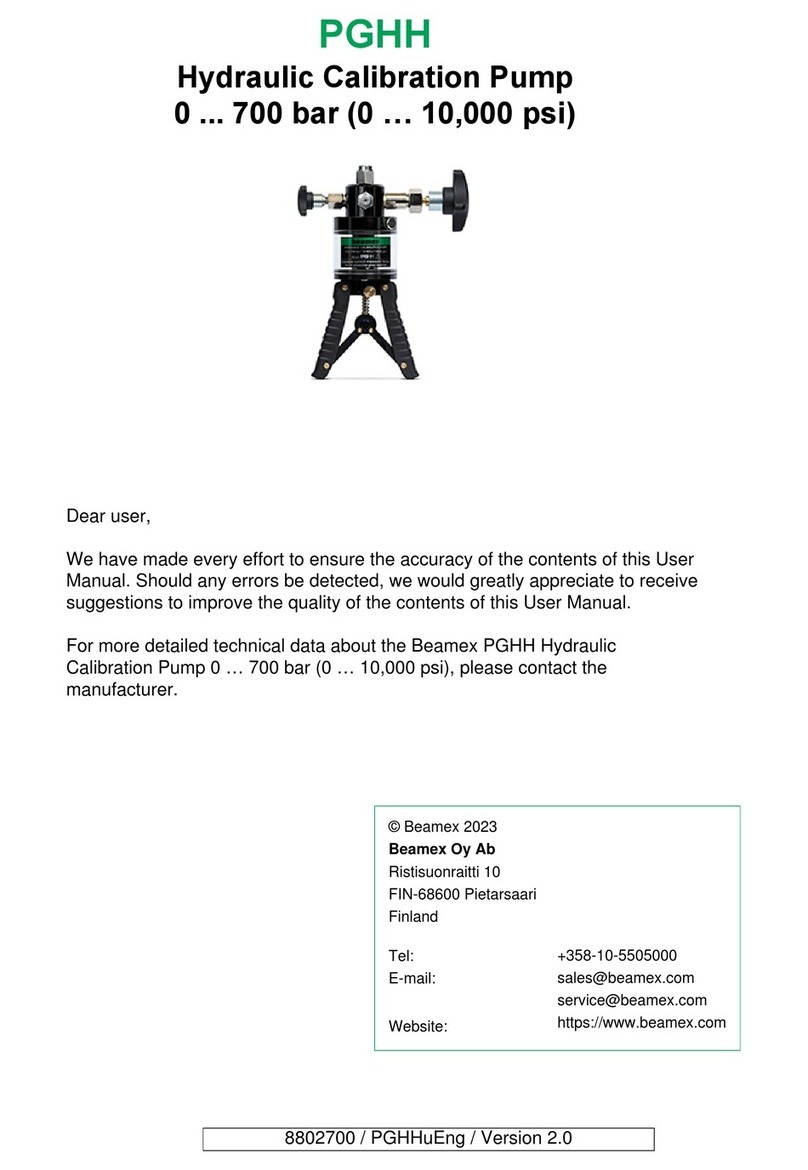

Dear user,

We have made every effort to ensure the accuracy of the contents

of this manual. Should any errors be detected, we would greatly ap-

preciate to receive suggestions to improve the quality of the contents

of this manual.

For more detailed technical data about the Instruction manual for

Beamex®PGPH High Pressure Pneumatic Pump, please contact the

manufacturer.

© Copyright 2013, 2015

BEAMEX OY AB

Ristisuonraitti 10

FIN-68600 Pietarsaari

FINLAND

Tel +358 - 10 - 5505000

Fax +358 - 10 - 5505404

Internet: http://www.beamex.com

8804400 / PGPHuEng / Version 1.1

CONTENTS

DESCRIPTION ............................................................................................. 1

Standard Accessories.........................................................................................1

Optional Accessories ..........................................................................................1

Connections and Parts........................................................................................2

Connection Diagram ...........................................................................................3

OPERATION.................................................................................................3

Keep in Mind.......................................................................................................4

TROUBLESHOOTING/MAINTENANCE .....................................................5

Seal Replacement...............................................................................................6

Cleaning the Pump..............................................................................................6

Leak Tests...........................................................................................................6

Leak Test for Positive Pressure..................................................................6

Leak Test for Negative Pressure (Vacuum)................................................6

SPECIFICATIONS........................................................................................7

The Pump Unit....................................................................................................7

Pressure Measurement Hoses (Optional Accessories).......................................8

Connections................................................................................................8

WARNINGS AND CAUTIONS .....................................................................9

Hose/connector

set for connect-

ing a calibrator's

high pressure

module to

PGPH

Hose/connector

set for connect-

ing the instru-

ment to be cali-

brated to PGPH

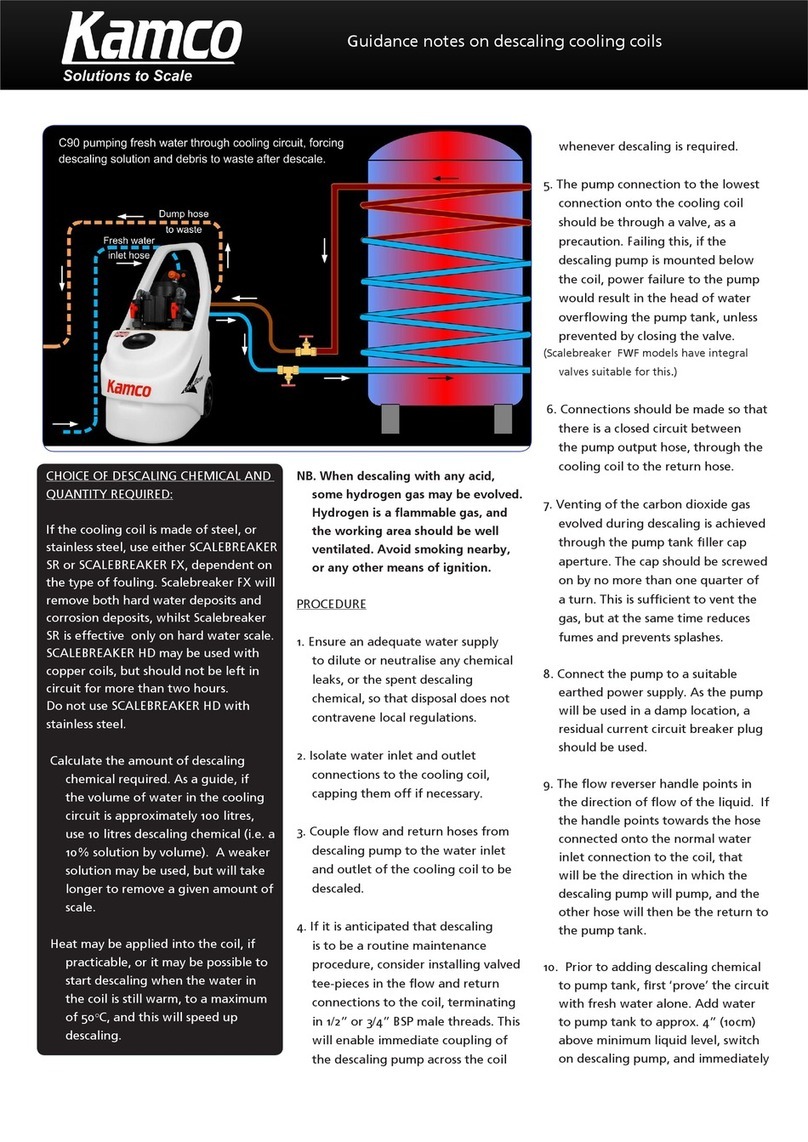

Connections when calibrating a transmitter using an internal pressure module.

Communication

cable.

Hose/connector

set for connect-

ing the instru-

ment to be cali-

brated to

PGPH.

Connections when calibrating a transmitter using an external pressure module.

1

DESCRIPTION

The PGPH High Pressure Pneumatic Pump is designed to manually generate up to

140 bar (2000 psi) gauge pressure or up to -0.95 bar (-14 psi) vacuum for quick and

accurate calibration of pressure gauges, transducers and other pressure measure-

ment instruments.

Standard Accessories

The standard accessories are as follows:

One G ¼’’ (male) plug for Pressure connectors

A set of seals (o-rings), type: NBR70 for Pressure connectors (size 6 × 2).

Guarantee leaflet

This Instruction Manual

Optional Accessories

The optional accessories are as follows:

ITEM

ORDER CODE

Carrying case

8003315

Service seal kit

8003180

Tube of grease for the Fine Adjust stem

0005180

400 bar hose/connector set for connecting the instru-

ment to be calibrated to PGPH

8003380

400 bar hose/connector set for connecting a calibra-

tor's high pressure module to PGPH (*

8003365

*)Not needed when used high pressure module is an External Pressure Module (EXT).

2

Connections and Parts

Pump lever

Shut-off valve. Isolates the pump form the measurement circuit.

Release valve. Clockwise to close, anticlockwise to open.

Pressure connector, G ¼", for instrument / calibrator. Hand tightened.

Vent connection/hole

Fine Adjust handwheel. Rotating clockwise increases pressure.

Pressure connector, G ¼", for instrument / calibrator. Hand tightened.

Equivalent with Pressure connector

Pressure/Vacuum selector. Pull out for pressure and push in for vacuum.

Do not change when pressurized!

Selector lock

Pump body

3

Connection Diagram

Atmosphere

Pump

Shut-off valve

Release valve

Calibrator

(reference)

Fine Adjust

Instrument to be calibrated (DUT)

Pressure/Vacuum selector

OPERATION

Preparation

1. Select Pressure Mode .

2. Open Shut-off valve (counterclockwise) and Release valve.

3. Rotate Fine Adjust to mid position

4. Close Release valve

5. Connect instrument to be calibrated (Device Under Test, DUT) to Pressure con-

nector and the calibrator (pressure module, reference) to Pressure connector

. The location of the instrument and the calibrator may also be interchanged.

Pressure connectors and are equivalent. See also Leak Tests on page 6.

Calibration

6. Pump pressure/vacuum .

7. Close Shut-off valve (clockwise). See also notes further on.

8. Adjust pressure by rotating the Fine Adjust handwheel.

9. Repeat stages 6 to 8 until instrument's maximum pressure / deepest vacuum is

reached

When maximum pressure / deepest vacuum is reached continue as follows:

10.Gently open Release valve to release pressure/vacuum and close when ap-

proaching next calibration point.

11.Adjust pressure by rotating the Fine Adjust handwheel.

12.Repeat stages 10 and 11 until atmospheric pressure (or the instrument's meas-

urement span's pressure closest to atmospheric pressure) is reached.

End by opening Shut-off and Release valves. If you want to do several repeats,

restart from stage 3.

4

Keep in Mind

Immediately after a pressure change, the pressure may change slightly due to the

stretching/shrinking of the pressure measurement hose. Thermodynamic effects may

also cause pressure variation. In that case, adjust the pressure back to required value

using the Fine Adjust handwheel.

Do not exceed the max. operating pressure of the pump and the hose. Also observe

the pressure limit set by environmental conditions.

Ensure that there always is a reliable pressure indicator connected to the pump when

the pump is used.

If there is a strong counterforce while operating the pump lever, but no pressure

change is indicated, stop pumping and locate the fault. Always keep a reliable indi-

cator connected to the measurement system.

If the pump fails to indicate a pressure change after considerable pumping action of

the handle, check to assure that the connections between the pump, the hose end

and the attached instrument(s) are tight and retry pumping. Also check to assure that

all the unused output connectors are properly plugged.

If a pressure increase still cannot be obtained, it is possible that one or more of the

seals in the Pressure Pump is leaking and needs to be replaced.

Do not continue pumping if the functionality of the pump is not normal. Locate

the fault before you continue using the pump.

A full list of warnings is at the end of this manual.

5

TROUBLESHOOTING/MAINTENANCE

Hard to Pressurize Using Pressure Lever

CAUSES

SOLUTIONS

The Shut-off valve is not open.

Open the Shut-off valve .

Release valve is not closed.

Close the release valve .

The o-ring in Pressure connectors or

is missing, misplaced, or broken.

Replace the o-ring.

Pressure / Vacuum selector is in

wrong position.

Pressure: pull it out;

Vacuum: push it in.

Pipeline jamed with impurity.

Open the clean-out bolt at the bot-

tom of the pump and clean.

Hard to Fine Adjust Using Fine Adjust Valve

CAUSES

SOLUTIONS

The Shut-off valve is not closed.

Close the Shut-off valve .

Calibrator or instrument to be calibrated

is not connected tightly.

Check Pressure connectors and

. Re-tighten if necessary. Hand-

tightening should be sufficient.

The o-ring in Pressure connectors or

is missing, misplaced, or broken.

Replace the o-ring.

The end surface of the instrument's con-

nection thread is not smooth.

Use a PTFE washer in Pressure

connector.

The instrument's, calibrator's or hose's

thread does not match the thread on

PGPH's Pressure connectors or .

Use proper adapter.

Impurities inside the Fine Adjust volume

or connection.

Repeat pressurizing several times

and then release it suddenly, make

airflow bring the impurity out.

Hard to Turn the Valves or Handles

CAUSES

SOLUTIONS

Valve closed too tight after the previous

calibration.

Do not close shut off valves and

handles too tightly.

The new pump does not run smooth.

The new pump needs time to run in.

Lack of lubrication in threads.

Lubricate the thread.

6

Seal Replacement

Depending on the frequency of use, the main piston seals (and others) will eventually

need replacing. The replacement seals are part of an optional Service kit and the kit

includes instructions for replacing/fitting the seals.

Cleaning the Pump

PGPH has a plugged clean-out hole at the bottom of the pump. Open the plug and

remove any possible impurities inside the pump.

Leak Tests

If you want to test the pump and the connected measurement system, do as follows:

If you do not already have a calibration measurement system connected to the pump,

connect an accurate enough pressure measurement instrument, e.g. a Beamex

EXT250 pressure module to the pump. Plug any open connections.

You'll also need a clock to measure time.

Leak Test for Positive Pressure

Increase pressure using constant change rate up to pump's full scale positive pres-

sure (140 bar / 2000 psi). Start your clock.

After five minutes, record the pressure indication, p5.

After ten minutes, record the pressure indication, p10.

Calculate the leak, Lp, using this equation:

5

105

pppp

L

If Lpis less than 0.01 (1 %), the system is leak free.

Leak Test for Negative Pressure (Vacuum)

Decrease pressure using constant change rate down to pump's full scale negative

pressure (-0.95 bar / 95 kPa / -14.0 psi). Start your clock.

After five minutes, record the pressure indication, pv5.

After ten minutes, record the pressure indication, pv10.

Calculate the leak, Lv, using this equation: Lv= pv5 - pv10 [kPa].

If Lvis less than 1 kPa (approx. 0.14 psi), the system is leak free.

7

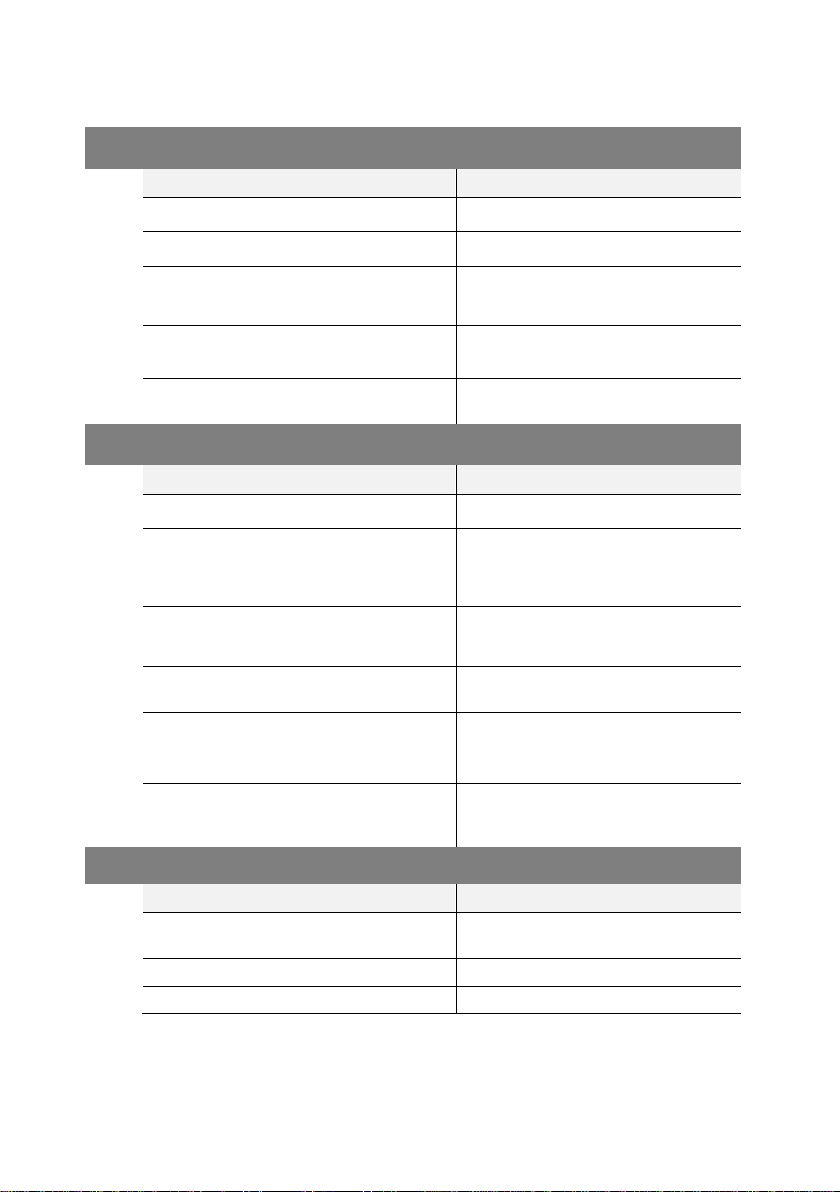

SPECIFICATIONS

The Pump Unit

Dimensions Pump lever down Pump lever up

Height 178 mm / 7" 506 mm / 20"

Length 540 mm / 21¼" 450 mm / 17¾"

Width 270 mm / 10½"

Weight 7.1 kg / 15.7 lb

Pressure range (* -0.95 bar /-14 psi to 140 bar / 2000 psi

Safety Pressure 180 bar / < 2600 psi

Relief Valve PGPH includes a built-in relief valve.

Pressure media Clean air

Temperature 0 ... 50 °C

Humidity < 85 %RH

Pressure resolution 0.1 mbar / 0.002 psi

Output connectors

Two G ¼" female connectors. One for the instrument to be calibrated and

another for the calibrator.

Clean-out connection: G ¼’’ female (plugged)

*)If local atmosphere pressure is 1 bar / 14.5 psi, the vacuum can reach to -0.95 bar / -14psi.

If local atmosphere pressure is P, the vacuum can reach to -0.95×P.

8

Pressure Measurement Hoses (Optional Accessories)

Length 1 m / 3 ft 3.3”

Internal diameter 2 mm / 0.08"

External diameter 5 mm / 0.2"

Operating pressure*@ 0°C (+32°F): 768 bar 76.8 MPa 11148 psi

@ 30°C (+86°F): 693 bar 69.3 MPa 10051 psi

@ 50°C (+122°F): 630 bar 63.0 MPa 9137 psi

@ 80°C (+176°F): 535 bar 53.5 MPa 7767 psi

@ 100°C (+212°F): 485 bar 48.5 MPa 7036 psi

@ 120°C (+248°F): 428 bar 42.8 MPa 6213 psi

Bursting pressure @ 20°C (68°F) 1950 bar 195.0 MPa 28200 psi

Operable temperature range -20 °C to +100 °C / -4 °F to +212 °F

Smallest bending radius 20 mm / 0.78"

below -20°C (-4°F) 30 mm / 1.18"

Connections

End connectors in 400 bar hose/connector set for connecting the instrument to be

calibrated to PGPH (Code 8003380):

PGPH end: G1/4" male

Instrument end: G 1/4" NPT male

End connectors in 400 bar hose/connector set for connecting a calibrator's high pres-

sure module to PGPH (Code 8003365):

PGPH end: G1/4" male

Calibrator / pressure module end: G1/8" male

Beamex reserves the right to make modifications to the specifications and this manual without

any further notice.

9

WARNINGS AND CAUTIONS

Read the instruction manual carefullyprior to setting up and using the pressure

pump. The pressure built up internally during use can be extremely high.

Only personnel with good experience and knowledge of high pressure media,

high pressure instruments and connections are allowed to work with the pres-

sure pump. Incorrect use may result in damage to the pump, the instrument

connected to the pump and/or personal injury.

Use eye shields. The built-in relief valve may blow nearby particles in random

directions.

Do not connect the pump to an external pressure source.

Vent external systems before connecting to the pump.

Ensure that all connections are made correctlyand that the hoses and connect-

ors are free of impurities and undamaged. Do not use faulty hoses or connect-

ors.

Use only measuring hoses provided by Beamex or other reliable suppliers. Ob-

serve the effect of the operational conditions to the maximum pressure allowed

in the hose. The specifications of Beamex hoses can be found on page 7 of this

manual.

The environmental conditions may restrict the allowable maximum pressure to

a lower level than the pump and the hose enable. In that case please consider

using a relief valve.

Always depressurize PGPH when it is left on its own.

Avoid possible damage when suddenly apply pressure to low pressure and

small chamber gauges.

Do not exceed the safety pressure limit (180 bar / < 2600 psi).

Compressed air may cause problem in explosive or corruptive environment.

Do not shift the pressure/vacuum selector to vacuum mode under pressure.

Do not over tighten connectors to avoid any damage.

Store the pump in the dry and non-corruptive environment.

If the pump is accidentally dropped, it may be damaged. Do not use the pump

before it is inspected at Beamex’s service.

Do not use PGPH in any other way than as described in this manual.

Any safety problems or damages caused by incorrect operation, are beyond

Beamex's responsibility.

BEAMEX OY AB

Ristisuonraitti 10

FIN-68600 PIETARSAARI

FINLAND

Phone +358 - 10 5505000

Fax +358 - 10 5505404

E-mail sales@beamex.com

Internet http://www.beamex.com

Beamex Inc

2152 NW Parkway

Suite A

Marietta, GA 30067

U.S.A.

Phone 800 888-9892,

+1-770-951-1927

Fax +1-770-951-1928

E-mail beamex.inc@beamex.com

Beamex Limited

Newtown Grange Farm Business Park

Desford Road

NEWTOWN UNTHANK

Leicestershire LE9 9FL

United Kingdom

Phone 01455 821 920

Fax 01455 821 923

E-mail beamex.ltd@beamex.com

Representative:

Table of contents

Other BEAMEX Water Pump manuals

Popular Water Pump manuals by other brands

Danfoss

Danfoss PAHT G Operation guide

Kärcher

Kärcher AT manual

Dover

Dover PSG WILDEN XPR460 Engineering, operation & maintenance

CRANE PUMPS & SYSTEMS

CRANE PUMPS & SYSTEMS DEMING 7365 Series Installation and operation manual

Pentair

Pentair DKG instruction manual

EINHELL

EINHELL GC-SP 5511 IF Original operating instructions

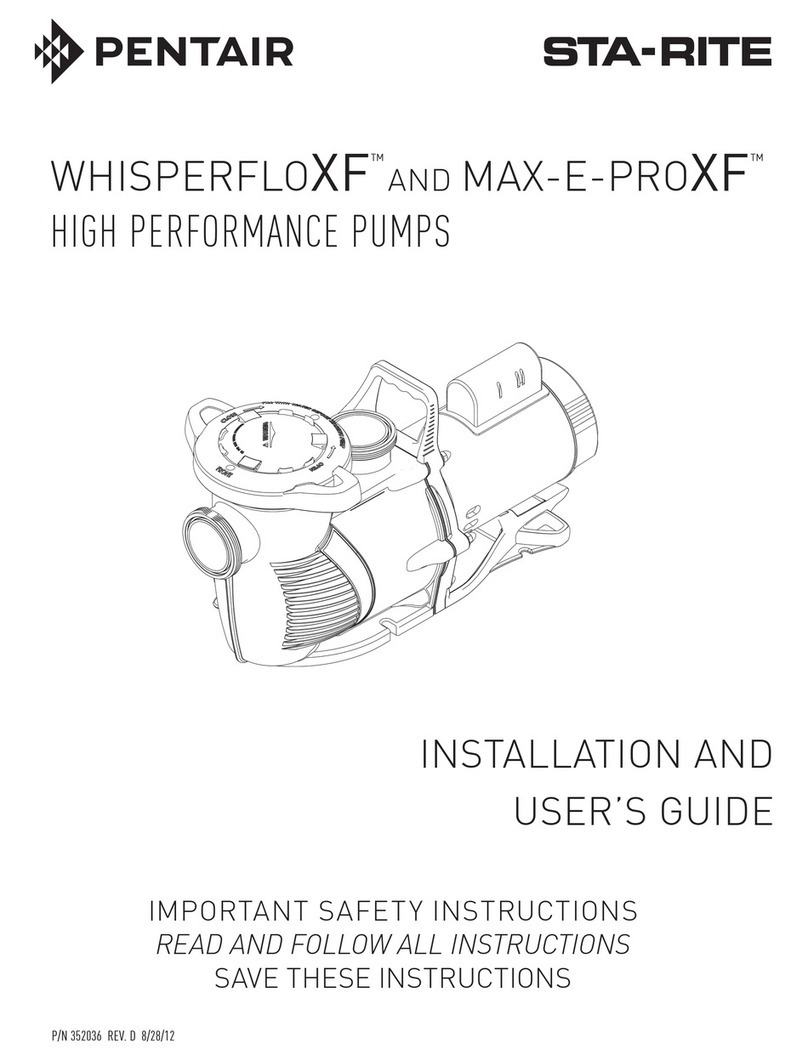

Pentair

Pentair WhisperFloXF Installation and user guide

York

York 4 SYK 2 Series manual

ProMinent

ProMinent alpha Series General operating instructions

Bühler technologies

Bühler technologies P4.3 Brief instructions

Maruyama

Maruyama MP2500E2 instruction manual

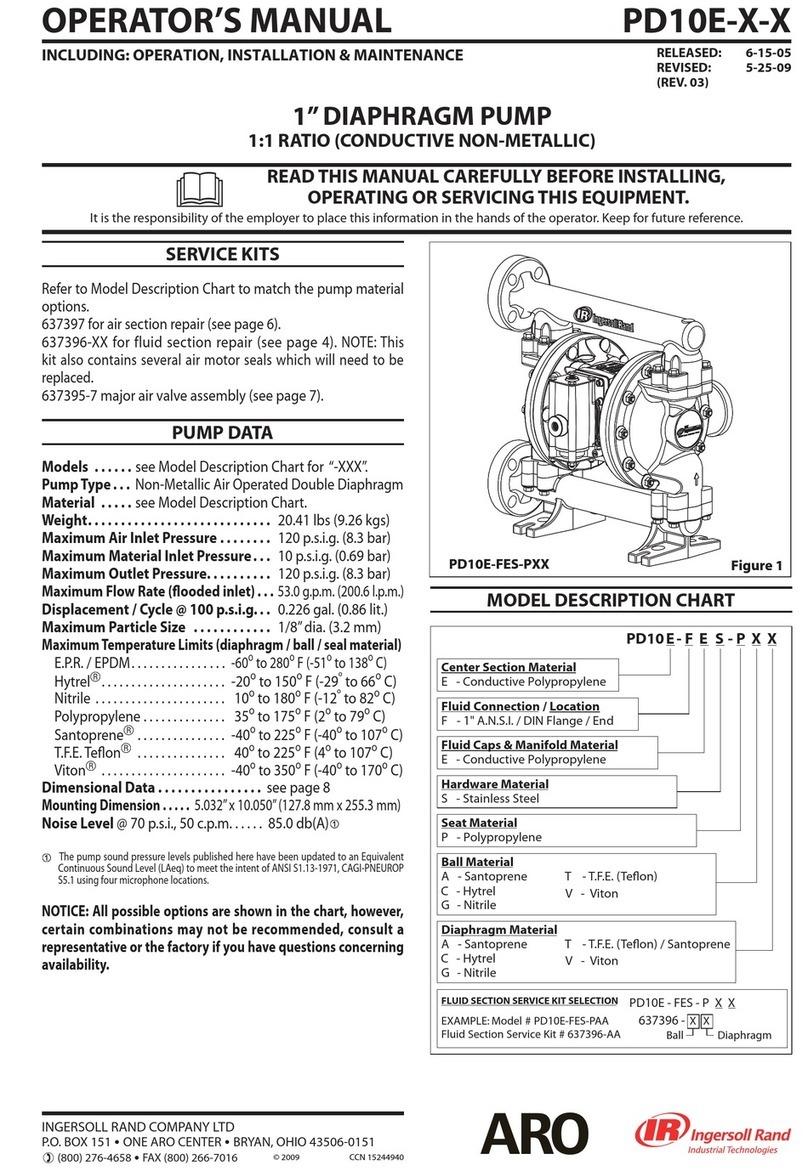

Ingersoll-Rand

Ingersoll-Rand PD10E-X-X user manual