Beast FLAT BAR 2.0 User manual

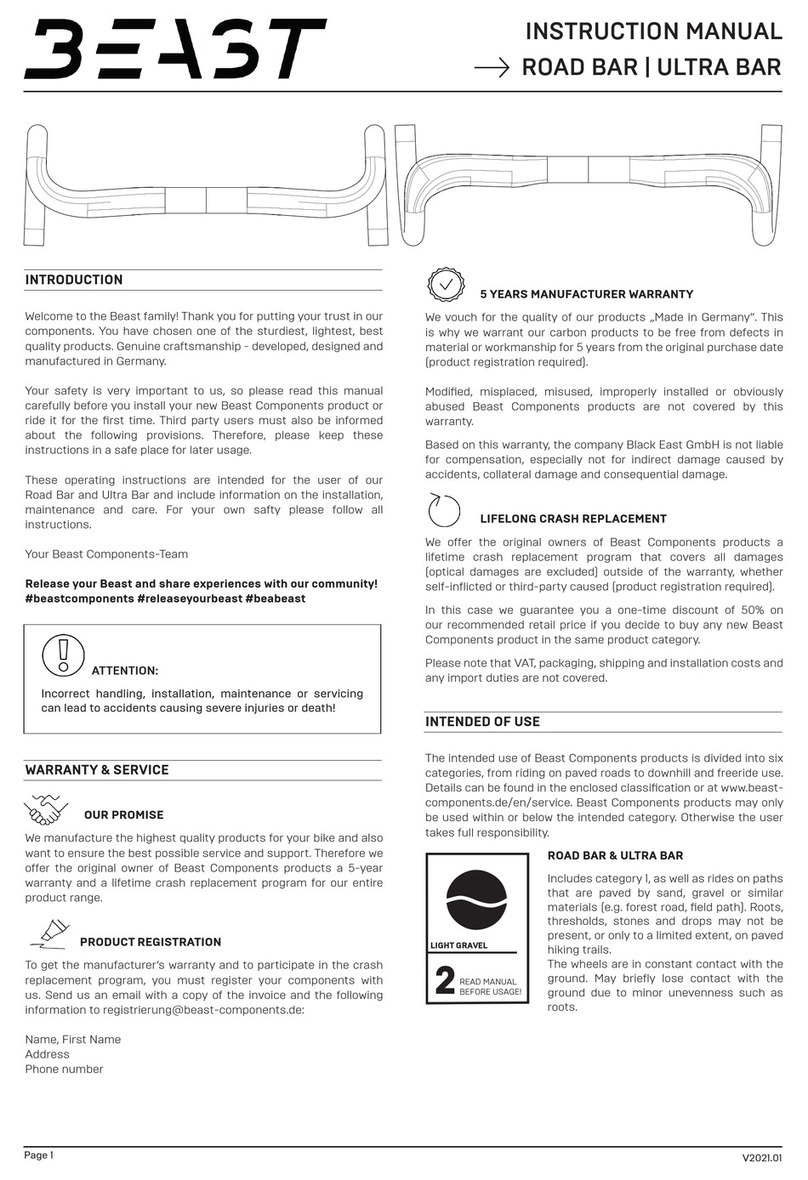

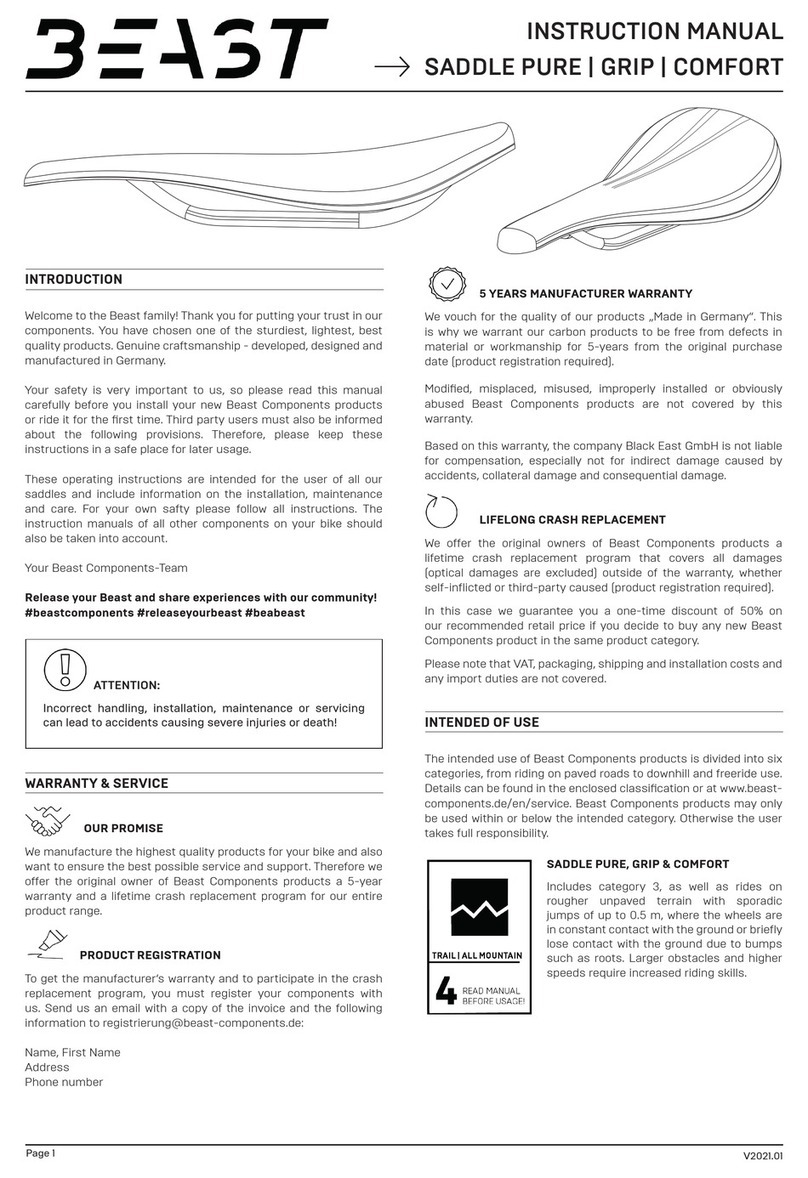

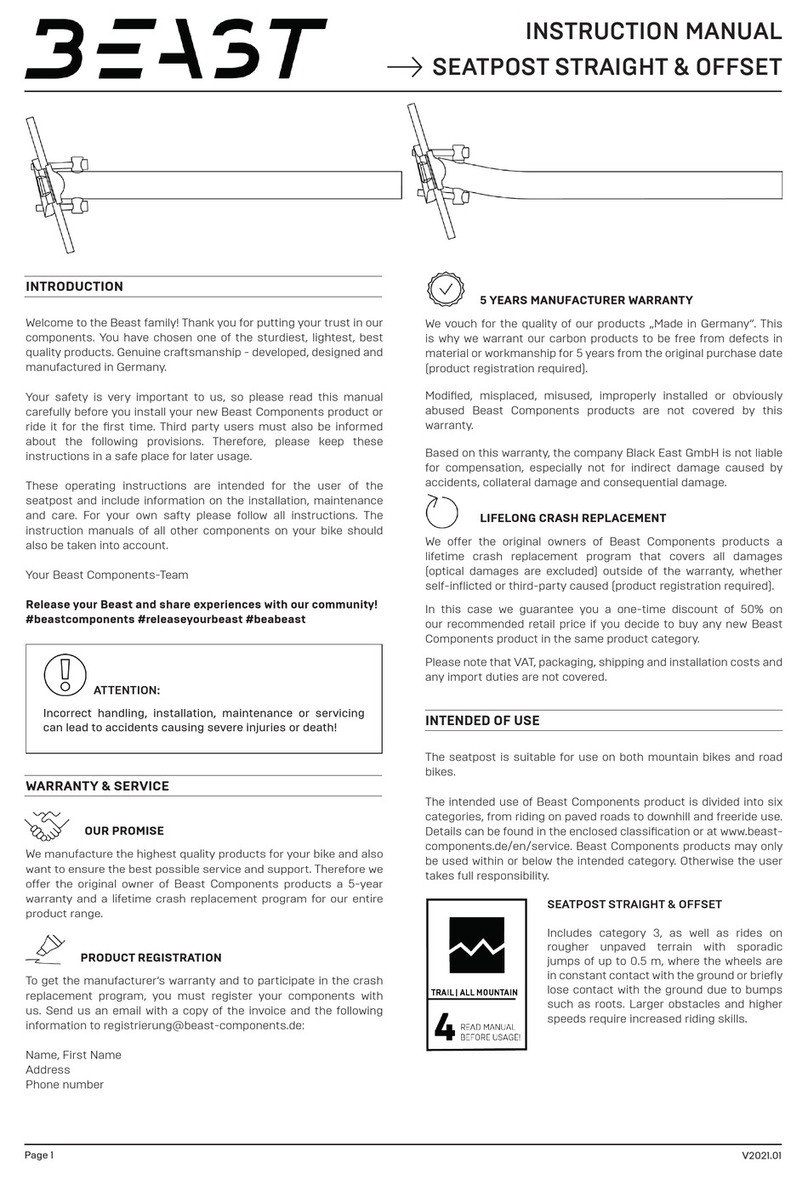

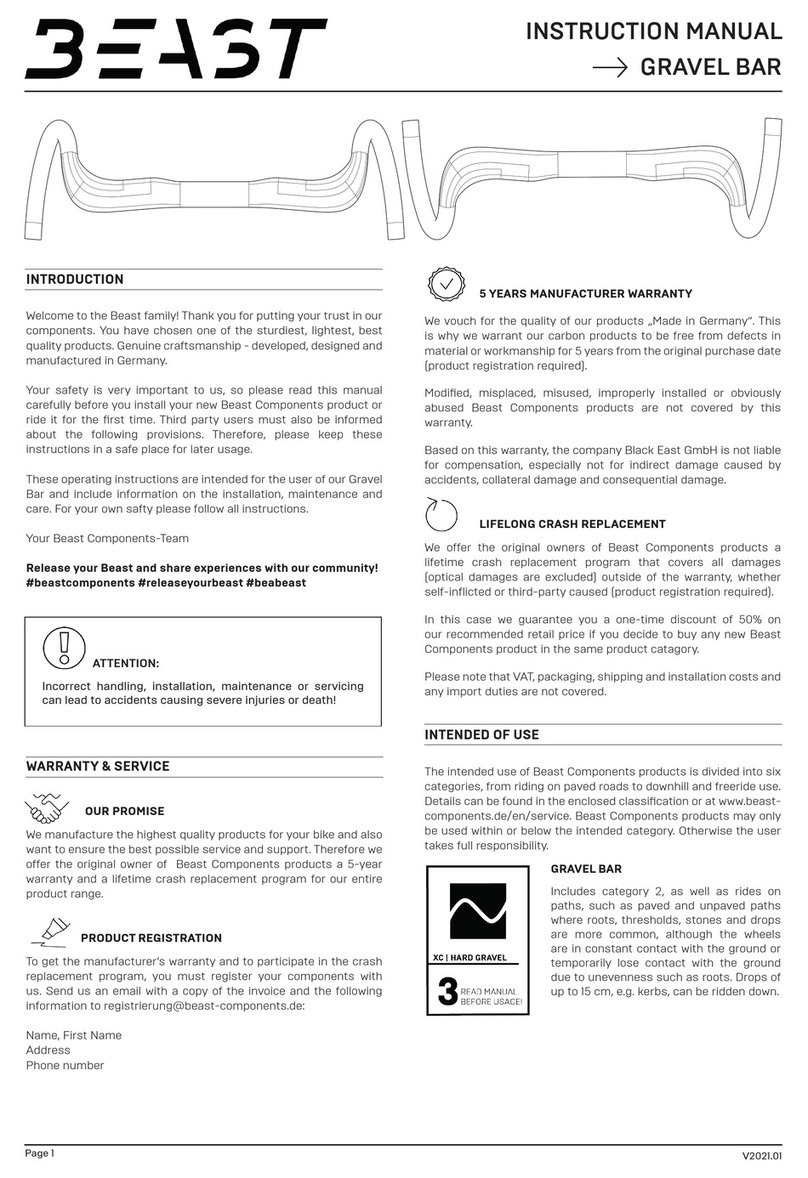

INSTRUCTION MANUAL

FLAT BAR 2.0

INTRODUCTION

Welcome to the Beast family! Thank you for putting your trust in

our components. You have chosen one of the sturdiest, lightest

and best quality products. Genuine craftsmanship - developed,

designed and manufactured in Germany.

Your safety is very important to us, so please read this manual

carefully before you install your new Beast Components product or

ride it for the first time. Third party users must also be informed

about the following provisions. Therefore, please keep these

instructions in a safe place for later usage.

These operating instructions are intended for the user of all our Flat

Bars 2.0 and include information on the installation, maintenance

and care. For your own safty please follow all instructions.

Your Beast Components-Team

Release your beast and share experiences with our community!

#beastcomponents #releaseyourbeast #beabeast

WARRANTY & SERVICE

OUR PROMISE

We manufacture the highest quality products for your bike and also

want to ensure the best possible service and support. Therefore we

offer the original owner of Beast Components products a 5-year

warranty and a lifetime crash replacement program for our entire

product range.

PRODUCT REGISTRATION

To get the manufacturer‘s warranty and to participate in the crash

replacement program, you must register your components with

us. Send us an email with a copy of the invoice and the following

Name, First Name

Address

Phone number

5 YEARS MANUFACTURER WARRANTY

We vouch for the quality of our products „Made in Germany“. This

is why we warrant our carbon products to be free from defects in

material or workmanship for five years from the original purchase

date (product registration required).

Modified, misplaced, misused, improperly installed or obviously

abused Beast Components products are not covered by this

warranty.

Based on this warranty, the company Black East GmbH is not liable

for compensation, especially not for indirect damage caused by

accidents, collateral damage and consequential damage.

LIFELONG CRASH REPLACEMENT

We offer the original owners of Beast Components products a

lifetime crash replacement program that covers all damages

(optical damages are excluded) outside of the warranty, whether

self-inflicted or third-party caused (product registration required).

In this case we guarantee you a one-time discount of 50% on

our recommended retail price if you decide to buy any new Beast

Components product in the same product category.

Please note that VAT, packaging, shipping and installation costs and

any import duties are not covered.

INTENDED OF USE

The intended use of Beast Components products is divided into six

categories, from riding on paved roads to downhill and freeride use.

Details can be found in the enclosed classification or at www.beast-

components.de/service. Beast Components products may only

be used within or below the intended category. Otherwise the user

takes full responsibility.

FLAT BAR 2.0

Includes category 4, as well as rides on very

rough and partly blocked terrain with sporadic

jumps of up to 1.0m and occasionally rides in

designated sport and bike parks. Very high

standards of riding skills are required.

For components in this category, it is

essential to ensure that an intensive check

for possible damage is carried out after each

ride. Previous damage can lead to failure

even at much lower loads.

ATTENTION:

Incorrect handling, installation, maintenance or servicing

can lead to accidents causing severe injuries or death!

Page 1 V2021.01

V2021.01

GENERAL INFORMATION

Damage can lead to failure of the components and thus to serious

injury or even death. Externally damaged or defective components

must not be used under any circumstances and must be replaced

immediately. If you are unsure, contact us or your dealer.

WEIGHT LIMIT

The Flat Bar 2.0 is not subject to any weight restriction.

SHORTEN CARBON HANDLEBARS

The Flat Bar 2.0 may be professionally shortened, but only to a width

that the brake levers can be mounted on the provided clamping

area. For this purpose wrap the affected areas with crepe tape.

Shorten carbon handlebars only with a fine-toothed carbon blade

or a Dremel. The use of a metal pipe cutter is not permitted. After

trimming, the crepe tape can be removed and, if necessary, the

ends deburred with fine sandpaper.

APPEARANCE

Our components are 100% handmade. Thereby it can come to

different appearances. It makes each component unique and has no

influence on the safety. By direct incidence of light you get a great

view of the individual fibers with partly shimmering shades.

INSTALLATION

INSTALLATION COMPATIBILITY

You can use your Flat Bar 2.0 with all conventional stems. The

diameter of the clamping area of the stem should be 31.8mm

(±0.15mm). The width of the handlebar clamping of the stem must

not exceed 60mm.

Make sure that the handlebar clamp of the stem as well as the brake

and shift levers have no sharp edges. We do not recommend to use

them. If you still intend to do so, please remove burrs from all sharp

edges in the clamping area of the handlebars carefully with a file

and abrasive and round them off. Please note that this measure

may void the manufacturer‘s warranty. Contact the manufacturer

if necessary.

INSTALLATION ON THE STEM

• Use the supplied carbon assembly paste for mounting the

stem to reduce the necessary tightening torque, thus relieving

the material. To do this, apply the assembly paste to the

clamping areas.

• The handlebars may only be mounted with grease-free screws.

• Position the handlebar in the center and do not tighten the

stem bolts to the maximum torque immediately, instead

tighten them gradually and alternately.

• Be sure to observe the maximum tightening torque of 5Nm.

When mounting the stem indentations in the handlebar can occur

depending on the design, mounting and tightening torques. This is

quite normal. If you are unsure about the safety, you can contact us.

INSTALLATION OF BRAKE AND SHIFT LEVERS

• Use the supplied carbon assembly paste for mounting the

stem to reduce the necessary tightening torque, thus relieving

the material. To do this, apply the assembly paste to the

clamping areas.

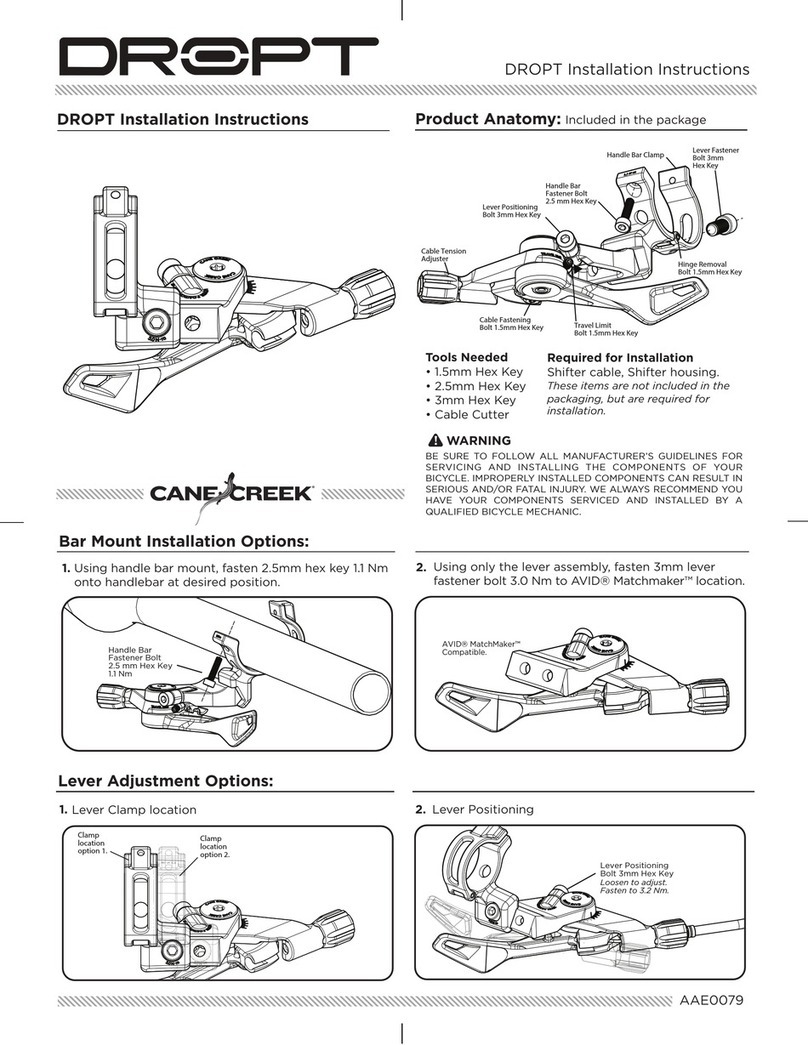

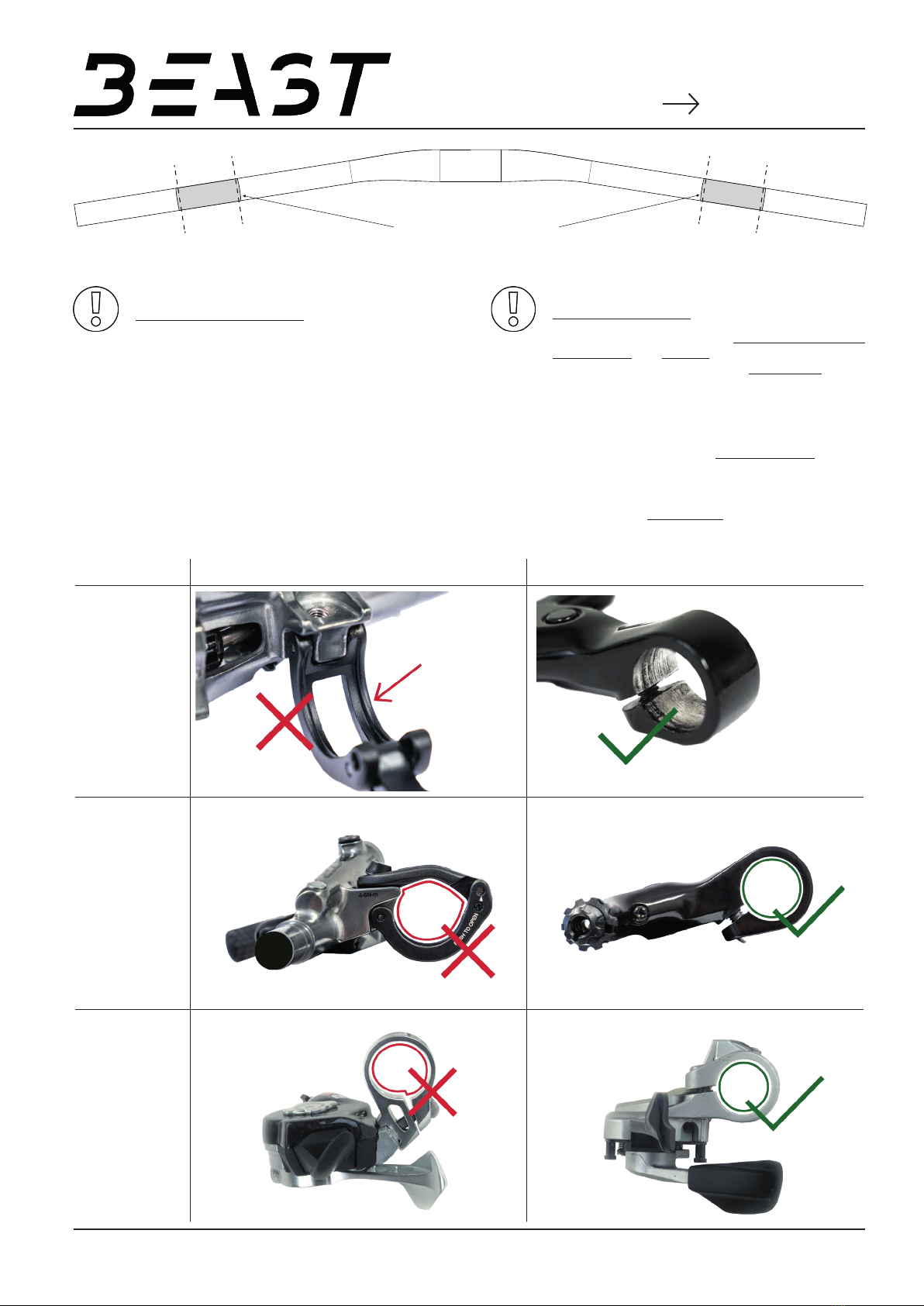

Attention: Distinction between unfavorable and favorable

clamp designs.

When mounting the brake and shift levers, a distinction

must be made between unfavorable and favorable

clamping designs. An overview of critical features of

unfavorable clamping designs can be found on the

next page. Please check very carefully whether your

components fall under this category. If you are unsure,

please feel free to contact us.

• If you intend to use brake and shift fittings with an unfavorable

clamping design, the tightening torque should be a maximum

of 3 Nm.

• If you intend to use brake and shift fittings with a favorable

clamping design, the tightening torque can be increased to a

maximum of 6 Nm.

Page 2

ATTENTION:

COMPONENT MOUNTING ON CARBON

HANDLEBARS

Some new brakes and shifts on the market have a very

unfavorable clamp design for carbon and lightweight

handlebars. The clamps are not round and the contact

surface is minimal. Loads are thus no longer distributed

evenly over the clamping area of the handlebars, instead

they lead in locally. In addition, the maximum Nm values

specified by the component manufacturers usually refer to

aluminum handlebars.

Due to this development our MTB handlebars have received

an upgrade. We use a special polyester prepreg mesh as

a top layer for the clamping area for the brake and shift

fittings. It has a high strength and creep resistance and at

the same time has a low sliding friction and sliding wear.

We use it exclusively in the clamping areas. Thus, punctual

loads are absorbed much better and distributed evenly over

the handlebars. Impressions of the clamps are reduced to a

minimum and the carbon layers underneath are protected.

Please read the following section carefully and follow the

instructions.

INSTRUCTION MANUAL

FLAT BAR 2.0

ATTENTION: TIGHTENING TORQUES

In general, the fittings should only be tightened that they

can just no longer be twisted. For this reason, the specified

maximum tightening torques should usually not have to be

used!

V2021.01

examples of unfavorable clamp designs

examples of favorable clamping designs

clamp with

narrow and small

clamping surface

/ clamping via

narrow bars

non-round

clamping

asymmetrical

clamping slot and

/ or oblique clam-

ping screws

Page 3

Attention: TRICKSTUFF brakes

The TRICKSTUFF brakes Maxima and Direttissima

have only a one-sided support of the brake pump.

Furthermore, the brake body is not twist-proof toward

the milling clamp. Due to this, even minimal, but adverse

forces on the brake pump and / or on the brake lever

connection can cause local damage to the handlebars.

After each fall, as well as after each impact against the

brake pump, the brake lever or the brake lever connection,

the carbon handlebar must be checked immediately for

signs of irregularities! In case of doubt, the handlebar

should be replaced. Otherwise, the handlebar may

suddenly break.

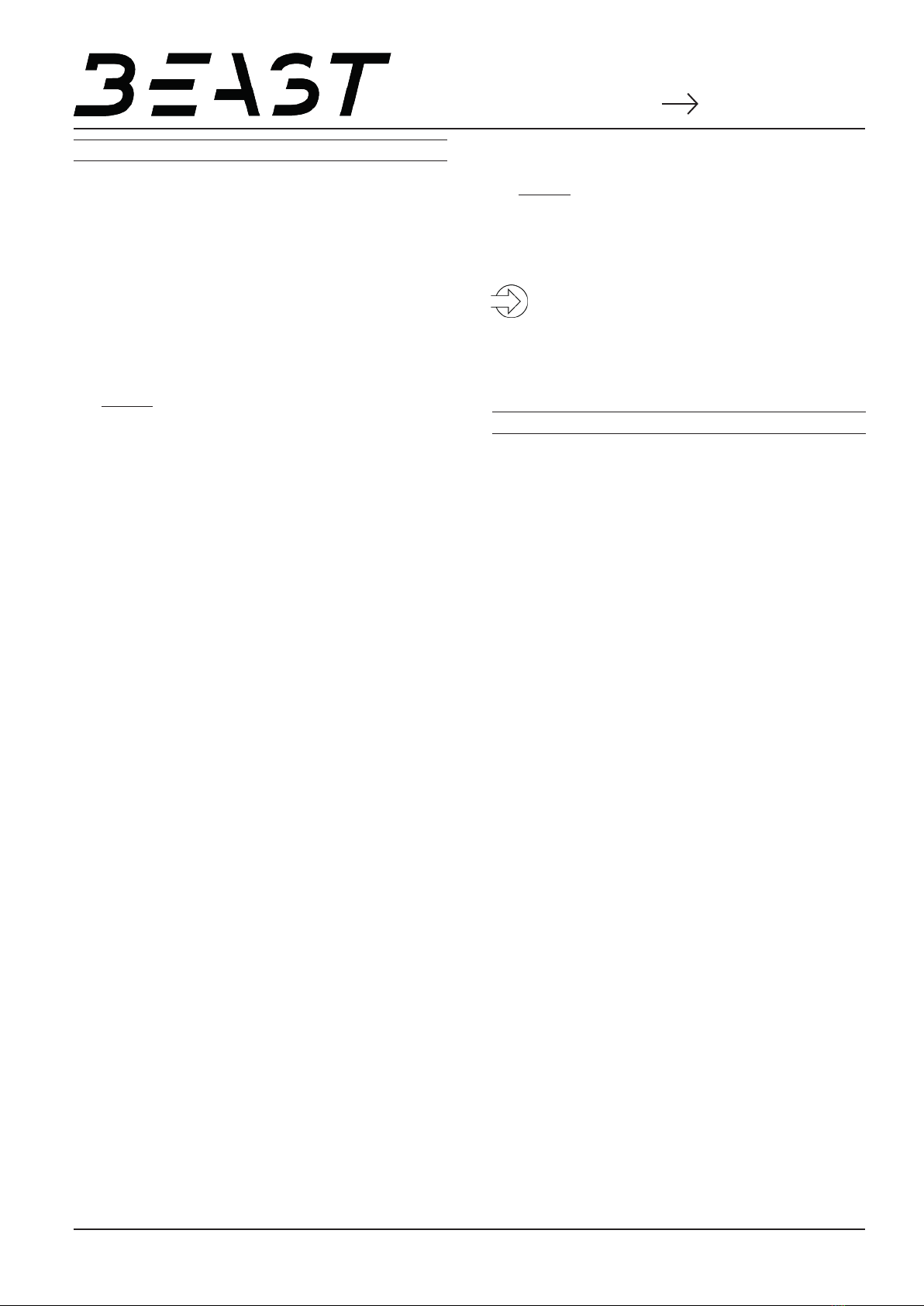

Attention: Clamping area

The brake and shift levers may only be mounted in the

clamping area. The distance between the levers and the

edge of the clamping area must be at least 2mm. Please

refer to the illustration above.

INSTALLATION OF HANDLEBAR GRIPS

Handlebar grips may be fastened with a maximum of 2Nm.

INSTALLATION OF BARENDS

The mounting of barends is not permitted on the Flat Bar 2.0.

INSTRUCTION MANUAL

FLAT BAR 2.0

clamping area of the

brake and shift levers

clamping area of the

brake and shift levers

safety distance to the border of the

clamping area of at least 2mm

V2021.01

MAINTENANCE AND CARE

Always inspect your Beast Components product for integrity before

riding. Damage can lead to component failure, resulting in serious

injury or even death. Defective components should not be riden on

under any circumstances and should be replaced immediately. If

you are unsure, contact us or a specialist dealer.

The following points should always be observed:

• After every crash and impact, the carbon handlebar must be

checked for cracks, nicks and dents. To do this, all of the fittings

must be unscrewed. Even if no obvious defects such as cracks,

deformation or the like are visible, we can not guarantee safe

operation. Please consult a specialist dealer or contact us. In

case of doubt, the handlebar should be replaced.

• Attention: It is mandatory to check the Flat Bar 2.0 for possible

damage after each race, in sports and bike parks because of

heavier loads.

• Regularly check whether the screws are tightened to the

correct torque (see item „Installation“).

• Inspect the handlebar for signs of material fatigue and

stresses, such as cracks and dents.

• Clean your handlebars only with water or, if necessary, with a

commercial detergent.

• Attention: Upon longer exposure, brake fluid may attack

epoxies and resins as well as other coatings used in carbon

components (Brake fluid is highly deliquescent). Therefore,

if brought into contact with any carbon component such as

handle bars please ensure that the affected area is thoroughly

cleaned with water to avoid any damage.

DISPOSAL AND ENVIRONMENTAL PROTECTION

The statutory regulations shall apply. Whenever possible, avoid

creating waste.

Waste, especially carbon, lubricants, cleaners and any other fluids

must be disposed in an environmentally compatible manner.

CONTACT

Black East GmbH

Beast Components

Hermann-Mende-Str. 5-7

01099 Dresden, Germany

+49 351 501 937 00

www.beast-components.de

Page 4

INSTRUCTION MANUAL

FLAT BAR 2.0

Other Beast Bicycle Accessories manuals