BeamTec Magnetron MPS 500 User manual

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

Magnetron Power Supply MPS 500

User Manual

August 2016, Rev2.1

EXCECUTIVE SUMMARY

The document contains a detailed description of the

start-up, configuration & interfacing of the power supply

MPS 500 User Manual Rev.2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

3

Table of content

1.Introduction 5

1.1. Intended Use 5

1.2. Liabilities and Warranty 5

1.4 Safety 6

1.4.1. Personnel Qualifications 6

1.4.2. Illustration Of Residual Dangers 6

1.4.3. General Safety Instructions 7

2. technical Data 9

2.1. General Data 9

2.1.1. Mechanical Data 9

2.1.2. ambience 10

2.1.3. Use and Operating Modes 10

2.1.4. STANDARDS 11

2.2. Mains Connection 11

2.3. Specifications 11

2.4 Features: 12

2.5. Interfaces 13

2.5.1. I/O interface 13

2.5.2. UART I ( RS232/RS485 ) 13

2.5.3 UART II BLUETOOTH 13

2.5.4 ETHERNET/IP 13

3. Installation 14

3.1. Unpacking 14

3.2. Mechanical Installation 14

3.2.1. Bench Top Unit 15

3.2.2. Rack Installation 15

3.3. Connecting 17

3.3.1. Rear Panel 17

3.3.3. Grounding 19

3.3.4. High Voltage Connectors HV1 and HV2 19

3.3.5. Interface Connector I/O 21

3.3.6. Vacuum Gauge Connector –„Gauge” 24

3.3.7 RS232/482 Interface Connector 25

3.3.8 Ethernet Interface 26

4. Using the Power Supply MPS500 28

4.1. Front Panel 28

4.1.1. Main Power Switch 28

4.1.2. Membrane Keyboard 29

4.1.3. High Voltage Indicator 30

4.1.4. Alphanumeric LCD display 30

4.1.5. Power Bar Identifier 30

4.1.6. Rotary Encoder with Press Button 31

4.2. Menu 31

4.2.1. Main Menu 32

4.2.3. Constant Power Mode Set 33

4.2.4. Constant Voltage Mode Set 33

4.2.5. Constant Current Mode Set 34

4.3. Submenus ( Main Menu ) 35

4.3.0. HV1 and HV2 output configuration 35

MPS 500 –User Manual Rev. 2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

4

4.3.1. Limits Settings 36

4.3.2. Ramp Settings 36

4.3.3. PI parameters for Constant Power Operation 37

4.3.4. Arcs Settings 37

4.3.5. Timer Or Continue Operating mode 39

4.3.6. Display Operating Mode Set –Timer, Vacuum or Arcs number 40

4.3.7. Load And Safe Options 41

4.3.7.1 LOAD the program 41

4.3.7.2 SAVE the program 42

4.3.8. SETTINGS options 42

4.3.9. SERVICE options 43

4.3.10. INFORMATION menu 43

4.4.0. COMMUNICATION options 44

4.4.0.1 INTERFACE Options 44

4.4.0.2 PARAMETERS Options 44

4.4.0.3 UNIT ADDRESS Option 45

4.4.0.4 SOFTWARE REMOTE Option 46

4.4.1 DISPLAY PARAMETERS Option 46

4.4.2 INTERLOCK TYPE option 47

4.4.3 BEEPER option 48

4.4.4 PRESSURE CHANNEL option 48

4.4.5. SAFE SETTINGS options 52

5. Additional Information 54

5.1 No Interlocks connected 54

5.2 Interlock lost during the normal operation 54

5.3 Overtemperature 55

6.Maintenance and Service 56

6.1 Maintenance 56

6.1.1 Cleaning 57

7 Storage and Disposal 58

7.1 Packaging 58

7.2 Storage 58

7.3 Disposal 58

8. Addition 59

8.1. Troubleshooting 59

9.Warranty Conditions 60

MPS 500 User Manual Rev.2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

5

1.INTRODUCTION

Please read this manual carefully to ensure optimum operating conditions right from the

start. This user manual handbook contains important information about the functionality,

installation, start-up and operation of the Magnetron Power Supply MPS500.

1.1. INTENDED USE

Power Supply MPS500 is a high voltage device which generates a high DC voltage of negative

polarity. MPS500 can be operated in three modes: Constant Power, Constant Voltage or

Constant Current.

The main field of application is the formation of plasma processes. The concept and design of

the power supply allows for safe and reliable integration of complex process control systems.

The device is referred to as MPS500 in the remainder of this manual.

1.2. LIABILITIES AND WARRANTY

BeamTec BeamTec company is not liable for damages resulting from improper use of the

device and the guarantee expires, if the user, or third party:

- ignores information contained in this manual,

- utilizes the product in a manner inconsistent with intended purpose,

- makes any modification or alteration of the product,

- unit should not be used with unauthorized accessories (compatible accessories, types

and models can be found in the product documentation)

BeamTec company reserves the right to make changes without prior notice. Illustrations may

vary depending on the version of the device.

MPS 500 –User Manual Rev. 2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

6

1.4SAFETY

1.4.1. PERSONNEL QUALIFICATIONS

All work described in this document may only be carried out by persons who have

suitable technical training and the necessary experience or who have been instructed by the

end user of the product.

1.4.2. ILLUSTRATION OF RESIDUAL DANGERS

This Operating Manual illustrates safety notes concerning residual dangers as follows:

Information on preventing any kind of physical injury.

Information on preventing extensive equipment and environmental damage.

Information on correct handling or use. Disregarding safety notes can lead to malfunctions or

equipment damage.

Note: Indicates particularly important, but not safety-relevant information.

DANGER

!

WARNING

!

CAUTION

!

MPS-10 Instrukcja obsługi Rev.1.0

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

1.4.3. GENERAL SAFETY INSTRUCTIONS

For all work you are going to do, adhere to the applicable safety regulations. Also

observe all safety notes given in this document and forward the information to all other users

of the product. In particular, pay attention to the following safety notes:

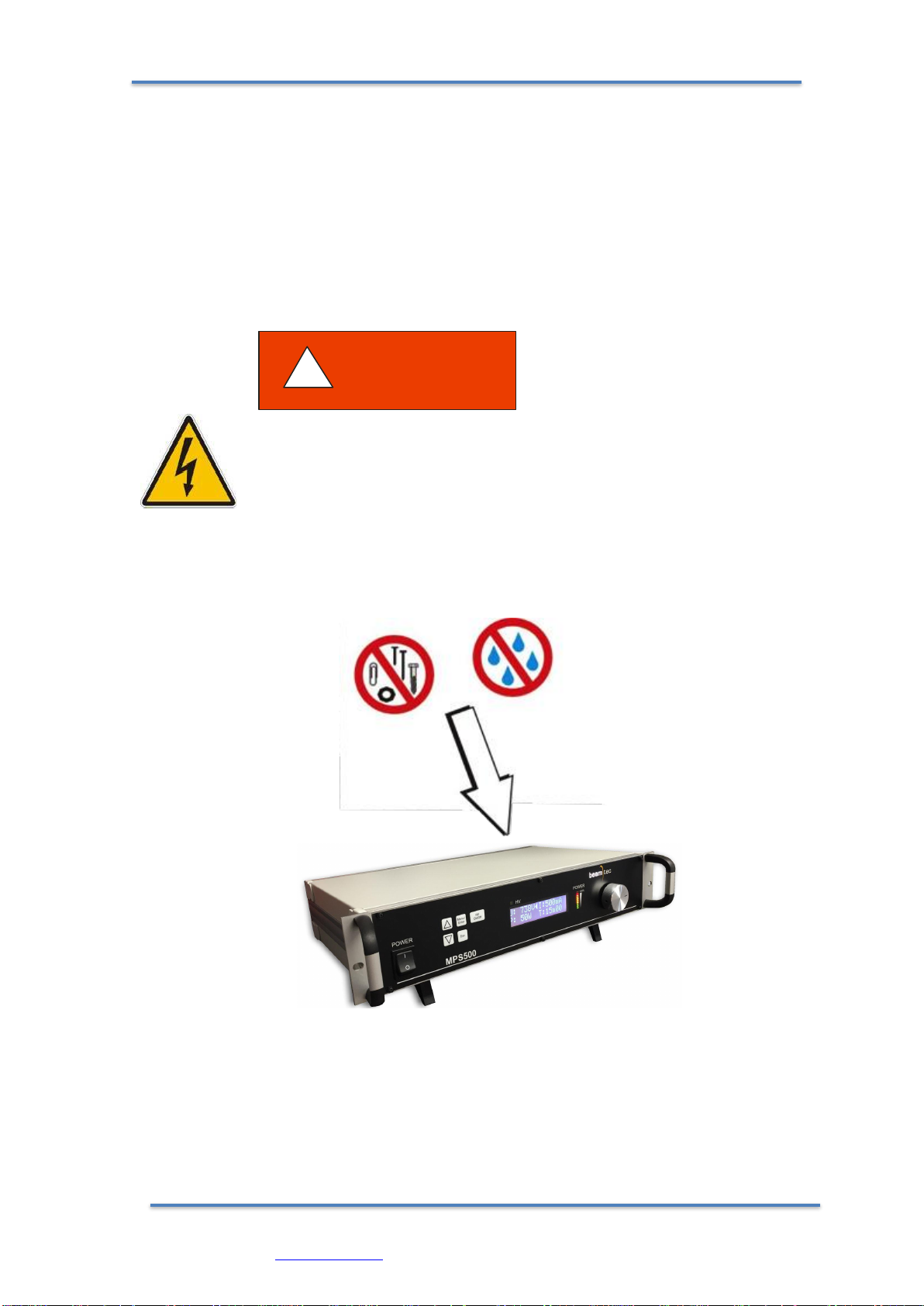

Fig 1.0.1 Do not insert objects through louvers and keep device dry

Mains voltage.

Contact with live parts is extremely hazardous when any objects are

introduced or any liquids penetrate into the device.

Make sure that no objects enter through the louvers of the device. Keep the

device dry.

DANGER

!

MPS 500 –User Manual Rev. 2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

8

Improper use.

Improper use can damage the MPS500.

Use the MPS500 only as intended by the manufacturer.

Improper installation and operation data.

Improper installation and operation data may damage the MPS500.

Strictly adhere to the stipulated installation and operation data.

WARNING

!

WARNING

!

MPS 500 User Manual Rev.2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

9

2. TECHNICAL DATA

2.1. GENERAL DATA

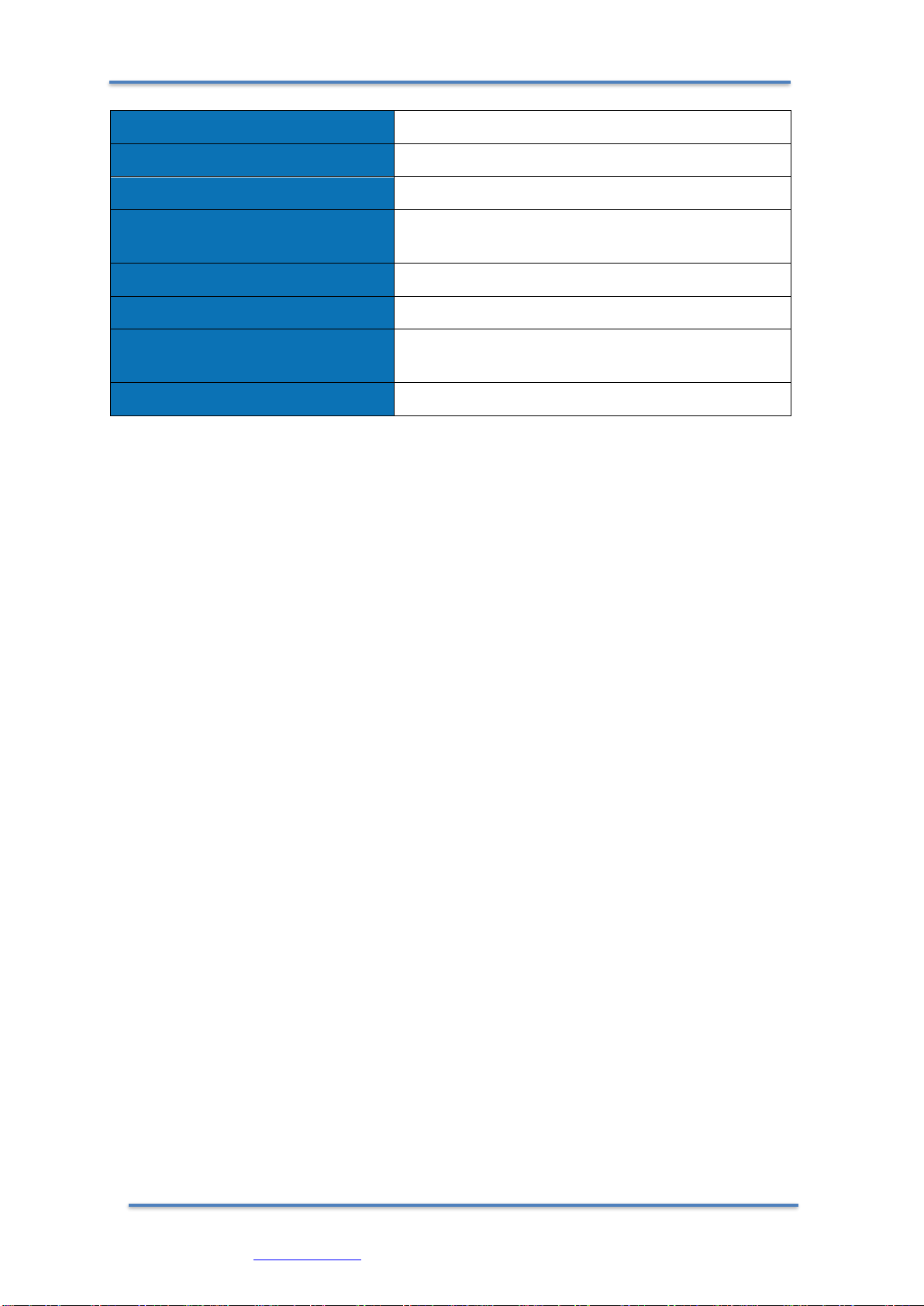

2.1.1. MECHANICAL DATA

Dimensions: Width: 482 mm

Height: 88,1 mm (2 HU)

Depth: 340 mm

See Fig . 2.1.1

Net Weight: 3,3 kg

Installation: 19” Rack standard or Bench Top unit

Fig. 2.1.1 Dimensions (mm)

Note: The image above is illustrative, rear panel connectors may differ depending on

the version of the device.

483 mm

87 mm

418 mm

310 mm

270 mm

MPS 500 –User Manual Rev. 2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

10

2.1.2. AMBIENCE

Temperature Storage: -10…+60 °C

Operation Temperature: +5…+40 °C

Relative Humidity: Max. 80 % (up to 31 °C), decreasing to max. 50

% (above 40 °C)

Use indoor only

Altitude: max. 2000 m n.p.m.

The degree of dust standard: II

Humidity resistance: IP20

2.1.3. USE AND OPERATING MODES

There are three common operation modes:

- manual control, with 5 buttons user interface on the front panel

- software remote control, with RS232/RS485 or Ethernet Interface

( All Read commands are accessible all the time, Write commands are

accessible only with activation of this function from the user menu –see

remote control for use )

- hardware remote control with I/O interface –see Fig.3.3.1

This mode is active with external signal only. In this mode all of the front

buttons are deactivated.

MPS 500 User Manual Rev.2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

11

2.1.4. STANDARDS

Conformity with the Directive relating to electrical equipment designed for use within

certain voltage limits 73/23/EWG

Conformity with the Directive relating to electromagnetic compatibility 89/336/EWG

Harmonized and international/national standards and specifications:

EN 61010-1 (Safety requirements for electrical equipment for measurement, control

and laboratory use)

EN 61000-6-2 (Electromagnetic compatibility generic immunity standard)

EN 61000-6-3 (Electromagnetic compatibility generic emission standard)

2.2. MAINS CONNECTION

Voltage: 230V for European, African, and Asian market

110V for American market

Frequency: 50 - 60 Hz

Current consumption: Max. 3,15A at 230V, 6,3A at 110V

Power consumption: Max. 600 W

Overvoltage category II

Protection class 1

Connection European appliance connector IEC 320 C14

Fuse T3,15A at 230V

T6A at 110V

2.3. SPECIFICATIONS

Input Supply Voltage

( Configurable with order )

90 to 132 VAC (50 to 60 Hz), 1 phase or

180 to 265 VAC (50 to 60 Hz), 1 phase

Current consumption

5 A max at 120 VAC and power 500 W

2,7 A max at 230 VAC and power 500 W

Output power

500W max

Output Voltage / Current

0–1000 VDC negative polarisation (1 volt resolution)

0–1000 mA (1 mA resolution)

MPS 500 –User Manual Rev. 2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

12

Regulation mode

Power, Voltage or Current mode

Ripple Noise

Switching: 2% p-p (50 kHz)

Ramp Up time

0.1 …. 65 s

Communication Interface

RS232 and LAN/Ethernet 100Mb, Bluetooth in

standard

Type of control

Local or remotely

Arc Detection

Response time < 95 ns

Dimensions

418 mm x 270mm x 87 mm ( 2U high unit - 19”

standard )

Weight

6.1 kg

2.4 FEATURES:

Operating mode: DC

Two high-voltage outputs - the ability to support two independent magnetrons

without having to use an external switch

Fast response arc detection/suppression

Switched control methods (I, V, P) for maximum performance,

The ability to connect one active vacuum measuring head (optional)

Transparent interface with OLED display and desk light identification parameters

Built-in timer

Stable power operation from just 2W

High acceptance output impedance - ability to work with magnetrons of different

sizes

Suitable for working with one or two magnetrons

User-friendly interface with OLED display, keypad and rotary encoder

MPS 500 User Manual Rev.2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

13

2.5. INTERFACES

2.5.1. I/O INTERFACE

Connector: D-Sub 25 female connector

Refer to chapter 3.3.5 for details

No of Digital Inputs: 6 –opto-isolated; 24VDC

No of Digital Outputs: 6 –OC type, opto-isolated; 24 VDC

No of Analog Inputs: 3 –voltage input type, opto-isolated ( 0..10V)

No of Analog Outputs: 3 –voltage output type, opto-isolated (0..10V)

Response time: 100 ms max

2.5.2. UART I(RS232/RS485 )

Connector: D-Sub 9; female connector

Transmission mode: 2400, 4800, 9600, 19200, 38400, 57600, 115200 bits/s

Data Length: 8 bit

Parity Control: none

Stop Bit: 1

Transmission Control: none

2.5.3 UART II BLUETOOTH

Transmission mode: 2400, 4800, 9600, 19200, 38400, 57600, 115200 bits/s

Data Length: 8 bit

Parity Control: none

Stop Bit: 1

Transmission Control: none

2.5.4 ETHERNET/IP

Connector: RJ45

Transmission mode: 100 MB/s

TCP/IP stack, IPv4

NOTE: The communication protocol is decribed in separate document

MPS 500 –User Manual Rev. 2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

14

3. INSTALLATION

3.1. UNPACKING

1. Visually inspect the transport packaging for signs of external damage

2. Unpack the MPS500 and put the packaging material aside

Note: Keep the packaging material for later use. The MPS500 must be stored

and transported in the original packaging material only.

3. Examine the MPS500 for completeness

4. Visually inspect the MPS500 for signs of damage

Damaged product.

Putting a damaged product into operation can be extremely dangerous.

Never attempt to put a damaged product into operation. Secure the damaged

product from unintended operation. Send a damage report to the haulage

company or the insurer.

3.2. MECHANICAL INSTALLATION

MPS500 can be used in the following ways: as a bench top device, mounted in

a control panel or mounted in a 19 "rack. In each case, consider the following

important safety information:

The temperature of the environment.

Exceeding the allowable temperature of the device may damage the unit.

DANGER

!

WARNING

!

MPS 500 User Manual Rev.2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

15

Make sure that the maximum permissible ambient temperature is not

exceeded, and the air can circulate freely through the ventilation slots. Do

not expose the device to direct sunlight.

3.2.1. BENCH TOP UNIT

MPS500 is supplied with a 4 prop-up feet, which, when the device is to be used as a

stand-alone device, must be installed as shown in Fig. 3.2.0

Fig 3.2.0

NOTE: The prop-up feet must be fixed only with the screws supplied. In

the case of rack mounting, prop-up feet should not be installed

3.2.2. RACK INSTALLATION

The MPS500 is designed for installation into a rack according to DIN 41 494 (19", 3

HU).

WARNING

!

MPS 500 –User Manual Rev. 2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

16

Ambient temperature.

Exceeding the maximum permitted ambient temperature may damage the device.

Make sure that the maximum permitted ambient temperature is not exceeded and

that the air can flow freely through the louvers. Do not expose the device to direct

sunlight.

Protection class of the rack.

If the product is installed in a rack, it is likely to lower the protection class of the

rack (protection from foreign bodies and water) e.g. according to the EN 60204-1

regulations for switching cabinets.

Take appropriate measures to restore the required protection class of the rack.

In case of rack installation, all of the prop-up feet have to be removed. To do this:

1. Turn the MPS500 off and remove the mains cable.

2. Carefully turn the MPS500 over to reveal the bottom as shown in Fig. 3.2.0.

3. Unscrew and remove the prop-up feet

4. Turn the MPS500 to the normal position and install in the rack

Note: To reduce the stress on the front panel, the device must be supported with rack

rails.

1. Insert MPS500 guides.

2. Screw the MPS500 using the supplied screws and plastic sleeves.

DANGER

!

MPS 500 User Manual Rev.2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

17

3.3. CONNECTING

3.3.1. REAR PANEL

AB C D E

F G H

Fig. 3.3.0 Rear panel MPS500

A –HV1 and HV2 output connectors type N-50/2-0/G1.07

B –fans and filters

C - RS232 interface Dsub 9 female ( RS485 optionally )

D –Ethernet interface RJ45

E –main power socket IEC C13

F –I/O interface connector Dsub 25 female ( see chapter 3.3.5 for details )

G –Vacuum Gauge Connector ( Dsub 9 )

H –grounding pin

MPS 500 –User Manual Rev. 2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

18

Screw for internal protective conductor.

The internal protective conductor is connected to the casing with a screw.

Do not turn or loosen this screw.

The configuration of the available connections and photographs of cables is described

in the following sections.

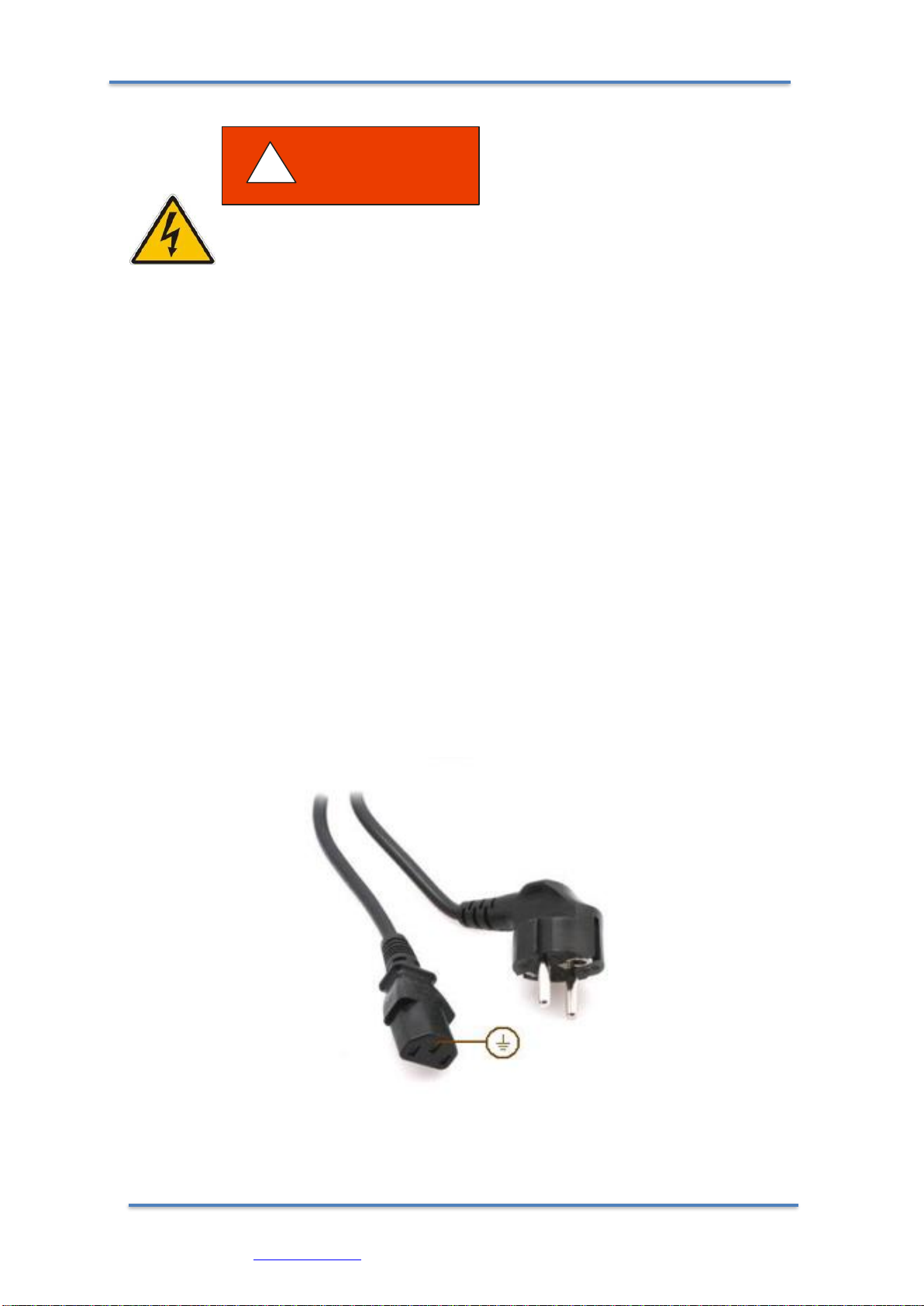

3.3.2. MAINS CONNECTION

The mains connection is designed for a mains cable which contains IEC 320 connector

on the device side. A mains cable is supplied with the device. If the plug is not

compatible with your wall socket, you should replace it with a suitable mains cable:

Three-conductor cable with protective ground

Conductor cross-section 3x1.5 mm2or larger

Fig. 3.3.1 Three-conductor cable with protective ground (example)

DANGER

!

MPS 500 User Manual Rev.2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

19

Mains power.

Improperly grounded devices can be extremely dangerous in the event of a

fault. Use three-wire mains or extension cables with protective ground only.

Plug the mains cable into wall sockets with protective ground only.

1. Connect the European appliance connector of the mains cord with the mains

connection of the device

2. Connect the plug of the mains cable with the wall socket

Note:

If the device is installed in a switching cabinet, the mains power can be supplied via a

switchable central power distributor.

3.3.3. GROUNDING

Grounding screw (Fig. 3.3.0, the reference H) should be used to connect the MPS500

with the main grounding system in which it operates. It is recommended to use a

cable with a minimum section of 2.5 mm2

If required, connect the vacuum system ground from the earthing screw using the

protective conductor.

3.3.4. HIGH VOLTAGE CONNECTORS HV1 AND HV2

The power supply is equipped with two HV outputs of N-50/2-0/G1.07 type. Output

configuration is set by the software user interface. Please refer to chapter 4.3.0

1

DANGER

!

MPS 500 –User Manual Rev. 2.1

BeamTec GmbH

Wolfgang-Paul-Str. 4, 89081 Ulm, Germany

http: www.beamtec.de , e-mail: info@beamtec.de tel.: +49 731 146620-0

20

2

Fig. 3.3.0 HV connector , N-50/2-0/G1.07 type

1 –HV1 ( - 1000 VDC )

2 –HV2 ( - 1000 VDC )

It is recommended not to run the device without a connected load. Doing

so can damage the power supply

CAUTION

!

Hazardous voltage.

After entering "Operate" mode (HV LED indicator on the front panel is lit),

the connector develops voltage levels dangerous to life and health. The

device must be turned off and completely isolated before any work

associated with connecting or disconnecting the high voltage cable. When

turned off, you must wait at least 15 seconds before attempting to connect /

disconnect the HV cable.

DANGER

!

Table of contents