© Copyright 1998, 2004, 2007, 2008

OY BEAMEX AB

Ristisuonraitti 10

FIN-68600 PIETARSAARI

FINLAND

Phone +358 - 10 - 5505000

Fax +358 - 10 - 5505404

Internet http://www.beamex.com

Beamex, Inc.

2270 Northwest Parkway, Suite 165

Marietta, GA 30067

U.S.A.

Phone: 800 888-9892,

+1-770-951-1927

Fax: +1-770-951-1928

Beamex Limited

Newtown Grange Farm Business Park

Desford Road

NEWTOWN UNTHANK

Leicestershire LE9 9FL

United Kingdom

Phone: 01455 821 920

Fax: 01455 821 923

Representative:

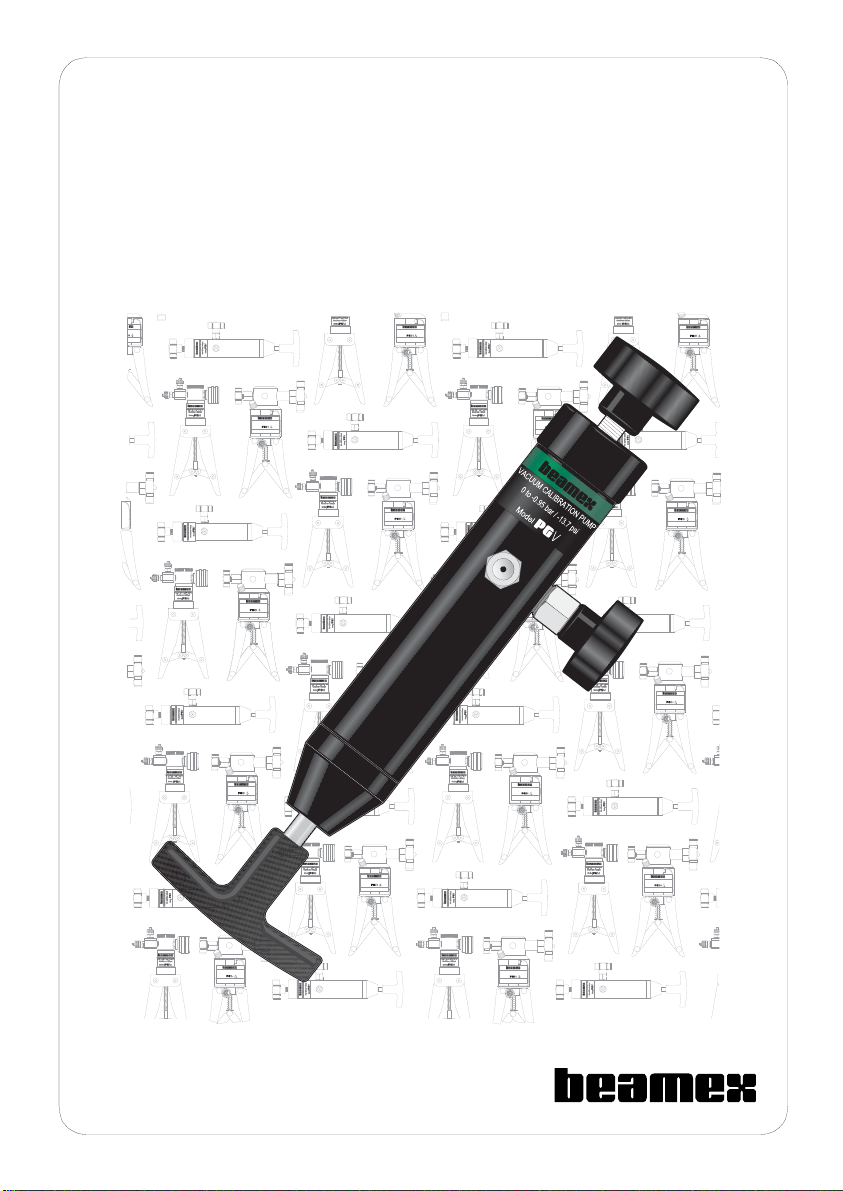

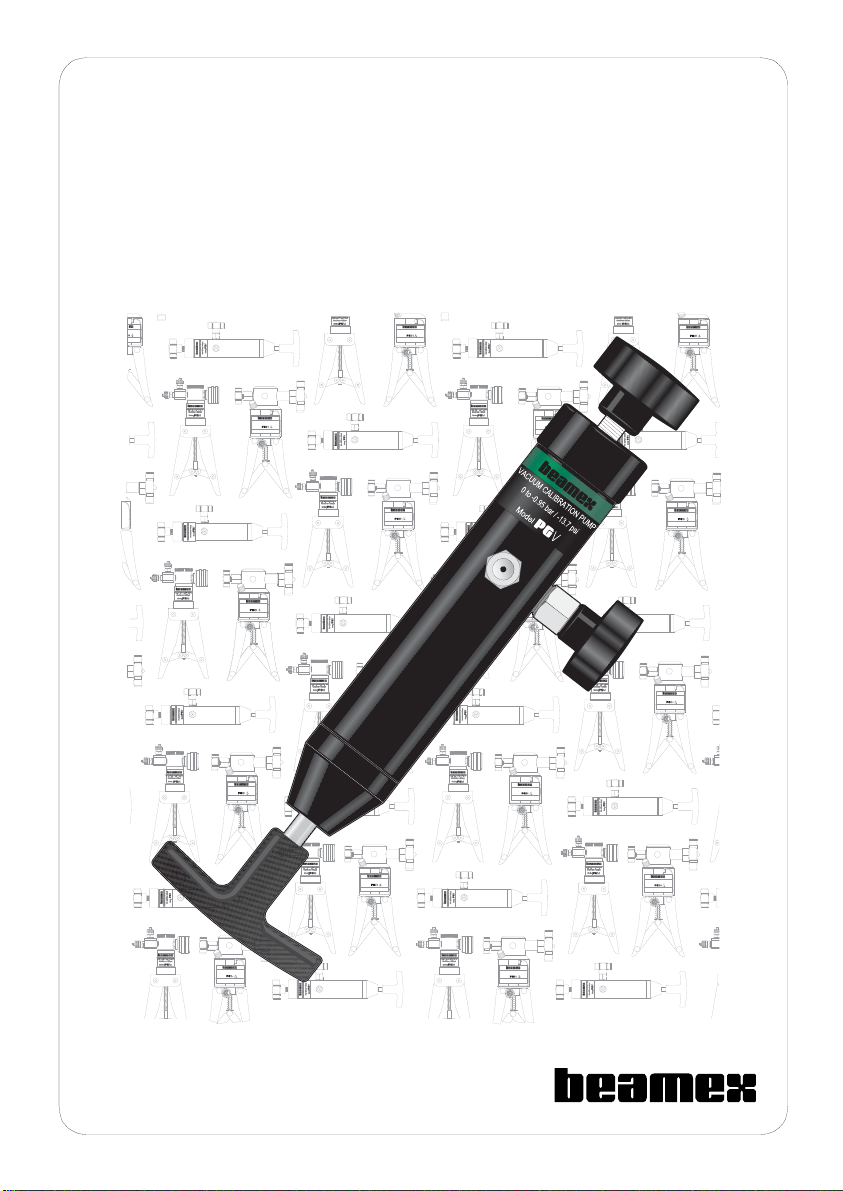

INSTRUCTION MANUAL

VACUUM CALIBRATION PUMP

MODEL PGV

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir

A T I O N P U M P

/ 1 0 0 0 0 p s i

S S U R E 7 0 0 b a r

s s re s e r v o i r

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir

P

R

I

M

E

H

I

G

H

H Y D R A U L I C C A L IB R A T I O N P U M P

0 t o 7 0 0 b a r / 7 0 M P a / 1 0 0 0 0 p s i

M o d e

M A X I M U M O U T P U T P R E S S U R E 7 0 0 b a r

D o n o t p r e s s u r iz e g a s s r e s e r v o ir