Table of contents

General ............................................................................................................................................................................... 3

Warranty ............................................................................................................................................................................. 4

Safety instructions ............................................................................................................................................................... 4

Instructions for the user................................................................................................................................................... 4

Instructions for installation and commissioning.................................................................................................................. 4

Intended use ....................................................................................................................................................................... 6

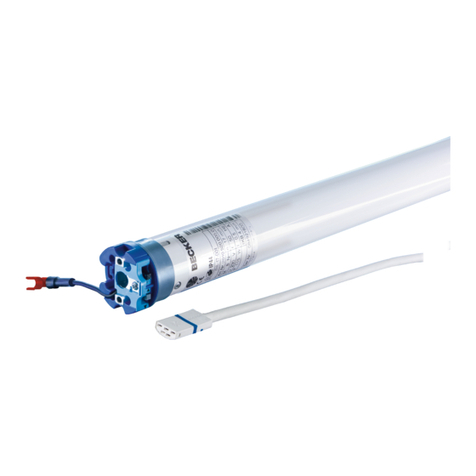

Assembling and disassembling the plug-in connecting cable................................................................................................... 6

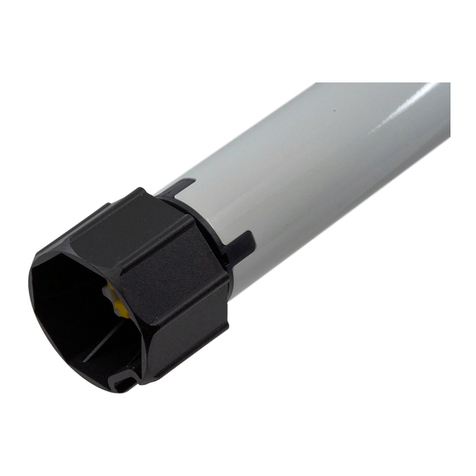

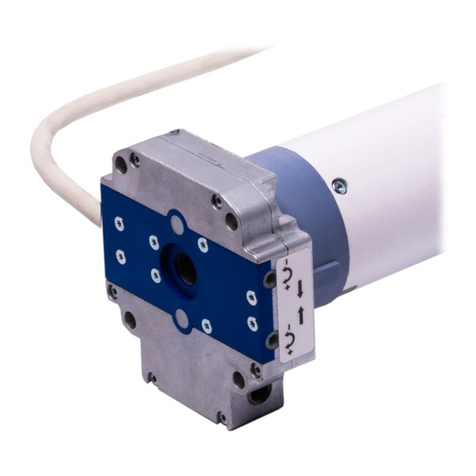

Assembly ............................................................................................................................................................................ 7

Compatible Centronic transmitters ........................................................................................................................................ 9

Commissioning with a CentronicPLUS transmitter ................................................................................................................ 10

Establish programming mode ........................................................................................................................................ 11

Programming the CentronicPLUS transmitter.................................................................................................................. 12

Adding additional transmitters to the installation .............................................................................................................. 12

Selection of the receiver for the setting mode.................................................................................................................. 13

Checking that the running direction is correct.................................................................................................................. 14

Intelligent installation management ................................................................................................................................ 15

Limit position status indicator ........................................................................................................................................ 15

Setting the limit positions............................................................................................................................................... 15

Lower point to upper point ........................................................................................................................................ 15

Extended point to retracted stop ............................................................................................................................... 16

Changing the set limit positions...................................................................................................................................... 16

Deleting the limit positions ............................................................................................................................................. 17

Intermediate positions I + II ............................................................................................................................................ 18

Restoring the wireless memory of the tubular drive to factory settings ............................................................................... 19

Commissioning with a Centronic transmitter......................................................................................................................... 21

Programming the master transmitter .............................................................................................................................. 22

Checking that the running direction is correct.................................................................................................................. 22

Intelligent installation management ................................................................................................................................ 23

Limit position status indicator ........................................................................................................................................ 23

Setting the limit positions............................................................................................................................................... 23

Lower point to upper point ........................................................................................................................................ 23

Lower point to upper stop ......................................................................................................................................... 24

Deleting the limit positions ............................................................................................................................................. 24

Intermediate positions I + II ............................................................................................................................................ 24

Programming additional transmitters.............................................................................................................................. 25

Deleting transmitters..................................................................................................................................................... 25

Overwriting the master .................................................................................................................................................. 26

Setting the limit positions with Auto-install (for ZIP applications with heavy end strip)............................................................... 27

Obstacle detection (for ZIP applications with heavy end strip) ................................................................................................ 27

Additional functions with CentronicPLUS/ Centronic ............................................................................................................ 27

Activating/deactivating the additional fabric untensioning function.................................................................................... 27

Restoring the factory settings of the tubular drive ................................................................................................................. 28

Local operation with a single button..................................................................................................................................... 29

Disposal ............................................................................................................................................................................ 29

Maintenance ..................................................................................................................................................................... 29

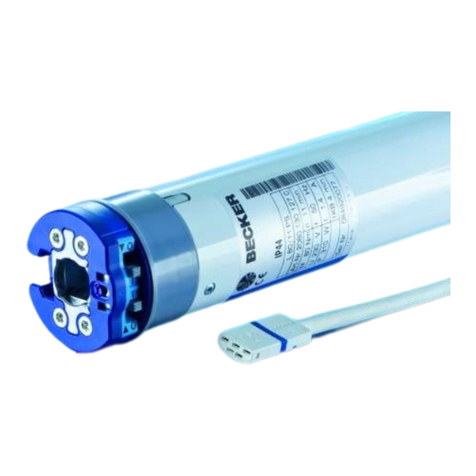

Technical data dia. 35 ........................................................................................................................................................ 30

Technical data dia. 45 ........................................................................................................................................................ 30

Error messages ................................................................................................................................................................. 30

What to do if...?.................................................................................................................................................................. 31

Sample wiring diagram ....................................................................................................................................................... 32

Declaration of conformity ................................................................................................................................................... 33

2-en