BECS BECSys3 115VAC User manual

Installation and Technical Manual

9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132 www.becs.com

Installation and Technical Manual Rev: H10

T

TA

AB

BL

LE

E

O

OF

F

C

CO

ON

NT

TE

EN

NT

TS

S

Warnings............................................................................. 1

Unpacking........................................................................... 2

General Guidelines ............................................................. 2

Firmware Version ............................................................... 2

Environmental Conditions .................................................. 3

Electrical Specifications...................................................... 3

Applicable Sensor Operating Ranges.................................. 3

Section A: Mounting the BECSys3 Controller.................. 4

A – 1: Mounting the Controller...................................... 4

A – 2: Wrapping the Fittings.......................................... 4

A – 3: Assembling the Flow cell.................................... 4

A – 4: Plumbing the Sample Stream.............................. 4

A – 5: Free Chlorine Sensor........................................... 5

A – 5.1: CCS140........................................................ 5

A – 5.2: ECL6............................................................ 5

A – 6: Sensor Preparations............................................. 6

A – 6.1: Sensors......................................................... 6

A – 7: Opening the Sample Stream Valve ..................... 6

A – 8: Plugging in the Sensors....................................... 6

Section B: Wiring the BECSys3 Controller....................... 7

B – 1: Wiring the Unit ................................................... 7

B – 2: Opening the Cover .............................................. 7

B – 3: Removing the Safety Shield................................ 7

B – 4: Disconnecting the Ribbon Cable......................... 8

B – 5: Wiring Directly to the Unit ................................. 8

B – 6: Wiring Power ...................................................... 8

B – 7: Supplying Power To The Relays......................... 8

B – 8: Wiring Relay 1.................................................... 9

B – 8.1: Line Powered ............................................... 9

B – 8.2: Common Powered........................................ 9

B – 9: Wiring Relay 2.................................................... 9

B – 9.1: Line Powered ............................................... 9

B – 9.2 Common Powered.......................................... 9

B – 10: Wiring Relay 3 ................................................ 10

B – 10.1: Line Powered ........................................... 10

B – 10.2: Common Powered.................................... 10

B – 11: Wiring a Flow Switch ..................................... 10

B – 11.1: Paddlewheel Flow Switch........................ 10

B – 11.2: Reed Flow Switch .................................... 11

B – 12: Wiring a Timer................................................ 11

B – 13: Wiring the Temperature Sensor ...................... 11

B – 14: Wiring a Free Chlorine Sensor........................ 11

B – 14.1: CCS140.................................................... 11

B – 14.2: ECL6........................................................ 11

B – 15: RS485 Network............................................... 12

B – 15.1: BECSys RCM .......................................... 12

B – 16: Fuses................................................................ 12

Section C: Dip Switch Settings........................................ 13

C – 1: Choosing pH Feed Direction............................. 13

C – 2: Choosing On/Off Control or TBP ..................... 13

C – 3: Relay 3 Functions.............................................. 13

C – 3.1: Probe Wash ................................................ 13

C – 3.2: Alarm Relay................................................13

C – 3.3: Dual pH Control .........................................14

C – 3.4: Cl/Br Booster..............................................14

C – 4: Temperature.......................................................14

C – 5: Replacing the Cover ..........................................14

Section D: Programming the Controller...........................15

D – 1: The Program Menu............................................15

D – 1.1: Entering the Program Menu .......................15

D – 1.2: Selecting Language ....................................15

D – 1.3: pH High Alarm Point..................................15

D – 1.4: pH Low Alarm Point ..................................15

D – 1.5: ORP High Alarm Point...............................15

D – 1.6: ORP Low Alarm Point ...............................15

D – 1.7: Temperature High Alarm Point..................16

D – 1.8: Temperature Low Alarm Point...................16

D – 1.9: ORP/ppm Set point.....................................16

D – 1.10: ppm High Alarm.......................................16

D – 1.11: ppm Low Alarm .......................................16

D – 1.12: Exiting the Menu......................................16

D – 2: The System Settings Menu................................17

D – 2.1: Entering the System Settings Menu............17

D – 2.2: ORP Span...................................................17

D – 2.3: pH Span......................................................17

D – 2.4: Time Base...................................................17

D – 2.5: pH Calibration (2 Point) .............................18

D – 2.6: ORP Calibration (2 Point) ..........................18

D – 2.7: Feed Delay..................................................18

D – 2.8: Enable ppm Set point Selection..................19

D – 2.9: Failsafe Timers...........................................19

D – 2.9.1: Booster Failsafe...................................19

D – 2.9.2: pH Failsafe ..........................................19

D – 2.9.3: Chlorine/Bromine Failsafe ..................19

D – 2.10: pH Dead-zone...........................................20

D – 2.11: Relay Test.................................................20

D – 2.12: ppm Probe Calibration..............................20

D – 2.12.1: CCS140 .............................................20

D – 2.12.2: ECL6 .................................................20

D – 2.13: Temperature Enable..................................20

D – 2.14: ORP Enable..............................................20

D – 2.15: Access Codes............................................21

D – 2.15.1: Operator Access Code.......................21

D – 2.15.2: Rep Access Code...............................21

D – 2.15.3: Recovering Lost Access Codes .........21

D – 2.16: Exiting The Menu.....................................21

Section E: Normal Operation ...........................................22

E – 1: Set points ...........................................................22

E – 1.1: Displaying the Set points ............................22

E – 1.2: Modifying the Set points.............................22

E – 1.2.1: pH Set Point.........................................22

E – 1.2.2: Chlorine Set Point................................22

E – 1.2.2.1: ORP Control..................................22

E – 1.2.2.2: ppm Control (Calculated)..............22

www.becs.com 9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132

Installation and Technical Manual Rev: H10

E – 1.2.2.3: ppm Control (Probe)..................... 22

E – 1.2.3: Booster Trigger Point .......................... 22

E – 1.2.4: Booster End Point................................ 22

E – 2: Single Point Calibration .................................... 23

E – 2.1: Single Point Calibration - pH ..................... 23

E – 2.2: Single Point Calibration - Temp................. 23

E – 2.3: Single Point Calibration – ppm .................. 23

E – 2.3.1: Calculated ppm.................................... 23

E – 2.3.2: ppm Probe............................................ 23

E – 2.4: Probe Error................................................. 23

E – 3: Alarms............................................................... 23

E – 3.1: pH High/Low alarms.................................. 23

E – 3.2: ORP High/Low alarms ............................... 23

E – 3.3: ppm High/Low alarms................................ 23

E – 3.4: Temperature High/Low alarms................... 23

E – 3.5: No Flow Alarm........................................... 24

E – 3.6: Flow Restored Delay.................................. 24

E – 3.7: Cl/Br Lockout............................................. 24

E – 3.8: pH Failsafe ................................................. 24

E – 3.9: Cl/Br Failsafe ............................................. 24

E – 3.10: Booster FAILSAFE.................................. 24

E – 4: Resetting a Failsafe Alarm ................................ 24

Section F: Troubleshooting.............................................. 25

F – 1: Calibration Error................................................ 25

F – 2: Probe Error ........................................................ 25

Section G: Upgrading Firmware...................................... 25

Section H: Maintenance................................................... 26

H – 1: Potentiometric Sensors (pH and ORP).............. 26

H – 1.1: Electrode Cleaning:.................................... 26

H – 1.2: Long-Term Storage:................................... 26

H – 2: CCS140 Free Chlorine Sensor.......................... 26

H – 2.1: Cleaning..................................................... 26

H – 2.2: Long-Term Storage.................................... 26

H – 2.3: Filling electrolyte....................................... 26

Section I: Feed Charts...................................................... 27

I – 1: Spa Feed Charts.................................................. 27

I – 2: Pool Feed Charts................................................. 28

Section J: Installation Diagrams ...................................... 29

J – 1: Pressure Filter Installation.................................. 29

J – 2: Vacuum Filter Installation.................................. 29

Section K: Replacement Parts.......................................... 30

Section L: Warranty......................................................... 31

Page 1

9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132 www.becs.com

Installation and Technical Manual Rev: H10

W

Wa

ar

rn

ni

in

ng

gs

s

Pay particular attention to the following warnings encountered in the pages of the

BECSys3 Installation and Technical Manual:

Warning: Various other warning boxes may be

found throughout the manual text.

Caution: Various other caution boxes may be found throughout the manual text.

Page 2

www.becs.com 9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132

Installation and Technical Manual Rev: H10

U

Un

np

pa

ac

ck

ki

in

ng

g

Your Shipping package should contain these items:

A. The BECSys3 Controller

B. pH Sensor

D. Flow Cell Kit

E. Rotary or Reed flow switch

F. This manual (not shown)

G. Optional Sensors (not shown)

A B C D

G

Ge

en

ne

er

ra

al

l

G

Gu

ui

id

de

el

li

in

ne

es

s

Proper installation and use of the BECSys controller depends on the specific needs of the application. Read the manual

completely before starting the installation and ensure all guidelines and recommendations are followed. All components

should be mounted and the flow cell plumbing installed and pressure tested before wiring the controller. Ensure

compliance with all applicable plumbing and electrical codes during the installation as well.

F

Fi

ir

rm

mw

wa

ar

re

e

V

Ve

er

rs

si

io

on

n

This manual was written for firmware v2.06. If you received newer firmware but did not receive a copy of the manual

covering that version of firmware, please contact your distributor.

Warning: The Sensors are very fragile and must be handled with care. The tips of the probes must be kept

wet at all times, requiring the wetting caps to remain in place until they are ready to be installed. The probes

must be stored in temperatures above freezing.

Rotary

Reed

or

Caution: The BECSys controller should not be installed where it is accessible to the public.

Page 3

9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132 www.becs.com

Installation and Technical Manual Rev: H10

E

En

nv

vi

ir

ro

on

nm

me

en

nt

ta

al

l

C

Co

on

nd

di

it

ti

io

on

ns

s

The BECSys3 is housed in a NEMA 4X (IP65) enclosure. It should not be used in explosive environments. The

BECSys3 should be mounted so that adequate ventilation is provided around the enclosure, preventing general

environmental specifications from being exceeded (see table below).

Environmental Specifications

Specification

Rating

Storage Temperature

-30 to 60 Deg C

Ambient Operating Temperature

-18 to 40 Deg C

Ambient Humidity

95% non condensing maximum humidity

E

El

le

ec

ct

tr

ri

ic

ca

al

l

S

Sp

pe

ec

ci

if

fi

ic

ca

at

ti

io

on

ns

s

The BECSys3 may be ordered in either an 115VAC model or a 230VAC model. Following are the electrical

specifications for each model:

Controller Ratings

115VAC Model

230VAC Model

Voltage:

115VAC 60Hz

230VAC 50Hz

Phase:

Single

Single

Current:

9.25 Amps Full Load

4.625 Amps Full Load

(¼ Amp – Controller)

(⅛ Amp – Controller)

(9 Amps – Relay Outputs, 3A X 3)

(4.5 Amps – Relay Outputs, 1.5A X 3)

Relay Output Ratings

115VAC Model

230VAC Model

Relay 1 (K1)

115VAC (max) – 3 Amps

250VAC (max) – 1.5 Amps

Relay 2 (K2)

115VAC (max) – 3 Amps

250VAC (max) – 1.5 Amps

Relay 3 (K3)

115VAC (max) – 3 Amps

250VAC (max) – 1.5 Amps

A

Ap

pp

pl

li

ic

ca

ab

bl

le

e

S

Se

en

ns

so

or

r

O

Op

pe

er

ra

at

ti

in

ng

g

R

Ra

an

ng

ge

es

s

Standard Sensors

pH

0.0 to 14.0 pH

Reed Flow Switch

Switch Point (On): 2.0 gpm

Rotary Flow Switch

Switch Point (On): 1.5 gpm

Optional Sensors

Temperature

32°F to 212°F (0°C to 100°C)

ORP

-1500mV to 1500mV

Amperometric ppm

0 ppm to 20 ppm

Page 4

www.becs.com 9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132

Installation and Technical Manual Rev: H10

S

Se

ec

ct

ti

io

on

n

A

A:

:

M

Mo

ou

un

nt

ti

in

ng

g

t

th

he

e

B

BE

EC

CS

Sy

ys

s3

3

C

Co

on

nt

tr

ro

ol

ll

le

er

r

A – 1: Mounting the Controller

The BECSys3 Controller and flow cell are mounted

separately. The BECSys3 enclosure should be

mounted to the wall with four anchor bolts, one

installed in each corner of the enclosure base. To

mount the BECSys3 properly, please use the

included mounting template and hardware. Drill the

holes for the anchors using a 3/16” drill bit. Install

the anchors in the wall. Remove the lid from the

unit and place the included screws in the four

corners of the box. Attach the screws into the

anchors. The BECSys3 and flow cell should be

mounted in a location that is free from chemical

fumes and excessive heat, isolated from electrical

interference, and near a power source protected by a

ground fault interrupter. The BECSys3 has a

NEMA4 weather resistant enclosure but should still

be protected if mounted outdoors.

A – 2: Wrapping the Fittings

When assembling the flow cell, first open the bag of

flow cell fittings and wrap each fitting two times

around clockwise with Teflon tape.

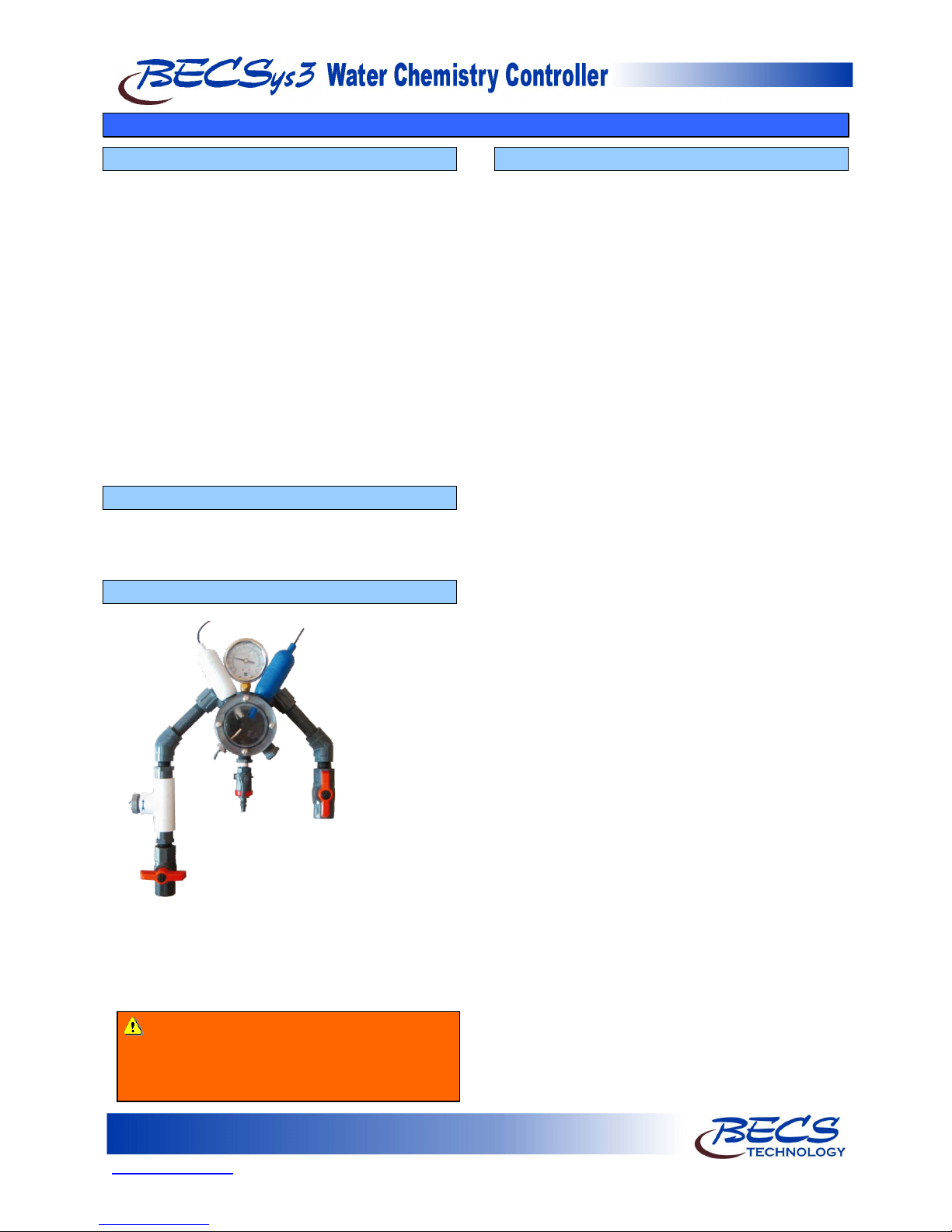

A – 3: Assembling the Flow cell

Assemble the flow cell as shown below:

When installing the pH or ORP (if included) sensors,

remove the wetting cap, and then remove any

existing Teflon tape from the sensor threads. Re-

wrap the threads with new Teflon tape. Rinse the

sensor tip in de-ionized water and install as shown.

A – 4: Plumbing the Sample Stream

Install the sample stream; ½-inch tubing is

recommended for sample stream pickup and return.

Make sure that you tap the supply off the

discharge side of the recirculation pump,

upstream

of the chemical injection points. The

sample should be filtered water. Connect the sample

stream pickup line to the flow cell and run the

sample stream return line from the flow cell to the

suction side of the main recirculation pump. Install

½-inch ball valves to allow isolation of the sample

lines.

Warning: These sensors should be hand-

tightened only. Tools are not necessary for

installing the pH or ORP sensor and will

damage the sensor housing.

Page 5

9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132 www.becs.com

Installation and Technical Manual Rev: H10

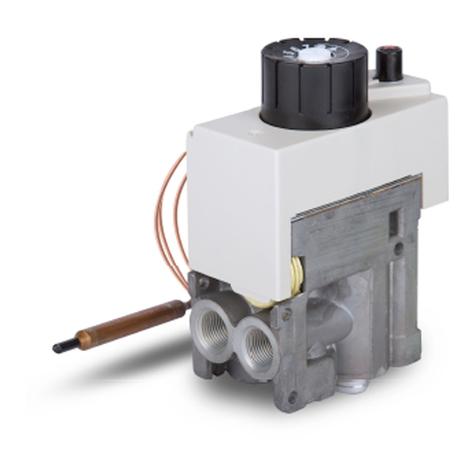

A – 5: Free Chlorine Sensor

The BECSys3 can be ordered to accept two different

Free Chlorine Sensors: the CCS140 or the ECL6.

A – 5.1: CCS140

The CCS140 Free Chlorine Sensor can be

connected to the BECSys3 using the appropriate

option board. The CCS140 Free Chlorine Sensor

is mounted in a flow cell which includes a flow and

psi restrictor assembly as shown below:

The CCS140 Free Chlorine Sensor requires a

constant flow rate and a constant pressure. This

helps ensure that the ppm level will remain stable.

Here is the recommended method for plumbing

the free chlorine sensor flow cell:

Admission pressure must be above the regulated

pressure (15 psi is the limit on the sensor). Run

the sample stream through a flow restrictor valve

(to maintain flow rate, minimum flow rate

requirement is 8 gph). Take the stream through

the flow cell. Discharge the sample stream to a

free outlet (for example into a surge tank).

The CCS140 Free Chlorine Sensor is supplied with

a yellow protective cap. This cap has an inner

sponge that is used to keep the sensor membrane

hydrated. This cap should be saved for long-term

storage.

The sensor can remain in the flow cell for short-

term interruptions in measurement. To prevent

membrane dehydration, the flow cell must not

drain off. If this is not ensured, then remove the

sensor from the flow cell and slide the yellow

protective cap, moistened at the inner sponge,

onto the measuring end of the sensor.

The voltage applied by the controller to the

CCS140 Free Chlorine Sensor polarizes the surface

of the gold cathode. The polarization period (30

minutes) must elapse before calibration is

performed based on the results acquired through

the use of a DPD test kit.

See Section H - 2.3 for filling the electrolyte.

A – 5.2: ECL6

The ECL6 Free Chlorine Sensor can be connected

to the BECSys3 using the appropriate option

board.

Caution: Amperometric chlorine sensors

require the use of a temperature sensor and

a properly calibrated pH sensor. Refer to

the instruction pamphlet included with the

sensor at the time of installation.

Warning: Negative pressure will damage the

sensor membrane.

Page 6

www.becs.com 9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132

Installation and Technical Manual Rev: H10

A – 6: Sensor Preparations

NOTE: As soon as you install the sensors,

immediately move on to the next step to insure that

they always stay wet.

A – 6.1: Sensors

The pH and ORP (if included) sensors are shipped

with a wetting cap covering the measuring end.

This cap contains a solution of pH 4 buffer

saturated with potassium chloride (KCl). Gently

remove the wetting cap by unscrewing the sensor

and sliding the cap off of the sensor body.

It is a good idea to save the wetting cap and

the box that the sensor came in for future

long-term storage.

During shipping, the air space inside the pH glass

may have moved into the bulb. Grasp the sensor

near the cable end and gently swing it through an

arc to force the internal electrolyte into the pH

bulb. Rinse the measuring ends of potentiometric

sensors with de-ionized or distilled water before

installation into a flow cell.

A – 7: Opening the Sample Stream Valve

Open the sample stream valve and check for leaks.

Note the reading on the compound pressure gauge

and make sure that it shows a positive and steady

pressure. The sample stream should be about 2-20

psi at the flow cell. If this is not the case, then adjust

the valves or relocate the point at which the sample

stream is connected to the recirculation system.

Negative pressure will destroy the sensors. Once

you have a positive and steady pressure, open the wet

test valve and make sure that it generates a vigorous

stream.

A – 8: Plugging in the Sensors

Remove the protective covers from the BNCs. Plug

the pH sensor into the coded BNC jack and the

ORP (if included) sensor into the coded BNC jack

on the bottom of the BECSys3 controller by twisting

them a quarter of a turn. Allow the sensors to rinse

in the sample water while you do the wiring (Section

B).

Page 7

9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132 www.becs.com

Installation and Technical Manual Rev: H10

S

Se

ec

ct

ti

io

on

n

B

B:

:

W

Wi

ir

ri

in

ng

g

t

th

he

e

B

BE

EC

CS

Sy

ys

s3

3

C

Co

on

nt

tr

ro

ol

ll

le

er

r

B – 1: Wiring the Unit

There are several ways that you can wire the relays and

power to the unit. The easiest is to use the cords

already installed in the unit. Plug the AC Cord into a

GFCI outlet (only for low voltage 110VAC-120VAC

applications) and connect the chemical feeders to the

female power cords (pigtails). The pigtails are labeled

with the below warning tags. Be sure to connect the

correct pigtail to the correct chemical feeder. You

must still remove the cover to install the Flow Switch,

and any other optional components.

The second way is to discard the pre-installed cords

and wire the unit directly.

B – 2: Opening the Cover

In order to wire the unit directly or attach the Flow

Switch (and any optional components), you must

open the cover. Remove the cover by loosening the

four screws at the corners with a screwdriver as

shown. NOTE: The screws do not need to be

totally removed, but only loosened. Once the

screws are loosened, carefully lift the top cover off of

the unit. The cover will still be connected to the

base by the ribbon cable. Set the moisture absorbent

packet found inside aside for now.

B – 3: Removing the Safety Shield

To remove the shield, remove the four screws using

a Philips screwdriver. Gently lift the cover straight

up and set it to the side.

Page 8

www.becs.com 9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132

Installation and Technical Manual Rev: H10

B – 4: Disconnecting the Ribbon Cable

We recommend that you disconnect the ribbon cable

by spreading the two holders at the end of the cable

attached to the cover as shown, unplugging the cable

and removing the cover.

NOTE: Be sure to store the cover in a safe, dry

place while you wire and set up the unit.

B – 5: Wiring Directly to the Unit

To wire the unit directly, you must remove the pigtails

already installed. You may use the ½-inch holes in the

casing to enable you to easily run wires to Terminal

Block 1 (TB1) inside the base of the unit.

NOTE: There are Terminal Blocks labeled TB1

and TB2 in both the cover and base of the

unit and they serve different functions.

Use the ½-inch cord grips provided and whatever

holes are convenient, but when you are all finished

wiring the unit, be sure to plug any unused holes with

a ½-inch NEMA 4x plug.

B – 6: Wiring Power

The main power input should be wired to TB1. The

black wire goes into the position labeled Line, the

white wire goes into the position labeled Neutral, and

the green wire goes into the position labeled Earth

Ground.

NOTE: The black and white wires are colored

brown and blue outside North America.

B – 7: Supplying Power To The Relays

All three of the relays may be configured to be

powered from either the L (Line) connection which

the controller itself is powered from, or their

individual C (Common) connections. As shipped

from the factory, all three relays are configured to be

powered from the L (Line) power connection. If

you wish to use the C (Common) input instead

(commonly used to interlock feeds with the

recirculation pump), you will need to move the black

hat jumpers located above TB2 to their upper

position for the desired relays.

NOTE: The relays inside the controller are solid-

state and can only switch AC signals. If

you need to switch DC power, an

external Mechanical Relay must be used.

Warning: Make sure power is disconnected

while you wire the unit

Warning: Unless specified at time of order,

controllers are configured for 115VAC and

should not be used at 230VAC. Always contact

BECS Technology, Inc. before attempting to

reconfigure a controller’s input supply voltage.

Page 9

9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132 www.becs.com

Installation and Technical Manual Rev: H10

B – 8: Wiring Relay 1

Relay 1 controls pH. You can configure the relay to

be powered from the same Line voltage as the

controller or from its own separate voltage input.

B – 8.1: Line Powered

Make sure the hat jumper is in the lower position

“L”. The black wire goes into the position labeled

pH Feed, the white wire goes into the Neutral

position next to that, and the green wire goes into

Earth Ground position next to that. Nothing

should be connected to the pH COM terminal.

NOTE: The black and white wires are colored

brown and blue outside North America.

B – 8.2: Common Powered

Connect the incoming power to the pH COM

terminal (the red wire shown below) and move the

hat jumper for the pH relay to the upper position

“C”. The black wire goes into the position labeled

pH Feed. Leave the Neutral and Earth Ground

terminals unconnected inside the controller. The

Neutral and Earth Grounds from the feeder must

be connected to the Neutral and Earth Ground of

the power source supplying this relay.

B – 9: Wiring Relay 2

Relay 2 controls ORP. You can configure the relay

to be powered from the same Line voltage as the

controller or from its own separate voltage input.

B – 9.1: Line Powered

Make sure the hat jumper is in the lower position

“L”. The black wire goes into the position labeled

Cl/Br Feed, the white wire goes into the Neutral

position next to that, and the green wire goes into

the Earth Ground position next to that. Nothing

should be connected to the Cl/Br COM terminal.

NOTE: The black and white wires are colored

brown and blue outside North America.

B – 9.2 Common Powered

Connect the incoming power to the Cl/Br COM

terminal (the red wire shown below) and move the

hat jumper for the Cl/Br relay to the upper

position “C”. The black wire goes into the

position labeled Cl/Br Feed. Leave the Neutral

and Earth Ground terminals unconnected inside

the controller. The Neutral and Earth Grounds

from the feeder must be connected to the Neutral

and Earth Ground of the power source supplying

this relay.

Page 10

www.becs.com 9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132

Installation and Technical Manual Rev: H10

B – 10: Wiring Relay 3

Relay 3 may be used for Dual pH control, Alarm,

Cl/Br Booster, or Sensor Wash (Refer to Section C

on how to configure this). You can configure the

relay to be powered from the same Line voltage as the

controller or from its own separate voltage input.

B – 10.1: Line Powered

Make sure the hat jumper is in the lower position

“L”. The black wire goes into the position labeled

Auxiliary, the white wire goes into the Neutral

position next to that, and the green wire goes into

Earth Ground position next to that. Nothing

should be connected to the AUX COM terminal.

NOTE: The black and white wires are colored

brown and blue outside North America.

B – 10.2: Common Powered

Connect the incoming power to the AUX COM

terminal (the red wire shown below) and move the

hat jumper for the Aux relay to the upper position

“C”. The black wire goes into the position labeled

Auxiliary. Leave the Neutral and Earth Ground

terminals unconnected inside the controller. The

Neutral and Earth Grounds from the feeder/device

must be connected to the Neutral and Earth

Ground of the power source supplying this relay.

B – 11: Wiring a Flow Switch

A Flow Switch must be used in the operation of a

BECSys3 Controller.

A paddlewheel flow switch or reed flow switch is

incorporated into the flow cell to disable chemical

feed in the event of loss of flow.

B – 11.1: Paddlewheel Flow Switch

Connect the wires to CN5 in the cover of the unit.

The black wire goes to Ground, the white wire

goes to Flow, and the red wire goes to +12V.

With the paddlewheel flow switch, whenever the

wheel spins, the green “flow” light on the flow

switch will be on.

Warning: NEVER BYPASS FLOW

SWITCH CONNECTIONS

The Flow Switch is a critical safety device which

prevents uncontrolled chemical feed.

Uncontrolled feeding of chemicals can result in

injury or death.

Warning: Failure to incorporate a Flow

Switch and Flowcell into the sample

Stream of your BECSys chemical controller

can result in injury or death to swimmers in or

around the pool if the recirculation pump

should fail or shut down.

Warning: A check valve must be installed with

the paddlewheel flow switch to prevent backflow

when the system is shut down. If a check valve is

not installed, backflow could give the controller a

false reading of flow and continue to pump

chemicals into the pool.

Page 11

9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132 www.becs.com

Installation and Technical Manual Rev: H10

B – 11.2: Reed Flow Switch

The reed flow switch is a (2) two-wire switch.

Connect the wires to CN5 in the cover of the unit.

The black wire goes to the terminal labeled Flow,

and the red wire goes to the terminal labeled + 12.

NOTE: Unlike the paddlewheel flow switch, the

reed flow switch is a directional switch.

Make sure it is installed with the flow

arrow in the proper direction. No check

valve is required with the reed flow switch.

B – 12: Wiring a Timer

One advantage of the BECSys3 Controller is that the

unit can be used with a timer to control the feeder and

still not lose power to the sensor. Most controllers

work with a timer by cutting all power, which then

means that the sensor goes through an erratic period

(up to two minutes) every time power is restored.

With BECS units, the sensor continues to function

even when the timer cuts power to the feeder so there

is never a loss in accuracy.

If you have decided to use a timer to interrupt the

chemical feed, wire the timer in parallel with the flow

lead of the flow switch.

Timer

Flow Switch

B – 13: Wiring the Temperature Sensor

The optional temperature sensor is wired to CN5 in

the cover of the unit. The white wire goes to the

terminal labeled "+", and the black wire goes to the

terminal labeled "-".

B – 14: Wiring a Free Chlorine Sensor

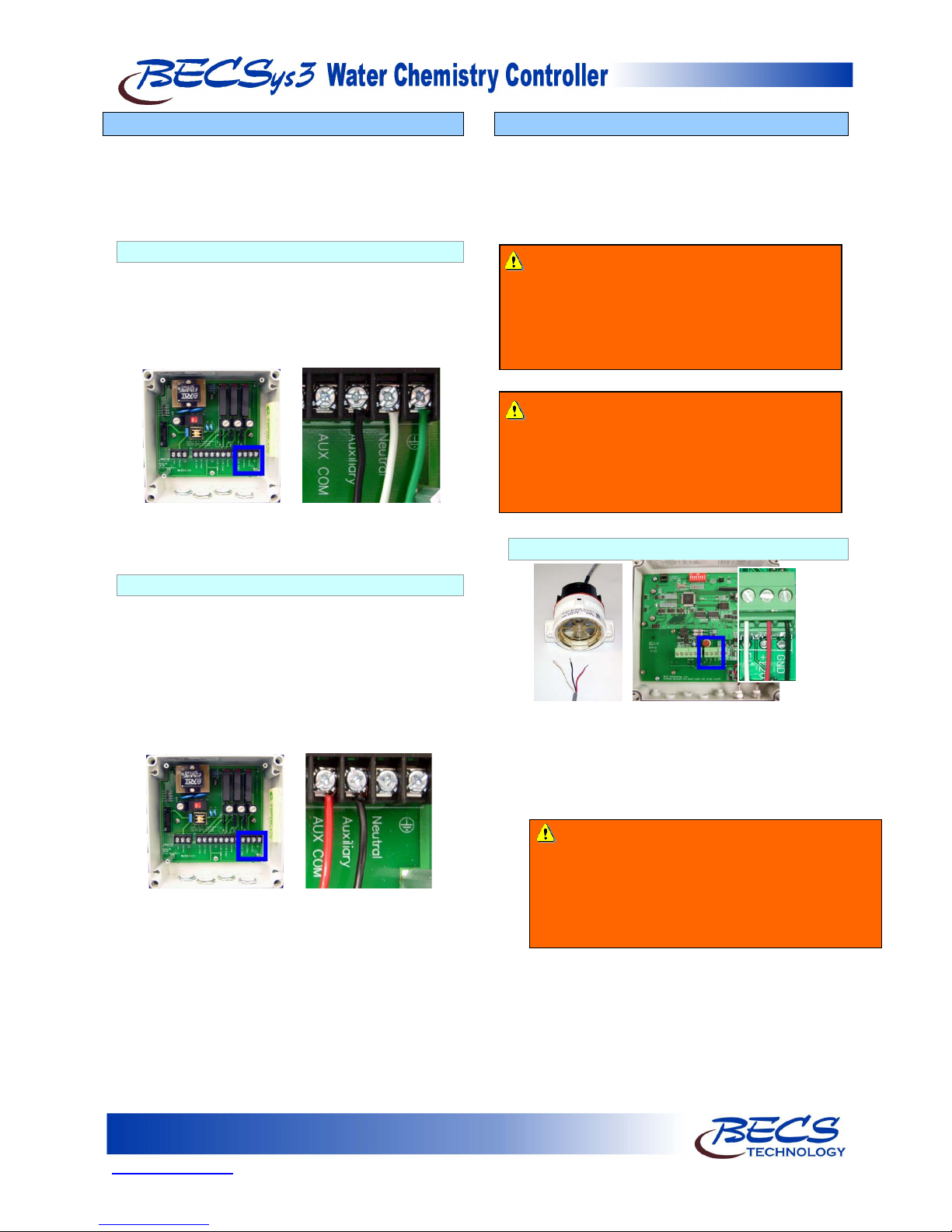

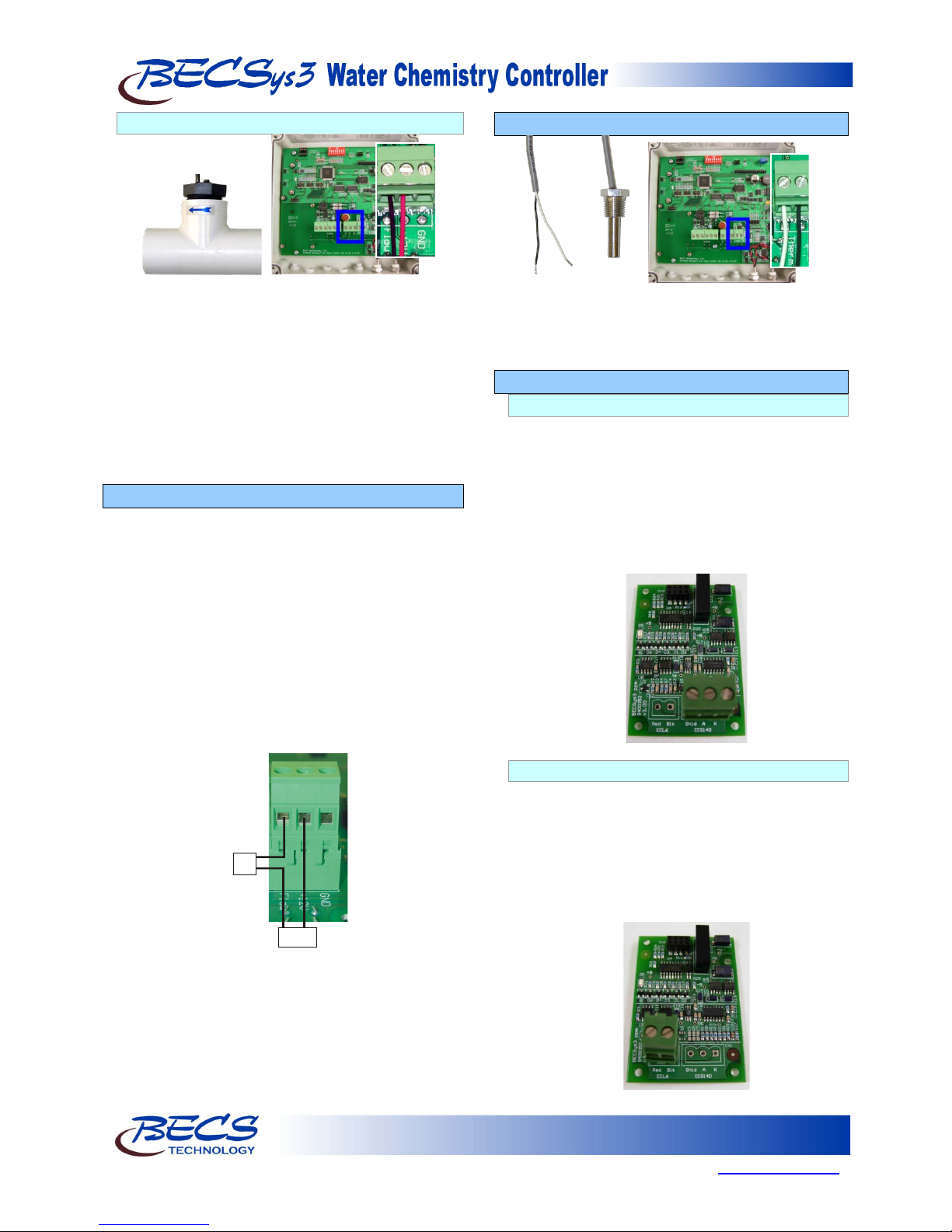

B – 14.1: CCS140

The CCS140 Free Chlorine Sensor is wired to the

option board inside the controller. If you ordered

your controller with the option board, it is located

on the lower left side of the lid. There is a three

position pluggable terminal block where the wires

will be connected. Connect the red "A" wire to

the A terminal, the "K" white tip with transparent

wire to the K terminal, and the thick unlabeled

wire to the ground terminal.

B – 14.2: ECL6

The ECL6 Free Chlorine Sensor is wired to the

option board inside the controller. If you ordered

your controller with the option board, it is located

on the lower left side of the lid. There is a two

position pluggable terminal block where the wires

will be connected. The red wire goes to the

position labeled “red” and the black wire goes to

the position labeled “black”.

Page 12

www.becs.com 9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132

Installation and Technical Manual Rev: H10

B – 15: RS485 Network

B – 15.1: BECSys RCM

If you have ordered a BECSys RCM, or the site has

a BECSys RCM already installed, you may connect

your BECSys3 to it. The BECSys RCM provides

data logging and remote access of up to 32

BECSys3 controllers per site.

Recommended wire: 22 gauge shielded twisted pair

(1 pair: 2 conductors + shield).

For outdoor use, use NEC type PLTC.

For indoor use, use NEC type CMG general, CMR

riser (through floors), or CMP plenum as required

by the local wiring code.

Connect the wires to CN4 in the cover of the unit.

There are two RS485 terminal blocks to allow daisy

chaining of units. It doesn’t matter which

connector you use – whichever is easiest. For each

unit, wire as follows:

From BECSys3

To BECSys RCM

A

A

B

B

SH

Shield

Refer to the BECSys RCM manual (included with

your BECSys RCM) for more information on how

to configure the network.

B – 16: Fuses

115VAC Model (F4):

¼ Amp 250V Time Lag Fuse (¼” x 1¼”)

BECS Part Number: 8140086

230VAC Model (F4):

¼ Amp 250V Time Lag Fuse (¼” x 1¼”)

BECS Part Number: 8140086

Relay Fuses (F1 – F3):

3 Amp 250V Time Lag Fuse (¼” x 1¼”)

BECS Part Number: 9140088

RS485 Fuse (F1 CPU Board):

¼ Amp 250V Time Lag Microfuse (5.08mm)

BECS Part Number: 8140059

Page 13

9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132 www.becs.com

Installation and Technical Manual Rev: H10

S

Se

ec

ct

ti

io

on

n

C

C:

:

D

Di

ip

p

S

Sw

wi

it

tc

ch

h

S

Se

et

tt

ti

in

ng

gs

s

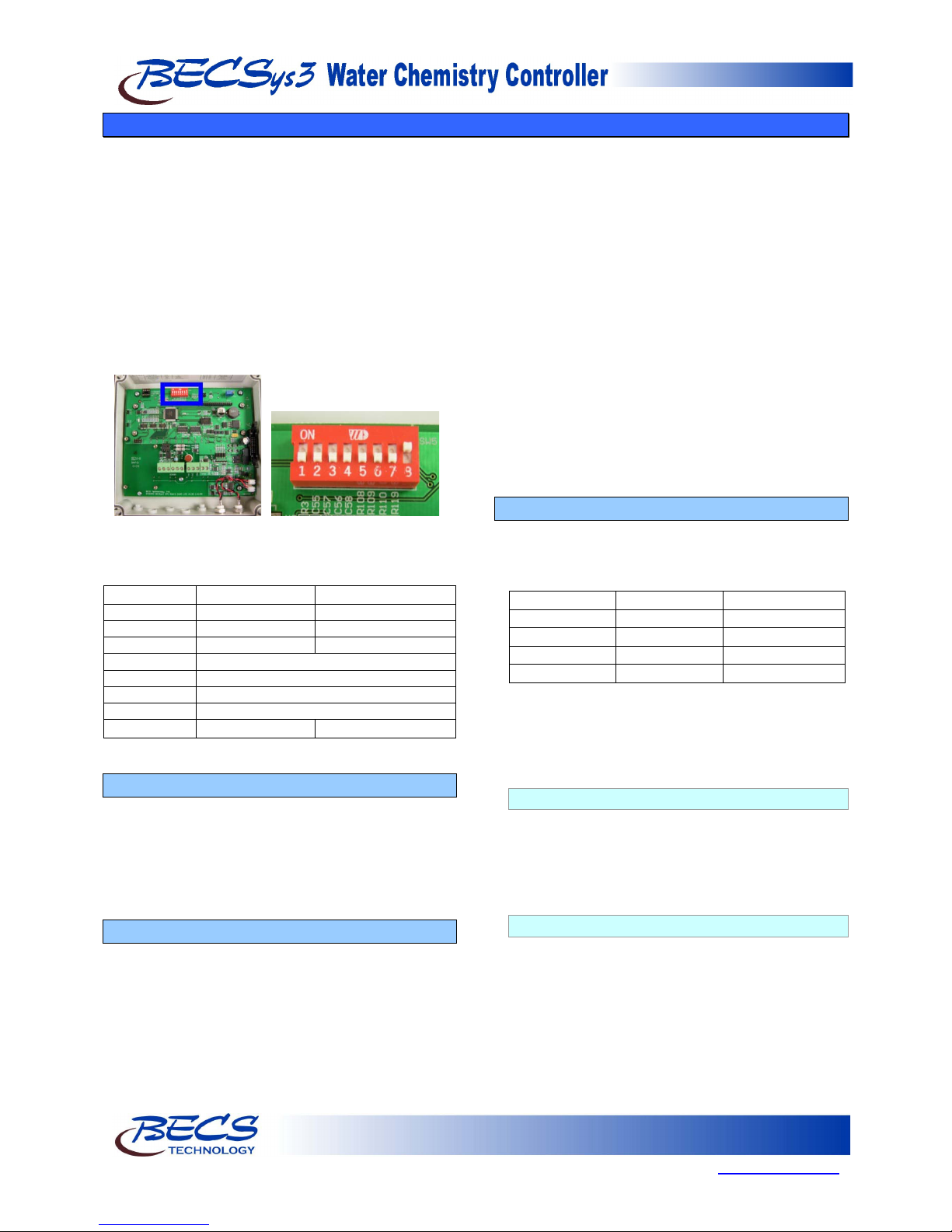

The BECSys3 controller comes preprogrammed for

pH feed down (acid or CO2), Time Based Proportional

feed mode, Probe Wash, and temperature shown in °F.

These factory settings are appropriate for most

systems. If you would like to change these settings,

you must change the internal dipswitches.

To change the dipswitches, first unplug the BECSys3

power cord and open the cover of the unit (as

explained in Section B - 2).

The photograph shows the dipswitch bank (SW5) in

the cover of the unit.

The following chart indicates the positions and

functions of the switches.

Dip Switch

OFF

ON

1

pH Feed Down

pH Feed Up

2

pH TBP Control

pH On/Off Control

3

ORP TBP Control

ORP On/Off Control

4

NOT USED

5

NOT USED

6

Relay 3 Function*

7

Relay 3 Function*

8

Temperature °C Temperature °F

* See Section C – 3

C – 1: Choosing pH Feed Direction

Relay 1 controls pH. It can be set to feed down

(acid) for use with chemicals such as carbon dioxide

or muriatic acid, or to feed up (base) for use with

chemicals such as caustic soda or soda ash. (If you

are using Dual pH then Relay#1 is set as Feed Up

and Relay#3 is set as Feed Down).

C – 2: Choosing On/Off Control or TBP

In general, if you are using a motor driven chemical

feeder then you should choose the On/Off option.

If you are using a solenoid driven or pulsed

diaphragm chemical feeder (such as Pulsatron, most

LMI models or most Prominent Models), you should

choose the TBP (Time-Based Proportional) option.

This feature helps to hold a set point and to

minimize over-shoot by making a standard feeder

mimic the action of more sophisticated modulating

feeders.

If you choose the On/Off option and are feeding up

then the controller will activate the chemical feeder

whenever the pH or ORP falls below the set point

and continue to feed until the pH or ORP rises

above the set point plus hysteresis at which point it

will stop.

If you choose the TBP option the controller will

activate the chemical feeder whenever the pH or

ORP falls below the set point and will feed for a

fraction of the Time Base depending on the amount

of deviation from set point. The balance of the Time

Base, the feeder will be paused. The smaller the

deviation, the less time the feeder is ON. The feeder

will continue this feed and pause cycle until the

BECSys3 achieves the set point plus hysteresis.

C – 3: Relay 3 Functions

Relay 3 can be used for several different functions.

To select the function of Relay 3 move switches 6

and 7 to the positions shown in the following chart:

Dip Switch 6

Dip Switch 7

Function

Off

Off

Probe Wash

Off

On

Alarm

On

Off

Dual pH

On

On

Cl/Br Booster

NOTE: You will only have an Alarm Relay when

the dip switches are set accordingly. The

Alarm LED will still flash when the

controller is in Alarm.

C – 3.1: Probe Wash

Setting Dip Switches 6 and 7 to the off position

configures Relay 3 for Probe Wash. The Probe

Wash will begin 12 hours from power-up, run for

approximately 2 minutes, and then come on again

every 24 hours after that running for 2 minutes.

C – 3.2: Alarm Relay

Setting Dip Switch 6 to the off position and Dip

Switch 7 to the on position configures Relay 3 for

Alarm. The Alarm Relay will turn on any time

there is an alarm state (No Flow, pH High, etc).

Alarm points are set in the Programming Section

of this manual (Section D).

Page 14

www.becs.com 9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132

Installation and Technical Manual Rev: H10

C – 3.3: Dual pH Control

Setting Dip Switch 6 to the on position and Dip

Switch 7 to the off position configures Relay 3 for

dual pH control (pH feed down).

C – 3.4: Cl/Br Booster

Setting Dip Switches 6 and 7 to the on position

configures Relay 3 for a sanitizer booster. When

the ORP level drops to the Cl/Br Booster Trigger

point, Relay 3 will activate an alternate sanitizer

feed until the ORP reaches the Cl/Br Booster End

point.

C – 4: Temperature

With Dip Switch 8 On, temperature is displayed in

Fahrenheit. With the Dip Switch Off, temperature is

displayed in Celsius.

C – 5: Replacing the Cover

Now it is time to put the cover back on the unit. But

before you do, give your wiring one last check and

make sure that you reconnect the ribbon cable (as

shown). Line up the small holes in the cable end

with the pins attached to the cover and gently press

the cable into place. Make sure the two holders

attached to the cover close back over the cable end

to hold it firmly in place.

Replace the safety shield using the screws that were

removed. Be sure to align the holes with the fuse

holders. You may have to adjust the fuse holders

slightly to align the shield properly. Finally, place the

cover back on the unit and tighten the four screws at

the corners to secure it in place.

Page 15

9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132 www.becs.com

Installation and Technical Manual Rev: H10

S

Se

ec

ct

ti

io

on

n

D

D:

:

P

Pr

ro

og

gr

ra

am

mm

mi

in

ng

g

t

th

he

e

C

Co

on

nt

tr

ro

ol

ll

le

er

r

D – 1: The Program Menu

D – 1.1: Entering the Program Menu

To enter the program menu, press and hold both

the Cal and Up key for three seconds. At the end

of three seconds, one of two things will happen.

If the Operator and Rep access codes have been

set, the unit will prompt you for an access code.

Use the Arrow keys to change the current digit,

and press the Set Points key to go to the next

digit. Press the Enter key when you have

finished entering your code. Once the access

code has been entered, the controller will either

display the first menu item or display "Access

denied" if the code you entered is invalid.

When the LCD screen clears, release the keys

and “Program Menu” should appear at the top

of the display.

Once in the program menu, use the Arrow keys to

scroll to the setting you wish to change. Press the

Enter key to select the setting, and then use the

Arrow keys to modify the value. Press the Enter

key again to enter the new value and return to the

menu. To exit the program menu, scroll to the

“Exit menu” option and press the Enter key.

NOTE: After five minutes of no programming

activity, the Time-Out feature will

automatically exit the programming

menu.

D – 1.2: Selecting Language

The BECSys3 can be programmed to display in

three different languages. Pressing the Enter key

will display “Modify Value” and the current

selected language. Use the Arrow keys to select

between ENG (English), ESP (Spanish), and FRA

(French), and press the Enter key to select the

language you would like to use for the display.

D – 1.3: pH High Alarm Point

Pressing the Down Arrow displays pH High

Alarm followed by the current pH high alarm

point. To change this setting, press the Enter key,

use the Arrow keys to input the value you would

like, and then press the Enter key again to save the

new value.

D – 1.4: pH Low Alarm Point

Pressing the Down arrow displays pH Low Alarm

followed by the current pH low alarm point. To

change this setting, press the Enter key, use the

Arrow keys to input the value you would like, and

then press the Enter key again to save the new

value.

D – 1.5: ORP High Alarm Point

Pressing the Down arrow displays ORP High

Alarm followed by the current ORP high alarm

point. To change this setting, press the Enter key,

use the Arrow keys to input the value you would

like, and then press the Enter key again to save the

new value.

D – 1.6: ORP Low Alarm Point

Pressing the Down arrow displays ORP Low

Alarm followed by the current ORP low alarm

point. To change this setting, press the Enter key,

use the Arrow keys to input the value you would

like, and then press the Enter key again to save the

new value.

Page 16

www.becs.com 9487 Dielman Rock Island Ind Dr, St. Louis, MO 63132

Installation and Technical Manual Rev: H10

D – 1.7: Temperature High Alarm Point

Pressing the Down arrow displays Temp High

Alarm followed by the current temperature high

alarm point. To change this setting, press the

Enter key, use the Arrow keys to input the value

you would like, and then press the Enter key again

to save the new value.

D – 1.8: Temperature Low Alarm Point

Pressing the Down arrow displays Temp Low

Alarm followed by the current temperature low

alarm point. To change this setting, press the

Enter key, use the Arrow keys to input the value

you would like, and then press the Enter key again

to save the new value.

D – 1.9: ORP/ppm Set point

This option is only shown if the controller is configured for

ppm control. Pressing the Down arrow displays

ORP/ppm SP followed by the current setting.

This option selects whether to use an ORP set

point or a ppm set point for the main Cl/Br feed

control. It is set to ORP by default. To change

this setting, press the Enter key, use the Arrow

keys to change between ORP and ppm, and then

press the Enter key again to save the new value.

D – 1.10: ppm High Alarm

This option is only shown if the controller is configured for

ppm control. Pressing the Down arrow displays

ppm High Alarm. If the controller is configured

with a ppm probe, the current ppm high alarm

point will be displayed on the screen.If the

controller is using calculated ppm, the current ppm

high alarm point will be displayed using the LEDs.

To change this setting, press the Enter key, use the

Arrow keys to input the value you would like, and

then press the Enter key again to save the new

value.

D – 1.11: ppm Low Alarm

This option is only shown if the controller is configured for

ppm control. Pressing the Down arrow displays

ppm Low Alarm. If the controller is configured

with a ppm probe, the current ppm low alarm

point will be displayed on the screen. If the

controller is using calculated ppm, the current ppm

low alarm point will be displayed using the LEDs.

To change this setting, press the Enter key, use the

Arrow keys to input the value you would like, and

then press the Enter key again to save the new

value.

D – 1.12: Exiting the Menu

Pressing the down arrow displays Exit menu.

Pressing the Enter key exits the menu.

Other manuals for BECSys3 115VAC

1

Table of contents

Other BECS Controllers manuals