Beast RS25 User manual

INTRODUCTION

Welcome to the Beast family! Thank you for putting your trust in

our components. You have chosen one of the sturdiest, lightest,

best quality products there is. Genuine craftsmanship - developed,

designed and manufactured in Germany.

Your safety is very important to us, so please read this manual

carefully before you install your new Beast Components product or

ride it for the first time. Third party users must also be informed

about the following provisions. Therefore, please keep these

instructions in a safe place for later usage.

These operating instructions are intended for the user of the

wheelset and includes information on the installation, handling,

maintenance and care of the wheelset. Please follow all instructions.

Your Beast Components-Team

Release your Beast and share experiences with our community!

#beastcomponents #releaseyourbeast #beabeast

WARRANTY & SERVICE

OUR PROMISE

We manufacture the highest quality products for your bike and also

want to ensure the best possible service and support. Therefore we

offer the original owner of Beast Components products a 5-year

warranty and a lifetime crash replacement program for our entire

product range.

PRODUCT REGISTRATION

To get the manufacturer‘s warranty and to participate in the crash

replacement program, you must register your components. Send us

an email with a copy of the invoice and the following information to

Name, First Name

Address

Phone number

5 YEARS MANUFACTURER WARRANTY

We vouch for the quality of our products „Made in Germany“. This

is why we warrant our carbon products to be free from defects in

material or workmanship for five years from the original purchase

date (product registration required).

Modified, misplaced, misused, improperly installed or obviously

abused Beast Components products are not covered by this

warranty.

Based on this warranty, the company Black East GmbH is not liable

for compensation, especially not for indirect damage caused by

accidents, collateral damage and consequential damage.

LIFELONG CRASH REPLACEMENT

We offer the original owners of Beast Components products a

lifetime crash replacement program that covers all damages

(optical damages are excluded) outside of the warranty, whether

self-inflicted or third-party caused (product registration required).

In this case we guarantee you a one-time discount of 50% on

our recommended retail price if you decide to buy any new Beast

Components product in the same product category.

Please note that VAT, packaging, shipping and installation costs and

any import duties are not covered.

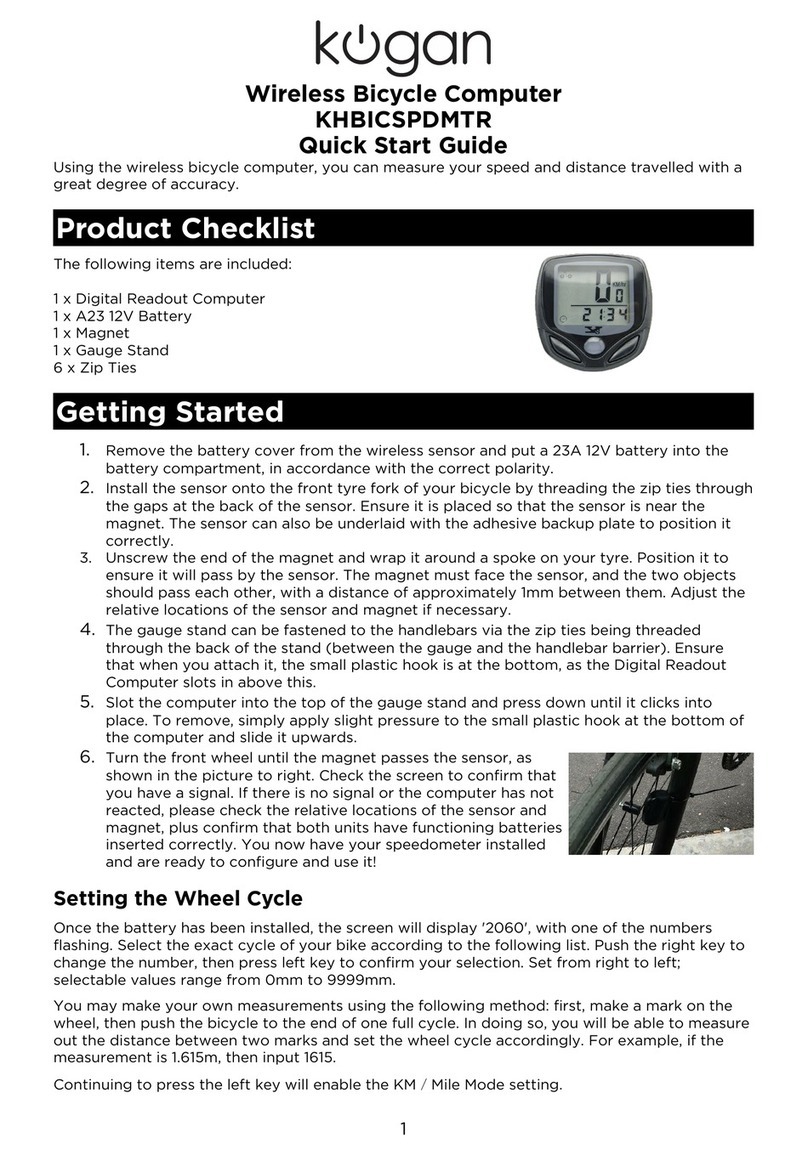

INTENDED USE

The intended use of Beast Components products is divided into

six categories, from riding on paved roads to downhill and freeride

use. Details can be found in the enclosed classification or at www.

beast-components.de/service. Beast Components products may

only be used within or below the intended category. Otherwise the

user takes full responsibility.

CATEGORY 1 / ROAD: RS25, RX25, RR40, RX40, RX60, RX80

CATEGORY 2 / LIGHT GRAVEL: GR40

CATEGORY 3 / XC & HARD GRAVEL: GR25, XC25, XS30, XC30

CATEGORY 4 / TRAIL & ALL MOUNTAIN: TR30

CATEGORY 5 / ENDURO & HYBRID: ED30, HY30, HY35

CATEGORY 6 / DH: DH30

INSTRUCTION MANUAL

WHEELSET

V2021.01

Page 1

ATTENTION:

Incorrect handling, installation, maintenance or servicing

can lead to accidents causing severe injuries or death!

V2021.01

Page 2

GENERAL INFORMATION

Our wheelsets are approved for tubular as well as tubeless systems.

Beast Components wheelsets are to be used exclusively with brake

discs. When used with rim brakes, they will be seriously damaged,

posing an enormous safety risk for the rider and third parties.

Modification of the wheelsets are not permitted and will void your

warranty.

WEIGHT LIMIT

Except for the RS25 and the XS30, our rims are not subject to any

weight limits. The system weight (bike, rider and equipment) of the

RS25 and the XS30 should be a maximum of 115kg and must not be

exceeded.

APPEARANCE

Our components are 100% handmade. Thereby it can come to

different appearances. It makes each component unique and has no

influence on the safety. By direct incidence of light you get a great

view of the individual fibers with partly shimmering shades.

WHEELSET ASSEMBLY INFORMATION

The choice of components as well as the spoking pattern and the

wheel construction itself influence the intended use of the entire

wheel and can significantly restrict it. Beast Components therefore

recommends to maintain the wheels by an experienced specialist.

This will ensure a long and problem-free service life.

If your wheelset should need maintenance or service, you or your

dealer will find information on the assembly of your wheelset in

this section and in the table on the following page. If there are any

questions, please contact us.

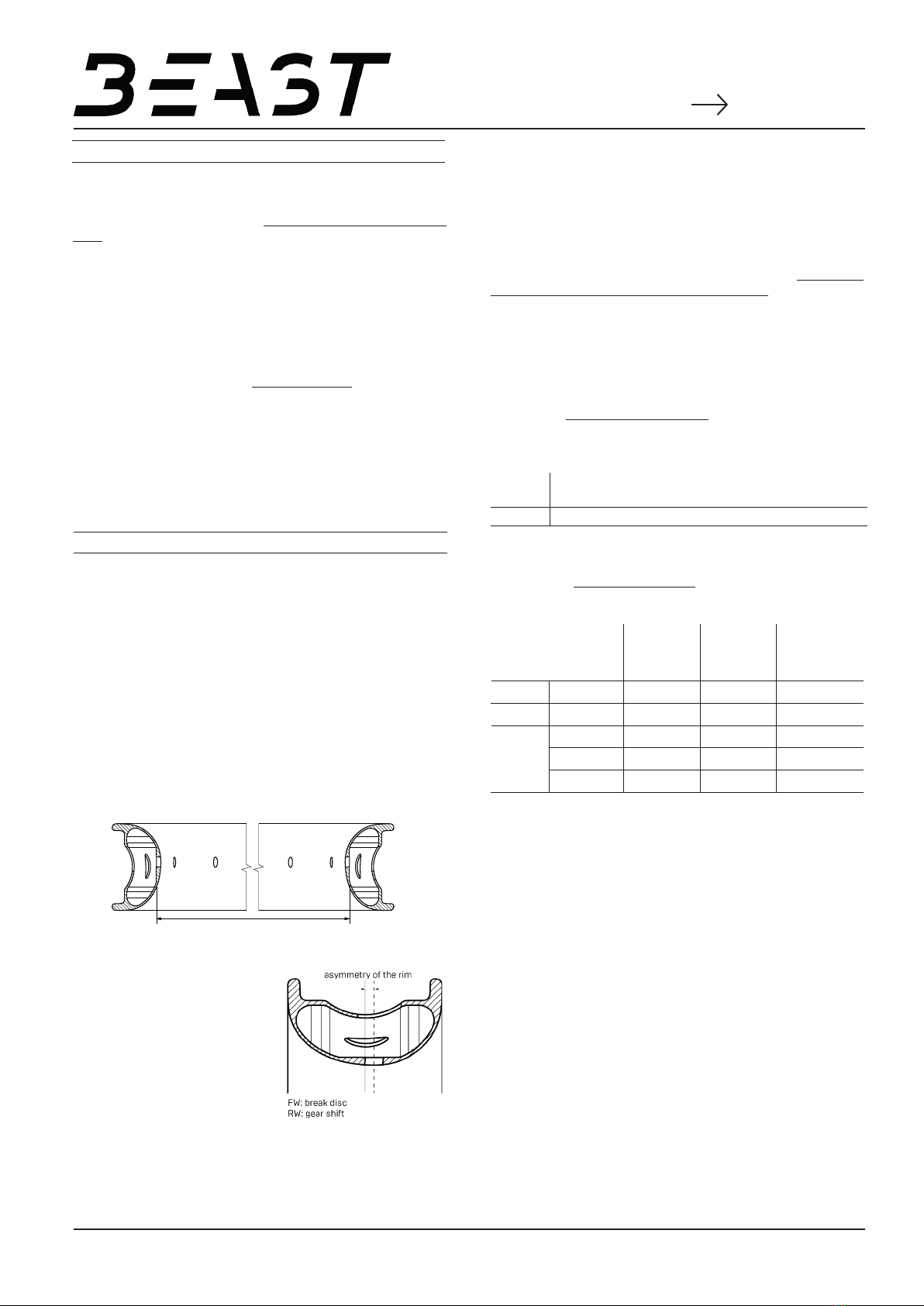

EFFECTIVE RIM DIAMETER (ERD)

The ERD is the direct distance between the opposite nipple seats.

The ERD tolerance is +1mm. Please refer to the table on the next

page for the exact ERD details of the respective rim.

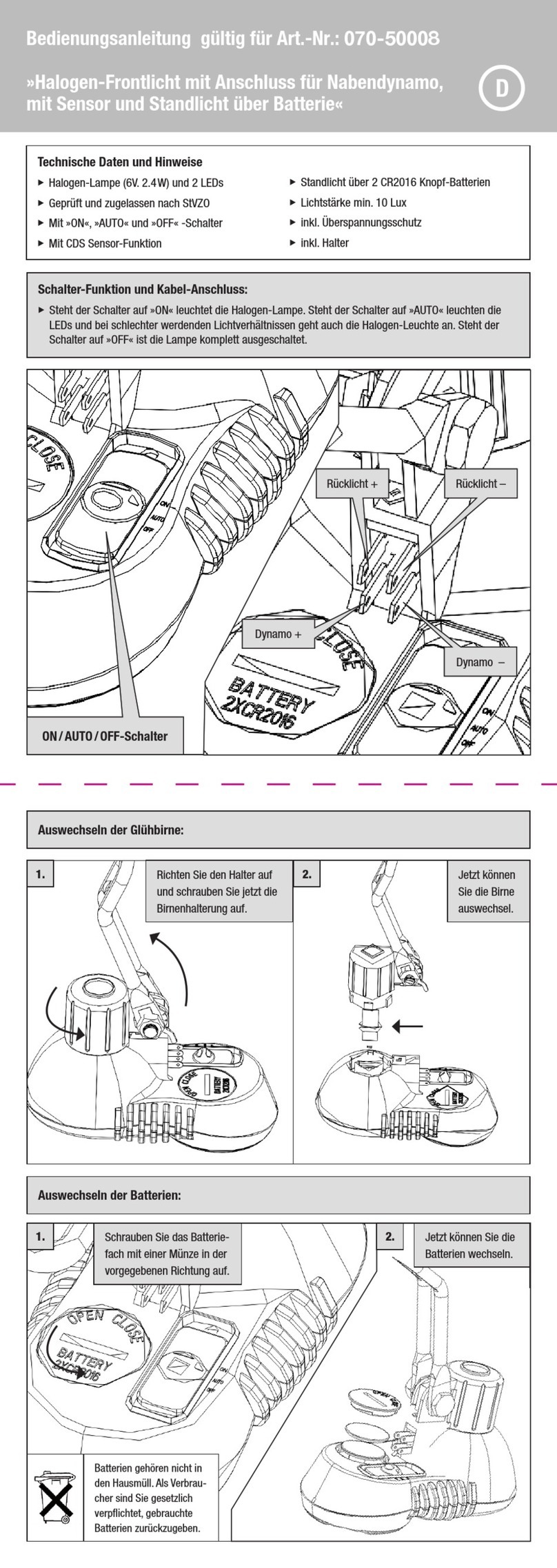

ASYMMETRY OF THE RIMS

Please note the possible

asymmetry of the rim depending

on the rim model (see table on

next page). The asymmetrical

offset must point away from the

brake disc on the front wheel

and away from the gear shift on

the rear wheel to compensate

for the flange offset of the hubs.

NIPPLE

For optimal power transmission, we recommend to use as external

nipple „Sapim Polyax Double Square 14G 16mm“ with Secure Lock.

These must be positioned between the nipple and the rim and must

fit correctly on the inner surface of the rim.

WASHERS

When building up wheels with external nipples, it is essential to

use washers called „MG Washer“ from Newmen. These must be

positioned between the nipple and the rim and have to fit correctly

on the inner surface of the rim.

It is recommended to apply grease between nipple and washer to

prevent abrasion of nipple and washer.

SPOKE TENSION

The following maximum spoke tensions should neither be exceeded

nor undercut. Otherwise the spokes may break or the rim may be

damaged.

maximum allowable spoke tension of the higher

tensioned wheel side [N]

FW / RW 1200

TOLERANCES

The following maximum tolerances should not be exceeded or

undercut.

lateral

runout

[mm]

radial

runout

[mm]

concentricity

[mm]

ROAD RS, RX, RR ± 0,2 ± 0,2 ± 0,2

GRAVEL GR, ± 0,25 ± 0,2 ± 0,2

MTB

XC, XS ± 0,25 ± 0,2 ± 0,2

TR, ED, DH ± 0,3 ± 0,2 ± 0,3

HY ± 0,4 ± 0,2 ± 0,3

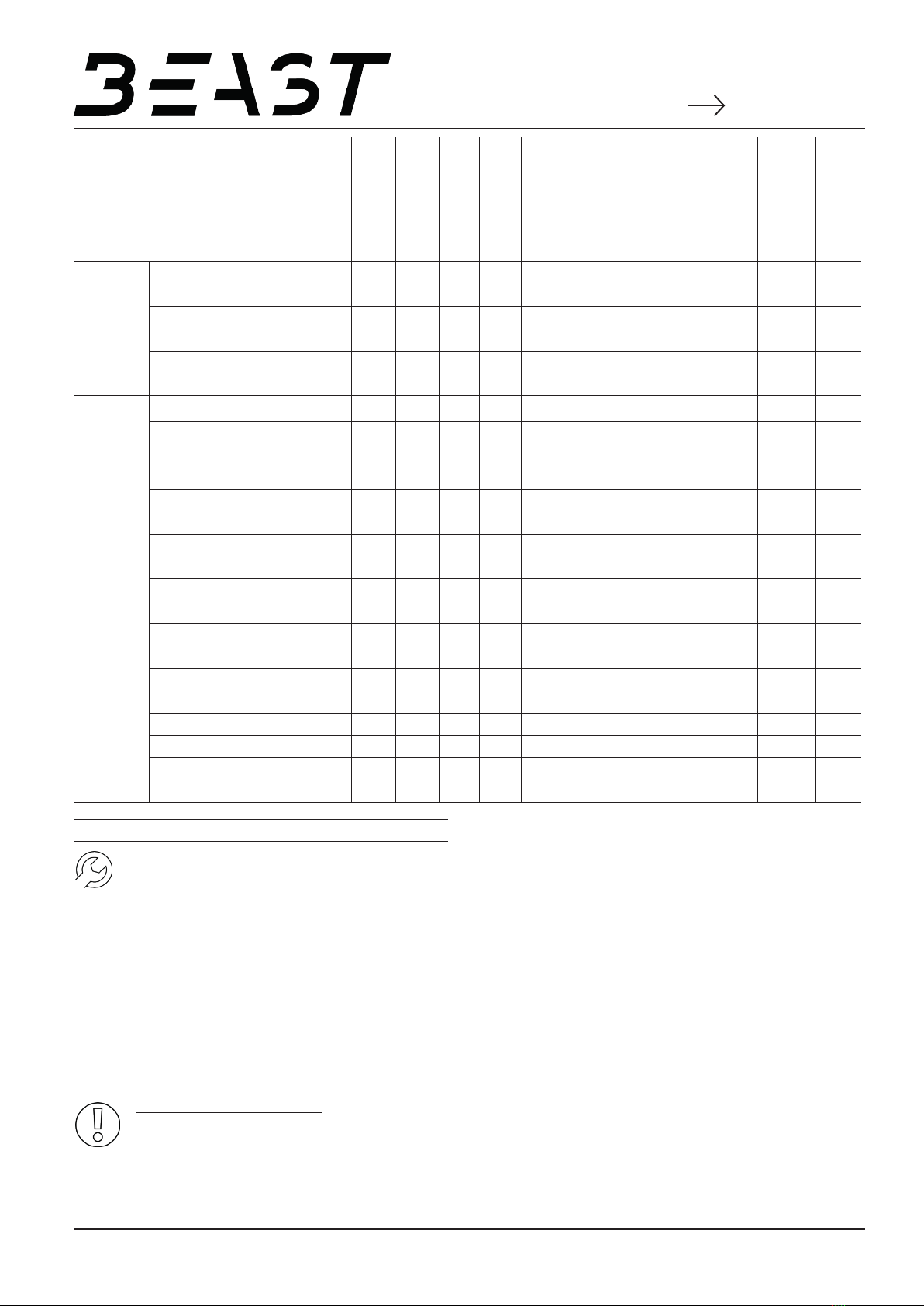

ERD

INSTRUCTION MANUAL

WHEELSET

categories

weight limit

asym. offset (mm)

ERD (mm)

spokes used

nipple

washer

ROAD

RS25 | 700C | 24 holes 1 115kg - 587 Sapim CX-Ray & Sprint (RW drive side) internal -

RX25 | 700C | 24 holes 1 - - 587 Sapim CX-Ray & Sprint (RW drive side) internal -

RR40 | 700C | 24 holes 1 - - 557 Sapim CX-Ray & Sprint (RW drive side) internal -

RX40 | 700C | 24 holes 1 - - 557 Sapim CX-Ray & Sprint (RW drive side) internal -

RX60 | 700C | 24 holes 1 - - 517 Sapim CX-Ray & Sprint (RW drive side) internal -

RX80 | 700C | 24 holes tba tba tba tba tba tba tba

GRAVEL

GR40 | 700C | 24 holes 2 - - 557 Sapim CX-Ray & Sprint (RW drive side) internal -

GR25 | 650B | 24 holes 3 - 2 550 Sapim CX-Ray & Sprint (RW drive side) internal -

GR25 | 700C | 24 holes 3 - 2 587 Sapim CX-Ray & Sprint (RW drive side) internal -

MTB

XC25 | 27,5“ | 28 or 32 holes 3 - 2 550 Sapim CX-Ray & Sprint (RW drive side) internal -

XC25 | 29“ | 28 or 32 holes 3 - 2 587 Sapim CX-Ray & Sprint (RW drive side) internal -

XS30 | 29“ | 28 or 32 holes 3 115kg 2 596 Sapim D-Light external yes

XC30 | 27,5“ | 28 or 32 holes 3 - 2 551 Sapim D-Light external yes

XC30 | 29“ | 28 or 32 holes 3 - 2 587 Sapim D-Light external yes

TR30 | 27,5“ | 28 or 32 holes 4 - 2 550 Sapim D-Light external yes

TR30 | 29“ | 28 or 32 holes 4 - 2 587 Sapim D-Light external yes

ED30 | 27,5“ | 28 or 32 holes 5 - 2 551 Sapim D-Light external yes

ED30 | 29“ | 28 or 32 holes 5 - 2 587 Sapim D-Light external yes

HY30 | 27,5“ | 28 or 32 holes tba tba tba tba tba tba tba

HY30 | 29“ | 28 or 32 holes tba tba tba tba tba tba tba

HY35 | 27,5“ | 28 or 32 holes 5 - 3 550 Sapim Force external yes

HY35 | 29“ | 28 or 32 holes 5 - 3 588 Sapim Force external yes

DH30 | 27,5“ | 28 or 32 holes 6 - 2 552 Sapim Force external yes

DH30 | 29“ | 28 or 32 holes 6 - 2 590 Sapim Force external yes

V2021.01

Page 3

INSTALLATION

GENERAL INFORMATION

Before installation, make sure that the installation dimension of the

hub fits your fork and frame.

Please read the hub instructions carefully before installing the

wheelset. You can find these under:

https://www.dtswiss.com/en/support/manuals

Only use valves with a suitable diameter and sufficient length. The

valve hole must not be modified.

Do not use metal tire levers. These can damage the surface of the

rim, the tire or the tube.

Attention: Maximum tire pressure

The maximum tire pressure of the wheel and the

tire used must not be exceeded. Details can be

found in the enclosed note „Tire Pressure“ or at

www.beast-components.de/en/service.

FITTING TIRES WITH A TUBE

Attach the rim tape. Assemble the inner tube and tire according

to the manufacturer‘s specifications. We recommend using soapy

water or installation fluid. Pump the tires up to their maximum

approved pressure. The lower of the pressures specified for the rim

or tire applies (Details can be found in the enclosed tire pressure

information or at www.beast-components.de/service). Check the

tire seat. The tire must contact the rim evenly around its entire

circumference. Have the tire seat checked by a professional if in

any doubt. If necessary, reduce the tire pressure to the desired

operating pressure.

FITTING THE TIRES WITHOUT A TUBE

Make sure that the tubeless tape and a tubeless valve are mounted.

The Tubeless Tape and the valve must be used in the width and

height suitable for the rim. Please refer to the tables on the next

page.

Put sealant fluid into the tires. Comply with the instructions of

the sealant manufacturer. Assemble the wheels according to the

manufacturer‘s specifications. We recommend using soapy water

or installation fluid.

INSTRUCTION MANUAL

WHEELSET

INSTRUCTION MANUAL

WHEELSET

Pump the tires up to their maximum approved pressure. The lower

of the pressures specified for the rim or tire applies (Details can be

found in the enclosed tire pressure information or at www.beast-

components.de/service). Check the tire seat. The tire must contact

the rim evenly around its entire circumference. Have the tire seat

checked by a professional if in any doubt. If necessary, reduce the

tire pressure to the desired operating pressure.

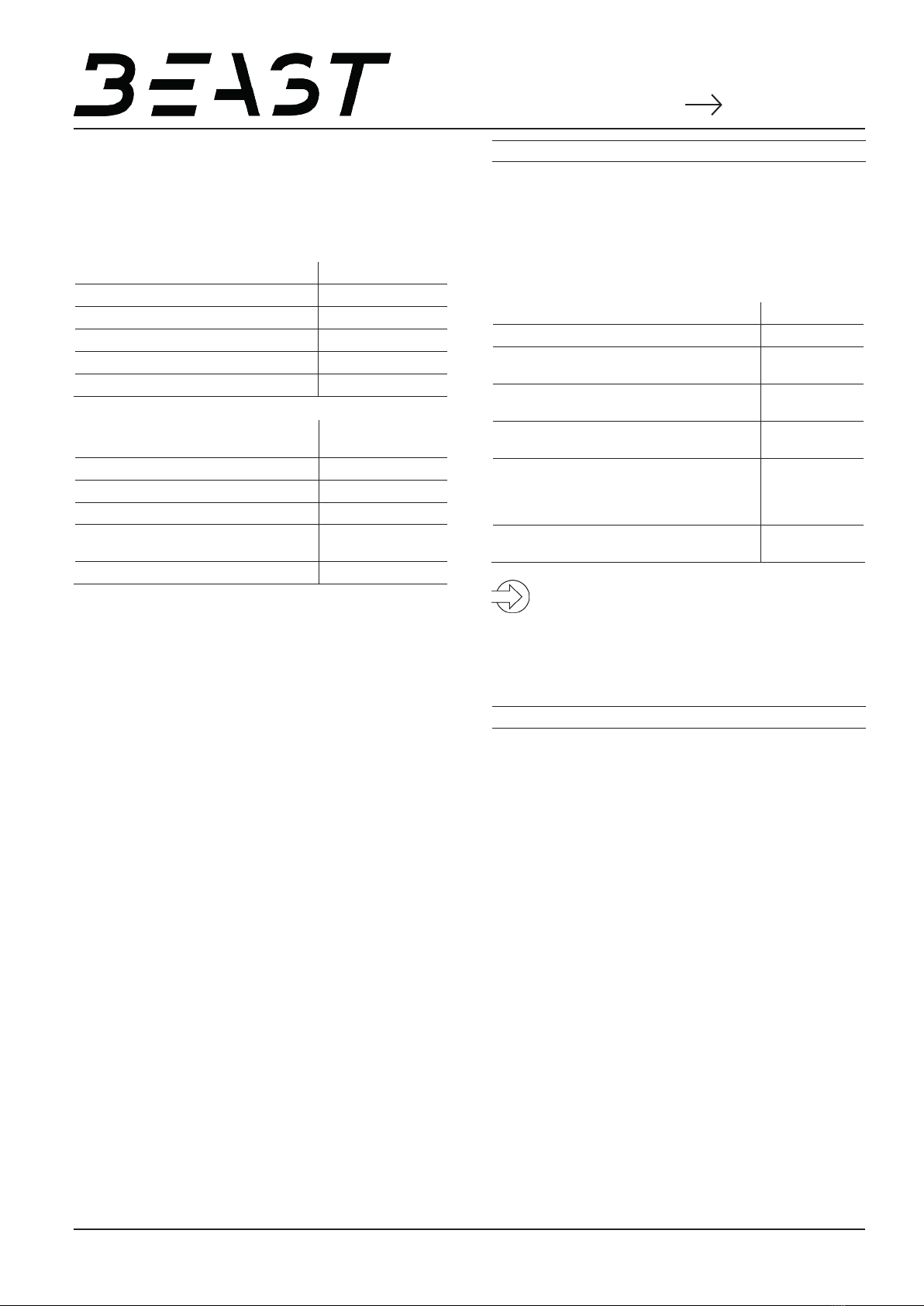

tubeless tape wide

RR40 22 mm

RS25, RX25, RX40, RX60, RX80 23 mm

GR40, GR25, XC25 27 mm

XS30, XC30, TR30, ED30, DH30, 32 mm

HY35 37 mm

minimum valve

length

RX80 91 mm

RX60 71 mm

RX40, RR40, GR40 51 mm

RX25, GR25, XC25, XC30, TR30, ED30,

DH30, HY30, HY35

36 mm

XS30 31 mm

ASSEMBLING THE CASSETTE

Choose the cassette suitable for the freewheel XD, XDR, Shimano

HG, Microspline or Campagnolo and assemble the cassette

according to the manufacturer‘s instructions.

BRAKE DISC

Assemble the brake disc according to the manufacturer‘s

instructions.

WHEEL

Ensure that the hub sits on the stop in the end of the dropout.

Observe the instructions provided by the manufacturer of the

quick-release clamp or the quick-release axle.

Check that the wheel is attached correctly before each ride.

MAINTENANCE AND CARE

Please always make sure that your Beast Components product is

intact before each ride. Damage can cause the component to fail,

resulting in serious injury or even death. Damaged components

should never be ridden on and should be replaced immediately. If

you are in doubt, contact us or a experienced specialist.

The following aspects should always be taken into account:

Task Interval

Check Tubeless Tape for damages every 6 months

Replace the Tubeless Tape every 12 months

Check spoke tension, runout and wear of the

wheel

every 10 opera-

ting hours

Check rim for damage before and after

each ride

Clean with soft cloth and a suitable cleaner.

Attention: Do not use high pressure cleaners

or aggressive cleaning agents!

after each ride

Check that the wheels are secured correctly

and Check air pressure

before each ride

DISPOSAL AND ENVIRONMENTAL PROTECTION

The statutory regulations shall apply. Whenever possible, avoid

creating waste. Waste, especially carbon, lubricants, cleaners and

any other fluids must be disposed in an environmentally compatible

manner.

CONTACT

Black East GmbH

Beast Components

Hermann-Mende-Str. 5-7

01099 Dresden, Germany

+49 351 501 937 00

www.beast-components.de

V2021.01

Page 4

This manual suits for next models

15

Other Beast Bicycle Accessories manuals