Becen BC-M400CMY User manual

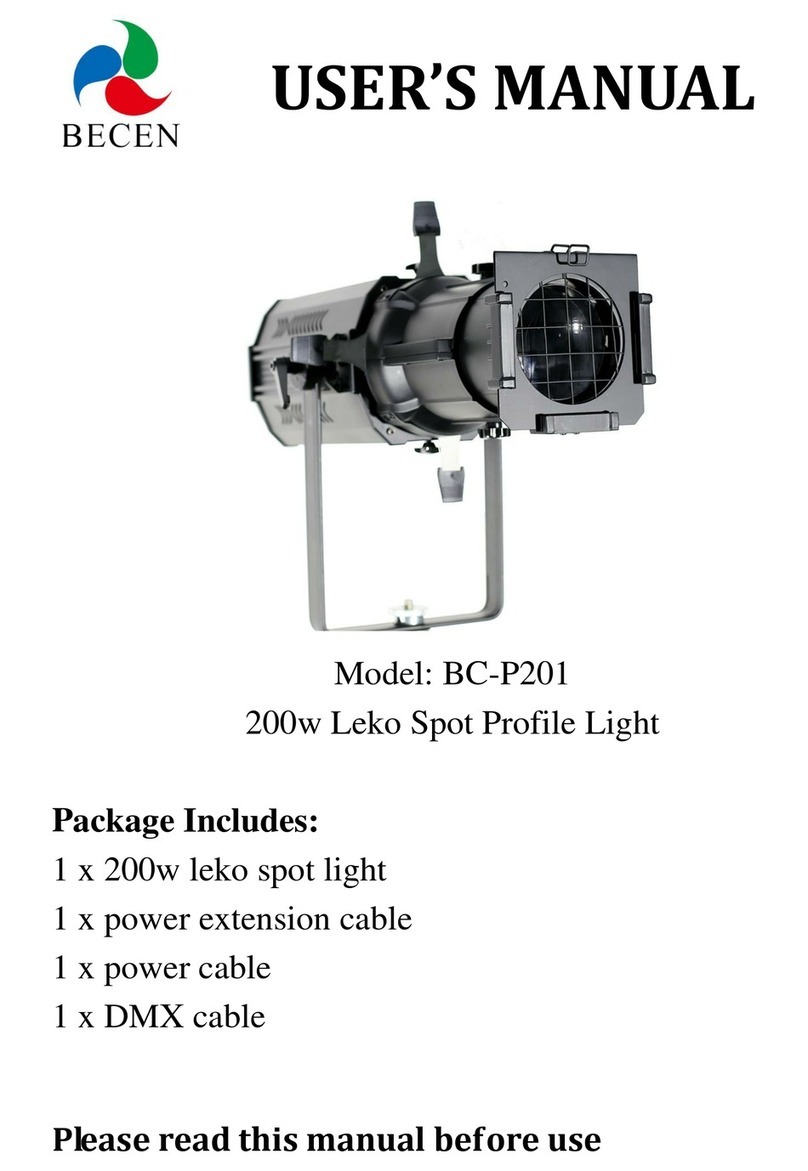

USER’S MANUAL

Model: BC-M400CMY

400w CMY Led Moving Head Light

Package Includes:

1 x led moving head light

1 x clamp

1 x handle

1 x safe cable

1 x power cable

1 x DMX cable

Please read this manual before use

Contents

Chapter 1 Safety Guidance and Parameters................................................................1

1. Safety guidance ................................................................................................1

2. technical specifications ....................................................................................2

Chapter 2 Panel Operation ..........................................................................................4

1. summary...........................................................................................................4

2. operate..............................................................................................................4

2.1. Use intuitive touch or auxiliary input for lamp lamps ............................4

2.2. Parameter numerical input ......................................................................4

2.3. Set the Boolean parameter.......................................................................5

2.4. Subpage (parameter) ...............................................................................6

3. Functional operation and parameter setting.....................................................6

3.1. Set up the DMX address code.................................................................6

3.2. Set up the lamp operating mode..............................................................7

3.3. Panel display settings..............................................................................7

3.4. Scene mode .............................................................................................8

3.5. Set the lamp operating parameters..........................................................9

3.6. View the current status of the lamp.......................................................10

Chapter 3 Channel Description.................................................................................12

1. channel table...................................................................................................12

Chapter 4 Common faults and use attention .............................................................16

1. Common fault handling..................................................................................16

2. Precautions for use.........................................................................................17

3. RDM Use Notes.............................................................................................17

4. Lighting installation .......................................................................................18

statement.....................................................................................................................19

1

www.szbecen.com

Chapter 1 Safety Guidance and Parameters

Attention

The equipment is well packaged when it leaves the factory. Please follow the user's manual, and the

machine failure is not covered by the warranty due to human reasons

1. Safety guidance

Please keep this instruction manual as a basis for a future consultation, and if you sell

this product to other users, please make sure that they also get it.

The lamp is only suitable for indoor drying places.

The installation and operation of the lamps should be carried out by professionals.

Equipment must be installed in a well-ventilated place, at least 50 cm from the adjacent

Ensure that the vents are

Do

The new lamp may have little smoke or odor, and will disappear after 15 minutes of

Before opening the lamp, please carefully check whether the power cord is damaged. If there is

Avoid flammable liquid, water, or metal and other electrical conductors from entering the lamp

interior to avoid electric shock or fire. If any foreign body enters the lamp, please cut off the

Avoid operating in a dirty and dusty environment,and clean and maintain the lamps regularly

Disconnect the power supply before replacing the fuse or light bulb.

There are no available parts inside the lamp, do not open the lamp shell without authorization

Do not operate the machine by yourself. Non-professional operation will cause damage to the

equipment or functional failure. If maintenance is needed, please contact the nearest authorized

service center.

2

www.szbecen.com

High temperature bulb explosion risk, do not open the lamp within 15 minutes of power

failu

Please replace the bulb when damaged, heat-

The light bulb will be very hot when the lamp is running. Do not touch it with your bare

Do not operate the machine when the bulb is not without a protective cover or the housing is

damaged.

BSW400 3in1 computer shake head light, using a single 400W LED light engine, set

light beam, pattern, staining in one, energy saving, super long life, fast heat

dissipation, powerful function, simple control. Design fixed disk and rotating disk,

the pattern effect can present multiple angles under the variable lens; the beam angle

can be doubled through the variable lens, making the beam more flexible. In addition

to the two-way rotating six prism, independent atomization effect and electric

focusing functions, to fully meet the dyeing needs of different occasions, very

suitable for bars, dance halls, nightclubs, performances and other entertainment

places.

2. technical specifications

Light source: 1 x 400W LED, optical engine

LED expected service life: 20,000 hours

Color temperature: 8,000 K

Standard mode: Ra> 80

LED expected service life: 20,000 hours

Adaptive power supply

Input voltage range:AC 190-240 V, 50 / 60 Hz

Power: 500 W

Power connector input / output

Signal input / output: three-core Canon head socket

Electric and dynamic linear focusing system

Beam angle: 4°-35°

Mixed color system: linear CMY mixed color

Linear CTO color temperature regulation of 2700K-6500K

Rotary pattern plate: 1 rotating pattern plate, 7 kinds of patterns plus white circle, can realize

running water, jitter, random dynamic and positive and negative direction slow and fast

conversion effect, special high temperature resistant materials, with hall, magnet positioning

with "slot and lock" system, easy replacement of Gobos

Fixed pattern plate: 1 fixed pattern plate, 12 fixed patterns + white light, can realize running

water, jitter, random dynamic and positive and reverse direction slow and fast conversion effect,

special high temperature resistant metal materials, with hall, magnet positioning

Color disk: 1 color disk, 8 fixed colors plus white, two-way rainbow effect, can realize the

half-color, full-color, single and two-color gradient and the positive and negative direction of

the slow and fast rainbow effect, with the hall, magnet positioning and any Angle automatic

error correction function.

3

www.szbecen.com

Prism system: equipped with two-way rotation and superimposed 4-prisms and 4-row mirrors

0-100% smooth dimming

Independent atomization effect

Outstanding strobe effect, with variable speed

No flashing under the HD camera

Horizontal scan: 540 degrees (16bit precision scan) electronic error correction

Vertical scan: 270 degrees (16bit precision scan) electronic error correction

X-axis / Y-axis position misstep automatic correction

Control panel: 4.8-inch LCD touch display, temperature display, Chinese and English display,

plus 4 physical buttons

Control protocol: DMX512, RDM, self-walk, voice control

DMX channel mode: 22C H / 26CH

Software upgrade: Update the software via a DMX connection

Cooling mode: use the axial fan to strengthen the cooling

Safety device:with electronic temperature overheating protection, electronic temperature

control automatic power off protection when overheating system failure

Intelligent fan speed regulation: when the lamps are not bubble or closed, the fan will

automatically slow down to reduce the noise of the fan and create a good performance

environment.

Working environment: -20 degrees, 40 degrees

Protection level: IP20

Product net weight: 22.5KG

Product Dimensions: 54 * 45 * 61CM (L * W * H)

4

www.szbecen.com

Chapter 2 Panel operation

1.Summary

1The schematic diagram of the lamp panel is shown in Figure 1. The above title shows the

name of the lamp, and the following status bar shows the signal of the current lamp, the bulb

status, the fault (when the fault information is not viewed, display "E RR", otherwise "N OR" is

displayed), etc.

This lamp supports DMX / RDM. When the lamp is searched by the RDM host, three letters

"RDM" will appear in the panel, indicating that the lamp is enumerated normally.

Display and operation are similar to "Android operating system", with fingertips or blunt hard

objects click the corresponding item can operate.

Note: Never use sharp or sharp display to prevent damage.

1Figure 1 shows a schematic representation of the panel

2.operate

2.1Use intuitive touch or auxiliary input for lamp (touch enabled product)

The left area is the TFT display area and the touch area. With the content of the panel, you can

complete the parameter setting or view the state and other operations.

On the right area is the auxiliary input. If you do not use the TFT's own touch function, you can

use the auxiliary input to select the items to set or view and complete the operation.

2.2 Parameter numerical input

When the selected parameter item needs to enter a numerical value, the window as shown in Figure

2 opens:2

5

www.szbecen.com

2 Figure 2. Value setting page

Set the value: you can directly pull the slider bar to quickly set the required value, or click the

"up" or "down" button on the right to accurately set the required value, or set it with the

auxiliary input.

Application value: When the data is set by the "up" or "down" button, and then press the

"apply" application button in the lower left corner, the value is immediately sent to the lamp,

but the value is not saved.

Save the value: at any time, click on the "OK" key in the lower right corner, namely, save the

current value to the internal memory, the next boot to save the value applied to the lamp.

2.3 Set the Boolean parameter

When the parameter is set to a Boolean value (such as ON or OFF), then directly click on the

corresponding item to switch the parameter value, which will be saved to the internal memory.

Press the parameter option on the right, and the corresponding option becomes gray. When

releasing the hand, the corresponding parameters are changed and saved. If you press the

parameter option is not the parameter that you want to change, then move your finger

elsewhere on the screen, and the corresponding parameters will not change.

Important Boolean parameters are determined by the determination window, as shown in Figure

3 below:3

3Figure 3 determines the input window

6

www.szbecen.com

2.4 Subpage (parameter)

3. Functional operation and parameter setting

Enter the setup interface, as shown in Figure 6-1:

In the main interface, you can enter the corresponding parameter setting interface by selecting

six buttons.

In the parameter setting interface, you can press the left blue option and quickly switch to the

other setting interface.

3.1 Set up the DMX address code

The D MX address, channel mode, etc. can be set on the page shown in Figure 6-1.

The menu setting of the lamp optimizes the address setting. Several setting address code operations

are as follows:

Select "Last" or "Next", the lamp will automatically calculate the next or last address code

according to the current address code and channel data, which can be quickly set;

Click on the address code value to enter the value editing window, where any valid address

code can be set, the lamp can automatically obtain the current number of channels of the lamp,

and automatically filter the unusable address code (512-the current number of channels).

The lamp supports the R DM protocol, and the lamp address code can be set remotely via the R

DM.

Provide two push-buttons:

Channel mode: Different channel modes can be selected periodically;

Light lamp reset: reset all motors.

7

www.szbecen.com

3.2 Set up the lamp operating mode

The operation mode of lamps and control lamp gun can be set through the page shown in Figure 6-2.

The lamp supports four operating modes (DMX mode, self-walking mode, sound control mode and

scene mode). Please refer to the previous section for detailed parameter value setting. The specific

parameter description is shown in the following table:

running mode

DMX

pattern

Console mode, receiving DMX signal, RDM signal

Self-walkin

g mode

The lamps are run automatically according to the built-in program

Sound

control

mode

When the lamp detects a strong sound, the lamp automatically runs

a scene following the built-in program, otherwise maintain the last

scene

Scene Mode

01

Run as a set scenario, and support custom editing for up to 10

scenarios

1~10

Outputs the specified scene

volunt

arily

Automatically cycle output scenes in the set scene time

(non-0) order, and scenes with time 0 automatically skip

ignored

Master from

choice

When the non-DMX mode works, select the data output mode, and

the lamp automatically detects the DMX status and automatically

switch the output to prevent data conflict

main

engin

e

The lamp runs built-in, if DMX has no signal, output data

(synchronization), otherwise data is not output

slave

Lamps run as built-in, without data output (not

synchronized with other lamps)

volunt

arily

If the DMX has no signal, the lamp runs as built-in,

otherwise, the lamp works as the DMX signal

Light bulb

switch

(Bulb light source) pop up the confirmation dialog box, select

"SURE" to confirm the current operation, turn on or off the bulb,

and the switch time interval is limited to 30 seconds

close

The current bulb output is already turned off

open

The current light output is already turned on

Scene mode is suitable for a single set or a small number of lamps, just output a fixed

scene, or need to run a simple program, you can be edited in the scene page without

connecting to the console.

If the light source is the bulb, wait 10 minutes before turning on the bulb after turning it

off.

3.3 Panel display settings

Lighting lamps support bilingual Chinese and English, inverted display,etc. Enter the corresponding

parameters as shown in Figure 6-3. The specific menu content is shown in the following table:

8

www.szbecen.com

Display settings

language

Set the displayed

English

English display

the

Chinese

language

Chinese display

Screen

protection

Set the content or mode of the screen within 30 seconds

close

Keep the last operation page, bright screen

pattern 1

Out of the screen

pattern 2

Black screen, showing the address code of the current

lamp in the lower left corner

pattern 3

Display trademark information, address code and

operation mode

Screen

rotation

Set the display direction of the screen

close

No reversal is shown

open

Reverse display

voluntari

ly

Automatically detect the hanging direction of lamps

and automatically switch the display direction

DMX

indicate

Set the mode of DMX signal indicator

pattern 1

Bright with signal, no signal out

pattern 2

Out of signal, bright when no signal

pattern 3

Flash with a signal, and extinguish with no signal

The signal

indicates

brightness

Set the brightness of the signal indicator lamp

1~10

Ten grades

Screen

backlight

Set the brightness of the screen backlight after 10 seconds without

operation, all bright during operation

1~10

Ten grades

Touch

screen

switch

Select whether to disable the touch screen. When the screen touch

is accidentally damaged, disable the touch function and set the

lamp with auxiliary input

Touch

correction

When the screen touch is not accurate, you can enter the

correction page correction screen

Lamps that support touch operation. If a bad touch phenomenon occurs, you can enter the

correction page to recorrect the touch accuracy of the touch screen. Under normal circumstances,

please do not enter this page. If the touch is damaged, select to disable the touch switch.

3.4 Scene mode

Enter the page shown in Figure 6-4, and the lamps enter the scene editing mode. Under this

page, the lamp does not receive the DMX console data, and the edited data is reflected on

the lamp immediately.

The content of the page depends on the currently selected channel, and the channel content

and order displayed match the lamp channel table. Through this page, 10 scenes can be

edited, as shown in the following table:

9

www.szbecen.com

Scene mode

Scenario

selection

Select the current required operation scenario

1~10

10 Scene Format

Scene

time

Sets the time when the current scene is automatic in 0.1 seconds

0

The current scene does

not participate in the

automatic scene output

1-255

0.. One second to 25.5

seconds

1. X axis

0-255

Set the data of each

channel, and the display

content and sequence

correspond to the channel

table of the lamp

……

0-255

……

0-255

N.functio

n

0-255

If the valid reset data is edited in the reset channel in the scene, the lamp will be reset, but

after the reset, the value of the corresponding reset channel will be automatically reset to

prevent multiple continuous reset.

View this page for the current channel table order of the lamp. Please refer to the detailed

channel description for the specific channel data.

3.5 Set the lamp operating parameters

Enter the page shown in Figure 6-5 and adjust the field parameters of lamps to facilitate the field

installation of lamps:

advanced setup

X axis

reverse

Set the X-axis rotation direction

close

Don't reverse

open

opposite direction

Y axis

reverse

Set the direction of the Y-axis rotation

close

Don't reverse

open

opposite direction

Optical

coupling

correctio

n

Set whether the lamp detects the XY misstep and corrects it

close

No correct position after loss of step

open

Correct the position automatically after the misstep,

and the misstep fault is recorded

X-axis

offset

Set the position of the zero point of the lamp X-axis

4-150

Y axis

offset

Set the position of the Y axis

4-48

data-hold

Set the output state of the lamp when the lamp has no D MX signal

close

There is no signal, so the motor and the light source

return to the position and state when the reset is

complete

open

No signal, maintain the last frame of D MX data

10

www.szbecen.com

output

Turn on

the light

mode

Set the way the bulb first turns on after it is powered on

On the

electric

bubble

Turn on the light bulb first when going on, and reset

the lamp after 30 seconds

Followed

after

reduction

Return the lamp after 3 seconds, and turn on the bulb

after the reset is completed

Manual

foaming

After the reset, open the bulb manually through the

menu or console

Factory

setting

The confirmation box, select "SURE", the lamp parameters return

to the factory settings

When choosing the electric bubble mode, the lamp will wait for the bulb for 30 seconds, so

that the bulb can fully start, the internal voltage is stable enough, and then start the reset

program. If the field power capacity is stable, it is recommended that the electric bulb

mode is opened.

When the lamp cannot correct the position, first check if the optical coupling correction is

turned off.

When removing the signal, if the lamp position is not output as intended, check the Data

Hold setting first.

When setting the X Y offset, after completing the setting, please control the X Y with the

maximum stroke first to check the setting, and the X Y will not hit the positioning rod or

shell.

3.6 View the current status of the lamp

Entering the page shown in Figure 6-6, you can view the information and real-time status of the

lamps to know the use status of the lamps. If the lamps need after-sales service, please provide the

status information displayed on the page for the judgment basis, as shown in the following table:

status information

Motor

information

Displays the information status of all the motors and signals in the lamp

Hoare

Not shown, it means that the motor has no Hall correction, 0

means that the motor leaves the correction position point,

and 1 means that the motor is at the correction position point

state

Displays the motor reset completion state

X axle

Displays the real-time position value of the X-axis optical

coupling feedback

Y axle

Displays the real-time position value of the Y-axis optical

coupling feedback

optocoupler

Shows the level state of two signals with X and Y axis,

binary

Fault /

status

record

Display the last 8 failure records of the lamp reset and operation, the failure

record is not saved after the power failure, when the next power cycle is

valid

11

www.szbecen.com

error data

Total number of faults detected after power

12::03

Power-up time in minutes when a fault occurs

Hall error

The motor does not detect an effective Hall signal when the

corresponding motor is reset

Hall short

circuit

The Hall signal detected by the motor is always valid when

the corresponding motor is reset

Optical

coupling

failure

No effective photocoupling signal is detected when the

corresponding motor is reset

fall out step

The corresponding motor is out of step during operation

Crash rod

Crash the positioning lever when the motor is reset

Bulb failure

Light bulb accidentally extinguished

Sensor

failure

Temperature sensor signal is not normal,

Fan error

The main fan is not working properly

Lighting

status

Displays the critical status data for the current fixture for reference

communicat

ion

0~100%, Communication quality of lamp internal data link

miscount

The total number of error frames detected after power on,

accumulated

Light source

temperature

Displays the temperature of the current light source, and "- -

- -" indicates no detection

Display

plate

temperature

Displays the temperature of the current display board or the

ambient temperature nearby

Sensor 1

temperature

Displays the current motherboard temperature or the

ambient temperature of the motherboard installation

location

Version

information

Display the information and version of the current lamps, and be an

important reference for after-sales maintenance

equipment

Name of lamp, as with equipment information of RDM

model

Model of lamp as model information of RDM

display

board

Firmware version and serial number of the display board

Main board

1

Firmware version and serial number of motherboard 1

Light

source time

Record the total accumulative time of light source opening, the user will

manually clear, as a reference for regular maintenance of light source

Lamps time

Record the total accumulative time of lamp opening, unit minutes, do not

clear

12

www.szbecen.com

Chapter 3 Channel description

1. channel table

This lamp has 2 channel modes, 22CH / 26CH

Channel order can be viewed in scene mode. Channel mode is set in the Address Settings page.

Detailed data are shown in the following table:

channel table

channel 1

channel 2

name

numeric value

description

CH1

CH1

X axle

0-255

0-540 degrees

CH2

CH2

X axis

fine-tuning

0-255

0-2 Degrees

CH3

CH3

Y axle

0-255

0-270 degrees

CH4

CH4

Y axis

fine-tuning

0-255

0-1 degrees

CH5

XY velocity

0-255

From fast to slow

CH6

CH5

aiming

0-255

0-100% dimming

CH7

CH6

stroboflash

0-3

Guan Guang

4-103

From slow to fast pulse strobe

104-107

opening the light

108-155

From slow to fast gradually

open strobe

156-207

From slow to fast gradually

closed strobe

208-212

switch

213-251

From slow to fast to random

strobe

252-255

opening the light

CH8

CH7

pigment

0-9

white light

10-19

Color 1

20-29

Color 2

30-39

Color 3

40-49

Color 4

50-59

Color 5

60-69

Color 6

70-79

Color 7

80-89

Color 8

90-99

White light + color 1

100-109

Color 1 + Color 2

110-119

Color 2 + Color 3

120-129

Color 3 + Color 4

130-139

Color 4 + Color 5

13

www.szbecen.com

140-149

Color 5 + Color 6

150-159

Color 6 + Color 7

160-169

Color 7 + Color 8

170-179

Color 8 + Color 9

180-215

From fast to slow forward flow

water

216-220

cease

221-255

From slow to fast, the reverse

flow water

CH9

CH8

CTO

0-255

CH10

CH9

C

0-255

CH11

CH10

M

0-255

CH12

CH11

Y

0-255

CH13

CH12

pattern

0-4

white light

5-9

Pattern 1

10-14

Pattern 2

15-19

Pattern 3

20-24

Pattern 4

25-29

Pattern 5

30-34

Pattern 6

35-39

Pattern 7

40-44

Pattern 8

45-49

Pattern 9

50-54

Pattern 10

55-59

Pattern 11

60-64

Pattern 12

65-69

From slow to fast jitter pattern

2

70-74

From slow to fast jitter pattern

3

75-79

From slow to fast jitter pattern

4

80-84

From slow to fast jitter pattern

5

85-89

From slow to fast jitter pattern

6

90-94

From slow to fast jitter pattern

7

95-99

From slow to fast jitter pattern

8

100-104

From slow to fast jitter pattern

9

105-109

From slow to fast jitter pattern

10

14

www.szbecen.com

110-114

From slow to fast jitter pattern

11

115-119

From slow to fast jitter pattern

12

120-127

Pattern 12

128-190

From fast to slow forward flow

water

191-192

cease

193-255

From slow to fast, the reverse

flow water

CH14

CH13

Rotation

pattern

0-9

white light

10-19

Pattern 1

20-29

Pattern 2

30-39

Pattern 3

40-49

Pattern 4

50-59

Pattern 5

60-69

Pattern 6

70-79

Pattern 7

80-89

From slow to fast jitter pattern

1

90-99

From slow to fast jitter pattern

2

100-109

From slow to fast jitter pattern

3

110-119

From slow to fast jitter pattern

4

120-129

From slow to fast jitter pattern

5

130-139

From slow to fast jitter pattern

6

140-149

From slow to fast jitter pattern

7

150-200

From fast to slow forward flow

water

201-205

cease

206-255

From slow to fast, the reverse

flow water

C15

CH14

Pattern

rotation

0-127

0-400 degrees

128-190

From fast to slow forward flow

water

191-192

cease

193-255

From slow to fast, the reverse

flow water

15

www.szbecen.com

CH16

Rotation

fine-tuning

0-255

CH17

CH15

Prism 1

0-63

Remove the prism

64-127

Prism 1

CH18

CH16

Prism 1

rotation

0-127

0-400 degrees

128-187

From fast to slow forward flow

water

188-195

cease

196-255

From slow to fast, the reverse

flow water

CH19

CH17

Prism 1

0-63

Remove the prism

64-127

Prism 1

CH20

CH18

Prism 2

rotation

0-127

0-400 degrees

128-187

From fast to slow forward flow

water

188-195

cease

196-255

From slow to fast, the reverse

flow water

CH21

CH19

atomization

0-127

not have

128-255

atomization

CH22

continue to

have

0-255

CH23

CH20

amplify

0-255

grow from a small beginning

into a mighty

CH24

CH21

focus

0-255

From far to near

CH25

Focus tuning

CH26

CH22

function

210-215

Reduction effect motor for

over 6 seconds

220-235

Reduction effect motor for

over 6 seconds

240-255

All cases are reset in more than

6 seconds

16

www.szbecen.com

Chapter 4 Common faults and use attention

1. Common fault handling

The lamps include the microcomputer circuit board, high voltage power supply and other

professional components. For your safety and product life, non-professionals do not remove the

lamps and related accessories without authorization.

Bulb not bright (except LED light source)

Possible causes: the bulb is not completely cooled, or the bulb reaches its life, and is treated as

follows:

Due to abnormal operation, the bulb is not completely cooled, should let the lamp body cool for

more than 10 minutes, so that its internal completely restored to the normal state, and then start

the power supply again;

Check whether the bulb has reached the service life, and should replace a new bulb;

Check whether the bulb and lamp lighter line leakage, shedding or poor contact;

Replace a new lamp lighter.

The beam looked dim

Possible reasons: bulb long use or light path is not clean, treated as follows:

Check whether the bulb has reached the service life, and should replace a new bulb;

Check whether the optical components or light bulbs are clean, and whether there is dust

accumulated on the light bulbs and other optical devices. The light bulbs and all components in

the lamps should be cleaned and maintained regularly.

The pattern projection is vague

Check if the electron focus channel values are appropriate for the current projection distance.

The lamps work intermittently

Cause: Internal line enters protection state and handles as follows:

Check whether the fan is running normally or whether it is dirty, causing the internal

temperature of the lamp to rise;

Check whether the internal temperature control switch is in a closed state;

Check the bulb for service life and replace a new bulb.

No console control is accepted after the lamp is normally reset

Possible reasons: signal line failure or abnormal lamp parameter setting, handled as follows:

Check the starting address code and the connection of the DMX signal line (whether the signal

line cable is intact and whether theAlcock head connection is loose);

17

www.szbecen.com

Add a signal amplifier, add 120 ohm terminal resistance;

The lamps cannot be started

Available reasons: poor power line, treated as follows:

Check whether the insurance on the power input socket is fused and replace the insurance;

Lighting have poor line contact due to vibration in long-distance transportation

Check input power supply, computer board and other plug devices.

2. Precautions for use

Check whether the local power supply meets the product rated voltage requirements, leakage

protection device, overcurrent protection device to meet the load requirements;

Do not use a damaged power cord with insulation, and cannot lap the power cord to other

wires;

The lamps and lanterns are using strong air refrigeration, easy to accumulate dust, it must be

cleaned once a month, especially the heat dissipation tuyere, otherwise it will be blocked due to

the dust accumulation, resulting in poor heat dissipation, so that the lamps and lanterns appear

abnormal.

When installing lamps, the fixed screws must be tightened, and equipped with a safety cable,

and regular check;

In the installation and positioning, any point on the lamp surface and any easy burning

explosive, the minimum distance is 10 meters, the distance from the irradiation is 2.5 meters,

please do not install the lamps directly on the surface of combustible substances;

It is recommended that the continuous working time of lamps should not exceed 10 hours, and

the interval between the continuous starting of lamps should not be less than 10 minutes,

otherwise it will not be triggered normally because of the overheating protection of the bulb;

The closing time of using the on-off valve should not exceed 5 minutes. If the light is closed for

a long time, the console (light gun control channel) should be used to turn off the light gun;

In order to ensure that multiple lamps can better comply with the scene effect, the lamps should

not always be in the unfinished current scene, that is, to start the next scene action, it is best that

this state is not more than 3 minutes, to ensure that multiple lamps can run synchronously;

During the use process, the lamps should be stopped in time to prevent other faults.

3.RDM Use Notes

RDM is an extended version of DMX512-A protocol, is the remote device management (Remote

Device Management) protocol, traditional DMX512 protocol communication is one-way

communication, protocol is based on R S-485 bus, R S-485 is multi-sharing, half-duplex protocol,

the same time allows only one port for the host output, so, pay attention to the following points

when using R DM:

18

www.szbecen.com

To use a console or host device that supports the R DM protocol host;

To use the two-way signal amplifier, the traditional unidirectional signal amplifier is not

applicable to the RDM protocol, because the R MD protocol needs feedback data, the use of the

one-way amplifier will block the returned data, resulting in no search for lamps;

All lamps must be set to D MX mode to ensure that there is only one host on the signal line;

An 120ohm impedance matching resistance must be inserted between the terminals 2 and 3 of

the terminal plug. When the signal line is relatively long, reducing the signal reflection will use

the differential signal more stable, which is conducive to the quality of communication;

When the lamp receives D M X control, but cannot R DM search the lamp, first check the

signal amplifier, and then check whether the signal line 2,3 lines have bad contact.

4. Lighting installation

Lamps can be placed horizontally, oblique and upside down. We must pay attention to the

installation method when oblique and inverted.

4As shown in Figure 4, before the positioning of the lamp, to ensure the stability of the

installation site, in the reverse hanging installation, must ensure that the lamp does not fall

down on the support frame, need to use a safety rope through the support frame and the lamp

lift for auxiliary hanging, to ensure safety,. Prevent the lamps from falling and sliding.

When the lamps are installed and tested, pedestrians are not allowed to pass below. Regularly

check whether the safety rope is worn and whether the hook screws are loose.

Our company shall not bear any responsibility for all the consequences of the falling of the

lamps due to the unstable installation of the hanging.

4Figure 4 Schematic diagram of the inverted lamp

Table of contents

Other Becen Lighting Equipment manuals

Becen

Becen BC-P100 User manual

Becen

Becen BC-246Z User manual

Becen

Becen BC-P186S User manual

Becen

Becen BC-W403 User manual

Becen

Becen BC-LE300 User manual

Becen

Becen BC-P419 User manual

Becen

Becen BC-M230B User manual

Becen

Becen BC-WR912 User manual

Becen

Becen BC-M200 User manual

Becen

Becen BC-P201 User manual