Table of contents

General ............................................................................................................................................................................... 3

Warranty ............................................................................................................................................................................. 3

Safety instructions ............................................................................................................................................................... 4

Instructions for the user................................................................................................................................................... 4

Instructions for installation and commissioning.................................................................................................................. 4

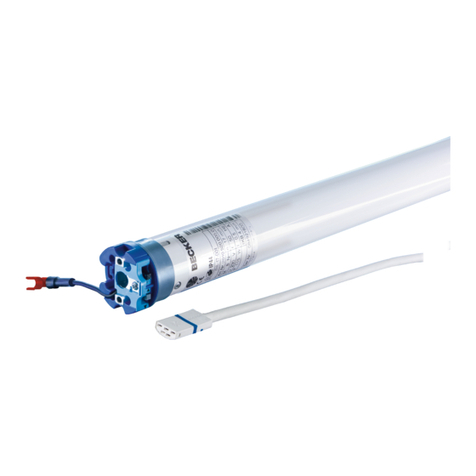

Intended use ....................................................................................................................................................................... 6

Assembling and disassembling the plug-in connecting cable................................................................................................... 6

Assembling the plug-in connecting cable .......................................................................................................................... 6

Disassembling the plug-in connecting cable for tubular drives dia. 35. ................................................................................ 7

Disassembling the plug-in connecting cable for tubular drives dia. 45 and dia. 58 ................................................................ 8

Installation........................................................................................................................................................................... 9

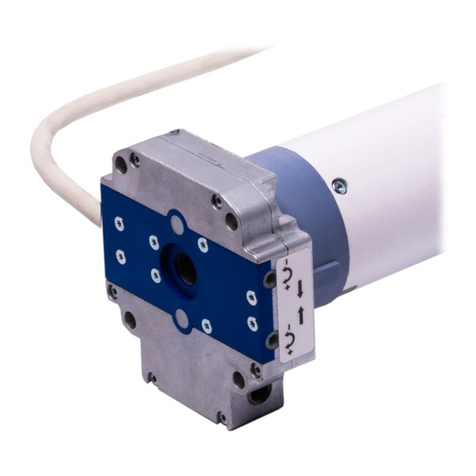

Assembling the drive ....................................................................................................................................................... 9

Undoing the mounting pin................................................................................................................................................ 9

Drive adapter safety catch ............................................................................................................................................... 9

Assembling the drive adapter with safety catch on the drive shaft................................................................................... 9

Disassembling the drive adapter with safety catch on the drive shaft ............................................................................ 10

Assembling and disassembling the drive adapter with separate drive adapter safety catch............................................. 10

Assembling and disassembling the drive adapter with screw connection ...................................................................... 10

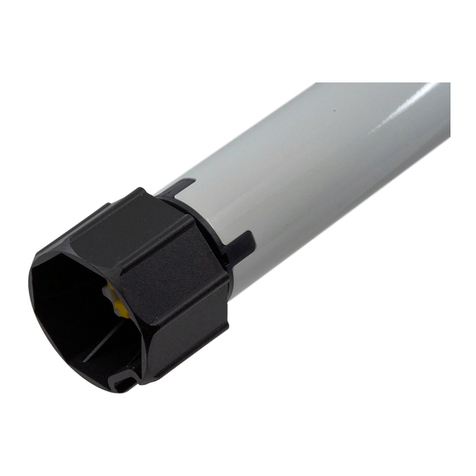

Mounting the drive in the tube ........................................................................................................................................ 10

Setting the limit positions with the switches on the drive head ................................................................................................ 12

Deleting the limit positions with the switches ........................................................................................................................ 14

Adjusting the limit positions with a rotary switch or a locking button ........................................................................................ 15

Deleting the limit positions with a rotary switch or a locking button ......................................................................................... 16

Setting the limit positions using the programming unit........................................................................................................... 17

Changing the additional stop behaviour function with the programming unit ........................................................................... 19

Deleting the limit positions using the programming unit......................................................................................................... 20

Setting the limit positions with Auto-Install............................................................................................................................ 22

Torque detection ............................................................................................................................................................... 23

Activating/deactivating the additional fabric untensioning function with the programming unit.................................................. 24

Activating/deactivating the additional fabric tensioning function with the programming unit ..................................................... 24

Information for the electrician ............................................................................................................................................. 25

Disposal ............................................................................................................................................................................ 25

Maintenance ..................................................................................................................................................................... 25

Technical data dia. 35 ........................................................................................................................................................ 25

Technical data dia. 45 ........................................................................................................................................................ 26

Technical data dia. 58 ........................................................................................................................................................ 26

Certificate of Suitability....................................................................................................................................................... 26

What to do if...?.................................................................................................................................................................. 27

Sample wiring diagram ....................................................................................................................................................... 28

2